What is this

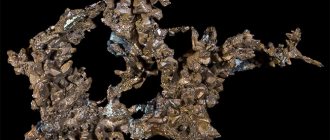

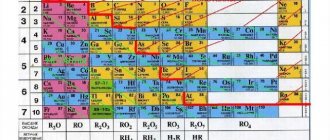

Strip is a rolled steel cut into longitudinal strips. Translated from English, the term “stripes” means strip or tape, which fully reflects the essence of the material. Metal strips are cut from sheets of structural steel containing a low percentage of carbon. A slight inclusion of alloying components ensures ductility and strength.

The general term “strip” means two types of rolled metal (bars) with a similar shape and manufacturing method:

- strip is a raw material intended for processing various types of metal products;

- the tape is a finished product, ready for use without the need for further processing.

Galvanized steel strips equipped with a polymer coating are popular. Applying a layer of polymer improves the characteristics of metal strips with a width of 10-1600 mm with a rolled sheet thickness of 0.25 to 5 mm.

Material for production

There are special requirements for the metal from which the strip is cut. Among them is the ease of rolling the finished product into something like huge rolls. The popularity of strip material in the construction market is explained by the possibility of varying the width of the unrolled strips. The length of steel strips is limited by the weight of the roll - a maximum of 10 meters.

The base steel from which the strip is obtained must be:

- galvanized or stainless;

- have a low carbon content (no more than 0.25%).

The Gosstandart requirements for processing the strip surface are not so strict due to the use of high quality steel grades for the production of rolled metal sheets. Despite the lower quality indicators of low-carbon steel, the strips do not lose their resistance to twisting.

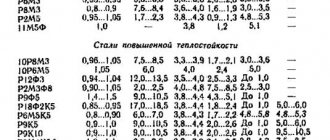

GOST parameters for steel strips made from different materials do not coincide in individual indicators. If the tape is cut from low-carbon material, GOST 503-81 sets the strip thickness to 0.05-4 mm with a width of 4-500 mm. To produce strips from carbon material, their width according to GOST 103-76 should be 11-200 mm with a thickness of 4-60 mm.

Kinds

There are the following types of strips on the metal products market:

- solid steel strip exhibits high ductility with a low level of cold brittleness and is suitable for welding;

- durable galvanized tape is characterized by good flexibility, resistance to corrosion processes, the tape can be easily cut;

- a version of galvanized strip covered with a polymer coating gives products made from it a beautiful appearance;

- Durable stainless steel tapes are equipped with the maximum level of anti-corrosion protection.

The characteristic feature of the strips is associated with their high corrosion resistance. This is explained by the method of manufacturing steel sheets, which are first hardened by hot rolling, then subjected to cold rolling.

Advantages

- High strength and impact strength provide maximum protection against the risk of various defects (chips, cracks).

- Any type of tape is designed for long-term use due to guaranteed resistance to corrosion.

- The material is easy to work with; ordering it is not difficult due to the choice of geometric characteristics (width, thickness).

- High-strength products made from steel tape do not require additional processing if they are used as fastening material.

- No special conditions are required for transportation or storage - the strip is usually stored in compact rolls.

Processing any product with strip tape increases load resistance, enhances impact strength, and improves stability. The flat but flexible surface is convenient and does not create problems with operation. Galvanized strip is easy to process and cut; the material can be easily profiled, stamped, and rolled.

What are they made of?

Steel strips of different widths are produced on rolling mills using the hot rolling method. Standard quality carbon steel strip and alloy steel strip are used as raw materials. Metal steel must comply with GOST. It is produced with increased precision, ranging in size from 3 to 10 meters. Subsequently, steel strips are used as a blank for the production of welded pipes. Metal strips are part of long shaped rolled products and comply with the standard (GOST 535-88). After rolling on slitting lines, the strip is wound back into a roll and in this form is used as raw materials and blanks in other production processes:

- in the woodworking industry;

- in stamping technologies;

- for packaging operations during transportation of finished products;

- when installing plastic windows and plasterboard structures.

