MIG/MAG welding technology

MIG/MAG welding is carried out in semi-automatic mode.

The automatic welding machine operates in an atmosphere of inert or active gaseous substances. During welding, an arc lights up between the workpiece and the welding wire (electrode). Under the influence of the heat of the arc, the material being welded is completely melted. As a result of this process, a weld pool is formed. It is protected from oxygen by a gaseous substance supplied by the burner nozzle. Over time, the elements in the weld pool begin to crystallize, forming a weld. It is necessary to select a shielding gas in accordance with the material of the part being welded and its thickness. When welding non-ferrous metals in a semi-automatic mode, mixtures of argon or helium are used. When welding cobalt or copper materials, nitrogen is used. When welding steels, carbon oxides are used. To improve the strength of the ignited arc and accelerate the formation of the weld, mixtures of MIG and MAG gases are often used.

The following types of MIG/MAG welding are distinguished:

- Large droplet: carried out without short circuits.

- Fine: During welding, small particles of metal are separated from the metal. This type of welding is carried out without short circuits.

- Without short circuits: produced during welding of materials at low voltage welding current.

In semi-automatic drop transfer welding, the welding current density increases, which leads to an increase in arc voltage. As a result, the character of the electrode changes. Large particles are separated from the welded product. The disadvantage of this type of welding is high spatter rates. For this reason, the quality of welding of parts in the ceiling position decreases.

Welding with small droplet transfer is carried out at high voltages and high density welding current. With it, the welded material in a molten state flows into the weld pool. Therefore, this welding method is also called jet welding. When welding products with small droplet transfer, the intensity of heat transfer increases, which leads to a change in the shape of the weld. The main difference between this method of semi-automatic welding is the stability of the burning arc. This means that the welding current voltage does not change.

When welding parts without causing short circuits, the metal in the molten state is transformed into a drop, which leads to an increase in the voltage and length of the burning arc to maximum values. The intensity of the current supply remains unchanged, so the material in the molten state moves into the weld pool until a short circuit occurs.

In addition to semi-automatic MIG/MAG welding, there are 2 other types of welding: MMA and TIG. The decoding of these abbreviations means “manualmetalarc” and “TungstenInertGas”. The main difference between MIG/MAG welding and MMA and TIG welding is the high potential when supplying electrodes and gaseous substances. This increases the welder's work efficiency. Unlike MIG/MAG technology, TIG or MMA welding does not require a large number of machines and tools, because the welding process is different in manual mode.

Unlike other metal welding technologies, MIG/MAG welding has the following features:

- Small time costs for changing welding wires.

- The welding process is fully automated.

- Metals can be welded in any spatial position.

The main disadvantage of this technology is the large losses due to the spattering of molten material, which is associated with the powerful radiation of the burning arc and restrictions on the supply of welding current. When MIG/MAG welding of products, it is also necessary to purchase special welding machines (semi-automatic) that act as a source of electricity and a gas distribution mechanism.

Seam formation

In MIG/MAG welding, a weld is formed by melting the electrode wire. As a result of this process, the basic welding materials crystallize. The resulting seam is reliably protected from exposure to atmospheric air by a gas film. Its size and shape depend on the characteristics of the transfer of material into the weld pool. As heat transfer increases, a small depression is formed in the weld pool, which affects the weld formation procedure.

Aluminum welding capabilities

I would like to note that aluminum is a very “capricious” material for welding. Due to the refractory oxide film on the surface, temperatures above 2000 degrees are required to form a weld pool. But the metal itself melts from 660 degrees, which leads to increased fluidity and burns.

Aluminum connections using manual arc welding are performed in accordance with GOST 14806-80 and 27580-88. In production and workshops, two methods are used - TIG and MIG. The first involves the use of an inverter and a burner with a non-consumable electrode, as well as argon as a shielding gas.

We will describe the best models of machines with their capabilities for this type of aluminum welding in detail in a separate article. Subscribe and don't miss out!

Dmitry Yagolnik

Welding Equipment Expert

The second method is implemented by semi-automatic machines with a fed wire that excites an electric arc. To isolate the weld pool from the external environment, use a mix (80% argon and 20% carbon dioxide) or pure argon. The process and equipment for it are described in more detail in this article.

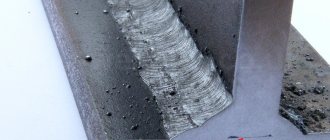

As a result, using the TIG method, more accurate, narrow seams with beautiful flakes are obtained, but welding is slow. When using a semi-automatic machine, the speed of welding aluminum increases, but the width of the seam is uneven and there is more spatter. It will take more time for subsequent processing. Is there an alternative?

Equipment

You already know what MMA TIG MIG is, now let’s talk about the types of machines for each type of welding work.

With inert gas

The gas is in cylinders with specific markings; a reducer is installed on top that regulates the amount of gas supplied. The MIG method uses inert gases, which are much more expensive than active analogues; for example, the price of carbon dioxide is 45 times less than argon, and compared to helium, the cost is reduced by another 3.5 times.

