Causes of burn-through

Welding work is accompanied by various activities, where ultimately both objective and subjective reasons may arise that cause burn-through of the weld. Objective reasons include the natural properties of metals, which can affect the quality of work to varying degrees. All characteristics associated with the technological process of welding - equipment, accompanying materials, etc. are of a subjective nature. to some extent, it is possible to justify the occurrence of the cause of weld burn-through on the part of the welder only by objective signs, and even then, laboratories give an opinion about the properties of the metal, which the welder must know about before starting production work.

Taking into account the normative and regulatory provisions, the only correct definition of the occurrence of a defect is given, where weld burn-through is a complex of mutually exclusive factors that worsen the technical properties of the metal products being welded.

- Incorrect preparation mode for surfaces to be welded.

- Inconsistency or malfunction of process equipment.

- Incorrect selection of the class of fluxes or shielding gases, which became the basis for the causes of burn-through.

- Low qualification of a welder.

- Violation of the welding process, in particular deviation from technical documentation, incorrect selection of welding equipment, as well as related materials.

The last category has several justifications, allowing you to see the weld burn-through only in the photo, where a specialist and supervisory structures make the appropriate technical conclusion and recommendations. Violation of the technical process is caused by non-compliance with the current parameter of the welding equipment, incorrect choice of arc length, etc.

Welding thin metal. How not to burn

Welding thin metal

For experienced welders who have been working with welding for many years and for beginners, it is important to know the basic features of welding thin metal in order to avoid problems when welding products and not burn through the metal. Thin-sheet metal is becoming widespread in the manufacture of cars, boats and various modern goods, increasing the profitability of production.

In order not to burn through the metal, when welding it is necessary to select the correct mode on the welding machine (semi-automatic, inverters) and select electrodes. Any careless movement of the electrode can contribute to the formation of a through hole (the metal is burned) and the product becomes unusable. If the electrode does not come into close contact with the metal, a poor connection of the welded surfaces occurs due to a poor-quality weld or its absence, and lack of penetration is formed.

Important features during operation

Welding work with thin-sheet products requires knowledge, experience, qualifications and the use of various technological techniques that will help weld workpieces without leaks or burns.

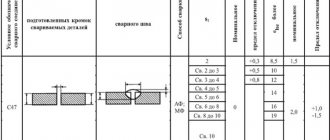

- When welding, it is necessary to choose the right electrode with a diameter corresponding to the thickness of the thin metal (0.5 to 2.5 mm) so as not to burn through the metal sheet. When using the thinnest electrodes, you need to choose them with a high melting coefficient and stable combustion in order to obtain a high-quality seam at low currents.

- Thin metal cannot be heated too much, as the geometry of the sheet changes (bends in waves) and burns out. Welding is carried out in one direction, along the seam without deviation. To create minimal heating, the parts are placed in a vertical or inclined (inclination angle of 30-40 degrees) direction and cooked from top to bottom.

- Careful processing of the edges of thin metal sheets from rust and contamination is necessary for better welding. Aligned and cleaned sheets should be located close to each other, without a gap, and fixed with special devices (clamps, clamps) so that they do not move or bend. Welding should be done with short seams of 7-10 cm.

- Correct configuration and adjustment of a microprocessor-controlled DC inverter allows you to select the minimum power and obtain the current required for a certain type of work and avoid operational failures. The choice of welding current is carried out depending on the thickness of the metal and the diameter of the electrode. When welding thin metal with thin electrodes, a current in the range from 10 to 90 A is used.

For 1.5 mm electrodes, the current is set to 30-40 A, and for 2 mm – 40-60 A.

When the voltage in the electrical network is low, the current power must be increased accordingly. When using an inverter, experts use the reverse polarity method, in which the holder is connected to the positive terminal of the device, and the ground to the workpiece. As a result, the electrode heats up more, the thin-walled metal is smaller and the work goes faster, resulting in a high-quality seam. For novice welders, it is convenient to use an inverter with anti-stick and arc forcing functions, which can relieve voltage when the electrode approaches the metal surface too close, and when the arc stretches, increase the voltage and the process is not interrupted.

Welding methods

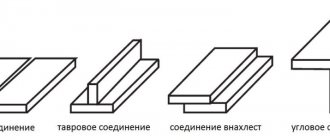

There are various techniques when welding thin workpieces to avoid through-burn and perform the job efficiently:

- When welding an entire seam using a continuous method, it is important to correctly select the current power and the speed of the electrode. When the electric arc moves very quickly, the melt zone does not have time to warm up, the seam is not welded and the connection does not have the required strength or tightness, and if it moves quickly, holes can form. When welding without separation, it is difficult to avoid burn-through, so an intermittent method is used.

