General design of an electric scooter

To understand how to assemble a scooter yourself, you need to understand its design. The structure consists of the following parts:

- Frame;

- Wheels;

- Electric motor;

- Controller;

- Accumulator battery;

- Brakes;

- Controls.

Design Features

The device uses an electric motor that runs on a built-in high-capacity battery. In addition to this part, any described vehicle consists of the following components:

- frames - metal or plastic;

- wheels;

- brake system;

- body kit and electronics.

A Li-On or Li-Po battery is used as a power source. Depending on the volume of blocks installed, the electric scooter can travel distances of up to 50 km. Some models have a gasoline internal combustion engine; as a rule, their travel range is higher, as is their speed. The design of the proprietary device also includes a gearbox with variable speed control. Operating current is supplied to the electric motor through a centralized wiring system from power supplies or a generator. All major electronics are usually enclosed in a sealed box that completely blocks moisture from entering.

Electric scooters weigh approximately 15–20 kg, so they can be lifted if necessary. You can charge the device from any outlet; it takes about 6 hours. You can make such a product yourself, but before you make an electric scooter, you should prepare everything you need.

Frame

Wheels

Brake system Electronics

Battery

Frame (base)

The easiest option is to take a frame from a factory scooter. The disadvantage of this option may be the additional load on the frame. After all, the weight of additional equipment will be added to the person’s weight. The undoubted advantage of this is its relative simplicity.

The second option is manufacturing, as they say, from scratch. The advantage of this method is that the device will take into account all individual wishes and characteristics.

For making your own frame, a square pipe with a wall thickness of 2-2.5 mm is suitable. True, here you will need additional skills for designing and calculating the base, skills in working with materials and tools.

Required tools and materials

Before you get started, there are a few preparatory steps you need to take. The first step is to draw up drawings of the future product and indicate on them all the necessary dimensions. In addition, you will need to collect all the required materials and tools in advance.

For work you will need the following items:

- an ordinary scooter (even the cheapest one is possible);

- an electric drill or screwdriver, the motor of which can be powered by a 12V battery;

- overrunning clutch from the car starter;

- gearbox and axle from a grinder;

- 3 bearings for roller wheel;

- chain and sprocket from a bicycle;

- lithium battery (2.2 A, 12V);

- metal corners;

- wires of different sections;

- fasteners.

Wheels

Wheels are divided by size into micro, mini, midi and maxi. The first have a size of less than 20 cm, the second - 20 cm, the third - from 25 to 30 cm, the fourth - more than 30 cm.

Note!

- DIY induction heater ♨️ - reviews of the best manufacturing options. Varieties of homemade device designs + step-by-step master class (160 photos)

Do-it-yourself Gauss cannon: TOP-130 photos of the best ways to create it yourself. Design features + master class for beginners

- DIY clamps - a step-by-step master class for beginners. Schemes for manufacturing different designs + 170 photos

The choice of wheels to be installed on the scooter depends on its operating conditions. If you drive on smooth roads, then micro-sized wheels are suitable. An electric scooter with them will be light and compact.

If the roads are of average quality, with small cracks and unevenness or are paved with tiles, then the mini option is better. If you plan to move on poor asphalt or dirt roads, then it is necessary to install midi or even maxi size wheels. Inflatable wheels are also suitable.

Simple homemade scooter

“In fact, life is simple, but we persistently complicate it.” (Confucius)

Many people probably still remember how in the 70s our fathers made us scooters with wheels made of ball bearings. How this thundering miracle aroused extraordinary pride in us, and white envy among the neighboring boys. But time passes, everything changes... The fashion for scooters has returned again, only our children are already riding them. And about four years ago, having assessed my capabilities, I decided to make a scooter from a children’s bicycle that had become small.

I’ll warn you right away that you will need here: a welding inverter with electrodes (preferably 2), an angle grinder and a meter of profiled rectangular pipe. And since the scooter has been made for a long time, I will only explain some of the nuances.

I got it like this:

Quite responsive for acceleration and quite fast. And now, in order. First, we saw off the back and front parts of the bike. And in front we saw off the frame tube parallel to the steering tube.

We measure the profiled pipe and make V-shaped cuts with a grinder at the bends. Bend and cook. We also thoroughly weld the attachment points to the rear and front units. We extend the steering column with an additional pipe, which we also weld to the original bicycle one.

A bolt with a wedge assembly passes inside this pipe. Naturally, the original bolt turned out to be short and I had to saw it in half and weld a piece of wire (6mm) into the middle. Cooked it in a vice to get it smooth. Pay special attention to the distance from the site to the ground surface. It should be minimal, taking into account the unevenness of the road. I had to redo it; I raised the platform too high.

