Features of semi-automatic aluminum welding

There are several reasons that forced engineers to develop welding equipment taking into account the peculiar properties of aluminum, among them:

- increased thermal conductivity, 5-6 times higher than that of steel;

- fast-forming, inconspicuous oxide film with high density and high melting point;

- low melting point;

- formation of a crater at the end of the seam.

A modern semi-automatic aluminum welding machine allows you to overcome the difficulties of work. This is achieved by special parameters of welding equipment.

- The high thermal conductivity of aluminum requires a maximum welding current of the machine of at least 200-500 A.

- High-quality welding is performed using pulsed current. The high-voltage pulse destroys the oxide film, and in the rated voltage mode a weld pool is formed. This mode also reduces splashing. Cheap welding machines operating on direct current produce low-quality seams.

- A wide range of welding current adjustments does not allow raising the welding temperature so much that metal burns will form.

- A special software function that correctly completes the weld without creating a crater.

- Increased wire feeding speed with four rollers with Teflon liner. This will prevent the wire from curling into rings.

Devices that support such functions and parameters provide professional quality welding.

Parameters for selecting an aluminum welding machine

Any argon arc welding machine is set up before work. What parameters should you pay attention to?

Current power characteristics

Aluminum is welded using high-frequency alternating current; it is better if the current is pulsed, the arc will be stable. To weld thick-walled workpieces, a current of 250 A is required. Most inverters have a maximum rating of 200 amperes; they can also weld thick workpieces, if it is a device with high efficiency and a set of additional functions that ensure the quality of seams.

Inverter category

On the shelves there are household, semi-professional, and professional welding machines that are used to weld aluminum:

Household current generators are compact and easy to transport from place to place. They are powered from a standard 220 V network. They are purchased for a small amount of work. Under intense conditions, simple inverters do not work for a long time and fail.

Semi-professional models necessarily have additional functions and several welding modes. This equipment is heavier and has more components. The devices are purchased for small private workshops.

Professional welding machines are designed for heavy loads; it is not advisable to purchase them for personal purposes or field work.

Functionality

By purchasing a machine with an MMA function, you can weld aluminum and other metals: carbon and alloy steels, copper, brass. MMA/TIG welding machines are convenient for small workshops and for personal use.

Semi-automatic machines are convenient for working with thin-walled metal; they are purchased for auto repair shops where body repairs are carried out. Universal 3-in-1 devices expand the range of equipment use. They weld not only aluminum, but also other capricious metals in manual, electric arc, and semi-automatic welding modes. They have a system for supplying protective gas to the working area. The cost of the equipment is high. It will pay for itself with a large volume of field work or in the workshop. It is used in the installation of metal structures, including aluminum.

Pros and cons of semi-automatic aluminum welding

Before choosing a welding machine for aluminum welding, you need to weigh the positive and negative aspects of the technology. After this, decisions can be made.

| pros | Minuses |

| relatively low price | mandatory use of gas |

| availability of consumables on the market | difficulty in selecting wire thickness when working with materials of uncertain composition |

| quick preparation for work and high speed of the process | |

| versatility, works with different metals |

Criterias of choice

Before purchasing such complex equipment, you need to determine the scope of work that you decide to perform with its help. For professional use you will need one model, and for home use another. Moreover, they must meet the requirements placed on them and operate with the least amount of energy and other consumables.

If you find it difficult to choose, then perhaps you should entrust the purchase of a welding machine for welding aluminum to a professional. This will eliminate problems during operation.

The best models of devices for working with aluminum

Tiger device model

If you believe the opinion of consumers, the champion in its class is the powerful programmable TIG welding machine from the Tiger brand. It's lightweight, feature-packed, and features high-performance electronics to deliver incredible power in a small package.

Equipment of this brand is suitable for mechanized and even robotic production, and is available in 170 and 210 A versions. The DC model has a source for welding with direct current, and AC/DC also has an alternating current.

Model Invertig PRO

The inverters of the Invertig PRO series have proven themselves well. Devices of this class are easy to use, reliable, easy to operate, and combine advanced welding technologies. They are highly energy efficient, have maximum operating time, and air or water cooling of the burner.

Almost all the energy they consume is converted into a welding arc. Such devices are an ideal choice for mechanized or automatic production.

Welding inverters for argon-arc welding of the Mitech brand (AC/DC) are used in combination with non-consumable tungsten electrodes. They are suitable for permanently connecting parts made of steel and non-ferrous metals, including aluminum. The basis of the unit is a high-frequency transformer with a ferrite core. But the main feature of the device is the use of power transistors from the world's leading manufacturers Toshiba and Fuji (Japan).

Functionality of welding machines

Manufacturers are constantly improving semi-automatic welding machines for welding aluminum alloys. The result is a variety of modes and additional features that enhance the quality. Of course, the price also increases.

In order not to overpay for unnecessary functions, you need to understand why they are needed. Perhaps this is just a marketing ploy by the manufacturer.

MIGPulse is one of the most common and universal welding methods with non-contact transfer of a drop from the electrode to the weld pool. In this mode, the electrode never touches the bath. One drop is formed in one pulse and is transferred by the arc to the welding zone. The process of metal fusion occurs during its cooling in the background phase of applying voltage between pulses. This mode allows you to reduce the wire feed speed. Welding speed and arc power are controlled by the height and width of the peaks and the distance between them. The mode does not create splashes and reduces the risk of cold rubbing.

DoublePulse MIG - in this mode, the pulse current has two levels. The high phase drives the drop into the melt zone. In the low phase of the pulse, the metal is welded and cooled. The operator can adjust the level of the pulse pads and adjust the length of each pulse. It fully controls the shape and amplitude of the voltage and can perfectly select the welding mode.

The S4T mode allows you to control the burner. If the machine has a “Quick Start” function, which is activated by pressing the torch trigger, the operator can start welding aluminum without preheating - cold. After releasing the trigger, the welding current is reduced to operating current.

DownSlope - ensures crater welding at the end of the seam, smoothly reducing the welding current.

Adjusting the arc inductance reduces spatter and improves connection quality. Varies depending on the thickness of the wire.

Digital control significantly reduces the time for setting welding parameters. Thanks to synergic control, almost all welding parameters are set automatically. The operator is only required to indicate the thickness of the wire and the type of metal. The computer has several welding programs in memory, which allows you to instantly set the ideal operating mode.

The 4-roller mechanism ensures smooth wire drawing. Unlike welding machines for ferrous metals, where it is enough to have a 2-roller filler material supply system, in a semi-automatic machine for welding aluminum alloys it is necessary to use only a 4-roller mechanism. This is due to the fact that the wire for welding aluminum is not hard and soft and can get tangled, forming rings. Therefore, it requires a more complex feed system with tension adjustments and Teflon channels.

How to choose a machine for semi-automatic aluminum welding

The choice of equipment depends on the work conditions and the requirements for the quality of the connection. To achieve the best results, it is recommended to weld aluminum semi-automatically with a pulse mode. This is the name of the method of non-contact transfer of filler material into the weld pool. Drops of molten metal are formed at the tip of the wire, which are pushed into the melt zone under the action of a short-term current pulse. Compared to jet and large-droplet metal transfer, the method is characterized by lower heat input and low spatter coefficient.

Modern devices with synergetic control have built-in intelligent systems that independently select optimal operating parameters based on the wire diameter and type of shielding gas. At the same time, the likelihood of defect formation is minimized.

When welding aluminum with a conventional semi-automatic machine, the operating parameters are set manually.

Review of popular models

The industry offers a lot of semi-automatic welding machines. The review describes three popular models, sorted from simple and cheap to complex and expensive.

VEGAMIG 180/2 TURBO

A household welding machine operating from a single-phase network in MIG/MAG mode, designed for welding aluminum, ferrous metals and stainless steel in an argon environment. The unit creates a welding current in the range from 30A to 170A with a power consumption of 5.2 kW.

Although the device is considered a household device, not every apartment has wiring that can withstand a load with a current of 23A. Therefore, before turning on the device, pay attention to what current strength the network in your home, garage or workshop is designed for.

The semi-automatic welding machine VEGAMIG 180/2 TURBO for aluminum supports the use of wire with a diameter of 0.8-1 mm and can weld sheets up to 2 mm thick. The arc is formed by direct current.

Equipped with two step regulators:

- current strength;

- wire feed speed.

There are no automatic adjustments, therefore, when working with the device, the welder should rely only on his knowledge and experience.

When choosing a welder, pay attention to the protection class. VEGAMIG 180/2 TURBO is classified as IP21, which means that it cannot be used outdoors.

PICOMIG 180 PULS

Mobile inverter semi-automatic MIG/MAG welding machine, supporting pulse welding mode. In total, the device supports four types of welding at a professional level:

- MiG/MAG;

- MiG/MAG PULS;

- MMA;

- TiG DC.

The device is powered by a single-phase network, consumes 6.4 kVA and supports a maximum welding current of 170A.

The unit is equipped with an automatic adjustment system, an electronic control unit and a digital display.

The device comes with a minimum set of “readytoweld” accessories.

SPEAKER ALUMIG 300 P DpulseSynegric

The universal welding machine operates in semi-automatic MIG/MAG and manual MMA arc welding modes. Thanks to a wide range of workflow settings, the unit welds not only aluminum, but also non-ferrous and ferrous metals, stainless and galvanized steel.

The device is powered by a three-phase network and can create a maximum welding current in the following modes: MIG - 300A and MMA - 250A. This is enough to ensure high-quality work in industrial environments. The device can be used wherever the electrical network can provide a power of 10.60 kVa.

The device has a number of useful functions, including:

- MIGPulse;

- DoublePulse MIG

- S4T mode;

- fast start;

- DownSlope

- and etc.

The welding machine is equipped with a computer with digital display for synergic control. The memory stores 10 programs of the most frequently used processes. The transition from one type of welding to another takes a few seconds. Synergic control automatically sets the current strength, frequency and pulse shape depending on the thickness of the wire and the type of metal.

How to configure the equipment correctly

The complexity of welding aluminum is due not only to the chemical properties of this metal, but also to the need to strictly adhere to the optimal modes for performing this technological operation. In order to thoroughly understand the rules for performing such a complex process, it is not enough to simply watch a training video; it is important to understand the nuances of this operation.

The features of the process under consideration, which the training video will not tell you about, include the following.

- Before starting welding, it is important to correctly select and set the operating modes of the semi-automatic machine (voltage, current, welding wire feed speed, polarity).

- In order for the resulting weld to have the required quality and reliability, it is necessary to select the right consumables.

- If you watch a video demonstrating semi-automatic welding of aluminum, you will notice that this process is accompanied by the formation of a large amount of soot. This should also be taken into account when performing such a technological operation.

Like any complex technological process, welding aluminum parts using a semi-automatic machine requires careful preparation, which includes the following activities:

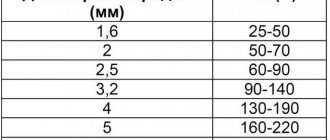

- tips for welding equipment are selected that are optimally suited for filler wire of a certain diameter;

- the surfaces of the parts that need to be cooked are thoroughly cleaned;

- semi-automatic welding modes are selected, which depend on several parameters: the thickness of the parts to be joined, the type of connection, etc. (to make it easier for you to select welding modes, you can use special tables or parameters that are specified by the requirements of the relevant GOSTs);

- When welding aluminum semi-automatically, the tip of the device is positioned at the required angle to the surface of the parts being joined.

Scheme of welding when welding aluminum

When welding aluminum, which has high thermal conductivity, it is very important to control the degree of heating of the workpieces being joined in order to prevent them from overheating and, as a result, deformation.

Conclusion

When choosing a semi-automatic welding machine for aluminum, you should understand exactly what you need it for. It’s one thing when you need to weld something at the dacha and another thing when you provide welding services or start production. Welding machines are not cheap, so choose the best option, taking into account:

- welding current strength;

- presence of synergetic management;

- versatility and the possibility of manual welding;

- protection class;

- completeness;

- presence of software functions and settings memory for different processes;

- price.

You should also make sure that your electrical network supports the power consumption of the device you are purchasing.

If you are interested in the topic of semi-automatic aluminum welding, express your opinion, offer ideas or argue with the author in the comments block. This is interesting.

Advantages of mechanized gas-shielded gas welding

Properly organized semi-automatic aluminum welding provides a number of advantages:

- High performance. Compared to argon arc welding, the MIG process is 3 times faster.

- Easy to use. Unlike the argon arc welding method, even a novice welder can quickly master the semi-automatic welding method. In this regard, making welded joints of aluminum parts with your own hands is popular among amateurs.

- Equipping the semi-automatic machine with a pulse mode allows you to achieve high quality welds and accuracy of geometric dimensions. This minimizes wire losses due to spattering.