When welding MAG, carbon dioxide or nitrogen is used as protection, but to avoid a negative impact on the result, wire with the addition of manganese or silicon is used, since they do not allow the molten metal to oxidize.

With non-melting rod

In the CIS countries, the TIG method is argon arc welding, named after the gas used for protection; a non-consumable electrode simplifies the entire process, and the absence of foreign inclusions allows you to obtain a high-quality seam. The pulsed version of the welding process is similar in its properties to TIG, only a non-constant current is used, this mode is found in MAG/TIG units. It is used for joining thin sheets, since there is no overheating or warping of the surface, and the seam joint has the appearance of scales.

The MMA welding process was described in detail earlier, recall that it is characterized by the formation of an arc between a consumable electrode and the workpiece.

After hardening, the seam is covered with scale from the frozen slag, which is easily removed by tapping the surface with a hammer.

Semi-automatic

Almost all service stations have a MIG/MAG welding machine installed, because its use produces a high-quality seam that does not require additional processing. Inverters are used because they are connected to a regular electrical network, have small dimensions and weight, and are also mobile.

The power source for most devices is identical, so manufacturers have launched the production of universal equipment that allows you to operate in different modes, you just need to change the burner.

Additive wire

MIG MAG TIG methods use special installations in semi-automatic machines for continuous supply of wire, the characteristics of which determine the quality of the seams. When a powder type of additive is used, shielding gas is not needed.

The following types are used in production: aluminum-based, steel, partially or fully copper-plated, and flux-cored wire. The last two options are of particular quality and widespread - the absence of splashes is guaranteed, which increases the quality and speed of welding.

Semi-automatic station wagon

The Triton MIG device is a striking example of versatility; it belongs to equipment for professionals.

The compact-sized inverter is installed on small wheels, produces a current of no more than 250 A, ensures normal operation in all existing modes, and carries out seams using Spot/Stitch technology. The package includes three burner options that are easy to replace. At peak mode, the operating time is 60%, and at 200 A - 100%. For reliability and ease of ignition activation, there is a special function and contact activation of the arc. The equipment allows you to connect different metals, as well as galvanized sheets.

Spot/Stitch

In this mode, the equipment operates in the following way: a drop of molten wire is transferred to the product in the absence of short circuit (short circuit), so there is no overheating and warping of the surface. A similar technique is used to firmly connect stainless steel sheets or galvanized workpieces. A slight heating increases the life of the device and improves overall performance.

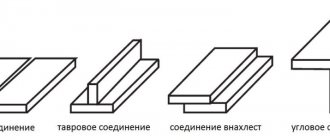

Types of welding

With the help of mig mag and mma welding, metal structures and individual parts are firmly connected by melting the edges and forming a single whole. As a result of welding, a strong seam is formed, which has high strength, even under oscillatory loads. You will learn what TIG and MMA are, as well as the decoding of the abbreviations MIG and MAG, in the following sections.

Manual welding option

MMA welding, what is it, the abbreviation literally translates as manual arc welding , which uses an electrode coated or coated with flux. A transformer or inverter is used as a current source. When melted, the rod coating becomes liquid and protects the molten metal from oxidation by air.

After the welding process is completed, the slag covers the seam joint with a durable layer, which is removed by the welder to visually check the quality of the joint. Similar welding is performed when connecting direct or alternating current, with the first option using direct and reverse polarity. MMA is the most common welding in any production.

MIG/MAG

What is MIG welding - a semi-automatic process of joining metals by feeding filler wire, and protection is performed by inert gas . The difference in the abbreviations MIG/MAG is due to the spelling in English or German. The performer guides the torch along the junction of the structure or workpieces, and the thin wire, melting, forms a seam of ideal width.

MIG welding is a process based on the use of an inert gas, which is heavier than air and envelops the weld pool, preventing oxidation of the molten metal. MAG - uses aggressive gases, which include oxygen molecules; welding of metals occurs by combining the created and natural environment.

Advantages of the method

The main advantages of these progressive methods of joining metals:

- The prostate of welding technology, accessible to novice welders.

- High quality seam connection and similar productivity, since there is no time spent changing electrodes.

- Welding is performed in all spatial positions, with low heat input, which is suitable for joining thin sheet metal.

- There is no need to carry out subsequent processing of the seam.

- Long seams are performed without stopping and re-activating the arc, which greatly simplifies the entire process.

It is because of these advantages that MIG/MAG is used in automatic automobile assembly lines where robots are used for welding work.

Rectifier or inverter?

Experienced welders choose an inverter for everyday work , because additional modes and built-in functions simplify the technology, this is especially true when connecting parts and structures made of aluminum, stainless steel and complex refractory alloys. The weight of the device and the ability to connect to any electrical network also matter.

The transformer is characterized by exceptional operational reliability and low cost, but consumes much more electricity . Its mass is significant, so it is not very mobile, and it is used for the simplest types of welding.

TIG

The exact decoding of the abbreviation means tungsten in an inert gas ; a thin rod of a similar metal is used as an electrode, which is sharpened in a certain way. When welding, filler wire is used, which, when melted, fills the recess between the workpieces.