The board is screwed on top and the scooter is generally ready. The only thing missing is the brakes. They can be used from an old bicycle (regular rims). In general, you can leave the pedals, and lengthen the seat tube and you will get a hybrid, a kind of bicycle scooter.

If desired, you can install an electric motor with a gearbox on the site, and a battery on the trunk. But that's a completely different story.

Engine

A wheel motor can be used as a motor. It can be purchased separately or taken from a broken hoverboard. A motor from a cordless electric drill can also be used as a propulsion device. Some craftsmen use a screwdriver or a car radiator cooling engine as an engine.

Engine power is selected depending on the conditions in which you intend to drive. For children, it is better to take low-power engines. For driving at speeds up to 30 km/h, a motor with a power of up to 300 Watts is suitable.

For fast driving, you can use motors with a power of 350-400 watts. Such an engine will allow you to reach speeds of up to 40-50 km/h. It is important to consider safety issues here.

Bravery and stupidity! Do-it-yourself powerful electric scooter from an ordinary one.

Over the past 20 years, technological progress has given us many incredible innovations and solutions that have greatly impacted our quality of life. One such technical innovation is the electric scooter. This is a portable personal electric vehicle that can be carried in the subway and quickly move around the city at a distance of 15-30 km. Which you can ride in the park in the summer, go to work, get adrenaline, and be incredibly mobile. We charge from the mains for 3-4 hours, and you can go again.

And now you want an electric scooter. Where can I get it? There are two options: buy or build yourself. What? Yourself? How is this possible?

Build an electric scooter with your own hands? Maybe! And in this article I will tell you how to make an electric scooter with your own hands. But first, let's figure out why this is needed. Maybe it's easier to buy?

Yes, it's easier to buy. But it's expensive. And buy what? Front nature scooter? Which, to put it mildly, doesn’t cost a lot of money while standing? Of course, there are expensive models that go fast and cost a lot of money, but often manufacturers working for the European market impose speed restrictions that cannot always be circumvented. What if tomorrow you want something faster, more powerful, or, on the contrary, lighter, so that you can carry it with one hand in the subway without straining. So here it is. Self-assembly of the scooter allows you to make any modifications to the constitution, changing the power and weight according to your needs.

Well, you have decided that buying is not your way, and you want to assemble a personal vehicle with your own hands. To do this, you will need the ability to wield a soldering iron, hold a screwdriver in your hands, drill holes in metal with straight hands, and our Chinese friends will do the rest for you. And so, if you love to design and see no barriers to realizing your creative abilities, we are ready to provide you with the necessary details, advice and parts to create your own vehicle.

First you need to decide what it will be. Will it be a large, powerful scooter on inflatable wheels that will shoot long distances, wrapping asphalt around the wheels, or will it be a folding lightweight scooter that you can easily carry with one hand in the subway, getting to work or a gym in another area, bypassing the stuffy public transport.

Let's start with a folding design, we need to choose a folding scooter with a rear shock absorber, we will need to replace its rear fork with an extended one, install a motor there, buy a controller, a battery, put it all in somewhere and connect it.

Let's start by choosing a scooter for our experiments. There's simply very little choice here. Some years ago, the Chinese came up with a two-suspension scooter frame on which different manufacturers began to make different scooters. That's what we need. The more expensive the manufacturer, the better the quality of the spare parts from which it is assembled. A folding double-hung frame in a trailer cannot be reliable, but we have no choice. An electric scooter will have the same problems as a regular scooter and you need to be prepared for this. Its moving parts will also become loose. Dangle, creak, make noise. The more moving parts there are, the more you need to keep track of it all. This applies to purchased folding scooters and homemade ones. Why choose a dual-suspension scooter? And the first step will be to replace the rear fork and wheel with a motor.

And so, assembling an electric scooter with your own hands, step by step.

- We change the rear fork to an extended one and install a motor wheel there.

- Assembling a housing from an aluminum profile

- We make fastenings for the lid on which we will stand with our feet.

- Making a lid

- Installing the controller and throttle grip

- Installing the battery and machine

- Connecting

Below is a detailed description and photo from the repair of my home scooter, which is already 3 years old. Over the course of 3 years, I got tired of the frame play and therefore made it non-folding, reinforcing it with thicker bolts in the play areas. Also, over the course of 3 years, several different cases and batteries were replaced on it, so everything had to be adjusted to fit the holes already made earlier. I recommend that you first bend the side ribs to notice what will be where and then drill and then there is a greater chance that everything will be smooth and neat.

