Car battery charging voltage from generator

Normally charged battery

– a prerequisite for a comfortable ride.

In the cool season, it is especially important that the battery

ensures reliable starting of the car engine.

Modern cars, especially business class ones, have a battery charging control unit that monitors the main parameters of the process. Economy category vehicles do not have such devices. Experienced drivers do this task without the help of others. Let's look at how to have more complete control over the battery charging

.

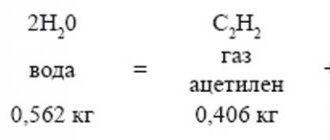

Capacity replenishment speed

There is an opinion that for normal battery charging, the charge current should be 10% of its capacity, i.e. with a battery 50 Ampere hours, the charging current will be 5 Amperes. Under these conditions, the battery

will reach its capacity up to 10 hours.

Imagine, you were turned on by the wires of another car in the winter, and in order to fully charge the car battery, you need to drive the car for 10 hours straight, that is, drive about five hundred kilometers.

It is believed that to replenish the battery charge to the nominal value, it is enough to drive 30 kilometers in a normal cycle, and in city traffic jams half that. That is, if your work is located more than 10 kilometers from home, this is enough not to worry about recharging the battery outside the car.

The case is different when work is close to home. You spent the capacity when starting the car, quickly drove to work, and then also home. After a week or two, your battery . And not at all because there is something wrong with the car, it’s just the rhythm of the drive.

In this case, you should think about warming up the engine even in the warm season just to ensure that the battery

was always in a charged state.

Let's return to the charge current. If it is enough to drive a car 30 kilometers to fully charge the battery, and not 500, as in the example, therefore, the charging current of the car generator is not 5 Amperes, but much higher.

Generator and battery

So, the gene is almost the main device in the machine. If it does not work, then the car will be impossible to move.

Generator breakdowns can be different, and the reason does not always lie in the unit itself. So, the gene may simply not receive energy from the internal combustion engine.

As for the battery, modern TOP class cars have a special control unit installed that controls the main parameters of the charging process. But on budget car models, such blocks are absent for obvious reasons. Owners of these cars (including domestic ones) have to monitor and control charging themselves.

Charge current and battery capacity

Charge current

The charge current is the primary consideration during battery charging. In other words, all the main parameters depend on its value.

As a rule, it is customary to talk about a 10 percent charging current for the battery capacity. This is the minimum value that can ensure a normal battery charge. For example, if the battery capacity is 50 A, then the charge should be 5 A. With this charge value, a completely discharged battery will gain its capacity to standard parameters in 10 hours.

Now let's imagine this situation. The car stalled due to a discharged battery on the road, and this happened in winter. Using the lighting method, the car was started from another car. And so, in order for the battery to be fully charged, you will have to drive non-stop for 10 hours. This is approximately 500 kilometers.

Although, to minimally replenish the battery charge, it will be enough to drive 30 km in normal mode, and in urban traffic conditions - even half as much. It turns out that if you drive long distances all the time (more than 15-30 km), then you don’t need to worry about recharging the battery.

How to check charge and capacity

But what about those car owners who drive less? The battery capacity is completely consumed during the process of starting the car in winter; the driver reaches his destination and turns off the car. Let's say there is still a little charge left, the car starts, and the driver drives home. The next day the car cannot be moved. The reason is that the battery is dead.

Attention. It is extremely important, especially for those motorists who drive short distances, to warm up the car engine. This is done so that the battery has time to receive a charge from the generator.

Problems with the gene

Generator again? Yes. And it’s scary to even imagine that it doesn’t recharge the battery. In this case, even a 1000 kilometer run of the car will not provide anything for charging.

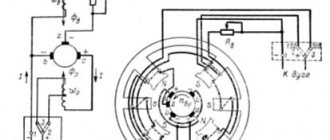

The gene, in fact, has a simple structure. It is a regular electric motor, but manufactured taking into account higher voltage generation. A better way to imagine how a gene works is to connect an LED to a regular electric motor. As soon as the motor is started, the LED will light up. This is the elementary work of a current generator.

The gene consists of 4 main parts, not counting the body. These are the stator, rotor, brushes and relays. In modern units, relays and brushes are created together and combined into a control unit. The stator is the stationary part of the gene, the rotor is the movable part.

Components and structure of the gene

The generator may fail, and therefore not charge the battery, for several reasons. Let's look at the most famous ones.

