Information about the manufacturer of the tabletop drilling machine model 2СС1М (2СС1)

Manufacturer of the tabletop drilling machine model 2СС1М (2СС1) Saratov plant of heavy gear cutting machines, SZTZS , founded in 1947.

Machines produced by the Saratov Plant of Heavy Gear Cutting Machines, SZTS

- 2СС1м, 2СС1

— tabletop drilling machine Ø 6 - 5A250p

gear planing machine for cutting spur bevel wheels Ø 500 - 5С276п

gear cutting machine for cutting spur bevel wheels Ø 500 - 526

— semi-automatic gear cutting machine for cutting bevel wheels with straight teeth Ø 610 - 5A26

- gear cutting machine for cutting bevel wheels with straight teeth Ø 610 - 5230

— semi-automatic gear cutting machine for cutting bevel wheels with straight teeth Ø 320 - 5S280p

gear cutting machine for cutting bevel gears with circular teeth Ø 800 - 528с

- gear cutting machine for cutting bevel wheels with circular teeth Ø 800

2SS1M tabletop drilling machine. Purpose and scope

The 2SS1 tabletop drilling machine has been manufactured according to TU 2-024-4345-83 since 1983.

2СС1 drilling machine has been manufactured according to TU 2-024-5748706-002-88 since 1988.

2СС1 machine is designed for drilling holes and cutting threads in small parts made of cast iron, steel, non-ferrous alloys and non-metallic materials in industrial enterprises, repair and household workshops.

On the 2SS1M it is also possible to mill non-metallic materials with end mills.

The spindle of the 2СС1 receives 3 rotation speeds from three-stage drive pulleys, which provides free choice of cutting speeds in the range from 600 to 1600 rpm.

The end of the spindle is an external shortened Morse taper KM2, designation B16 according to GOST 9953 (Shortened tool tapers) - shortened cone: D = 15.733 mm.

The shortened cone B16 corresponds to a three-jaw drill chuck of the 10th and 13th standard sizes in accordance with GOST 8522 (Three-jaw drill chucks) with a clamping range of 1..10 mm and 1..13 mm, respectively.

An example of a symbol for a 3-jaw drill chuck, size 10, with a connecting conical hole B16:

Cartridge 10-B16 GOST 8522-79

Cartridge 13-B16 GOST 8522-79

The drilling depth is measured using a dial mounted on the gear shaft. The dial division price is 1 mm of drill feed.

The belt tension design allows you to quickly change the position of the belt on the pulleys to obtain the desired cutting speed.

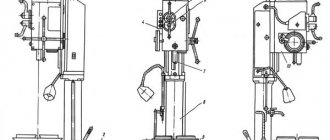

Using a stand to install the machine makes it possible to drill the ends of long parts, such as shafts.

The 2SS1M drilling machine allows you to perform the following operations:

- drilling

- countersinking

- deployment

- reaming

The spindle speed depends on the diameter of the drill installed in the chuck:

- 1..5 mm - 1600 rpm

- 5..7 mm - 1000 rpm

- 7.5..13 mm - 600 rpm

Drilling holes larger than 6 mm is carried out followed by reaming.

As the hardness of the material being processed increases, the rotation speed should be reduced.

Main technical characteristics of the 2ss1m tabletop drilling machine

Manufacturer: Saratov Plant of Heavy Gear Cutting Machines.

- Maximum drilling diameter: Ø 6 mm

- Maximum drilling depth: 70 mm

- Maximum height of the workpiece installed on the work table: 250 mm

- Spindle speed limits per minute - (3 stages) 600, 1000, 1600 rpm

- Spindle end - B16 , external shortened Morse taper 2 according to GOST 9953

- Standard drill chuck - Chuck 10-B16 or Chuck 13-B16 according to GOST 8522-79

- Electric motor power: 0.18 kW

- Machine weight: 53 kg

Morse cone instrumental shortened

Tool taper - Morse taper is one of the most widely used tool mounts.

It was proposed by Stephen A. Morse around 1864. The Morse taper is divided into eight sizes - from KM0 to KM7 (in English: MT0-MT7, in German: MK0-MK7).