- We change the rear fork to an extended one and install a motor wheel there.

When assembling, there is an option to encounter some difficulties, which can be solved with the help of a drill, file and spacers purchased at the crepe market.

- Assembling a housing from an aluminum profile

You can use any profile that suits your task. I used 50mm. Since it was necessary to place a 48V 10Ah battery inside

We cut the profile to size, glue it for a moment, drill small holes for self-tapping screws, and place it on metal screws. We bend the profile according to the shape of the deck.

3) We make fastenings for the lid on which we will stand with our feet.

It was decided to make the fastening from bolts.

Choose options with thicker lengths yourself depending on the selected case.

You can also use self-locking nuts. Like mine on the front two pillars.

Someone will have a question. How will a thin lid support my weight on these four points? Answer: it’s easy. Because there are much more than four points. After all, in addition to the four bolts, there are also the sides of the body. But the main load will be on the battery. More precisely, on a clever battery design that you can order from us. Or you can make it yourself.

The secret is that the lid rests on squares of thick plastic 3-4 mm thick, inserted between the cells.

- Making a lid

The cover is made from an aluminum profile using metal scissors.

Inner part of the lid.

It is necessary to remove the excess internal ribs of the lid. This is easy to do with pliers; if you kind of pinch the edge of the rib and start twisting the pliers, then this rib will easily wrap around them. It is better to seal the inside with film. I used a folder for papers.

- Installing the controller and throttle grip

Everything is clear with the throttle.

We take the controller out of the aluminum case and seal it with household tape.

I used an infinion 6 fet controller. But he had to saw down the textolite so that it would fit.

There is also a budget Bafang 500W controller in a small case that has 3 recovery speeds and draws 14 amps from the battery. But its main advantage is that it fits into this deck without a housing and does not need to be finished. You can also purchase it from us.

A hole is drilled into the side of the deck. There are holes in the controller heatsink that you can use to secure it through this hole.

Also, the compartment with the controller and wires must be closed with a lid. I made the cover from a laptop matrix cover, although any sheet plastic will do.

When this scooter was made, there were no throttle grips with a built-in voltmeter yet, so it was necessary to fence the volt-ampere at the base of the steering wheel. Which added a lot of wires. Now everything is simpler.

And no problems.

Installing the battery and machine

The battery is wrapped with tape for better insulation from moisture. It also makes sense to glue the battery to the deck with double-sided tape or glue. Between the battery and the metal deck you need a gasket made of something dense. I used a plastic paper folder.

The automatic switch, also known as the scooter switch, is an obligatory part of the program. I have it glued to the battery, but you can place it wherever you want.

Connecting

Everything is simple here. We connect, make sure that there is no pinching and that the wires are rubbed with metal.

And now he is ready.

Accumulator battery

The distance the scooter travels depends on the battery. There are several types of batteries: lead-acid, lithium polymer, lithium ion, lithium iron phosphate. The former are known for their use in motorcycles and cars. They are heavy and have a small number of charge-discharge cycles compared to other types.

Note!

- DIY rocking chair: TOP-120 photos of the best manufacturing options. Master class on creating a rocking chair at home

- Smokehouse from a gas cylinder - the best master class on making a homemade smokehouse with step-by-step photo diagrams for beginners

- Do-it-yourself compressor: TOP-130 photo reviews of finished compressors. Step-by-step instructions + diagrams and drawings

Polymer and ionic are the most suitable in terms of weight, technical characteristics and price. For lithium-polymer batteries, the number of discharges and charges is up to 800, for lithium-ion batteries – up to 1000 cycles. Both types are lightweight and dependent on ambient temperature. In cold weather the discharge occurs faster. In addition, there is a danger of fire or explosion when overcharging.

The lithium iron phosphate battery is not afraid of mechanical damage, is resistant to low temperatures, is not afraid of overcharging and has up to 2000 charge-discharge cycles. But it is heavier and more expensive than polymer and ion batteries.

You can buy a ready-made battery pack, or you can assemble it yourself, for example, based on 18650 batteries. Which one to use depends on personal preferences and available resources.

Battery installation is done in different ways. Can be installed below in a platform called a deck. This option is preferable as it does not raise the center of gravity. But in this case, additional protection against impacts and mechanical damage is required.

Another location for installing the battery is the steering column. There, either a hanging container is made, or installation is carried out in a rack if it is made of several pipes.

Note!

- Do-it-yourself wind generator: TOP-170 photo reviews of finished devices. Detailed DIY instructions for beginners

- Do-it-yourself spot welding - the best master class on making homemade spot welding with step-by-step photo diagrams of do-it-yourself work

- Do-it-yourself tennis table: TOP-150 photos of the best manufacturing ideas. Master class on creating a tennis table at home

No matter how the battery is mounted, it must be protected from moisture. Waterproofing of a self-made electric scooter is carried out using electrical tape, sealants, and the manufacture of moisture-proof covers.

How to make an electric scooter?

There are now quite a lot of offers on the Internet for purchasing electric scooters of various capacities, designs and sizes.

But their cost is often not affordable for everyone. As you know, the cheapest way to get something is to create it with your own hands, using only raw materials, improvised tools and used parts of other devices. Here is a small step-by-step instruction on how to assemble your own electric scooter with your own hands with minimal investment.

The scooter is designed for a maximum speed of about 30 km per hour, will have about 3 horsepower and can travel about 18-20 km on a single charge.

Step 1: Parts and Tools

Below is a basic set of the most important components (parts) used and the tools required. As much as possible, stock up on used parts from various electrical appliances that often gather dust in your attic or garage.

How to make a good electric scooter, and what you need for it:

Details:

- Wheels - 12.5-inch low-speed pneumatic.

- Motor – 3x CIM.

- Transmission. CIMs are high-speed, low-torque motors, so in addition to reducing RPM, a chain drive requires a gearbox. Franken or Andy Mark Toughboxes (from 2005) are suitable options.

- Motor controller + choke – Kelly KDS72200E, 72V, 120 A, 200A controller is quite suitable.

- Batteries – 8 pcs. (the quantity depends on the required power).

- Aluminum angle, channel, flat rod in various sizes.

- Shock absorbers - two rear shock absorbers from mountain bikes will do.

- Nuts, bolts, studs, washers and screws - many different sizes.

- 1/2″ stud – 1-2 m and nuts for it.

- 1/2" 8 mm stainless steel rod + roll clamps - for support points in the suspension.

- Power switch.

- Fuse holder, fuse.

- High current connectors.

Tools:

- Drill/screwdriver – with a lot of bits.

- Band saw (if any) – with metal cutting blades.

- A lathe is not necessary, but will ensure drilling perfectly aligned holes much easier than with a hand drill.

- Sanding machine – for smoothing sharp corners.

- Torch burners and aluminum-zinc soldering sticks.

- Large assortment of clamps.

- Soldering iron + solder - one with a very thick tip for soldering large power connectors and batteries, and a replaceable tip for finer work.

- Lithium battery charger with power supply.

- At least 2 adjustable wrenches and a set of open-end wrenches from 10 to 26 numbers.

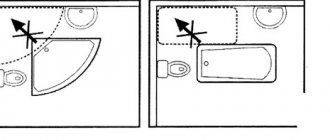

Step 2: Selecting a scooter base

Making a new homemade electric scooter must start from the base - the frame of a former regular scooter.

The base from any classic Razor scooter will do, especially the front and rear wheel suspension, which uses springs and shock absorbers rather than rubber, and it has a more elegant folding mechanism.

Converting a regular scooter into an electric scooter is the easiest way, but there will be a problem with space for hanging equipment.

It is unlikely that you will be able to use old wheels. As a rule, they are always worn out, and the bearings are loose or broken. So you will have to buy new base wheels (preferably with replacement tires). When selecting a frame and wheels, keep in mind that the future structure should rise 10-15 cm from the surface of the ground with the wheels mounted.

Step 3: Rear Suspension

To accommodate good wheels, you will need to build a completely new aluminum rear suspension. A few cheap mountain bike shock absorbers with a spring force of approximately 250-300 kg/cm will come in handy here.

Similar parts are sold in large quantities at specialized markets/shops, and there are also many of them at online auctions. The shock absorber mounts are made from 1/4″, two 2″ and 1″ U-channel aluminum.

Step 4: Fork

Like the rear suspension, the fork and front suspension will also receive significant upgrades due to the new wheels. Here you can also use springs and shock absorbers from a mountain bike fork to create a new pair of shock absorbers with a pivot at each end.

This design is much simpler and more reliable than a telescopic fork. With this design, the front wheel can be easily centered in front of the steering column axis. It is very important to install the wheel slightly forward - this will significantly increase the steering characteristics. Don't be afraid to raise the front of the scooter a couple more inches if necessary.

Step 5: Wheels

To secure the wheels to the rest of the scooter, you need to make your own axles from 1/2" threaded rods (studs) and matching nuts.

The inner diameter of the wheel bearings will fit at 5/8″, so to get a 1/2″ axle that will fit snugly around the bearings you will need appropriate shims.

