A table circular saw is a stationary electric tool designed for cutting workpieces from a wide variety of materials - wood, plastic, metal. When installing a special disk, you can even work with ceramic tiles. Such units will prove to be truly indispensable in summer cottages where various construction works are being carried out; in an apartment they will help to save time and effort during repairs. In particular, with the help of this tool it will be possible to cut plywood, parquet boards, laminate, door panels, and panels made of plastic.

Construction stores offer a wide selection of sawing machines, so it’s quite easy to get confused in the assortment. To prevent this from happening to you, we decided to compile for you a rating of the best table saws. In this article we will not only talk about the most popular products, analyze the characteristics of the models, but also provide some tips on how to purchase the product wisely.

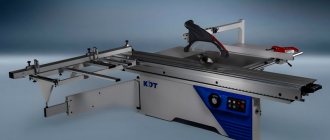

Design

Most often in private and industrial use there are units that dissolve wood using the rotational movement of a special disk blade. They are as compact as possible and can be used both in production and at home, by reducing the size and installing engines of moderate power.

The design is based on a frame - a supporting body on which the cutting table is mounted. There is a slot in the middle of the table for installing a cutting blade. The workpiece is fed longitudinally and transversely with support on the table.

Using this device you can perform various operations:

- Unravel boards and beams into thinner (narrow lumber).

- Cutting sheet materials: furniture panels, particle boards and fiberboards, plywood sheets, as well as various polymer materials.

Materials

How to make a machine for a circular saw with your own hands? First of all, you need to choose materials.

Tabletop

The key requirement for a tabletop is resistance to increased loads, vibrations and shocks. It is important that the surface is smooth enough and does not bend under the influence of a weight of 50 kg. Optimal materials include the following:

- metal - it is permissible to use steel or duralumin;

- Laminated chipboard or plywood, which is resistant to moisture;

- textolite

You should not make the tabletop from plastic, chipboard, or OSB. Such raw materials are considered unstable to vibration. It is acceptable to use natural wood. But in this case the design will be very expensive.

bed

Wooden beams can be installed on the base of the table. It is recommended to secure them under the cover in order to increase rigidity. It is best to use timber made of hard wood - beech or oak. They are characterized by their low cost and ease of fastening using self-tapping screws.

Motor

Experts advise using a motor with a power of no more than 1000-1200 W. Otherwise, using the device may be dangerous. In addition, a powerful saw requires a heavier and more stable table.

Rotation transmission

It is permissible to use a belt drive for construction. In this case, rotation is transmitted to the working shaft using a V-belt. The pulleys on the machine can be the same size. Therefore, the rotation speed of the working shaft will be the same as that of the engine.

Criterias of choice

Under the general name, wood sawing machines are a broad category of products, so when choosing, you need to take into account several parameters at once.

Device class

As in many other areas, the classification of wood sawing machines is based on their intended use.

It is customary to distinguish three categories of products:

- S3 is a tool designed for household needs. Suitable for small-volume and short-term work that may be required in a private household. The electric motor usually has built-in overheating protection. When it is triggered, you must wait until the system cools down. This usually happens after 15 - 20 minutes of work under load.

- S6 are semi-professional machines; they have a large margin of durability and performance. They may also have the ability to install equipment for dissolving large-sized materials. Suitable for work such as construction on site or for use in small businesses.

- S1 – professional machines. Their high cost is compensated by their high power, reliability, and the ability to operate continuously for a long period of time, which is usually 5–8 hours. Such units are not found in private farms, since they do not pay for themselves even with intensive work. But for the woodworking or furniture business they are a real godsend.

Power Options

Household machines are powered according to the standard accepted in residential premises and private households: 220 - 230 Volts.

Electric motors are designed to put less stress on the wiring. However, it is advisable to connect all sawing machines without exception through a starter, which will automatically open the circuit when overloaded.

Expert opinion

Levin Dmitry Konstantinovich

Professional equipment and some mid-level devices are equipped with powerful electric motors, the power of which requires a three-phase network, that is, 380 Volts. In commercial workshops this is not a problem, but for domestic use you will have to negotiate with the electricity supplier and conclude an agreement.