Production stages

The technology for manufacturing strip strips is surprising in its simplicity and accuracy. Thin sheets of metal with specified characteristics or rolled material are fed to production equipment for cutting (longitudinal). What happens next:

- The rolled metal sheet is fixed on high-precision equipment. Then the base is heated to almost a temperature of 300-350 degrees before being sent for rolling.

- At the hot processing stage, the required dimensions of the metal sheet are formed. After hot rolling, the material must cool before proceeding to leveling the surface.

- During the cold rolling stage, the sheet is cleared of scale. After finishing, a coating (polymer or galvanic) is applied to a perfectly smooth surface to improve performance.

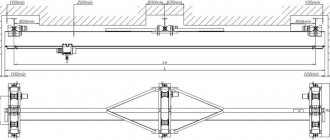

- When the sheet is ready for automatic cutting, it is transported to disk cutters (maximum 10 knives). Before slitting, the sheets are rolled into rolls weighing no more than 10 tons.

- At the final stage, the cut strips are wound into coils or cut into blanks of a length specified by the customer.

Previously, production was accompanied by an oxidation procedure - alternating heat and cold treatment. Modern technologies of new methods of influencing metal have made it possible to abandon this stage.

The use of modern equipment makes it possible to evenly spread sheet material into strips of a given width and clearly control it down to the millimeter.

For the production of hot-rolled strips, stainless steel coils are selected. The final product, after automated slitting, turns into raw material that requires further processing. Modern-looking hot-rolled strips are easy to use (packaging material) and withstand mechanical loads and impacts.

Applications

Strip tape also finds its application in household use, fulfilling a role that was not originally intended for it. It is used with pleasure, for example, by summer residents. And for a wide variety of purposes:

- strengthening fences and fences;

- flooring and fixing of roofing coverings;

- decorative design of the surrounding area.

Such high functionality and diversity of applications is explained by the consumer properties of strip-type tape.

As mentioned above, strip tape, depending on the tasks assigned to it, can be steel, galvanized, made of plastic or some composite materials. In addition, a variety of spraying can be applied to the surface of the canvas, starting with ordinary paint and ending with various powder or composite suspensions. It is quite obvious that the method of surface treatment affects not only the functionality of the product, but also its cost. In any case, strip tape is distinguished by its high strength, durability and versatility.

Galvanized strips can truly last 50 years or more , especially if they are not subjected to shock, mechanical stress and stretching. A simple stainless steel strip is somewhat inferior to its zinc “brother” in terms of effective service life, but it is noticeably better in terms of cost. As for plastic, polymer and composite materials, in the hands of a good, diligent owner, they can serve him well for many, many decades.

Galvanized strip

The process of galvanizing steel blanks for dismantling is accompanied by coating the sheets with a special composition containing zinc. Performing such a procedure protects the smooth surface of the iron from oxidation, which in the future threatens the formation of rust. A protective film of zinc prevents oxygen from reaching the metal coating by forming a galvanic couple with less activity of iron.

Technology

The following galvanizing technologies are used for the steel base:

- the limitations of the hot method are related to the dimensions of the bath for molten zinc;

- the cold method does not require special equipment and strict temperatures;

- the galvanic method allows you to create the exact thickness of the protective barrier;

- The diffusion process creates a high quality zinc layer.

Thanks to the spraying of zinc, it is possible to create a plastic coating that is resistant to cracking.

Advantages

The process of galvanizing a steel base provides the following useful properties:

- low cost of raw material with minimal maintenance costs;

- long service life while ensuring high reliability and predictability;

- resistance to damage during transportation, installation, and maintenance of structures.

The strip, cut from galvanized steel sheet, has a completely protected surface. The zinc coating guarantees complete protection even in the presence of microscopic flaws on the surface of the substrate prior to galvanizing. The products will not require additional processing or painting, and the quality of zinc treatment can be easily checked visually.