Manufacturers of electric scooters make their parts unique and unsuitable for other models. Therefore, you will have quite a large choice of wheels.

The nuts are screwed together until their flanges press against the outside of the wheel bearings. To secure the spacers in place, a second nut is additionally screwed on. Four more nuts are used to secure each wheel to the frame.

Step 6: Gearbox

Since the CIM motors we plan to use are relatively high speed, low torque motors, a gearbox is needed to reduce the output speed of the motors to an acceptable level. A homemade electric scooter, made with your own hands, will not be able to work without a gearbox: this is not a toy car, here you need to ensure a smooth start.

In principle, any two-speed gearbox will do. Again, we select used ones for the lowest price. We cut out the gearboxes to eliminate as much wasted space as possible and remove the housing completely to create a 3-motor transmission with a single output shaft.

We install the gearbox on the scooter using the original bolt holes built into the gearbox and some aluminum angle pieces bolted to the scooter frame. Finally, 21 sprockets are attached to the output shaft for a #35 chain.

Step 7: Chain Tensioner

The most difficult part of a future electric scooter in terms of installation and subsequent adjustment is the chain tensioner.

Due to its location, when the scooter's suspension is compressed, the effective length of the chain between the sprocket on the gearbox and the sprocket on the rear wheel increases.

It must maintain (compensate for) additional chain tension. In addition to the chain tensioner, the scooter also needed an idler sprocket.

When driving on uneven surfaces, jumping or minor body impacts, the chain may fly off the rear sprocket. To prevent this from happening, you will have to machine a special limiter. You won’t be able to build an electric scooter with your own hands using a regular screwdriver: the torque is too small.

Step 8: Brake

Motors and drive chains are great, but being able to stop your scooter in time is even more important. Since disc brake rotors are simply large spinning metal discs attached to a wheel, you can simply use the wheel's drive sprocket as a disc brake.

It will be necessary to build a caliper to grip the sprocket from an aluminum block. To do this we use an aluminum U-channel, two brake pads, springs and several bolts. You can use absolutely any pads - this is a racing car.

We attach the right brake pad to a rod that passes through the caliper, springs and aluminum suspension frame. As the spring expands in the middle, the brake is inactive and, if necessary, the brake cable pulls the two halves of the caliper towards each other so that they both move towards the sprocket and compress it on both sides, providing braking.

Step 9: Steering Wheel

For greater and more confident control, we will need a wider steering wheel, because our wheels will be quite wide. Almost any handlebar from both the Soviet model and modern mountain bikes will easily fit.

We fix it on the steering column, having previously adjusted the clamp with an aluminum bracket with bolt tightening. If the steering wheel is quite thick, then you can easily place a throttle and a hall sensor in it.

Step 10: Frame (base)

How to make an electric scooter from an ordinary scooter? The original frame from a standard Riser scooter will be quite small. It can be used as the main platform for attaching an additional surface made of lightweight materials.

This will provide more space for hanging components such as batteries. The new surface can be made of carbon fiber or high-strength plastic - this will significantly increase its wear resistance.

We screw the new base on top of the old one using countersunk stainless steel screws.

Step 11: Mounting and Connecting Electronics

We install the electric motor controller on the front side of the gearbox as close as possible to the aluminum corner of the frame to leave as much space as possible for the batteries.

The main power switch is bolted directly to the scooter's deck, while the fuse holder and fuse itself are bolted to the bottom of the frame (you can use an aluminum angle or channel).

It is better to use a 200A fuse as this is the peak current of the motor.

All electrical connections must be made using durable, conductive connectors. DIY electric scooter diagrams and connection drawings can be easily found on the Internet for various types of engines, gearboxes and batteries of any power.

Step 12: Battery

To minimize the weight of the entire structure and the energy reserve, the best option would be to use 5 Ah lithium polymer batteries (for example, LiPo from HobbyKing).

With this volume, 8 batteries will be enough; we take one more as a spare. Large batches often contain defective elements. Of course, they can be replaced later in the store with a new battery, but it is better to immediately take them with a reserve. As a result, we will get a battery with characteristics of approximately 60V and approximately 600W of output power.

Step 13: Battery Holder

A DIY electric scooter build is not complete without a battery attached to it. In this case, it is necessary to consider the possibility of quickly replacing power supplies. To install the batteries on the scooter frame, we build a small aluminum or plastic box.

It is better, of course, to use polycarbonate and cover it with carbon fiber for greater strength. The box must be fixed with bolts with a countersunk head so that when moving its head does not cling to the legs and does not protrude on the surface of the frame.

Step 14: Final Assembly Stage

The final stage will be assembling and soldering the entire structure together. To do this, we use a screwdriver with bits, open-end wrenches and a screwdriver. Tighten all bolted connections tightly and double check them.

That's about it - assembling the electric scooter with your own hands is complete, you can go for the first field tests, after which you can modify or improve the resulting model.

Source: https://nakolesah.guru/kak-sdelat-jelektrosamokat/

Controller

The controller is, one might say, the brain of the engine. How the scooter will ride and its acceleration at the start depends on it. Selected according to engine parameters. If the motor consumes 36 V, then the controller must be 36 V.

The power is selected taking into account the reserve for the starting load and forced movement. As a rule, a reserve of 2-2.5 times the current is taken. That is, if the motor has a power of 300 Watts, then its rated current is 8.3 A (300W/36V). This means the controller must withstand up to 21A.

Battery

The main characteristics of the battery, which are indicated in the catalogs, are its rated voltage and capacity; the larger these parameters, the better. Both of these parameters affect the most important parameter of the battery - energy (power) reserve. This parameter will determine how far you can travel without recharging.

Energy (power) reserve is measured in watt hours (Wh or Wh). For a powerful motor, the energy reserve value must be at least 450 Wh. For average – 250-300 Wh. For the weak – 180-200 Wh. These are the average values of factory modifications. No one forbids powering a medium-power engine from a capacious battery with an energy reserve of 500 or even 600 Wh, as a result the travel range will increase to 50-70 km. That's the beauty of DIY.

Control

The scooter controls consist of a power switch, gas and brake handles. It is better to make gas in the form of a hook, because it is safer. In case of an unforeseen situation, such a handle is instinctively released.

The brake handle must be equipped with a switch that will turn off the engine when pressed.

Now let's look at a few instructions on how to make an electric scooter using different engines.

With a hoverboard wheel

It's enough to make a scooter using a broken hoverboard. Such a device will look quite aesthetically pleasing. In addition, it will have good technical characteristics.

The manufacturing scheme for an electric scooter from a hoverboard is as follows:

- Take one motor-wheel from a hoverboard;

- If we use a frame from a finished scooter, then make a fork to attach the rear wheel under the wheel from a hoverboard. If we make the frame ourselves, then we immediately take into account the fastening;

- Install the motor controller;

- Install the battery;

- Install the throttle handle and the power button.

After installing all the parts and elements, we check the functionality and use it for your pleasure.

Homemade scooter on skis

I probably won’t discover America by saying that children know how to baffle their parents... My daughter has a scooter with small wheels, which she no longer likes because of the same small wheels, photo from the Internet.

And a small bicycle, again with small wheels, which is not satisfactory for the reason that my knees touch the handlebars, photo of a real bicycle.

This is the last time we see him. In the background is a White horse, already with large wheels.

So, the task was set to make a scooter out of a bicycle with large wheels. Having scratched the top of my head, I went to the garage... More on that later... Since a scooter with small wheels is no longer available, and at the “technical advice” my daughter and I decided to make a scooter on skis. What you need: free time (there’s plenty of it during the holidays!), scooter, pieces sheet metal and mini skis.

We disassemble the skis and drill through holes with a diameter of 4 mm.

Then we select the required sheet metal, 2mm thick, and mark it.

Before welding the cut parts, I decided to do this.

Trying it on for skis...Normal!

This is the main mechanic and initiator of all this disgrace.

We paint, dry, and put this “sandwich” together

Next, field tests on the Bardykovka River. The slide is right next to the garage...

It took two evenings, 3 hours each, to build this scooter—with an assistant. And in one I think faster. There are not many photos without a description (as I said above, more on this later) of our parallel project “Scooter on Big Wheels” with my daughter. The construction of the scooter occurs from the rear.

Post by user MishGun086 from the DIY community on DRIVE2

Using a screwdriver

One of the simple options is to make an electric scooter with your own hands from a screwdriver. In this way, it is unlikely that you will be able to make a powerful and high-speed scooter. But this is undoubtedly the most accessible and cheapest option. For this you will need:

- Screwdriver;

- Regular scooter;

- Bicycle chain;

- Bicycle sprocket;

- Wires.

The sequence of actions is as follows:

- A bicycle sprocket is rigidly attached to the rear drive wheel.

- A small drive sprocket is made of metal, which is clamped into a screwdriver.

- A screwdriver holder is made from square pipes or corners.

- The holder is attached to the frame using bolts or rivets. The holder must be attached in such a way that it is possible to adjust the chain tension.

