A flaw detector is a device for detecting defects in products made from various metallic and non-metallic materials using non-destructive testing methods. Defects include violations of the continuity or homogeneity of the structure, zones of corrosion damage, deviations in the chemical composition and dimensions, etc. The field of engineering and technology involved in the development and use of flaw detectors is called flaw detection. Flaw detectors also include leak detectors (hydrogen leak detectors and helium leak detectors), thickness gauges, hardness gauges, structuroscope, introscopes, steeloscopes, etc.

Application area

Flaw detectors are used in almost all areas of industry. Some flaw detectors allow you to check products that move at significant speed (for example, pipes during the rolling process), or can themselves move at high speed relative to the product (for example, rail flaw detectors, carts and cars). There are flaw detectors for testing products heated to high temperatures.

— Acoustic (ultrasonic) flaw detectors

— Pulsed ultrasonic flaw detectors

Pulse flaw detectors use the echo method, shadow and mirror-shadow testing methods. The echo method is based on sending short pulses of ultrasonic vibrations into the product with a flaw detector and recording the intensity and time of arrival of echo signals reflected from defects. To control a product, the echo flaw detector sensor scans its surface. The method allows you to detect surface and deep defects with different orientations. With the shadow method, ultrasonic vibrations, having encountered a defect on their way, are reflected back into the flaw detector. The presence of a defect is judged by a decrease in the energy of ultrasonic vibrations or by a change in the phase of ultrasonic vibrations enveloping the defect. The method is widely used for testing welds, rails, etc. The mirror-shadow method is used instead of or in addition to the echo method to identify defects that give a weak reflection of ultrasonic waves in the direction of a separate-combined transducer. Defects (for example, vertical cracks) oriented perpendicular to the surface on which the transducer is moved (the input surface) produce a very weak scattered signal and a bottom signal.

Other methods of acoustic flaw detection:

— An acoustic emission flaw detector is based on the reception and analysis of acoustic emission waves that arise in a product when cracks develop during loading.

— A velocimetric flaw detector is based on measuring changes in the speed of propagation of elastic waves in the area where defects are located in multilayer structures, and is used to detect areas of adhesion between metal layers.

— An acoustic-topographic flaw detector is based on excitation of powerful bending vibrations of a given (in the first version of the method) or continuously changing (in the second version) frequency in the controlled product with simultaneous visualization of the vibration pattern of the surface of the product, for example. by applying a fine powder to this surface. With sufficiently strong vibrations of the surface of the product with a given frequency, powder particles from places that do not belong to the nodes gradually shift to the vibration nodes, drawing a picture of the distribution of nodal lines on the surface. For a defect-free isotropic material, this picture is clear and continuous. In the defect zone, the picture changes: nodal lines are distorted in the place where inclusions are present, as well as in areas characterized by mechanical anisotropy. properties, or are interrupted in the presence of delamination. If the second version of the method is used, then in the presence of delamination, the section of the upper layer of the product located above it is considered as an oscillating diaphragm fixed at the edge; at the moment of resonance, the amplitude of its oscillations increases sharply, and the powder particles move to the boundaries of the defective zone, outlining it with great accuracy. The flaw detector operates at frequencies of 30–200 kHz. The sensitivity of the method is very high: in a multilayer product with a top sheet thickness of 0.25 mm, defects with a length of 1-1.5 mm are detected. There is no dead zone, scanning is not required - the emitter is pressed against the surface of the product at one point.

Parameters that you should pay attention to when choosing a flaw detector

- Measuring range and resolution . The main accuracy parameters of a flaw detector, which determine the depth of penetration of the probing effect into the material, as well as the accuracy of determining the size, location and configuration of the defect.

- Scan speed . This parameter determines the overall performance of the inspection system based on the flaw detector. Increasing the scanning speed usually leads to a decrease in measurement accuracy.

- Installation method . Flaw detectors can be mounted directly on the production line, and also come in a compact version suitable for carrying.

- Degree of protection . Since flaw detectors can be used in unfavorable and aggressive conditions, it is necessary to pay attention to their protection parameters. This may be the IP/IK index or other characteristics indicating the level of protection of the flaw detector from external influences (moisture, pressure, etc.)

- Temperature Range . Exceeding the temperature range leads to an increase in the measurement error and can cause the flaw detector to fail.

If you liked the article, click on one of the buttons below

An eddy current flaw detector is a device designed to measure and detect cracks in various types of surfaces made of ferromagnetic steels and alloys. Its design is very interesting, just like its brother – the magnetic flaw detector. We will discuss them in this article.