- Bearing problem. A fairly common problem, especially when the gene is quite worn out. As you know, the rotor or the moving part of the gene rotates on bearings. The latter wear out over time, become clogged with dirt and jam. The consequences are as follows: the rod stops rotating. But it is extremely difficult to determine such a problem from the outside, and the owner operates the gene with flying bearings for some time until the drive belt breaks.

- Stator winding. It simply burns, which also occurs due to the penetration of dirt or moisture into the gene. This causes a short circuit, and boom... the winding burns out. Accordingly, battery charging stops.

Stator winding short circuit

- Brush unit. Problems with it occur quite often due to the fact that the brushes are graphite and constantly move along the stator tracks. Over time, they naturally wear out.

- Tablet, relay. It fails, the gene is no longer able to charge. More precisely, the relay regulator is no longer able to control the strength and voltage of the current, and chaos occurs throughout the entire electrical system of the car.

These are the main 4 common reasons for gene failure. The unit should be checked periodically to avoid various problems, including providing constant current to the battery.

Battery life

battery life is more than five years. Used cars imported from abroad have fully working seven- to nine-year-old batteries on board. charging the battery from the generator how to check the charging process is in progress. There, however, the storage conditions for cars are different, and the temperature in winter is higher.

There are three reasons for the low durability of the battery: violation of the battery charging mode, quality of the battery , human factor, in other words, laziness.

Let's start with the first one. If the battery is not charged to full capacity all the time, the plates undergo a sulfation process. Sulfation, or the formation of lead sulfate on the plates, can be compared to a stomach ulcer in humans, only in humans it can be treated, but a battery ulcer is practically untreatable.

There are various methods of complete discharge-charge, charging with pulsed currents. Maybe there is some percentage recovery, but if the battery

I lay down completely, then alas...

The quality of the battery depends on the manufacturer. How to remove the battery on a Ford Focus 2? Modern technologies only affect the increase in battery capacity while reducing the size and weight, respectively, the amount of lead.

How to choose battery ? If there are two different copies with the same capacity, starting current, cost, it is better to buy the one that is heavier, it has more lead, it will last longer.

About the human factor. The biggest mistake car owners make is parking the car in the fall with the battery until spring.

If the battery is

spends it in a discharged, not even fully charged state, and even in the cold with a reduced electrolyte density, it is unlikely to survive until spring.

If you periodically use your car in winter, then regularly (a couple of times a week) you need to start the car and warm it up for at least fifteen minutes, checking the charging voltage.

Reasons for battery discharge

The driver is required to keep the main source of electricity in the car in a charged state. This is especially important in winter, when cold snaps can significantly affect battery performance. Also, the following situations may be the reasons for discharge and poor charge reception:

- depletion of the battery's service life (occurs during prolonged or improper use due to the destruction of lead plates);

- the equipment has electrical leaks that ensure rapid battery discharge during parking;

- The battery is charged intermittently or incorrectly from the car's alternator.

In the first case, it is enough to replace the battery with a new one to eliminate the problem. When purchasing, you need to choose an electrical appliance of appropriate capacity. In the second situation, you will need to identify a problem with the wiring or additional voltage consumption. To do this, the consumers are tilted back one by one, and at this time measurements are taken using a multimeter. The method helps to determine the problem of current leakage.

To solve the third problem, the generator's performance is monitored. Before checking the battery charging from the generator, we test the degree of belt tension and its possible slipping on the pulleys.

If there is no opportunity or ability to perform the procedures yourself, then the car is taken to a car service center. Diagnosing such problems does not take much time from specialists , since typical breakdowns are most often identified.

Visual control

Visual diagnostics can and should be done at least once a week.

In summer, it is imperative to monitor the electrolyte level either through the light or through the electrolyte filling holes. If the battery is maintenance-free, monitor the indicator window.

When it goes

the recharging process (the charging current is too high, it is possible when the generator is faulty),

is

boiling away. This leads to an increase in acid concentration, corrosion of the plates, and an even greater increase in current and temperature.

Video - charging voltage of a car battery from a generator, leakage currents and other checks:

Such an avalanche-like process can destroy the battery.

in a couple of hours. Therefore, if you see any changes in the paint above the battery installation site, foreign deposits, or a change in the shade of the battery case near one of the cans or electrolyte refill caps, immediately determine the cause.

If the battery

during constant operation it is not in the green zone, which means that the charging process is disrupted.