- The bicycle chain is measured and cut to size.

- A control button is attached to the handle.

This option is good because you don’t need to place the entire device next to an outlet to charge.

The battery is simply removed from the screwdriver and placed in a standard charger. There is also no risk of fire or explosion of the battery from overcharging.

Gasoline scooter from scratch

Hello everyone, I suggest you read the instructions for making a homemade scooter with a gasoline engine. The homemade product is made quite reliably, a powerful disc brake is installed, the frame is welded from profile pipes, the scooter is even equipped with a footrest. The power unit is an engine from a lawn mower with an automatic centrifugal clutch. Of course, the engine is too powerful for such a homemade product, so unlocking its full potential may be impossible and life-threatening. If the project interests you, I suggest you study it in more detail.

Materials and tools used by the author:

List of materials:

- boards, plywood (or similar); — rectangular profile pipes; — spare parts from an old bicycle; — chain drive from a moped, motorcycle (or similar); — disc brake from a bicycle or moped; — wheels for trolleys; — engine from a lawn mower; - sheet metal; — threaded rods, nuts, washers, etc.; - dye; — fittings; — spring for the footrest.

List of tools:

- welding machine; - Bulgarian; - drilling machine; - spanners; - Grinder.

Scooter manufacturing process:

Step one. Rear axle

Let's make a rear axle for a scooter; a threaded rod will be used as it. The author's wheel has two bearings, which are pressed into a steel pipe. In order for the bearings to be tightened with a threaded rod, a spacer must be made between them. The author uses a piece of plastic plumbing pipe as such a spacer.

Step two.

Installing the driven sprocket and brake disc Next, you need to attach the driven sprocket to the rear wheel. It needs to be installed from the wheel rim with a gap so that there is room for the chain. To obtain this gap, the author made a “spacer washer” from thick sheet metal. You can use several of these washers to get the desired gap.

Step three. Making the front fork

Let's make a front fork; for this, the author adapted an old bicycle fork. We simply cut off the excess from it, flatten the edges of the tubes with a hammer and drill holes with a step drill. In the end, all that remains is to screw the front wheel to the fork. Of course, we first clean the fork from rust and old paint. The bushing with bearings for the steering wheel will also need to be cut off from the bicycle frame.

Step four.

Frame assembly For the frame you will need rectangular profile pipes. First we weld a rectangle, in the rear we automatically get a fork for the rear wheel.

In the front part we weld a bushing from the bicycle steering; in addition, the author strengthened the front part using parts cut from an old bicycle fork. It all turned out quite interesting, but at the same time strong. We seal the open sides of the pipes with steel plates to prevent dirt from getting inside, which causes rust.

Step five. Rear brake mount

We mount a disc brake mount on the rear fork. The author cut it out of sheet steel, drilling mounting holes in the right places. We weld this part well to the frame.

Step six. Drive sprocket installation

A drive sprocket must be installed on the motor shaft; it must be as small as possible in order to obtain high torque. To install the sprocket, we saw off the nose of the engine; it is made of plastic; the author cuts it with a hacksaw. The sprocket will be held in place with a cotter pin. The cotter pin must be strong, made of carbon steel, otherwise it can easily break off when driving.

Step seven. Engine Installation

We will install the engine on the frame, we will have it as a circuit, and we will fasten it with the help of screws that hold the gas tank. We cut steel tubes and weld them with sheet steel, and then drill holes. We screw these tubes to the engine, and then weld a steel plate to them. The result is a convenient and reliable bracket.

Step eight. Finishing touches

Finally, we lengthen the handlebar using a piece of pipe, and also weld the seat from the bicycle. We make a kickstand for the scooter so that you don’t have to rest it against walls, fences, and so on. The author welded a reliable footrest from rebar. When everything is ready, all that remains is to paint the metal parts. As a result, the scooter will look “like it came from the factory.”

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Recommendations

Making an electric scooter with your own hands is not a very complicated process, it is creative and interesting. On the Internet you can watch a video on how and what you can use to realize your idea.

As a result, it is possible to make a device of an unusual design with outstanding technical characteristics. There may be mistakes and failures along the way. It is worth noting that a homemade version may not always be cheaper than a factory one.

It all depends on what materials and parts to use. However, repairing a do-it-yourself electric scooter will definitely be easier, because you will know all the parts and components.

And you yourself are responsible for their reliability. After all, if you repair a scooter purchased in a store yourself, this may void the factory warranty.

When making an electric scooter, it is important to consider such points as frame strength and engine power. Its rated voltage and current. Select the correct controller and battery based on engine parameters.