Morse taper standards: GOST 25557 (Tool cones. Main dimensions), ISO 296, DIN 228. Cones made according to inch and metric standards are interchangeable in everything except the shank thread.

For many applications, the length of the Morse cone turned out to be excessive. Therefore, a standard was introduced for nine standard sizes of shortened Morse cones (B7, B10, B12, B16, B18, B22, B24, B32, B45), these dimensions were obtained by removing the thicker part of the cone. The number in the designation of a short cone is the diameter of the thick part of the cone in mm.

Russian standard for shortened cones GOST 9953

Tool cones are shortened.

Russian standard for drill chucks GOST 8522

Three-jaw drill chucks.

- B7 - Morse cone KM0 , D = 7.067 mm;

- B10 - Morse cone KM1 , D = 10.094 mm. Cartridge 4-B10 (0.5÷4 mm);

- B12 - Morse cone KM1 , D = 12.065 mm. Cartridge 6-B12 (0.5÷6 mm), Cartridge 8-B12 (1÷8 mm);

- B16 - Morse cone KM2 , D = 15.733 mm. Cartridge 10-B16 (1÷10 mm), Cartridge 13-B16 (1÷13 mm);

- B18 - Morse cone KM2 , D = 17.780 mm. Cartridge 16-B18 (3÷16 mm);

- B22 - Morse cone KM3 , D = 21.793 mm. Cartridge 20-B22 (5÷20 mm);

- B24 - Morse cone KM3 , D = 23.825 mm;

- B32 - Morse cone KM4 , D = 31.267 mm;

- B45 - Morse cone KM5 , D = 44.399 mm.

Where D is the diameter of the cone in the main plane.

Garage, drilling machine. — DRIVE2

Hi all!

Even before purchasing a garage, I knew exactly what kind of machine park I needed. All sorts of grinder drills don’t count, these are hand tools, we’re talking about machines, and this list looks like this: 1. Sharpener2. Drilling machine

3. Lathe

My parents gave me a sharpener on the 30th day of the jam, but I still couldn’t get around to using a drill – frankly, it’s not an essential purchase, and the budget is quite significant. But that didn’t stop me from looking around and thoughtfully choosing what exactly I needed. These are the thoughts I want to share.

So, it all starts with the budget: 15tr is a psychological barrier, we don’t consider anything more expensive. In this budget, we are given either new Chinese machines like Caliber and other clones, or second-hand machines made in the USSR. I won’t ramble on with my thoughts: having had the opportunity to work a lot on the Chinese and the Soviet school 2SS1M, I can say that the crafts of our lesser brothers do not deserve attention at all. But a Soviet machine in good condition and with a good cartridge is a more than worthy thing.

In total, we are looking for a Soviet drill, if possible not very expensive and in the best possible condition. I have been doing this regularly for the last six months, the trend is very unpleasant - prices are rising by leaps and bounds. Today they ask for 10 tr for frankly worn-out rubbish, which is generally beyond the line of evil and good. So if anyone is soaping up, but is stalling for time, it’s time to give birth

Fortunately, the councils produced machines in abundance and the 2SS1M we were interested in was the most popular model, positioned as a machine for vocational schools, schools, small workshops and was distributed there almost forcibly. Therefore, sometimes machines from storage appear on the market, completely new in preservatives, but the price tag on them is usually appropriate - from 15 rubles and above. However, let the seeker find! (With)

Actually, a six-month search through advertisements bore fruit - a new machine appeared in the Saratov region for a reasonable price. True, I had to drive 250 km to get it, but there’s not much choice here - either a dead copy under my nose, or a new one for the same money, but I’ll have to ride it. I chose the second option - I’m not at all eager to restore a copy killed by someone when I don’t have to do it.