Of particular importance is the design of the burner, where a non-consumable electrode is located in the center, and a protective gas consisting of pure argon or its mixtures is supplied around it. This technique requires thorough preparation of the performer and high-quality equipment; heating here is minimal, so overheating of the metal does not occur.

Used for alloying aluminum and thin stainless steel sheets.

Welding wire

In most cases, when asked what MIG MAG is, one hears the answer that it is welding using electrode wire, although the role of the wire is not the main one here. The main thing is the gas atmosphere. But a lot depends on the quality of the wire. Semi-automatic welding machines use different types of wire, there are four in total:

- aluminum;

- steel (stainless steel);

- copper-plated;

- powder

The last two types are the most convenient to use and, therefore, the most common. They provide spatter-free welding, a fairly high speed, and you can buy them without any problems. Flux-cored wire is in great demand in both amateur and professional welding.

Aluminum Welding Wire

The presence of a special powder inside, consisting of antioxidants (various ores, ferroalloys, complex chemical compounds), allows you to weld metals without gas - its role is played by the powder burning in the arc.

Unlike the electrode coating in MMA welding, it practically does not emit toxic fumes, since it is contained in the wire in a volume of 15 to 40% of the total volume of the material. The wire is essentially a hollow flexible tube filled with powder. It must be protected from deformation - a broken wire is unsuitable for welding. Flux cored wire can be used for MAG welding. Under these conditions, the arc burns especially softly and stably.

The information in the article is presented in the form of a brief overview. Do you have any additions or more information about what MIG/MAG welding is, how to use it correctly and what kind of work it is used for? We and our readers are interested in practical experience. Write - the most interesting letters will certainly be published under the name of the author.

Operating modes

A welding machine with four modes (MIG, MAG, TIG, MMA) opens up wide possibilities. It allows you to create a seam in different positions, weld ferrous and non-ferrous metals, galvanized, thin and thick sheets.

Spot/Stitch

“Dot/stitch” - this is how you can translate the name of the mode. In it, the MIG MT 250 welds with stitches. The welding drop is transferred when there is no short circuit, which reduces heat input into the product being welded. This eliminates overheating and warping of the metal.

The mode is used when welding galvanized products and stainless steel. Reduced heating of the electrode and the part allows you to increase the performance of the device and its service life.

MIG/MAG

In MIG and MAG modes, the welding machine operates semi-automatically. The filler wire is fed evenly with the simultaneous supply of shielding gas.

The welder only has to move the torch along the future seam at a certain height from the part being welded. This ensures a high welding speed and a high-quality weld, thanks to protection from air oxygen by inert gas. The welding current can be adjusted over a wide range from 30 to 250 A.

TIG

Unlike most semi-automatic MIG MAG devices, the MIG MT 250 model can weld metals in TIG mode using direct current. The device provides for rapid ignition of the electric welding arc when the end of the electrode touches the part to be welded.

MMA

Traditional manual electric arc welding provides welding of ferrous metals and their alloys. Direct current allows you to obtain a stable arc.

A special function of the ARC-FORCE welding machine provides adjustment of the arc power, which allows you to obtain the required parameters and a high-quality weld.

Decoding abbreviations

MMA (RDS)

MMA (Manual Metal Arc) - manual arc welding with piece (coated) electrodes using an inverter or transformer. The technical literature of Soviet times used the designation RDS. The welding process occurs due to the melting of a metal rod - an electrode, coated with a special coating, which have their own classification. Its main purpose is to protect the weld pool from air, preventing oxidation of the metal. The molten rod forms a weld and the used coating remains as slag.

Covered electrode welding

RDS is possible on both direct and alternating current. With direct current, there are two options for connecting the ground clamp and the electrode holder, so there is welding with direct and reverse polarity. Alternating current does not have this feature - how to connect the electrode in this case does not matter. The given reliability rating of welding inverters will help you choose a machine that will last for many years.

Since the MMA method is the most popular due to its simplicity and relatively inexpensive equipment used, you should definitely familiarize yourself with the question of how to learn how to weld with electric welding yourself.

TIG(WIG) or RADS

TIG (Tungsten Inert Gas) – technology of arc welding in an inert gas environment with a non-consumable electrode. Tungsten is a very refractory metal with a melting point of about 3500 C, so it is the basis for the production of this kind of electrodes. Sometimes you can find other variations of this method:

- WIG (Wolfram Inert Gas) – the name is derived from the German spelling;

- GTA (Gas Tungsten Arc) – this abbreviation omits the chemical reaction of the shielding gas.

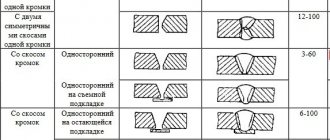

Because the electrode is non-consumable, the argon welding process occurs according to a different scenario:

- an electric arc is excited between the end of the electrode and the metal being welded;

- the welding seam is filled by supplying a special filler material - a rod - into the welding zone;

- the weld pool is protected by a gas cloud.

TIG welding process

Protective inert gas, i.e. a gas whose molecules do not chemically interact with the base and filler materials during the welding process; in this case, argon is used. That is why the name “manual argon-arc welding” or RADS was assigned to it.

Argon can be used when welding consumable electrodes - the MIG method, which will be discussed below.

In the technical characteristics of welding equipment, in addition to the TIG designation, it is always supplemented by a mention of the type of welding current DC (Direct Current) - direct current or AC/DC (Alternating Current / Direct Current) - alternating / direct current

In this case it is very important. For example, welding aluminum with argon is carried out using alternating current

MIG/MAG

MIG/MAG (Metal Inert/Active Gas) is a method of arc welding in a protective atmosphere of inert/active gas using a consumable electrode in the form of steel or other wire, depending on the type of metal being joined.

Schematic representation of the mig/mag method

MIG or MAG welding usually means semi-automatic welding. The main objective of this method was the idea of creating an “endless electrode”, thereby achieving significant welding productivity. Indeed, with the RDS method, you often have to change the electrode as it is used up, which in some cases is extremely inconvenient. As with TIG welding, shielding gases are used here.

The inert agent is usually argon and its mixtures, which is suitable, for example, for semi-automatic welding of aluminum and its alloys. The active gas, i.e., interacting with the metal being welded in the process, is usually carbon dioxide (carbon dioxide). You may hear from a welder the phrase “semi-automatic welding in a carbon dioxide environment,” meaning the MAG method.

This method is the most common due to its increased productivity compared to MMA, and gives a better result in the quality of the weld. The rating of household semi-automatic machines based on reviews of experienced welders will help you decide on the choice of a welding machine.

We hope that this article will help you understand the classification of basic welding methods, and will also be useful when choosing equipment and materials with English abbreviations.

Equipment requirements in the kit

Please note that not any inverter with the ability to weld with alternating current is suitable for organizing such a “tandem”. The same is true for other components. If you choose the wrong elements, the investment will not be worth it. I recommend that business managers and technologists purchase the following products.

Current source

I think it is best to use devices with activArc mode. This is premium equipment that produces an electric arc with high plasma pressure. It uses a system of regulators that controls the distance between the electrode and the workpiece, so that despite changes in arc length during manual welding, constant energy is supplied. The device can operate on high-frequency alternating current with a pulse. Then the penetration depth increases even more, and the amount of heat input is reduced. With a current source that supports the activArc mode, the weld is narrower and has smaller scales, compared to welding from a conventional inverter without this mode.

I am sure that a device with activArc will be suitable in production, where complex tasks need to be implemented. For example, this will allow you to weld aluminum with a thickness of 1 and 10 mm together, which is difficult to do with other equipment.

Can you share in the comments what else can be done to qualitatively weld aluminum workpieces with such a difference in cross-section?

Dmitry Yagolnik

Welding Equipment Expert

For business this provides the following benefits:

- save money on consumables;

- more reliable connections with good weld root welding;

- reduction in the volume of subsequent mechanical processing;

- no deformation due to temperature effects;

- products are of higher quality than those of competitors, or are produced in larger volumes.

In my opinion, the EWM Tetrix 351 AC/DC is perfect for the role of such a current source. This is an industrial inverter powered by 380 V and a welding current adjustment range of 5-350 A. It has comfortable rubberized handles and built-in wheels for easy transportation around the workshop. It can be moved at a construction site using a crane (there are hinges on the lid). Synergic control makes it easier to set up the machine - the welder only specifies the thickness of the workpiece and the type of metal. The water-type cooling system provides operation at 300 A with a duty cycle of 100%. With it, your production will be able to operate even in several shifts without harm to the equipment.

Feeder selection

To increase the welding speed due to the automatic supply of the additive, feed mechanisms are used. They are capable of pushing the wire and making oscillatory movements (back and forth), simulating manipulations by a welder. This promotes uniform transfer of metal droplets into the weld pool and the absence of high rollers in the seam (the latter will certainly exist if you use a conventional feed mechanism from a semi-automatic machine).

To complete the set, it is also important to buy a feed mechanism with the spotArc and spotMatic functions. The first creates pulsation for the metal in the weld pool. This helps to “throw” the base molten metal onto the joining line with minimal or no additive use. This mode is useful for setting tacks when assembling aluminum structures (frames, containers). It is beneficial for business with speed of execution and savings in consumables (filler wire). Since there are no high beads on the tacks, they are not required to be cleaned for subsequent penetration of the weld root.

We will tell you more about exclusive welding processes and modes from EWM in the following articles, don’t miss it!

Dmitry Yagolnik

Welding Equipment Expert

The second function of the feed mechanism (sportMatic) ensures minimal heat input when welding thin aluminum from 0.8 mm. As a result, there will be no tarnish on the reverse side of the joint. This saves up to 50% of labor costs in production.

Specifics of the burner and differences from conventional ones

The final link to complete the equipment is a specialized burner. Its main difference from a conventional TIG torch is the built-in additional channel for the passage of filler wire. Its end is fixed above the ceramic nozzle and ensures that the additive exits at an angle of 45 degrees relative to the tungsten electrode. The feed channel passes through the handle and does not interfere with the welder. There are two buttons on the handle: one to start the feed, and the second to turn on the power to the electrode.