It is necessary to protect the battery pack from damage. It is also worth taking care of the moisture protection of all electrical elements and connections to avoid short circuits. You should refrain from using an electric scooter in rainy weather.

Manufacturing methods

There are many different diagrams and instructions for making any model of vehicle available in the public domain. In some cases, a homemade electric scooter can consist of 80% of the usual one. You can also borrow components from an old bicycle. Such models are the easiest to assemble and do not require complex welding work. You can get a convenient vehicle even without using an electric generator if you have a simple electric motor from a drill. The battery capacity of the screwdriver is quite enough for a 1.5-hour trip. A more complex upgrade involves the creation of a finished frame structure from metal corners, sheets of steel, hot welded together. As a rule, the steering and wheel drive are taken from old bicycles or scooters.

To make the ride easier, improve cross-country ability and basic characteristics, you can install large-diameter wheels; they require an additional set of shock absorbers.

Conversion from a regular scooter and bicycle

The technically simplest way to create an electric scooter with your own hands is to remake a foot-type device or an old bicycle. To make the product yourself, you need:

- Choose a frame from an ordinary mechanical scooter. It is important to consider the width of the wheelbase and the size of the planned battery compartment. A case from any classic model can be suitable here.

- Take the suspension and steering from an old mountain bike. The spring force of 250–300 kg/cm is quite enough for a comfortable ride. Bicycle or disc brakes can also be used as brake pads. There is no need to invent something new here. It is enough to attach old or new brakes to the wheels.

- To fix the wheels selected in advance, make a homemade axle from threaded rods and nuts that match the size. Manufacturers of electric scooters rarely worry about unifying elements, so the choice in this case may be limited.

- To ensure smooth operation even when going uphill, prepare a small gearbox. It will reduce the output speed, increasing the engine's traction power.

- Install the chain tensioner. It is necessary to ensure smooth transmission of torque from the gearbox to the wheel through the chain. Moreover, on any bump without a tensioner, the last element can simply fly off.

- Install the steering wheel. Here again, old bicycles, for example, mountain bikes, will help out (the part can be removed from them).

- Connect the electronic “filling” and do the final installation. It is better to place the electric motor controller with a set of fuses closer to the steering wheel so that there is more space for installing the battery pack. Its diagrams can be found on the Internet, but it is better to purchase a new element. The electric scooter can be equipped with a CIM type motor. As batteries, you can take prefabricated Li-On blocks of standard power. For a basic 600 W assembly, 6 pieces are enough.

- Install the battery box. It can be assembled from thick-walled plywood on the steering rack, thus freeing up the platform below. It is allowed to install the box from below. The main task here is to remove the battery as quickly as possible if necessary.

It is also possible to assemble another scooter model based on a ready-made electric wheel ordered from China. This is essentially a full-fledged electric motor that does not require connecting a gearbox or chain drive. It can be installed on a standard bicycle or scooter wheel.

The frame of the product can be assembled on the basis of a children's bicycle, but with a modified bottom. The base is welded from metal tubes so that a smooth bend is obtained from the steering wheel to the rear drive wheel. In this case, it is worth leaving a cavity for mounting batteries. The handlebar will come from an old bicycle. The rear and front forks can be made from the same corners. They are welded to the “donor” frame, and holes are made in them for mounting wheels.

The disc brakes on a brand new electric scooter can be removed from a mountain bike. It is recommended to use a sheet of moisture-resistant plywood to cover the box. The battery pack can be assembled from the same type of Li-On batteries of the 18650 type. A capacity of 25 Ah with an operating current of 48 V will be quite sufficient.

With a screwdriver motor

A scooter made from an electric screwdriver is, of course, not the best idea for creating a truly powerful and reliable model, but it is definitely one of the most affordable and cheapest. This budget product will be based on ABS pipes. For the frame part you will need only 3 pieces - 2 long pipes and 1 shorter one. To cut them you need a hacksaw or jigsaw.

The next step in the work is to install the rear drive wheel. It is attached strictly parallel to the frame on metal bushings installed inside the pipes. Next you will need to install the fork and front wheel. To do this, a bushing is attached to a fork made from two pieces of pipe, which is tightly glued to the frame.

Installing a screwdriver is an important and almost final stage of work. Here you will need to make a special platform from plywood. The screwdriver itself can be secured with simple plastic ties, and tightly. The drive sprocket is attached through a rod pulled into it to the rear wheel drive. You can take it from any old bicycle. The chain is tensioned and cut to the desired length. The only control button can be placed on the steering wheel along with the brake handle, which is mounted on the rear wheel.