In total, this beauty was purchased for 9tr:

92 years old, from storage, without traces of use. All that remains is to add a good chuck to the machine, a machine vice and a workbench on which the machine will live... Fortunately, there is plenty of time until spring, there will be time to think about everything and make it the way I need. Moreover, I already came up with a workbench a long time ago

See you later!

www.drive2.ru

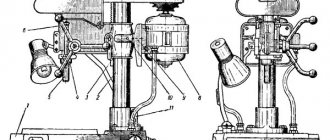

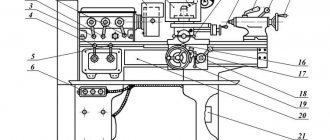

General view of the 2SS1M tabletop drilling machine

Photo of drilling machine 2СС1М

Photo of drilling machine 2СС1М

Photo of drilling machine 2СС1М

Photo of drilling machine 2СС1М

Photo of drilling machine 2СС1М

Driller 2SS1M – Restoration and modification – Drilling machines

The 2SS1M desktop drilling machine can successfully handle drilling and milling a small batch of workpieces. The unit performs drilling operations in steel workpieces, milling non-metals and turning wood.

The unit is designed for domestic use and work in single production.

The machine is equipped with a three-jaw lathe chuck and a clamp with a mounting kit.

As an option, a device is included that allows turning.

Specification of components of the drilling machine 2СС1М

- Machine base;

- Switch;

- Belting;

- Electric motor;

- Traverse;

- Pinol;

- Adjusting bolt;

- Spindle feed handle;

- Rack;

- Gear shaft;

- Protective casing (electric motor guard)

- Table;

- Table clamp handle.

Spindle head of tabletop drilling machine 2СС1М

The spindle head is based on a cast iron body. The housing contains a spindle unit, a belt tensioning mechanism, and local lighting of the machine.

An electric motor is attached to the back of the headstock.

Drilling machine 2SS1M: characteristics | mk-soyuz.rf

The 2SS1M desktop drilling machine can successfully handle drilling and milling a small batch of workpieces. The unit performs drilling operations in steel workpieces, milling non-metals and turning wood.

The unit is designed for domestic use and work in single production.

The machine is equipped with a three-jaw lathe chuck and a clamp with a mounting kit.

As an option, a device is included that allows turning.

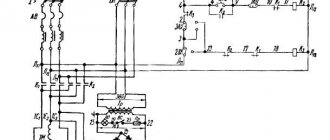

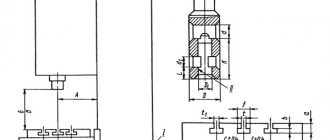

Kinematic diagram of the 2SS1M drilling machine

Kinematic diagram of a drilling machine

The torque on the spindle 1 arises from the electric motor 6 and is transmitted through the V-belt transmission 5. The spindle speed is adjusted by moving the drive belt to the appropriate stage of the stepped pulley.

The quill 2 is moved by the handle 3 through the rack and pinion gear 4.

Setting up the 2SS1M machine for drilling

Milling a groove in a wooden block on a 2SS1M machine

Bearing layout of the 2SS1M machine

Machine setup and operating mode

Setting up for drilling is done as follows:

- lift the quill with spindle 1 (Fig. 5) and with drill 3 fixed in chuck 2 to its highest position

- Set the movable table 5 in height so that the gap between the upper plane of the workpiece 4 and the end of the drill is at least 5 mm

- When drilling holes to a given depth, it is necessary to use a dial mounted on the gear shaft.

- Move the drill to the surface of the workpiece, then, turning the dial counterclockwise (looked from the dial side), align the “zero” division of the dial with the mark on the machine.

- The price of one division of the dial is equal to 1 mm of drill feed.

The required rotation speed of the tool is adjusted by rearranging the drive belt.

The following rotation speed is recommended depending on the drill diameter:

- Drill Ø up to 5 mm – 1600 rpm

- Drill Ø 5—7.5 mm — 1000 rpm

- Drill Ø 7.5-13 mm - 600 rpm

Drilling holes with a diameter greater than 6 mm should be carried out by subsequent drilling.

As the hardness of the material being processed increases, the rotation speed should be reduced.

When drilling large parts installed directly on the floor or stand 2 (Fig. 6), it is necessary to rotate the traverse 1 by 90°.

Having secured the end mill 2 in the chuck 1 (Fig. 2) and the stop 3 on the movable table 5, you can mill a groove in a wooden block 4 by manually feeding the block along the stop onto the cutter. The quill must be locked with bolt 9 (Fig. 2).

Attention! The duration of continuous operation of the machine under load is no more than 30 minutes. Resumption of work on the machine is possible when the electric motor cools down to a temperature of +50° C.