Power

Performance depends on engine power: it affects torque, that is, the ability to quickly dismantle large workpieces of dense wood. In portable desktop machines, the motor power rarely exceeds 1 kW. Universal floor-mounted units are already more powerful - 1 - 1.6 kW. And powerful models usually consume at least 1.8 kW. Assess the required power according to the nature of the planned work: if you plan to unravel plywood panels less than 1 cm thick, then a power of 800 W will be enough. And if there is a need to independently cut timber and boards for building a house, then it is better to choose machines of at least 1.5 kW.

Speed

When the blade rotates at high speed, it makes a precise cut, but it gets very hot and heats up the wood. High speed sawing is suitable for small to medium-sized pieces of dry hardwood. On viscous fibers of natural moisture, a rapidly rotating disk on a weak engine can stall. For thick wood, low-speed machines are used. They cut slower but with more force. The threshold difference is considered to be 2.5 thousand revolutions per minute.

Configuration

Do you already have a wood saw in your workshop?

Not really

Small units are tabletop. Their height is small, so for comfortable use it is better to place them on a workbench or durable desktop.

More powerful equipment has legs or a serious welded frame so that the cutting table is located approximately at the level of the waist of the person working at the machine. The mass of industrial specimens can reach several hundred kilograms, so they are installed permanently in a specially designated place.

A sawing machine may have one small table for placing lumber on it or special retractable elements, with the help of which the working surface can be significantly increased. This is justified when working with long or wide workpieces.

Extra options

Among the characteristics that are not of fundamental importance, but in every possible way optimize the process of working at the machine, you may also encounter:

- Smooth start . The engine lasts longer. There is no surge in electricity consumption, which prevents network overload.

- Speed stabilizer . Even under heavy load, the speed is maintained and the machine does not slip.

Specifications

Component Location

A review of the functional qualities of the machine should begin with a study of its technical characteristics. Since this type of equipment is intended for completing small-scale production lines, special attention is paid to operational parameters.

The weight of the machine directly depends on the type of modification. Thus, the weight of the original model with a built-in chip vacuum cleaner is 815 kg. For the model with the letter “K” this parameter is equal to 405 kg, and the designation “T” has a weight of 620 kg. This difference must be taken into account when arranging the installation site.

The same difference exists in the size of the equipment. The original model has dimensions 161 * 150.5 * 115 cm. The modification with the letter “K” is 141 * 160 * 109.5 cm, with the designation “T” - 138 * 130 * 125 cm.

Technical characteristics of circular saw equipment models Ts6-2:

- width of processed material – from 400 to 600 mm;

- the maximum permissible thickness of the workpiece when performing longitudinal cuts is from 100 to 125 mm;

- when cross-cutting, the thickness of the workpiece can vary from 110 to 135 mm;

- saw blade diameter. In the original model it can range from 315 to 500 mm. For modifications, this parameter is 400 mm;

- the original design has a mechanism for raising the saw support to a height of up to 10 cm;

- rotation speeds of the block with the saw blade are 2880, 3180 and 3000 rpm;

- for all models the final stop time of the saw is 6 seconds;

- desktop dimensions – 83*120, 82*111.5 and 70*130 cm;

- the desktop is located at a height from the floor level at a distance of 800 or 747 mm;

- the movable carriage changes its position by a distance of 100, 97.7 or 90 cm;

- the work table on a movable carriage has dimensions of 51*59, 45*60 or 55*70 cm;

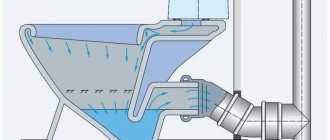

- parameters of the chip removal system. The diameter of the inlet pipe is 11 cm, the system capacity is 810 m3/h.

All models are equipped with electric motors with the same power, which is 4 kW. To connect the power plant, a three-phase 380 V power supply is required.

To ensure normal operation of the equipment, it is not recommended to stop the electric motor more than once every 10 minutes or no more than 6 times per hour. Thus, it is possible to increase the time of maintenance-free operation of the installation.