Charging check

Diagnosis is carried out using various methods. The main ones are: visual inspection, computer diagnostics and testing using physical measurements.

A caring owner must carry out a visual inspection of the gene and battery at least once every 7 days.

In addition, in the summer it is necessary to monitor the battery electrolyte stages. This is done through the provided battery window or through the light.

The electrolyte has boiled away

The electrolyte can boil out of the battery not only due to extreme heat, but also due to overcharging. That is, the gene can be faulty and produce more current than necessary. Obviously, the result of such a situation will not lead to anything good - the acid concentration will increase, the plates will corrode, and the current will increase even more.

It is not difficult to determine the boiling off of the electrolyte from a faulty gene. Such a process will a priori lead to the destruction of the battery. Alien plaque, transformation of the paint layer, etc. will be noticeable on the battery case. On batteries with a control window, the indicator will glow red rather than green.

How to measure battery charge (vehicle on-board voltage).

how to measure charging

car battery. VKontakte groups: .

The visual method also includes monitoring the “ battery”

" on the dashboard.

If it does not light up when the ignition is turned on, or does not go out after starting the engine, or flickers depending on the engine speed, then the battery charging is disrupted.

Another tip for visually checking the charging process. In the dark, pay attention to the brightness level of the low and high beams when changing engine speed. This is best done by lighting a white wall. If the brightness increases with increasing engine speed, it means that the voltage-current regulator in the generator is not working properly, you need to check the generator.

Diagnostics using devices

Experienced drivers remember that a garage tool always included a hydrometer and a load fork.

The battery hydrometer is used to measure the density of the electrolyte. Normal density is from 1.23 to 1.28 g/cm3. The lower the temperature, the higher the density must be, otherwise the battery will freeze and fail.

Using a load fork, you can identify a “rotten” can and repair it.

Now the cost of repairs will be more than the cost of a new battery, so these devices are not used in amateur practice.

The most universal device for monitoring battery charging is a multimeter. Sometimes you need to check the battery. Can the battery itself both on the blog and. How can I use it to check the battery charge?

First, before driving with a cold engine, measure the voltage at the battery. It must be at least 12.5 Volts. Turn on the ignition. Normally, the voltage will drop by 0.1 - 0.3 Volts, but still must be at least 12.4 Volts to start the engine.

How to check the operation of the generator

The battery in a car is an important element of the system, which is responsible for providing the car’s on-board network with electricity. The generator is used to charge the battery while it is active. Unstable operation of a device generating electricity causes a voltage drop in the network and failure to restore the capacity of the power source.

Normal generator performance means timely and complete replenishment of the battery charge level, which decreases under load. Checking the battery charge level from the generator is simple and can be done by the car owner himself.

Diagnostics of an automotive energy-generating device includes a visual inspection of the unit, its elements and related parts, as well as voltage and current measurements. At least twice a year, you should check the tension of the drive belt, excessive weakening of which leads to a decrease in the performance of the generator, and sometimes can lead to breakdown of the device. Once a year, you can check equipment elements - fasteners, diode bridge, voltage regulator and others. Timely maintenance of the battery will also guarantee the absence of problems - cleaning the terminals, adding distilled water.

Recharging the battery

The generator does not always undercharge the battery; it happens quite often when overcharging occurs, that is, the generator unit produces voltage above the prescribed norm. As a rule, the cause of overcharging is a faulty voltage regulator; it does not work as expected, and the generator continues to produce current when the battery is fully charged.

Without removing the generator from the car, the relay-regulator is checked in the same way as with undercharging, only in this case the multimeter shows the voltage of the on-board network when the load is on more than 14.7 V (readings can be even higher, for example, even more than 17 Volts) . Constant overcharging is dangerous because it:

- the electrolyte in the battery banks begins to boil;

- lead plates of the battery are exposed;

- sulfation occurs (destruction of the plates), the battery becomes inoperable;

- Due to increased voltage, light bulbs may burn out, electrical equipment may fail, and fuses may burn.

There is still a danger of a battery explosion, which occurs due to clogging of the holes in the plugs of the battery cans when the electrolyte is boiling.

On many VAZ cars of the “Classic” family (in particular, on the VAZ-2106), the voltage relay can be changed quite easily, as it is located separately, located next to the front fender of the car. The relay-regulator of the VAZ-2105 and 2107 type is located in the generator itself, it is a little more difficult to get to, but replacing it is also easy.

The generator is the source that is responsible for recharging the battery while driving. If the generator does not work properly or is unstable, the battery discharges too quickly and requires constant recharging from the electrical network. Since you can check the generator at home, if you have a problem with the battery quickly discharging, it is not necessary to go to a service station for diagnostics.

If a generator is suspected of malfunctioning, the car owner first tries to identify the breakdown himself. There are several verification methods that involve measuring both a removed and an undismantled device. The verification in both cases will be reliable. In addition to knowing how to check the generator, you need to find out the reasons why it may fail. Although the generator is a fairly reliable device, incorrect or careless operation of the car can cause it to fail prematurely.

What kind of charging should go to the battery from the generator?

It is traditionally believed that 13.5-14.5V should be supplied by the generator to the battery and this is absolutely enough to replenish the battery costs.

It is worth considering that using a battery with a higher power in a car than the manufacturer recommends also requires the installation of a more productive generating device.

It is necessary to take into account the load that the generator must withstand - it is calculated based on the maximum indicators of all electrical appliances and car systems.

Do not forget that the charging current from the energy-generating device will allow you to start the car in the cold season. In order to avoid problems with starting the car, we recommend purchasing generating equipment, the charge current of which will be approximately 10% of the capacity of the power source. That is, a battery of 100 A/h requires a generator that can produce 10A. Please note that for many cars, 100 amp equipment will operate at its maximum capacity, because the power consumption of the automotive system is in the region of 80 amps. Therefore, the choice of a source generating energy must take into account both the battery capacity and network consumption.

How to check the alternator voltage on the battery

The potential difference can be diagnosed in two ways - directly at the generating equipment and through the battery. The generator is directly connected to the power source with a thick wire, therefore, to check the level of potential difference, you can measure the voltage at the power source. To do this, you will need special devices - a voltmeter, multimeter or load plug.

The wires of the first measuring instruments are connected to the battery in any sequence. The plug must be connected to the battery terminals with strict observance of polarity. It is generally accepted that the normal voltage in the network should not be lower than 12 volts. At idle speed without turning on all the electrical appliances of the car, this indicator should be at the level of 13.5-14V. A drop in voltage values to 13.3-13.8 volts is considered acceptable.

At the same time, using conventional testing equipment, you can check the resistance of the generator elements - rotor, stator and diode bridge. Diagnostics of rotary equipment is carried out by its winding. It is necessary to connect the probes of the device with slip rings. If the multimeter gives readings from 2, 3 to 5.1 ohms, then this element is working. The current consumption of the winding should be within 3-4.5 amperes.

Its normal resistance is 0.2 Ohm. The diode bridge is checked by the presence or absence of resistance, the indicators do not matter. The only thing worth considering is that there should not be a zero dimension. Measurements are carried out in pairs - positive output and all plates on this side or minus and all elements.

We remind you that for normal charging of a car battery, the voltage supplied by the generator must be from 13.5 to 14 volts.

Charging the battery from the generator

While the vehicle is moving, the electricity generation installation generates charging voltage, which is the main resource for recharging the storage unit. The process of charging the battery from the engine is carried out in a gentle mode, completely eliminating the possibility of boiling the electrolyte in the banks.

What kind of charging should go from the generator to the battery?

How much should the battery be charged from the generator to ensure its full operation? It is generally accepted that to fully replenish the energy costs of a battery, a generating device with a charging current volume of at least 10% of the capacity of the storage device will be sufficient. In other words, for a 70 ampere/hour battery, the generation system must provide at least 7 amperes of charging current, which will be normal charging of the battery from the generator. The power of the storage source must comply with the recommendations of the vehicle manufacturer.

If a more powerful storage unit is used, the current value generated during operation of the car engine may not be enough to fully restore energy consumption. This can further lead to battery discharge and problems starting the engine. In addition, you should remember about the load from all electrical appliances that the machine is equipped with - the generating source must also cope with it.

How can an ordinary car enthusiast check whether the battery is charging from the generator?

How to independently check whether the generator is charging the battery?

Motor vehicles of the 21st century are equipped with on-board electronic systems that control the operation of all mechanisms, and also allow checking the battery charging from the generator. If the battery loses charge, its icon on the instrument panel will light up red. In addition, with the help of modern electronic devices you can monitor the voltage value in the network.

But what about those who have an old-style car, without bells and whistles? There are so-called “driver’s” methods that allow you to check whether the generator is charging the battery:

- Removing the terminal from the battery - if the generator malfunctions, the engine will immediately stall (only suitable for systems with mechanical ignition).

- Short circuit of the positive terminal to ground for a short time - check for a spark.

The above methods cannot be used when diagnosing modern cars - the control unit, fuses or diode bridge will instantly fail.

How to check the charging of the generator with a multimeter?

The operation of the generator set should be monitored and diagnostics of current, voltage and resistance values should be carried out at least twice during the year.

How to check if the battery is charging? Diagnostics of potential difference can be carried out using two methods:

- Directly on the generator winding.

- Through the battery pack, with which the energy generation source is inextricably connected directly with a large cross-section wire.

Let's connect the wires of the device in any order to the battery terminals and determine the mains voltage, the value of which should not be lower than 12 V. When the engine is idling with the load completely disconnected, the permissible voltage is determined by the range from 13.5 to 14 V. In this case, deviations of no more than 0.2 V down or up.

How many amperes does a car alternator produce per battery?

The current strength required by the electrical system of each car is individual and depends on the number of electricity consumers and their values. And also the charge current must be sufficient to charge the power source.

It is worth noting that ampere readings appear only when there is a load in the vehicle’s electrical system and, accordingly, the battery is discharged. After starting the car engine, the charging current is about 6-10 amperes and drops over time, because the battery is charging, taking on the main energy consumption. If you turn on additional equipment - headlights, radio or heated mirrors, you can see an increase in the charging current values.

When purchasing a generator, pay attention to its technical characteristics, which the manufacturer indicates on the case - that’s where you will find information about the maximum current that will flow to the battery.

In the table below you can see the approximate current values that the generator shows at different loads.

Table 1. How many amperes the generator produces under load.

Signs of a generator malfunction

In modern cars, breakdowns of the electrical system are one of the most common. A large number of electronics requires particularly careful monitoring of the operation and condition of the generator and battery, because their failure can immobilize the car. The most common signs of a generator malfunction are:

- battery indicator light on the instrument panel;

- unstable operation of the battery (its boiling over or undercharging);

- different intensity of headlights;

- extraneous sounds from the generator.

If you notice incorrect operation of the car, then perhaps the battery charging current from the generator is insufficient.

All malfunctions of electrical equipment, which includes the vehicle’s energy-generating device, are mechanical (deformation or breakage of fasteners, housing, malfunction of bearings, pressure springs, drive belt, etc.) or electrical (winding breaks, diode bridge malfunctions, burnout or wear of brushes , short circuits between turns, breakdowns, etc.).

Don’t write off a non-working generator: find out if there are repair kits and spare parts. Replace them if possible. If you cannot carry out repair work yourself, then take the generator to a workshop. Many craftsmen will be able to restore the unit at no extra cost and in the shortest possible time.

However, some breakdowns require the purchase of a new device that generates electricity. For example, a failing bearing that is soldered into the generator housing cannot be restored or replaced in most cases.

Remember that failure of this unit can be caused not only by wear and corrosion, but also by poor quality of elements and components; excessive load; external influence of salts, liquids, temperatures.

Other causes of low voltage

A small potential difference in the system is not always associated with a breakdown of the generator or a bad battery. If the diagnosis of these elements does not reveal any problems, then you should pay attention to the following:

- condition of the battery terminals - connection density and oxidation;

- electrical wiring problems - oxidation, violation of its integrity;

- output contacts to electrical appliances;

- correctly selected energy consumers.

Each contact must be tightly adjacent and intact, that is, there must be no formations (for example, sulfation) that will disrupt the flow of current. Incorrect connection of contacts leads to accelerated battery discharge even when the car is not running.

To improve the connection of the elements of the car's electrical system, it is necessary to clean all contacts and restore the integrity of the wires by replacing them or connecting them and wrapping them with insulating tape.

In conclusion, I would like to repeat that stable operation of the car requires constant monitoring of all elements, and the generator should attract special attention. The battery is charged from it and provides electricity to the entire car system. Pay attention to all elements: generator brushes, slip rings, voltage regulator, equipment winding.

The most correct measurements should be carried out when the battery is fully charged and in various modes. Remember that the manufacturer links the characteristics of the generator to the number of engine revolutions - they help produce a certain current.

Detailed video on how to check the generator:

Do you have experience diagnosing an alternator and solving problems in a vehicle's electrical system? Please share your experience and opinion with our readers in the comments. If you have questions about the topics covered, we will be happy to answer them.

Well, not so long ago I wrote an article about checking the battery with a load fork , actually this happens for two reasons: when the battery is already dying and needs to be checked, and when the battery is new, it also needs to be tested before purchasing. But is it always the battery? Why might it suddenly fail? It’s one thing if it’s winter and it’s really difficult for him to work, but another thing if it’s summer and he’s not “purr-murr” at all. AND even on the instrument panel, the battery sensor begins to blink occasionally, or is constantly on! In such situations, you should not run headlong for a new battery; first you need to establish the reason why it failed, because in 50% of cases it can be the generator. Moreover, the check is quite easy to do without removing it from the car, let’s read more...

Causes of battery undercharging

A car battery is an energy storage device: while the engine is running, it is charged from the generator, and then gives its energy to the starter to start the internal combustion engine. If the battery is not fully charged, it cannot provide normal cranking to the starter, causing problems:

- the engine does not start or starts with great difficulty;

- when the headlights or other consumers are turned on, the light on the instrument panel dims;

- the car has to be started by various unpopular methods - from a pusher, from a tow, by lighting it with another battery.

When there is undercharging, the indicator lamp on the instrument panel lights up at half intensity, the main reasons for this phenomenon are as follows:

- there is damage in the diode bridge - one of the diodes is broken;

- the relay-regulator (RR) is faulty;

- The generator brushes are worn out, or they do not fit tightly to the ring at the end of the armature (there is no reliable contact).

The voltage regulator (relay), more often than other parts, is the cause of this malfunction; it is one of the most vulnerable parts in the electrical part of the machine. To check or replace the relay-regulator, you often have to remove the entire generator assembly, but there are many car models where the removal and replacement of the RR can be done on site, without dismantling the generator assembly.

Why does the generator fail?

The generator itself has a simple structure; if you want, it’s a regular electric motor (only made to allow for large current generation), try to spin a regular electric motor and attach a light bulb or LED to it, it will start to light up - and there you have it, an elementary current generator.

Someday I will have an article in which I will tell you what the generator consists of. BUT today it is simple and exaggerated - this is the rotor (moving part), stator (fixed part), brush assembly, relay regulator , and of course the housing in which the whole thing is located.

And now the actual breakdowns.

- The bearings are jammed. This is a fairly common problem with already worn-out generators, the rotor in the housing spins on bearings, from time and moisture (dirt), they wear out and simply jam or wedge. If there is a wedge, then this is one thing - the rod stops rotating. But if wedging occurs, it is difficult to notice; the rod may or may not rotate. In any case, with such symptoms, the belt that turns the generator from the engine is more likely to break. THIS IS THE FIRST CALL.

- The winding on the stator or rotor has burned out. It is there in any case and most likely will be on the stator, so - also from moisture (salt on the roads), it can be corroded and it will simply short out or simply burn out, since copper wires are used there. Accordingly, current generation will stop.

- Failure of the brush assembly. This is also very common, brushes are graphite (often square) rods that run along the stator tracks. So, from time to time they simply wear out and need to be replaced.

- Failure of the regulator relay. This relay prevents the generator from recharging the battery, bringing the voltage and current within the desired range. Often it also fails and the battery does not charge at all! Need to watch.

In general, for these 4 main reasons, the generator may not work, so it must be checked before purchasing a new battery. It's likely that this is what you're dealing with.

What to do if the generator does not charge the battery

How to test a battery with a multimeter

In almost all cars, the following elements are responsible for powering the on-board systems and charging the battery:

- generator with built-in rectifier;

- relay-regulator;

- switching units and wiring.

The list, at first glance, is small, but diagnosing the cause of lack of charging and troubleshooting can cause certain difficulties.

Possible malfunctions and their solutions

First, let's find out why the generator does not charge. There are many reasons:

The alternator drive belt is broken, worn or loose. In this case, either the generator does not work at all, or the current it produces is not enough to charge the battery. It powers the onboard systems, but does not charge the battery.

The generator brushes are worn out. In this case, the generator, as a rule, does not produce anything at all, and the entire load falls on the shoulders of the battery.

Poor contact. This usually concerns the generator excitation circuits (see below), but the problem may also be caused by the battery terminals or on-board power supply wires.

Failure of diodes. A very common reason for careless lighting. If even several diodes fail, the on-board voltage will not be enough to properly charge the battery. Failure of the entire bridge, which is not uncommon, will lead to a complete failure of the power supply system, and the entire load will fall on the battery.

The relay regulator is faulty. There may be two options here. The first is a broken relay. In this case, the battery is not charged from the generator and takes on the entire load of powering the on-board systems. Second - the relay is closed. The generator produces very high voltage (above 14.5 V). The battery receives a high charging current and “boils”, the on-board systems burn.

The fuse has blown. In some car models, the generator excitation coil is powered through a separate fuse. If it fails, the generator does not produce voltage and the battery does not charge.

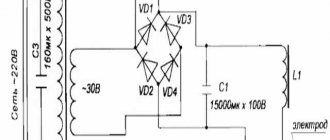

Typical battery charging circuit

Basically. Charging nodes on all brands of cars are very similar, so let’s look at the troubleshooting and repair methods for the VAZ 2106 model. Let’s take a look at the circuit diagram of the charging node.

Typical diagram of a VAZ 2106 battery charging unit

When the ignition is turned on, voltage from the battery is supplied to the generator excitation winding. The other end of the winding is connected through a relay regulator to the car body, which is the negative wire. After starting the engine, the generator begins to rotate thanks to the drive belt, and voltage appears on its power windings, made according to a three-phase circuit.

The alternating voltage is rectified using a rectifier bridge, which consists of six diodes. It enters the on-board network, powering consumers and simultaneously charging the battery. If the voltage at the generator output exceeds 14.5 V, then the relay-regulator will turn on, reducing the voltage on the excitation winding, and therefore at the generator output.

Troubleshooting

We will carry out troubleshooting from simple to complex.

- We check the fuse responsible for powering the generator excitation winding.

Mounting block with fuses VAZ 2106

- We check the quality of tension and wear of the belt. If it is deeply recessed into the generator pulley, and the pulley itself is polished to a shine, then we have obvious problems - we need to replace the belt or at least temporarily tension it to normal.

- We check the relay regulator. To do this, with the engine running, connect a voltmeter (multimeter) with a measurement limit of 20 V DC to the battery. Briefly close the input-output contacts of the relay-regulator (in the diagram above - the collector and emitter of the relay transistor). If the voltage on the battery rises to 15-17 V, then the relay is faulty. We change.

Relay regulator VAZ 2106

We inspect the excitation and power wiring

We pay special attention to the connecting blocks. They must be clean, without signs of burning, oxidation or dirt. Checking the brushes

They must have a smooth, polished end surface without burning or chipping. The length of the brushes itself should not be less than 12 mm.

- Checking the diode bridge. To do this, you will have to dismantle the generator and remove the back cover from it - the bridge is located there. We disassemble and disconnect the generator windings from the diodes - they are connected through ring terminals with a screw. We test the diodes with a multimeter in diode testing mode. In one direction the device will show several hundred Ohms, in the other - “infinity”. If the semiconductor rings both ways or does not ring at all, it is faulty. We replace the entire diode module.

Car tips

Actually, I already told you about them from above; if the generator refuses to work, then it is easy to notice even inside the cabin.

- All modern cars will be signaled by a warning lamp - “red battery” on the instrument panel. If it lights up or even blinks, then there is nothing good about it, you need to react immediately, otherwise a discharge is just around the corner.

- Weak glow from all instruments. The “warning lamp” may burn out, but if you notice that the instruments begin to glow dimly, this means that the car is running on the battery, and not on the generator. Again you need to check.

- Belt break. If you crawl under the hood and there you see a break in the belt that spins the generator, then you MUST CHECK THE OPERATION! Otherwise, again, you can kill your battery.

These are all obvious malfunctions, but it happens that the battery is dead and everything seems to be fine, but something inside is “gnawing” - maybe it’s the generator? How to check easily and quickly on a car without removing it? Question? And everything is quite easy here

Check without removing from the car

There are two 100% ways that I personally recommend to you.

1) Check with a multimeter . Of course, not everyone has it, but in fairness it’s worth noting that this is a fairly common device and let’s say your father, neighbor, friend will have it “anyway.” To begin with, we measure with the engine not running, at the battery terminals, the normal voltage should be about 12.5 - 12.7 V, ideally.

We start the car, do not accelerate, and do not turn on any electrical appliances - with the engine running, we measure the voltage, it should be within 13.8 - 14.5 Volts.

However, on modern cars, where a lot of electronics are crammed, manufacturers assure that 14.8 Volts IS ALSO NORMAL. More on this below. Next, we connect the load - headlights, heater, heated rear window, foglights, radio, after that the voltage should drop a little - but not lower than 13.7 - 14.0V. If it is lower, say 12.8 - 13V, then the generator is not working, you need to check it.

Normal battery voltage is 12.5 - 12.7V

After starting the car - 13.8 - 14.5V, on some modern cars - 14.8V

After turning on the maximum load, it should be - 13.7 - 13.8 V

If the voltage is below 13V, urgently CHECK THE GENERATOR

2) The old grandfather's method . You can check this on almost all machines, and this method works 100%. But everything needs to be done very carefully. So - we start the engine, turn on a small load (for example, headlights or heated rear window). And on a working engine, we need to remove the negative terminal from the battery, everything is unscrewed with a key to “10”. We remove it and put it to the side, you can simply lift it above the terminal.

If the car continues to work confidently, the headlights have not dimmed, then your generator is 100% working. If the car stalls immediately, it means that the generator is 100% not working and it urgently needs to be looked at. So I tested it on a VAZ 2101 and now it works on my AVEO.

Charging control with a multimeter

For those who don’t know, this is a special miniature device, which is most often produced by our eastern neighbors.

Its price on the market rarely exceeds 1000 rubles. The prefix “multi” means that it can measure a lot of useful things, but we are only interested in one parameter - voltage. It is its value that will allow us to draw conclusions about the performance of the generator. But before you check whether the battery is charging or not, it’s a good idea to make sure it’s working. Moreover, this can be done using the same multimeter. Having measured the battery voltage in idle mode, i.e. without load, indirect conclusions can be drawn about the degree of its charge. To do this you need:

- Set the multimeter switch to the position corresponding to the measurement of direct current, with a limit greater than 12 V. The limit in the photo is set to 20 V, but it can be different for different types of measuring instruments. It should only be noted that the lower the limit, the greater the measurement accuracy;

- Connect the multimeter probes to the battery terminals. In this case, it is not necessary to observe polarity; the design of the device allows this. If the connection is incorrect, the voltage value will be displayed with a “-“ sign;

- Read the readings of the device and, using the data in the table, draw conclusions about the state of charge of the battery.

Once again, these are approximate values. More accurate data can be obtained only by measuring the density of the electrolyte. And, nevertheless, if the voltage test showed that the battery is charged less than 50%. it follows .

Now you can check the charging from the car generator. The sequence of actions is the same as in the previous case. The main difference is that the test is performed at idle engine speed. Therefore, safety precautions should be observed. The voltage on the battery, during normal operation of the generator and relay regulator, should be within 13.7 - 14.3 V.

Now you need to turn on the low beam headlights and heated rear window. The voltage on the battery may drop slightly, but not lower than 13.5V. Otherwise, you need to look for the reason. You need to start with the alternator belt, or rather with its tension.

And one last thing. No matter how great the temptation is to switch the multimeter to the current measurement position, you should never do this. In parallel with the battery, only its voltage can be measured. Any attempts to measure the charge current will lead to a short circuit and, at a minimum, failure of the measuring device.

A properly functioning battery will ensure easy engine starting even in the coldest weather. The stable operation of the battery and the entire automotive electrical system certainly depends on the quality of the battery. The battery is supplied with voltage during engine operation by the generator. For this reason, it will be useful to know how to check the charging of the generator.

Battery overcharge

However, often it is not “undercharging” and “overcharging”. The electrolyte from the battery boils away and the battery also fails; there is nothing good about this either.

The first sign will be white streaks on the top of the battery, which means the electrolyte simply boils and evaporates. That is, the battery is charged, but the generator still “craps” charging it. The relay regulator has most likely failed here.

The check here is also elementary - you need to connect a multimeter or tester (whatever they call it) with the car running, and look at the charge. If it greatly exceeds 14.5 - 14.8 V, but is within the range of 15 - 15.2 V, it means that it is overcharging. We urgently change the relay-regulator, otherwise you will constantly boil your battery, ALSO NOTHING GOOD. It’s trivial that the plates may crumble.

Now let's watch the video version.

That’s all, he told me, exactly the methods without removing it from the car, and of course give it to a good auto electrician for repairs.

This is where I end, sincerely yours, AUTOBLOGGER.

(

36 votes, average: 4.42 out of 5)