I recommend that business managers and technologists pay attention to such proven models as comfyTig 18-1 HW 12P 3m flex or comfyTig 18-1 CW 12P 3m flex. They are designed for a maximum current of 300 A with a duty cycle of 60% and are ideal for operation for 6-8 hours. With a current of 210 A, the duty cycle is 100%. The burner can operate on direct and alternating current. The clamp clamps electrodes from 1 to 4 mm in diameter. Feed wire is allowed with a cross-section of 0.8-1.6 mm. The hose length is 3 or 4 m, depending on the required maneuverability of the welder and the size of the assembled structures.

Equipment used

We discussed what MIG welding is above. In essence, the processes taking place, this type of technology can be described as a specially organized melting of metals, supplemented by the presence of a special protective composition (inert gas). During this process, special equipment is used that supports it and equips it with mechanisms for full welding.

MIG MAG welding is carried out using any semi-automatic systems, including complex inverter equipment. The best and most suitable option for this technology is a mig type welding inverter. It can be used to weld all grades of steel, and it also works great with a variety of non-ferrous metals.

Equipment for gas shielded arc welding contains the following important components:

- DC or AC source (pulse inverter or conventional converter);

- Shielding gas cylinder. This element must be equipped with a gearbox;

- A set of hoses and cables that are required to supply the gas composition;

- Burners with a mechanism for advancing the melting rod.

A special wire made of aluminum base, steel or other materials is used as a consumable electrode. It is wound on a drum and fed into the welding area automatically. The feed speed is proportional to its diameter and welding current.

During the welding process, the welder brings the torch into the welding area and presses the handle. When an arc appears, the electric motor feeds the wire to the weld area, and gas under pressure blows into the weld pool and prevents atmospheric gases from entering the hot metal, which can cause its oxidation.

When carrying out MMA welding, an inert gas is used, which acts as a coating for a conventional electrode. But during this technology, the protective atmosphere is supplied from the outside in a ready-made state; it is not formed by burning the coating materials that are located around the steel rod.

Despite the fact that the semi-automatic MIG welding machine used is large and heavy, it has a number of positive qualities:

- During welding, no toxic components are released;

- The device provides easy ignition and retention of the arc;

- Have minimal wire consumption;

- Using these machines you can easily weld thin sheets.

Note! MIG/MAG shielded gas welding can operate with direct current with reverse or direct polarity. Sometimes sinusoidal current can be used

It all depends on the characteristics of the metal being welded.

The second type of semi-automatic welding is MAG (metal active gas welding), this process is carried out in a carbon dioxide environment. The whole process has the same principle as MIG welding, but carbon dioxide is pumped into the cylinder, which is much cheaper than inert gas.

However, its use has some limitations - it can be used to weld alloy and low-alloy steels. But at the same time, MAG technology is simple to carry out and has a wide range of functions that make the process easy and convenient.

The semi-automatic MIG/MAG welding machine can operate in two modes - with inert and carbon dioxide. The device has wide adjustment capabilities; it allows you to work with welding wire of any diameter. Filler material with a diameter of 0.5-4 mm is often used; the selection depends on the thickness of the material and its qualities.

Material from Miller - understanding the current-voltage characteristics and the difference between MMA and TIG

CC) Welding Machine for Training Purposes.

Understanding the personality of a DC (CC) welder can mean the difference between a successful or unsuccessful welding test, or the difference between a student who will pursue a career in welding and one who may abandon the profession after being disappointed with the results. Learn how to read a current-voltage (volt-ampere) curve and select the appropriate welding machine for training purposes.

True story: A young apprentice (let's call him Joe) took tests to become a MMA welder on pipelines using unfamiliar equipment. Joe failed several tests in a row, which had never happened before. Is it Joe's fault? Didn't he work out enough? No, Joe did everything right, but he chose the wrong equipment to do it. The instructor noticed Joe's troubles and put him on a different welding machine, and his next weld was flawless.

What Joe and many others have not paid attention to are the two different features (“characters”) of DC welders. You can learn a lot about the features of the device by looking at its current-voltage curve, the “birth certificate” of the welder:

1. MMA welding machines that can TIG weld . An example of this type of welding machine would be a DC generator, an 8-piece magnetic amplifier type unit, or a traditional welding machine with a large mechanical rheostat to control the current. Old welders call these machines “droopers” because of the shape of their current-voltage characteristics (see Fig. 1).

Figure 1 - The sloped I-V curve of a traditional MMA block (which can also TIG weld) allows the operator to control the heat output and shape of the weld by manipulating the electrode.

2. TIG welders that “ can weld MMA .” They have a falling DC I-V characteristic (see Fig. 2). An example of this type of welding machine is a regular TIG machine (Joe chose this type of welding machine with the E7018 electrode).

Figure 2 - Notice that the current-voltage curve on this modern TIG welder is almost vertical. The current will remain constant even if the operator changes the voltage (arc length).

There are also welders that work equally well in TIG and MMA, and these often use inverter technology (Joe used an inverter for his welding test). Welding machines of this type can generate both diagonal and vertical current-voltage characteristics (Fig. 3).