Manufacturers of sawing machines

Construction stores are filled with all sorts of options for such equipment, so quickly choosing the right model can be difficult. Experts recommend taking a closer look at units from well-known manufacturers, the quality of which is confirmed by positive user reviews:

- Makita Corporation - the main activity of the Japanese corporation is related to the production of professional-type electric and gas tools for construction work. The range includes over 1000 models, ensuring efficient processing of any materials. The advantages of the units include the reliability of the engines and the quality of components. They are often used for work characterized by extreme loads.

- Metabowerke GmbH is a German company that produces equipment for industrial and manual processing of materials. The Metabo brand's core slogan, “when you need reliability,” guarantees users the purchase of a powerful, durable and ergonomic tool that ensures efficient construction work in the toughest conditions.

- JET Equipment & Tools is an American manufacturer of metal and woodworking equipment. In 1988, the company was absorbed by the Swiss concern Walter Mayer AG. Household machines are assembled in the USA, Germany, and China. Professional units are supplied mainly from Taiwan. Every year, engineers develop new products whose design is improved in accordance with market requirements. Quality control at all stages of production allows us to produce reliable units.

- TechTronic inductries is a Japanese company that develops, produces and sells power tools and garden equipment under the Ryobi brand. All products are assembled at our own factories in the USA, Germany, and China. The popularity of the models is due to high quality, equipment with innovative technologies, the ability to carry out most of the assigned tasks, and low price.

- Einhell Germany AG is a German company that produces tools for construction, repair work, gardening and recreation. Its innovative products are represented in markets in more than 90 countries. The models are assembled mainly at Asian enterprises. In its work, the company adheres to the principle of combining simple solutions with high quality, which allows it to produce goods at an affordable price.

- Black +Decker is an American company that produces gardening equipment, power tools for construction work, and small household appliances. The advantages of the brand include the constant updating of the range, the models of which help solve most problems in arranging a summer house or home.

- Stavr is a Russian manufacturer of electrical construction tools and equipment for gardening. All models undergo thorough quality and performance testing. Refinement taking into account customer requirements allows us to produce ergonomic, reliable and safe units on the market.

- Caliber - a Russian company produces construction and garden tools at a low price . The range includes models whose technical parameters ensure their regular use in everyday life. Products are attractive due to the lack of bells and whistles and additional frills.

- Zubr OVK is a Russian company producing construction equipment . The brand’s devices are valued for their high reliability, quality, ease of use, and low price. By constantly updating the range and improving previously released units, the company is able to timely meet the growing needs of users.

- Bosch , a German corporation, is a reliable supplier of construction tools and household appliances . The brand's leading position in the market is due to the quality, reliability and functionality of its products.

- Proma -group is a Czech industrial group of companies that produces over 600 items of universal wood and metal working equipment of manual and automatic types. All materials and components undergo thorough testing before being sent to assembly plants, which guarantees the quality of the goods and compliance with accepted standards.

Which sawing machine is better

If you choose a unit by engine type, then motors of category S1 are considered the most powerful. They are designed to operate without interruption. In budget instruments, an element of the S3 series is installed, the duration of operation of which does not exceed 15 minutes. The higher the disk rotation speed, the better the quality of workpiece processing. The device will be more compact and mobile. A lower speed guarantees the accuracy of cutting wood of any density while working without stopping. Pull-out elements in the table allow processing of large-sized material. The level of safety and ease of use of the operator depends on the type of additional functions. The VyborExpert project team recommends paying attention to the following machines:

- The best inexpensive model is Zubr ZPDS-200-800;

- The unit with the best performance is Metabo BKS 450 Plus – 5.5 DNB;

- The most compact is Caliber EPN-900;

- Users' choice - Black+Decker BES720-QS;

- Best functionality – Bosch GTS 10 XC;

- The best option in terms of price/quality ratio is Metabo TS 216 Floor;

- The most convenient to use is the Ryobi RTS1800EF.

There are various models of machines on the market, so the main selection criterion is the area of use of the tool. For domestic needs, models with lower power are suitable. Professionals are advised to buy units that are designed for uninterrupted operation, which ensures their high performance. Almost all devices have pros and cons, so analyzing the reviews in the rating will help you understand which device is suitable for specific jobs.