Magnetic Powder Flaw Detectors

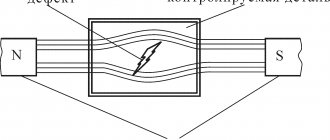

These flaw detectors allow you to monitor parts of various shapes, welds, and internal surfaces of holes, magnetizing individual sections or the product as a whole with a circular or longitudinal field created using a set of magnetizing devices powered by pulsed or direct current, or using permanent magnets. The principle of operation of a magnetic particle flaw detector is based on the creation of a stray field over defects with subsequent detection of them by a magnetic suspension. The highest density of magnetic field lines of the stray field is observed directly above the defect and decreases with distance from it. To detect a defect, magnetic powder suspended in air (dry method) or liquid (wet method) is applied to the surface of the part. In a magnetic field, particles are magnetized and connected into chains. Under the resultant force, particles accumulate above the crack, forming an accumulation of powder. Based on this deposition - an indicator pattern - the presence of defects is determined.

In what cases is an eddy current flaw detector used?

Among the huge number of flaw detectors for each highly specialized task, there is the most suitable type of device that can perform surface analysis with maximum efficiency. To detect and indicate a crack or other defect, an audio alarm is used, as well as a graphic image on the flaw detection display. The device can evaluate the depth of a crack or chip based on display readings using several standard samples.

The flaw detector has software specially designed for it to store specific settings in memory, as well as to create and determine the type of connection. Each eddy current device is equipped with a built-in memory module for storing the results of the procedure and for subsequent transfer to a desktop computer using an infrared port. If the flaw detector is used in automation lines, information can be transferred to a computer online.

The main features of eddy current flaw detectors are: control of work on the surface (including untreated), the ability to control parts even with a dielectric surface, identification of problem areas. Any modern device has the ability to quickly connect to a computer; there is even a special type of program for a more detailed determination of the scale of the problem.

Fluxgate flaw detectors

The magnetic flaw detection method is used, based on the fact that when a fluxgate (a sensitive element that responds to a change in the magnetic field) moves along the product, current pulses are generated, the shape of which depends on the presence of defects in the product. The high sensitivity of gradiometer flaw detectors makes it possible to detect defects with an opening width of several micrometers and a depth of 0.1 mm. It is possible to detect defects using a flaw detector under a non-magnetic coating up to 6 mm thick. The roughness of the controlled surfaces is up to Rz 320 microns. Flaw detectors - gradiometers are used to control cast parts, rolled products, and welded joints.

How is ultrasonic testing carried out?

The method is more often used to control the strength of welds. An ultrasonic weld flaw detector operates on the following principle. Certain deformations, called acoustic or elastic waves, propagate into the thickness of the metal. They come in several types:

- infrasound;

- sound;

- ultrasonic;

- hypersonic.

During the propagation of ultrasound, the medium through which it diverges performs measured oscillations relative to the equilibrium point. Longitudinal and transverse vibrations can act in solid bodies. Both types of waves allow you to control the strength of welds as accurately as possible. The speed of delivery and propagation of ultrasound directly depends on the strength and internal environment of the material under study. The intensity of the sound waves can be controlled.

As the sound wave travels, its intensity subsides. The density of the material can be judged from the rate at which this occurs. The device shows the ultrasonic attenuation coefficient, forming it based on their scattering and absorption indicators. The accuracy of the readings is high, which allows you to get a clear picture of the quality of welds, metal, and other solid materials.

Radio wave flaw detectors

Radio wave flaw detectors are based on the penetrating properties of radio waves in the centimeter and millimeter ranges (microradio waves), which allows them to detect defects mainly on the surface of products, usually made of non-metallic materials. Radio flaw detection of metal products is limited due to the low penetrating ability of microradio waves. This method determines defects in steel products, and also measures their thickness or diameter, the thickness of dielectric coatings, etc. From a generator operating in continuous or pulsed mode, microradio waves penetrate the product through the horn antennas of the flaw detector and, after passing through the received signal amplifier, are registered by the receiving device.

How does an eddy current flaw detector work?

Currently, eddy current testing is one of the advanced methods for monitoring defects. One of the most important advantages is the identification of a defect without direct interaction with the object , which allows you to look for chips, cracks, unevenness, and roughness even in hard-to-reach places. The advantages of this type of flaw detectors include high diagnostic speed and prompt solution to the problem. However, there are also disadvantages - high cost, limited range of materials of the studied bodies.

The devices have wide performance characteristics. The ambient temperature must be in a certain range - from minus 20 to plus 50 Celsius, and the relative humidity allowed for work should not exceed 80 percent. In the delivery package of an eddy current flaw detector, as a rule, you will find an information processing unit, various converters, batteries, a device for charging the device, a communication cable with a desktop computer via USB, and a disk with software. Of course, it is also very convenient to receive a special case for transportation and storage, test samples, a spare battery, additional scanning devices and a spare flaw detector sensor.