Figure 3 - I-V characteristic of an inverter that “changes properties” when switching between MMA and TIG modes. Also note how the arc force control percentages (arc force) increase the current as the voltage drops.

Reading the I-V curve

To interpret a current-voltage curve, you need to understand the relationship between arc length and voltage. A basic fact of the arc welding process is that as the length of the arc increases, the voltage increases. As the arc length decreases, the voltage drops.

Manufacturers design welding machines to weld in such a way that when the operator changes the arc length, the current is the opposite of the voltage. If the operator reduces the arc length (lowers the voltage), the current increases. If the operator increases the arc length (increases the voltage), the current decreases. Combined with this information, another basic fact that operators need to remember is that voltage represents electrical pressure. Pressure (voltage) controls the height and width of the weld, while current controls penetration.

Armed with this knowledge, repeat the analysis of Fig. 1. Experienced MMA welders know that “pulling a long arc” (increasing voltage while decreasing amperage) allows them to create a flat, wide bead with shallow penetration. A long arc also causes the weld pool to solidify faster because it reduces the overall amount of energy. Conversely, moving the electrode closer to the joint (increasing current while decreasing voltage) creates a narrower weld, deeper penetration, and a thinner (hotter) weld pool.

Thus, MMA welding machines with “drooper” characteristics (flat current-voltage characteristic) allow the operator to control the quality and appearance of the weld by manipulating the electrode. However, this welder, while ideal for MMA stick welding, is not well suited for TIG (below average). Imagine you are welding an outside corner on 18-gauge stainless steel. If for any reason you reduce the arc length (lower voltage), the "tig welder" will try to maintain the total output power (Watts) by increasing the amperage - and that additional amperage (penetration ) can burn a hole in thin material.

For this reason, manufacturers make welders "TIG only" so that voltage changes do not affect the current. As can be seen in Fig. 2, such a device provides a vertically incident current-voltage characteristic. It holds a constant current regardless of voltage (arc length), which is what caused Joe to fail during his MMA welding test. Joe may have been the best welder in the world, but the "TIG machine that could weld MMA" simply couldn't respond correctly to Joe's manipulation of the electrode.

Manufacturers of conventional TIG/MMA welding machines have overcome some of these limitations by adding arc force (more on this below). However, many schools have older TIG equipment without this feature or, if they have modern equipment, not everyone understands how to use arc force. Either way, students are at a disadvantage when learning to weld MMA. Additionally, TIG-specific machines have more complex controls that can be confusing for beginners. Finally, although many welders do very well, they simply cannot beat the benefits and efficiencies of new technology.

Choosing the right welding machine

Inverter technology allows manufacturers to create welding machines with “several characters”, with a current-voltage characteristic as in Fig. 3. In principle, since the I-V characteristic is controlled by microprocessors and high-speed current switching devices, the inverter can produce almost any kind of I-V characteristic. In short, inverters can perform all welding processes equally well.

For many applications, a CC/CV DC/DC converter with an output of 350 amps at 60 percent duty cycle will meet most welding needs. This type of device (such as the Miller XMT® 350 CC/CV Inverter) can train students in stick welding (MMA) and TIG welding in a wide range of applications, as well as train students in MIG and submerged arc welding processes. Note that for TIG-specific training and AC TIG welding on non-ferrous metals, an AC/DC TIG inverter such as the Dynasty® 350 provides maximum flexibility.

To help instructors select the best selection of equipment, Miller offers training equipment selection guidelines on its welding instructors web page, MillerWelds.com/instructors.

Miller generally recommends inverters because they provide schools with several benefits:

· This is the type of welding technology that the industry is adopting, so it makes sense to train students on the equipment they will use professionally.

· Inverters are about one-fifth the size and weight of conventional welders and take up very little space, which is important.

· Some inverters offer the ability to connect to single or three-phase power over wide ranges of primary voltage (for example, 115 to 460 or 190 to 630 VAC). In addition, inverters consume significantly less current, allowing more welders to be connected to the power supply.

Most importantly, the inverter offers advanced arc controls to help students get up to speed faster. An inverter can make a good welder out of an average student, allowing excellent students to reach their full potential.

Advanced Arc Control

To provide the operator with additional arc control, advanced DC welders offer arc force control. This feature allows operators to tailor the shape of the I-V curve to better suit different joint configurations and electrode types, and can produce an arc that experienced operators describe as “soft and flexible” or “hard and guiding.”

Figure 4 - Increasing the arc force makes it easier for this pipe welder to get good penetration on an open root pass with the E6010 electrode.

Under normal electrode welding conditions and arc length, the arc voltage is approximately 20 volts. However, some welding situations require a shorter arc length, such as when the operator must push the rod into a tight corner or deep bevel of an exposed root joint. In these situations, electrodes are known to have a tendency to "stick" (eg, the voltage drops so low that the arc goes out on its own). Arc force control overcomes this problem by increasing the current when voltage levels drop below about 20 volts (see Figure 3). Increasing the current increases the overall power, keeps the weld pool molten, preventing electrode sticking and making the welder's (operator's) job easier.

It should be remembered that inverters can adjust the welding output current thousands of times per second. Thus, the speed of a human hand pushing an electrode is nothing compared to the speed of a microprocessor! Working with the latest modern welding machines is like arithmetic on a computer compared to regular abacus.

For schools and training centers that want to teach MMA, TIG and MIG* welding, choosing the right machine can mean the difference between helping students become successful as quickly as possible or leaving the welding program in frustration. The industry as a whole is in desperate need of adding more skilled welding operators to its ranks. It is our responsibility to provide students and trainees with the tools to help them succeed.

*Don't forget about multi-process CC/CV welders that provide power for MMA, TIG, MIG, flux and air arc.

Figure 5 – About the author. After retiring from the U.S. Navy, where he was a submarine contractor, Neil Borchert joined Miller Electric Mfg. Co. in 1977 and worked as an instructor for 12 years. Today, as a business development manager, he works extensively with schools and educational institutions.

Arc setting

Each welder has his own ideas about how to adjust the arc force, which is adjusted by a knob on the front panel of the machine. Some general recommendations are as follows:

For open root welds on a plate or pipe, typically select an XX10 (6010) or XX11 (6011) electrode for the first pass. During this pass, the operator attempts to achieve complete penetration. By adding arc control, usually to the high end of the scale (say 5 or 6 out of 10), the operator can control the amperage (punch) along the length of the arc.

For deeper penetration, simply reduce the arc length by inserting the electrode into the connection. At this moment - and only at this moment - the arc force control is activated and provides the required current pulse. We repeat: Operators will only experience arc change when they reduce arc length to the point where voltage levels drop below 20 volts on most machines.

For electrodes not used on open welds, increase the arc force to the point where the electrodes do not stick during welding (perhaps 2-5 on a scale of 1 to 10).

If you are using the TIG mode, set the arc force to zero or turn it off (if you have a welder with separate settings for TIG and MMA, this will not make any difference). Typically the machine disables arc control when switching to TIG mode.

Original in English: Selecting a Constant Current (CC) DC Welder for Training Purposes

How does welding happen?

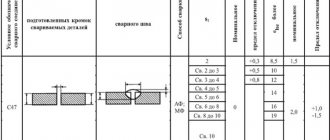

The choice of welding current is approximately determined by the graph:

or be according to Table 1.

MAG welding mode (CO2 environment)

Table 1

Welding is carried out at an open circuit voltage of 19-30 V, depending on the features of the semi-automatic machine. On most household and semi-professional semi-automatic welding machines, the current supply speed and voltage are constant and not adjustable. This is done for the purpose of automatic stabilization of the arc (autocorrection).

For welding different metals, the choice of wire diameter and welding current is of primary importance. The main relationships are shown in Table 2.

table 2

The mechanism for moving the welding wire is highly complex and provides very convenient semi-automatic functionality. The MAG/MIG semi-automatic welding machine is equipped with a feed system that allows:

- perform a soft start - the wire at the beginning of welding comes out at a lower speed and allows you to ignite and stabilize the arc;

- after stopping the feed, protect the wire from welding into the torch by stopping the current supply before the wire stops;

- prevent wire sticking at the beginning of the welding process;

- smooth regulation or ensuring a constant feed rate;

- perform pulse welding mode;

- change polarity (for cored wire).

As a rule, MAG/MIG welding is performed on a current of reverse polarity - on the electrode “+”, on the product “-”, but, depending on the tasks facing the welder and the parameters of the machine, direct polarity and alternating current are also possible.

The device can operate in the following modes:

- Short Arc - used below 200 A for thin metals;

- Spray Arc - current ≥200 A and wire diameter greater than 1 mm;

- Pulse Arc - welding with a large wire diameter and low current, used for non-ferrous metals, stainless steel and aluminum, complex alloys;

- Pulse on Pulse Arc - double pulse with variable current, used for decorative seams.

MIG/MAG welding technology

We learned what instant/mag welding is, but what is the essence of the operation of the semi-automatic welding machine used? It consists in the fact that in an atmosphere of inert gas between a metal product and a filler wire - a consumable electrode, an arc burns. It is this that melts the joints of parts and solder, forming a weld pool. And the process itself is carried out in a protective environment using helium or argon.

Arc welding in shielding gas (in a CO2 environment) with a consumable electrode is carried out in several modes. You can determine the most suitable one using the following table:

Welding in protective gases with a consumable electrode is carried out at an open circuit voltage of 19-30 V, it all depends on the features of the semi-automatic machine. Many household and semi-professional devices for semi-automatic welding have inconsistent speed and voltage, and these indicators are not regulated. This is done to automatically stabilize the arc.

But still, in order to do everything correctly, it is worth studying the important features of shielding gas welding:

- After the arc ignites, the consumable electrode or filler wire is fed along roller guides directly to the area of the welded joint;

- The shielding gas is under pressure; during welding, it is pumped into the torch and begins to actively blow through the weld pool;

- The arc and shielding gas flow during MIG welding protects the hot metal substrate from oxidation that can occur when exposed to atmospheric air. They also preserve the structure of the metal being processed;

- The inert gas used acts as a coating for a conventional electrode. The semi-automatic welding process provides direct protection without burning the rod's protective shell.

Automatic welding in a shielding gas environment can be carried out with different types of currents feeding the arc - alternating and direct, and it can also be carried out with any polarity of wires. The choice of these parameters may depend on the conditions of the upcoming work, mainly on the qualities of the metal products being welded.

The best semi-automatic MIG/MAG

The device will partially automate and speed up the process of joining metals.

1

Aurora OVERMAN 205 (MIG/MAG, MMA)

Rating:5.0

- NAKS certificate: no

- welding inverter

- manual arc welding MMA

- semi-automatic welding (MIG/MAG)

- Max. welding current: 180 A (MMA), 200 A (MIG/MAG)

- power: 8 kVA

Average price: RUB 36,100

The best semi-automatic welding machine for welding with consumable electrodes and wire in a protective gas environment and without it (flux-cored wire). The knobs adjust the supplied current and voltage. The inductance regulator changes the current in a small range, adapting the seam to the welding conditions: high or more diffuse and wide. Works in networks with voltages from 140 V and generates current up to 165 A - works with 4 mm electrodes. Long operating times for industrial applications guarantee improved cooling.

Peculiarities:

- stable operation in low-voltage networks;

- fine current adjustment;

- cooling by fan and four radiators;

- improved air entry tunnel.

2

Wester MIG 140i (MIG/MAG, MMA)

Rating:4.9

- NAKS certificate: no

- welding inverter

- manual arc welding MMA

- semi-automatic welding (MIG/MAG)

- Max. welding current: 140 A (MMA), 140 A (MIG/MAG)

- power: 4.70 kW

Average price: RUB 16,690

A good semi-automatic machine for welding with an electrode and automatically fed wire. With a peak current of 140 A, it will reliably weld metal up to 5 mm thick. Indicators notify about voltage supply and overheating. The red button turns the unwinder mechanism on and off. With a duty cycle of 60%, it is excellent for home and garage, in production (car repair, production of thin-walled metal structures) it is useful if you weld thin parts.

Peculiarities:

- current and voltage regulator;

- excellent welding in MIG/MAG mode;

- quick-release cables for changing polarity;

- protection against thermal destruction of electronic components;

- additive feed rate control.

3

STAVR SAU-200M (MIG/MAG, MMA)

Rating:4.8

- NAKS certificate: no

- welding inverter

- manual arc welding MMA

- semi-automatic welding (MIG/MAG)

- Max. welding current: 200 A (MMA), 200 A (MIG/MAG)

- power: 7.30 kW

Average price: RUB 19,601

Semi-automatic inverter for manual arc and gas welding. The representative of the new line is made on an updated technological base - IGBT transistors. They stabilize the arc during voltage surges, are less sensitive to thermal breakdowns and overloads, and improve the weld. There is a wire unwinding regulator, an overload and power indicator. At the bottom of the control panel is a reminder for selecting the current corresponding to the thickness of the filler material: electrodes, flux-cored and flux-free wire.

Peculiarities:

- options for simplifying work: hot start, anti-sticking, arc forcing;

- low voltage stabilization;

- work with wire up to 1 mm and electrode up to 5 mm;

- thick copper cables 2 m each.

Automatic feeder

The device for constant supply of filler wire delivers without slipping or chewing; a cassette weighing from 5 to 15 kg, with a diameter of 0.8-1.2 mm, is loaded into the inverter. The detailed configuration of the automatic feed looks like this:

- The welding hose consists of a flexible frame cable covered with multi-layer rubber that protects and insulates the power cable. Inside there is a spiral-type channel for continuous wire feeding and an insulated shielding gas supply hose.

- The additive supply mechanism carries out constant movement of the wire along the channel, consists of an electric motor and pressure rollers configured for a certain force.

- Compartment for installing a coil with wound wire. It is located next to the feed mechanism, and the container with the additive is located vertically or horizontally relative to the latter. Fixation occurs with a clamp or nut.

- The feed control unit makes adjustments. There are two methods - electronic, using a rheostat, or mechanical, using replaceable gears.

Modern models have digital displays where the exact wire feed speed is set to ensure the quality of seam formation.

V. P. Ignatenko, education: college, specialty: 4th grade welder, work experience since 2000: Automatic wire feeding makes the work of the performer easier and speeds up productivity, but you need to be careful and have some experience.

Applications and Benefits

Such equipment can be used in the same way as welding aluminum TIG or MIG separately. These are auto repair shops, mechanical engineering, ship repair, food and chemical industries (tanks, collectors, filters, highways, etc.). But thanks to the automatic feed of filler wire, welding processes will be completed faster. Since the arc burns between the tungsten electrode, it does not “walk” and is easier for the welder to control. The specialist has a free second hand with which to support the workpieces. There is no need to regularly unwind the wire from the spool and twist it into a more compact skein. All this increases the productivity of your enterprise.

For example, in production there will be no need to hire an additional group of welders and buy equipment for them in order to increase the volume of output. This can be done by the same workforce, provided they use a combination of EWM Tetrix AC/DC + TigSpeed devices and a specially configured burner.