Preparing the machine for operation

The specialist needs to know the operating instructions for the unit:

- The machine is secured to a workbench or work table using holes in the base.

- A drill of the required diameter is clamped in a spindle with a chuck.

- The handle moves the quill to its highest position.

- The workpiece is placed on the table and secured with clamps or other equipment.

- By moving the table, you need to establish a gap of at least 5 mm between the top plane of the part and the top of the tool.

The movement of the tool during processing is controlled by the dial ruler. The division value of the reading device is 1 mm, the mark corresponds to the amount of movement of the tool on the part. Before starting processing, you should connect the zero of the dial with the mark on the machine by rotating the dial counterclockwise.

Electrical equipment and electrical circuit of the 2SS1M drilling machine

Electrical diagram of the drilling machine 2СС1М

Power supply of the drilling machine 2СС1М ~220 Volts.

The machine is started by connecting plug Ш1 to the network, voltage 220 V and pressing the start button of switch B 1. When pressing the button of switch B1, the inching contact is turned on, turning on the starting winding PO and the working winding RO of the electric motor.

After turning off the switch button B1, the inching contact opens, turning off the starting winding of the electric motor.

To avoid failure of the working winding of the motor during an arbitrary stop, you should press the stop button of the switch.

Technical characteristics of the 2SS1M machine

| Parameter name | 2m112 | NS12A | 2SS1M |

| Basic machine parameters | |||

| Largest drilling diameter, mm | 12 | 12 | 6 |

| Maximum drilling diameter, mm | 13 | ||

| The smallest and largest distance from the end of the spindle to the table (base) | 0…400 | 20..420 | 0..370 |

| The smallest and largest distance from the end of the spindle to the table | No | No | 0..250 |

| Distance from the axis of the vertical spindle to the rack guides (overhang), mm | 190 | 185 | 150 |

| Desktop | |||

| Width of the working surface of the table (base), mm | 250 | 360 x 360 | 200 x 200 |

| Width of the working surface of the table, mm | No | No | 200 x 200 |

| Desktop rotation angle, degrees | No | No | 360° |

| Number of T-slots | 3 | 3 | 1 |

| Spindle | |||

| Maximum movement of the spindle head, mm | 300 | ||

| Spindle sleeve stroke, mm | 100 | 100 | 70 |

| Spindle speed, rpm | 450, 800, 1400, 2500, 4500 | 450, 710, 1400, 2500, 4500 | 600, 1000, 1600 |

| Number of spindle speeds | 5 | 5 | 3 |

| Spindle taper | Morse B18 | Morse B18 | Morse B16 |

| Drive unit | |||

| Main motion drive electric motor, kW (rpm) | 0,55 | 0,65 | 0,18 (1420) |

| Dimensions and weight of the machine | |||

| Machine dimensions (length width height), mm | 795 x 370 x 950 | 770 x 465 x 700 | 600 x 240 x 700 |

| Machine weight, kg | 120 | 121 | 53 |

- Household tabletop drilling machine 2СС1. Operating manual 2СС1.00.000 RE, 1989

- Household tabletop drilling machine 2SS1M. Operating manual 2СС1М.00.000 RE, 1989

- Barun V.A. Working on drilling machines, 1963

- Vinnikov I.Z., Frenkel M.I. Driller, 1971

- Vinnikov I.Z. Drilling machines and work on them, 1988

- Loskutov V.V Drilling and boring machines, 1981

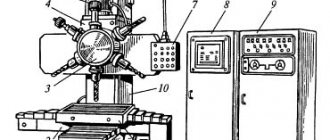

- Panov F.S. Working on CNC machines, 1984

- Popov V.M., Gladilina I.I. Driller, 1958

- Sysoev V.I. Handbook for a Young Driller, 1962

- Tepinkichiev V.K. Metal cutting machines, 1973

Bibliography

Related Links. Additional Information

- Classification and main characteristics of drilling-milling-boring group of machines

- Selecting the right metalworking machine

- Machine repair technology

- Methodology for checking and testing drilling machines for accuracy and rigidity

- Directory of drilling machines

- Manufacturers of drilling machines in Russia

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers