The screwdriver spins under load, what should I do?

Types of electrical faults

Electrical faults in screwdrivers can manifest themselves in the following form: the tool does not engage when the start button is pressed; the rotation speed of the chuck is not adjustable; it is not possible to change the direction of rotation when moving the lever; When the screwdriver is operating, sparking is noticeable and crackling and clicking noises are heard.

In circumstances in which the tool does not want to turn on when you press the start button, you need to check the entire electrical circuit along the chain (from simple to complex). First the battery is checked. The tester measures the voltage at the battery output. If the voltage is below the normalized value (indicated on the battery case), then you need to try to charge the battery first. If charging does not help, then the entire battery is removed and the voltage on each element is measured (the voltage should be 1.2 V). Repair in this case consists of replacing the faulty battery.

The second element in the electrical circuit is a push-button switch. Using the device, the performance of moving and fixed contacts is assessed. When the electrical signal does not pass through after pressing the push-button switch, you first need to clean the contacts with a small sandpaper.

If the fault remains, it is not practical to repair the button and it should be replaced.

Very often, tool repair involves replacing the brushes, because they are subject to active wear and burning. First, you should visually assess the condition of the contact brushes. If the brush wear is noticeable by more than 40% along its length, then it needs to be replaced. The repair consists of removing the brush holder from the body, removing the warped one and installing exactly the same, but new brush. In addition, capacitor breakdown often occurs; As follows, you need to check the capacitance of the starting capacitor. If the capacitance value does not correspond to the nominal value (indicated on the housing), the capacitor is replaced with a new one with the same capacitance.

Checking the functionality of the electric motor

The last thing in line to check is the electric motor as the most difficult element of the electrical part. If no damage is found to the contact and starting devices, and there is also no doubt about the reliability of soldering and the integrity of the supply wires, then the electric motor is checked.

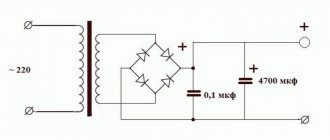

Diagram of a charger for a screwdriver.

Disassembling the engine begins with removing the armature from the stator. A visual inspection of the contact part of the commutator and winding is carried out. Mechanical damage or electrical short circuit and breakdown of wire insulation are noticeable by a change in color and the presence of soot. Anchor repairs are not carried out independently. It is either trusted to professionals or replaced with a new one. If no visual damage is detected, then an ohmmeter is used to check the operability of all windings separately.

Faulty battery or screwdriver cable

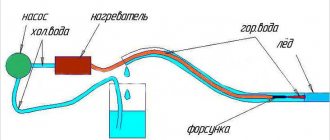

Everyone understands that, regardless of the “steepness” of a hammer drill, its operation is impossible without an energy source. Therefore, first of all, you need to check the serviceability of the battery if you have a mobile hammer drill and does not depend on the power source. The main reason for battery failure is its discharge or long-term use. The second reason can be eliminated by completely replacing the battery, and the first by simply recharging it using a rectifier included when selling the tool.

Screwdriver battery disassembled

As a rule, two batteries are included in the same kit: one is in use, that is, in operation, and the other is being recharged. If the charger fails, it would be more rational to replace it with a new one unless, of course, you are an expert in radio electronics.

If you own a corded screwdriver, first of all, if the motor does not rotate, check the entire electric drive chain: the socket, the cable plug and the cable itself. Believe me, it often happens that the socket fails (the contacts burn out), the cable plug may fail for the same reasons, and the cable itself may be damaged as a result of careless handling.

SCREWDRIVER

By the way, for such basic housework you don’t need a professional-class model at all. So don’t let the seller trick you into buying an expensive and unnecessary screwdriver that “can do anything!” For you, this functionality is excessive.

However, when choosing a screwdriver, the other extreme is also undesirable: by thoughtlessly saving when choosing a tool, you can greatly limit your capabilities and remain helpless in a situation when you need to tighten a screw with some force or drill a hole in hard wood. As you know, the miser pays twice.

READ What is an indicator screwdriver used for?

In a word, a screwdriver , like any other tool, must be selected for the tasks that you intend to solve with its help. The more functions, the more bells and whistles, the more expensive the tool. You have to pay for what you really need. to help you figure out what is needed and what is not, and therefore choose a screwdriver more intelligently.

Speed up!

High speed when choosing a screwdriver should not be an end in itself, although it is this parameter that many consumers consider to predetermine the quality of the screwdriver. This is not entirely true. And in this case: different speeds are needed, different speeds are important... High speeds are necessary for working with hard material. And with slow rotation, point work is better, and it’s easier to make a hole exactly in the place where it is needed. And it’s easier to work with thin, short self-tapping screws.