The production of strip tape is carried out in compliance with strict quality requirements to guarantee durability and reliability during its use. For this reason, the tapes can be extended by connecting individual strips.

Is a strip a hard metal or a pliable strip?

Many people ask the question, what is strip? What is it made of and for what purposes is it used? All these issues will be discussed below.

1 Meet this strip

Everyone knows the English word strip, which means “tape”; this is where the term strip, which got its name because of its appearance, takes its roots. Thus, it is a metal strip, the thickness of which does not exceed four millimeters, and plays the role of an auxiliary structural material. This product has also found wide application for the production of various products.

Polymer coated strip

Coiled steel coated with polymer is distinguished by durability, abundance of forming properties, and absolute anti-corrosion effect. Polymer products are widely used in construction to protect structures from damage and environmental aggression.

The starting material suitable for cutting into strips is thin sheet metal (cold rolled). Carbon or alloy steel is subjected to surface galvanization with the finishing application of a polymer mass of a given thickness. The complexity of the structure of polymer-coated steel sheet is justified by the main stages of its production.

Technology

- To protect the base metal from corrosion, the surface is coated with a zinc layer.

- At the passivation stage, the protective properties of the galvanized layer are enhanced by the application of an oxide film.

- To enhance the adhesion of the base, as well as the protective properties of the polymer, the blanks are opened with a primer mass.

- The finishing coating (polymer) is usually applied to the front side of the sheet, protecting it with a sheet of self-adhesive film.

The polymer layer is applied using one of the following methods:

- one-sided - only one side of the steel product is opened with the substance;

- bilateral - both planes are treated with the same or different polymer.

The choice of a certain type of polymer compound ensures that the final product obtains the specified chemical and physical characteristics.

Powder coating has become the most common method of applying the topcoat. It takes place inside a special chamber where a finely dispersed substance is sprayed under the influence of an electric current. The workpiece with particles tightly adjacent to the surface is subjected to polymerization in an oven.

The result of powder processing is a uniform distribution of the dye against the background of increased adhesion and strength of the created coating, which ensures a long service life.

Areas of use

A strip is a cold-rolled steel strip, the width and thickness of which can vary over a very wide range. The varieties of such tape can be different: there is a galvanized version, there are varieties with a polymer coating, and special-purpose products are also available, developed and manufactured to perform special specialized tasks.

The most widespread are metal products, which are most often used for the following purposes:

- production of straight-seam and wound pipeline structures;

- as irreplaceable elements when installing ventilation equipment, air conditioners, split systems;

- as an indispensable part in the construction of gutters, roofing structures, gutters, and plasterboard guides.

In addition, this type of tape is well known to anyone who has at least once been involved in repairs, wholesale purchases of products or goods packaged in boxes or briquettes. It is those very “straps” that have to be cut to access the contents that bear this name.

Where is steel strip used?

Packaging and transportation

Many people who were involved in large purchases of industrial and grocery goods have encountered metal strips. The outside of the packaging boxes is equipped with strip strips to protect their contents during transportation and loading and unloading operations.

Stiff metal belts are suitable for transporting pallets with pipes, rolled profiles, and timber. Before shipping, large-sized goods are packed in bundles, which are tied with strong, non-stretch strip tapes.

Packaging with various types of goods, wrapped with flexible steel strips, is not subject to deformation. Durable plates, similar in properties to slings, help to quickly move loads.

In addition to using packaging capabilities, metal tape with appropriate thickness and width parameters is used to securely fasten various structures and structures.

Pros of using strips

Galvanized strip is easy to maintain. It makes it possible to efficiently and quickly carry out the operation of packaging finished products using both manual and automated packaging machines.

It rests on the packaged product with its entire working surface, which makes it possible not to leave dents on the finished product.

Strip tape does not rust. It is effectively protected from the corrosion process.

In terms of strength, a strip is a steel strip that is superior to similar substitutes. For example, it has increased resistance to various shock loads from piercing objects.

Packaging finished products with strip tape gives a more aesthetic appearance, which cannot be said about other similar products.