Selecting the optimal cutting mode

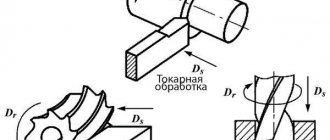

The optimal cutting mode is usually understood as the mode that provides the highest productivity (lowest machine time). The selection of cutting modes is made in a certain sequence. First, the cutting tool is selected, and then, based on the characteristics of the workpiece and the cutter, the milling mode is selected.

Selection of rational design and geometry of cutters. Sequence of cutter selection

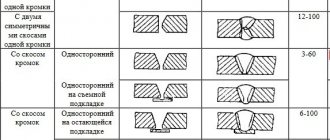

determined by the following: choice of tool material (cutter). Small cutters, shaped cutters and corner cutters are made primarily from high-speed steels. Therefore, the choice of tool material when working with such cutters, as well as in cases where it is impossible to provide a sufficient cutting speed, is predetermined. This is, as a rule, high-speed steel grades P18 and P12.

Selecting cutting mode parameters. The sequence of selection of cutting mode parameters is determined as follows.

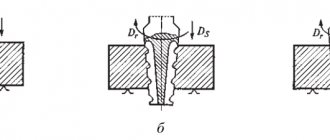

1. Selecting the cutting depth. In all cases where this is possible, you should work in one working stroke (i = 1). With increased requirements for accuracy and surface roughness, it is sometimes necessary to resort to two working strokes (the first is roughing, the second is finishing).

2. Feed selection. The choice of feed during the finishing stroke (surface roughness Rz 20 or less) is made depending on the specified surface roughness parameters.

Reference books on selecting cutting mode parameters, as well as other reference books for production purposes, provide data for selecting feed per tooth sz for various milling conditions.

3. Selection of cutting speed, cutter speed and feed per minute. After the diameter of the cutter D, the number of its teeth z, as well as t and sz are selected, proceed to the selection of υ, n and sm according to the tables for selecting cutting mode parameters when processing various materials (see reference books on selecting cutting mode parameters). These tables show the recommended values of υ, n and sm depending on D, t, z and sz. For changed operating conditions, the values determined from the tables are multiplied by the correction factors given at the end of these tables

Cutting speed

(122)

The cutting speed is calculated based on the largest diameter of the cutter teeth. The cutting speed can also be selected according to general machine-building standards.

Circumferential cutting force in milling

(123)

4. Adjustment of the sm value according to the machine’s passport data. Modern milling machines are equipped with drives that, as a rule, do not have stepless control of the minute feed sm (except for CNC machines) and the cutter speed n. Therefore, sm and n determined at the previous stage must be checked with the machine passport. If there are no values in the passport that correspond to those determined from the table, the nearest smaller values according to the passport are accepted as actual.

5. Checking the selected cutting mode for power. The cutting mode selected according to the standard tables and adjusted according to the machine’s passport data is checked based on the power of the electric motor.

Cutting power when milling with all types of cutters

(124)

The condition according to the formula Nres≤Nе.д.η must be ensured. The efficiency value η is taken from the machine passport, or the latter indicates the value of the effective power on the spindle Ne.dη, corresponding to the value of the actual number of spindle revolutions adopted at the previous stage of calculating the cutting mode

If the selected cutting mode does not meet this condition, it is necessary to reduce the set value of the minute feed sm to the value allowed by the power of the machine, and accordingly reduce the number of revolutions.

6. Determination of main time. To evaluate the effectiveness of the selected cutting mode, the main time is calculated.

When determining a number of cutting mode parameters, it is necessary to take into account the rigidity of the technological system (AIDS), which affects the durability of the cutting tool. As rigidity decreases, a corresponding reduction in standard feed and cutting speed is required. This change is determined by multiplying by correction factors.