Therefore, the ability to adjust the speed is important. There are screwdrivers with two or more speeds. Speeds of up to approximately 500 rpm are used for tightening self-tapping screws. Speeds from 500 to 1300 rpm are suitable for drilling operations.

There are models in which the speed is regulated by a regulator, in others - by pressing the start button. If there is no speed control, then when you press start, the maximum speed is immediately activated, which, as we noted above, is not always convenient.

What is a screwdriver?

Structurally, the screwdriver is a modified low-speed drill. This electric tool is intended for mechanizing the work of tightening/unscrewing self-tapping screws, screws, bolts, nuts and other fasteners. And also for drilling holes in wood, metal and brick.

Essentially, we are dealing with a drill-driver. This tool is often called that. But a drill- driver is not “two in one”. So don’t be under any illusions: even the most powerful drill/ driver is not a drill in the classical sense and will not save you from the need to additionally purchase one if that’s what you need.

To choose the right screwdriver , you need to understand to what extent you will need a screwdriver , and to what extent a drill? By answering this question, you will know exactly what technical parameters the model that suits you should meet.

Let's try to classify the tools on sale according to the type of work they perform.

If all you need, as you think, is to perform work that does not require much effort when driving screws (for example, assembling finished furniture), then you will be quite happy with a screwdriver . Compact and lightweight tool, but without adjustable speed.

To drive screws with a certain force, you will need a non-impact drill- driver . The word “drill” in the name means that this type of tool has a higher spindle speed (two speeds).

But it won’t cut it either when it comes to drilling wood and metal: here you need at least a two-speed hammerless drill/ driver with a rotation speed of at least 1600 rpm. But when the task becomes more complicated, drilling brick and stone cannot be done without an impact drill-driver equipped with a quick-release drill chuck.

Screwdriver motor speed cannot be adjusted

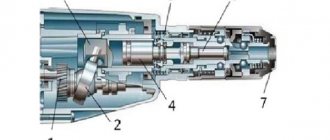

The lack of adjustment of the screwdriver motor speed significantly reduces the convenience of working with the tool, and also makes it impossible to perform high-quality work. The regulator is located in close proximity to the start button or is made as one piece with it, however, the speed control transistor is attached to the electric motor where it is cooled through the radiator grilles.

Location of the electric motor speed controller (7)

As practice shows, if such a problem occurs, it would be more correct to replace the speed controller completely with a new one. Fortunately, they are on sale and are relatively inexpensive. All attempts to repair it led to the same conclusion unless, of course, you are an expert in electrical engineering.

The screwdriver works intermittently

The usefulness and convenience of using a screwdriver when renovating a house is beyond doubt. Using this tool, joining wooden elements is much faster and easier. Do-it-yourself screwdriver repair has become a necessity for many.

Diagram of a cordless screwdriver.

Any tool, even the best quality, will eventually fail. There are many reasons for this. Repairing an automatic screwdriver is no exception to the rule; it is a completely natural phenomenon, and you need to prepare for it in advance.

Sources:

https://schemy.ru/info/perforator-treshhit-pri-nagruzke/ https://balkon-mebel.ru/shurupovert-prokruchivaetsya-pod-nagruzkoy-chto-delat/

Why does the chuck on a screwdriver crack and spin?

Different interpretations of the concept of “scrolling” should be taken into account. When the clutch - torque regulator (ratchet) simply works, then it is enough to select a different mode of its operation to completely screw in the screw.

If the screwdriver cracks and spins when working in previously used modes without problems, this may indicate the presence of one of the tool’s breakdowns:

- lack of a sufficient amount of grease of the appropriate type in the gearbox;

- the reduction shaft is bent - this can be a factory or acquired defect;

- received physical damage or the satellite fixation pin or the satellite itself was completely broken;

- wear of the working surfaces of plastic (less often metal) gears;

- failure of bearings, wear on the shaft.

Also, the reason that the screwdriver began to spin could be unreliable fixation of the bit in the chuck due to wear on its cams.

How to fix a screwdriver with your own hands?

Gone are the days when screws were screwed into the wall with a screwdriver. Now they can be easily driven into the surface with a screwdriver. If you suddenly had to freeze in confusion with a silent instrument in your hand, our article will help you.

A screwdriver is a popular and popular assistant for the caring home handyman. It can get "moody" like any other instrument. Fortunately, typical problems with screwdrivers have long been known, and the process for eliminating them has been described repeatedly. Repairing a Bosch, Makita or Interskol is usually simple and can be done at home.