Capillary flaw detectors

A capillary flaw detector is a set of capillary non-destructive testing devices. Penetrant flaw detection methods make it possible to detect with the naked eye thin surface cracks and other discontinuities in the material that form during the manufacture and operation of machine parts. The cavities of surface cracks are filled with special indicator substances (penetrants), which penetrate into them under the action of capillarity forces. For the so-called luminescent method, penetrants are based on phosphors (kerosene, noriol, etc.).

Story

The first flaw detectors operating on continuous sound were created in 1928 by S. Ya. Sokolov and in 1931 by Mühlhäuser. 1937-1938 - the world's first flaw detector using alternating current to control railway structures and wheel sets (MAGNAFLUX company, USA). Echo-pulse flaw detectors (principle of operation and device) were created for the first time in 1939-1942 by Firestone in the USA, Sprules in the UK and Kruse in Germany. The first echo-pulse flaw detectors were released in 1943 almost simultaneously (Danbury, USA) and Kelvin and Hughes Ltd. (London) source: ru.wikipedia.org

Ultrasound source

Despite the different methods of collecting analytical data, ultrasonic metal flaw detectors use a similar method of operation. The main part of the device is a plate made of quartz or titanium barium. The plate is located in a special probe (search head). The probe is slowly moved along the surface under study, recording the wave extinction coefficient. The wave is supplied due to the action of an electric current, as a result of which ultrasound beams are generated. Based on the data obtained, we can talk about the density of the connection, the presence of defects, cavities, cracks, and other unnecessary deformations.

Ultrasonic flaw detector: price, delivery

The site presents the best models of devices. The range of prices and functionality will pleasantly surprise the company's clients. You can clarify the exact cost of a flaw detector by using the electronic communication form, indicating the exact model of the device. All models of diagnostic equipment are described in detail. Here visitors will learn information about the manufacturer, functionality, dimensions, and area of application of a particular flaw detector. Additional questions should be clarified with the consultant.

The price of any ultrasonic flaw detector also depends on the manufacturer. The entire range of the site is covered by a manufacturer's warranty. Targeted delivery to the regions is carried out. Free consultations are available to clients. Promotions and sales, information about which is regularly updated on the portal, will help you save.

Diagnostic stages

Before starting the study, it is necessary to clean the metal from corrosion, paint, and other foreign matter. There is no need to clean the entire surface. It is enough to maintain a gap of up to 70 centimeters. In this form, the material is already ready for diagnostics, but it would be better to additionally ensure ultrasound permeability. For these purposes, grease, oil, glycerin, and other liquids containing fatty inclusions are used.

Before starting work, an ultrasonic weld flaw detector must be configured to achieve specific goals. There are several options here:

Scope of use

Using a flaw detector, you can detect defects in metals and their alloys, plastics, composite materials, wood, concrete structures, and adhesive joints.

This versatility ensures the demand for ultrasonic flaw detectors in various industries:

- Check welding connections before assembly.

- Obtaining permission to operate metal structures.

- Monitoring the continuity of coatings for the presence of pores and micro-holes in them before painting or applying a protective layer.

- Detection of corrosion and erosion damage to pipes in the oil and gas industry.

- Monitoring devices and pipes that are under pressure for thinning.

- Deviations in the sizes of finished industrial products.

- The presence of delaminations, microcracks, air voids in construction.

- Violations of the chemical composition of alloys in rolled pipes.

- Measuring the thickness of finished products from various materials.

GOST 14782-76, GOST 20415-2, as well as industry standards regulate the use of ultrasonic flaw detectors.

Field of application of ultrasonic flaw detector

Such devices are in greatest demand in the manufacturing sector. The diagnostic service can also be ordered privately to control welding seams during the construction of buildings, reconstruction of residential and industrial premises. Seam inspection is indispensable when you need to determine the degree of wear of water and gas pipes. Owners of the oil, chemical and engineering industries are actively purchasing equipment. Portable ultrasonic flaw detectors are used by geologists in the field, as well as laboratory assistants to examine small objects.

How to achieve the most accurate research results?

To obtain more accurate data, it is necessary to move the flaw detector probe in a zigzag manner along the surface of the material being examined. In this case, it is advisable to rotate the probe at least 10-15% around the axis of the metal. If the device emits any uncharacteristic vibrations, it is necessary to turn the probe as far as possible in the indicated place so that it becomes possible to accurately determine the dislocation of a poor-quality connecting seam. The search continues until the location of the matter where the ultrasound peak is highest is determined.

It should be taken into account that the ultrasound diagnostic device may produce errors due to wave reflection from the seams. For this purpose, additional research methods are used. If several diagnostic methods lead to the same answer, you can record the defect by recording the coordinates of the flaw. Equipment manufacturers, based on the requirements and rules of GOST, recommend diagnosing the same object at least twice with different devices.

The data obtained during operation of the ultrasonic flaw detector is recorded in a special journal or table. This allows you not only to quickly eliminate a flaw in the connection, but also to speed up re-diagnosis, because potential problem areas are already known.