Reasons for screwdriver failure

Screwdrivers fail for reasons traditional for such equipment. This may be due to improper operation, foreign bodies getting inside the screwdriver, voltage drops, lack of lubrication, untimely cleaning and replacement of consumables.

The screwdriver does not turn on

If one day you find that the screwdriver shows no signs of life, it means that one of the following has happened to it: • the battery has failed, • the power button does not work, • the armature has burned out.

It also happens that a screwdriver begins to live an overly active life and cannot “calm down” in any way: • the screwdriver whistles and creaks during operation, • the chuck taps, • the reverse does not turn on, • the screwdriver speed cannot be adjusted, • the engine continues to run even after of how it is turned off.

How to check the battery of a screwdriver?

First, you should check the performance of the battery. After disassembly, check the integrity of connections, contacts, wires, including for oxidation.

For a detailed check, a multimeter is used, and the voltage is measured at the battery terminals. On the battery case there is usually an output voltage value - 12V, 18V. The tester readings must strictly correspond to these values. If they are smaller, the battery slowly begins to fail and requires replacement.

Similarly, you can ring each element (if the battery is made up of several batteries). True, even if one battery fails, the entire set will have to be replaced.

Start button doesn't respond when pressed

When starting to repair the power button, you should have minimal skills in handling electronics. Disassembly of the apparatus and mechanism must be carried out with extreme care and attention. Otherwise, fragile structural elements may be lost or damaged.

After opening the case, it is advisable to schematically sketch or photograph the location of all the elements of interest, so that later you can correctly install them in place.

First, we inspect the contacts and clean them if they are darkened. With the button pressed, we measure the resistance on the wires that come to it. The resistance of working wires will be zero. If this is not the case, then a break has occurred and you need to change the wires or the switching mechanism assembly.

Replacing a burnt armature and brushes

If the armature fails, this will require replacing the entire motor. Let's hope that in your case only the motor brushes are worn out. Carefully open the case, disconnect the motor from the power button and connect it to the multimeter using probes. If there is little resistance in the circuit, the brushes are most likely worn out. They can usually be replaced without disassembling the engine by simply inserting new ones.

The engine starts and immediately stalls

With 90% probability we can assume that the gearbox has failed. This is probably due to the pin that is attached to the satellite. In this case, the gearbox assembly is replaced, especially if the gear teeth are ground off.

Why does a screwdriver whistle?

If the screwdriver begins to emit an uncharacteristic whistle that comes from the depths of the motor, it means that one or more problems have emerged. Either the motor magnet has fallen off, or the rotor bearing is clogged with dirt or dust. If the magnet is intact, it can be glued in place with superglue. If it breaks, replace it with a new one. A dirty bearing and the area around it must be thoroughly cleaned.

Main causes of malfunctions

Screwdrivers are either corded or cordless. Their main faults are almost the same, and the differences are related to the type of power supply.

Corded screwdriver

If the device does not turn on, first check the condition of the socket, and then, if it is working, inspect the plug. Often the screwdriver does not start because the contacts burn out. If both nodes are intact, you should inspect the cable to make sure that it is intact and not broken or bent. Possible causes may also be a faulty power button, worn out electric brushes, or a burnt-out motor winding.

If the equipment sparks, you need to look for a defect in the armature, electric brushes or motor commutator.

A self-starting screwdriver indicates that the power button has broken down.

If the cartridge is loose, the cause is damage to the gear shaft. If the chuck is jammed and the drill bit or bit cannot be removed, the clamping jaws are jammed. The reason is lack of lubrication or breakdown of the internal components of the cartridge. If this mechanism spins, the problem is the gearbox is faulty.

If the ratchet is defective, inspect the petals of its locking device, the spring and the pins.

Cordless screwdriver

If the equipment does not turn on, check the charger and battery health. When discharging quickly, its condition is diagnosed using a special tester.

Other malfunctions of a cordless screwdriver are similar to network equipment.

Screwdriver and its design features

You should start repairing a screwdriver yourself by becoming familiar with its design. The main element of a screwdriver is an electric motor. Screwdrivers come in both corded and cordless types. The use of a corded screwdriver is used less frequently, due to such a disadvantage as the need to connect the tool to a 220V network. Battery-type tools are more popular, as they allow you to carry out not only repair work at home, but also outside it.

The main components of a cordless screwdriver are:

- Frame. Typically, all screwdrivers are made of durable plastic.

- Start button. It is designed in such a way that the number of revolutions of the cartridge depends on the force of pressing it.

- Electric motor. Battery-powered tools use single-phase commutator-type and DC motors. The motor consists of a rotor, a stator in the form of magnets, and a brush assembly.

- Gearbox.

- Force regulator.

- Reverse switch.

- Battery. As a rule, it is removable and is often supplied with the product in duplicate.

- Cartridge. As a rule, quick-release chucks are used.

Some models are additionally equipped with LED backlights, as well as battery charging indicators. Returning to the problems with the screwdriver, it should be noted that any of the above elements can cause the tool to malfunction. What is needed for repairs? The first step is to find the cause of the breakdown, and then make the appropriate decision to eliminate it. The tool can be divided into two parts: electrical and mechanical. Initially, you need to find out what the problem is with the screwdriver not working: mechanical or electrical. This won’t be difficult to do, so let’s look at the breakdowns in more detail.

Mechanical faults

Mechanical malfunctions of screwdrivers can be identified by such a sign as the audibility of the operation of the electric motor. When you press the start button, you can hear signs of the electric motor running, but the tool chuck does not rotate or characteristic sounds of a malfunction are heard when rotating.

The design of the screwdriver is quite simple, but a significant drawback is that all the elements are almost 2-3 times smaller than those of an electric drill. Possible mechanical failures of a screwdriver include the following malfunctions:

- Cartridge failure. Despite the fact that quick-release chucks are more versatile and easier to use, their significant drawback is their low service life. It is impossible to repair the keyless chuck, so if the tool refuses to hold the drill or bit, the chuck should be removed and replaced with a new one. This is one of the most common malfunctions of the tool, but it does not require disassembling the screwdriver.

- Gearbox failure. The screwdrivers are equipped with a planetary type gearbox. Typically, in order to save money, manufacturers make gearbox gears from low-quality plastic or metal. This affects not only the power of the tool, but also its service life. If the engine runs when you press the “Start” button, but the cartridge does not rotate, then the problem lies precisely in the planetary gearbox. To find out the cause of its malfunction, you need to disassemble the tool and then determine the breakdown. If one gear fails, the gearbox should be replaced.

- Bearing wear. The bearing is located in the planetary gearbox, so it is replaced along with the gears.

- The force regulator is broken. This device in screwdrivers is used not only to increase or decrease the traction force of the tool, but also to increase safety. If during work the working attachment becomes jammed, then instead of turning the tool, the regulator will turn. Thus, the master will not get a dislocated arm, and the electric motor will be protected from high loads, from which it can burn out.

It should be noted that the small size of the mechanical part of the instrument somewhat complicates the process of instrument repair, so be sure to be careful when carrying out repair work.

Electrical faults

Unlike drills, screwdrivers operate primarily on batteries. This means that different electric motors are used in the design of these tools. It is not difficult to determine the malfunction of the electrical part of the screwdriver. If the battery is charged, but when you press the “Start” button you cannot hear the sound of the electric motor, then the cause is an electrical failure. Let's look at the main types of electrical faults in screwdrivers.

- Battery fault. Initially, you should pay attention to the battery. As a rule, screwdrivers use low-quality nickel-cadmium batteries. They have a significant drawback, which is the need to charge it only when it is completely dead. Such batteries cannot be recharged, as this shortens their service life. If one day the screwdriver refuses to function, then do not rush to disassemble it, make sure that the battery is functional and provides a charge. You can check by connecting a second battery. The battery charge can also be checked using a tester, which should show the appropriate voltage value.

- Charger fault. There is a special charger for charging the battery. If the battery is discharged even after you have charged it, you should check the integrity of the charger. Chargers usually have indicator lights for these purposes. If they are not there, then you need to use a multimeter.

- The power button is faulty. It is necessary to check the start button, since often the reason for its inoperability is oxidation of the contacts or dust. The tool should be disassembled and then the contacts should be cleaned. The buttons on screwdrivers usually have the function of regulating the speed of rotation of the chuck, for which a transistor is installed. If the tool works, but the speed control function is missing, then the transistor needs to be replaced.

- If the reverse function does not function, the breakdown can be corrected by cleaning the contacts of the polarity switch button.

- Motor malfunction. The electric motor is one of the most expensive structural elements of a screwdriver. If everything is checked and it is determined that the problem lies in the electric motor, then the cause should be found out. Most often, the problem occurs with brushes, which simply wear out over time. The brushes cannot be repaired, so they must be replaced. The armature should be replaced if a break is detected when testing its winding terminals. No one will rewind such a small rotor, so it’s easier to purchase a new unit. The stator of a permanent electric motor is presented in the form of 2-3 magnetic plates that do not fail.