- Intermittent or spot welding is often used when working with thin metals. This method involves short contact of the electrode with the metal surface, in which the arc is torn off for a moment and lowered to the same place, moving it a few millimeters. During the arc separation time, the metal has time to cool a little, but the main thing is not too much.

- When butt welding thin metal, a thin wire (diameter 2.5-3.5 mm) is used to lay it between the sheets so that on the front side it is flush with the surface and on the other side protrudes half the diameter. When welding, an electric arc is conducted along a wire, which receives a thermal load, and the metal is heated by peripheral currents. The seam is smooth and the wire is easily removed. An additional electrode can be used as a filler material to melt the main one.

- Copper plates, which have high thermal conductivity, can be placed under the joint and used as a non-remaining lining. They take away some of the heat, the metal does not overheat, which eliminates burns and lack of fusion. For a quality connection, the main thing is tight contact between the workpiece and the plate.

- The main thing when overlapping welding, if the design allows, is to preserve the surface located below from burning.

Welding galvanized and stainless steel

When welding galvanized thin sheet steel on the edges, the zinc layer is completely removed to clean steel in several ways:

- mechanically, using an abrasive wheel on a grinder, a metal brush, sandpaper;

- burning out by welding, which consists of passing an electrode twice along the seam, during which toxic evaporation of zinc occurs, and after each pass the flux must be removed. It is important to carry out the work outdoors or in a room with good ventilation.

Welding is carried out in two approaches with different electrodes: the first seam is made with rutile-coated electrodes, and the facing, top layer is made with the main coating (UONI-13/55, UONI-13/45), which is made wider.

When welding structures made of stainless alloy, problems arise due to the properties of the material (low thermal conductivity, high electrical resistance, increased expansion, shrinkage, etc.), which lead to deformation of the material, heating of the electrode, and through penetration. These difficulties can be solved using the following methods: welding with reduced current, the use of chromium-nickel, shortened (35 cm) electrodes, cooling the seam (with water, air). Various requirements are imposed on welded structures, therefore different electrodes (consumable, non-consumable) with inert gas protection are used.

After crystallization of the joint, slag is removed and inspected to ensure that the seam is strong and free of defects. By following important rules, methods, and technologies when welding thin workpieces, you can obtain a weld of high quality and reliability.

Types of defects

According to the general principles and provisions of technology associated with welding equipment, there are two types of defects:

- External. These are visible defects that can be seen with the naked eye. Such defects include lack of penetration, as well as burn-through of the weld.

- Internal. These types include cracks, chips, tension, pores, which can be identified in the laboratory.

Type of seam burn

Each defect detection system has its own rules and regimes, which have regulations developed by state standards.

Weld defects (diagram)

All types of seam defects are divided into three groups:

- external, the main ones of which include: cracks, undercuts, sagging, craters;

- internal, among which the most common are: porosity, lack of penetration and foreign inclusions;

- through - cracks, burns.

Main welding defects, their characteristics, causes and methods of correction

Cracks

. These are the most dangerous welding defects that can lead to almost instantaneous destruction of welded structures with the most tragic consequences. Cracks vary in size (micro- and macrocracks) and time of occurrence (during the welding process or after it).

Most often, the reason for the formation of cracks is non-compliance with welding technology (for example, incorrect placement of seams, leading to stress concentration), incorrect choice of welding materials, sudden cooling of the structure. Their occurrence is also facilitated by the increased content of carbon and various impurities in the weld - silicon, nickel, sulfur, hydrogen, phosphorus.

Correcting a crack consists of drilling out its beginning and end in order to prevent further spread, removing the seam (cutting out or cutting out) and welding.

Undercuts

.

Undercuts are indentations (grooves) at the transition point between the base metal and the weld. Undercuts are quite common. Their negative effect is expressed in a reduction in the cross-section of the seam and the appearance of a source of stress concentration. Both weaken the seam. Undercuts occur due to increased welding current. Most often, this defect occurs in horizontal seams. It is eliminated by surfacing a thin weld along the undercut line. Weld undercuts

Beads

. Sagging occurs when molten metal flows onto the base metal, but does not form a homogeneous connection with it. A weld defect occurs for various reasons - due to insufficient heating of the base metal due to low current, due to the presence of scale on the edges being welded, which prevents fusion, and an excessive amount of filler material. Sagging is eliminated by cutting and checking for lack of penetration in this place.

Weld bead

Burns

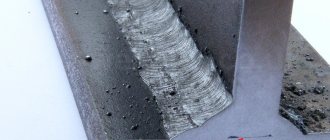

. Burn-throughs are welding defects that manifest themselves in through penetration and leakage of liquid metal through a through hole in the seam. In this case, a sag usually forms on the other side. Burn-throughs occur due to excessively high welding current, insufficient speed of movement of the electrode, a large gap between the edges of the metal, too small a thickness of the backing or its loose fit to the base metal. The defect is corrected by stripping and subsequent welding.

Burn through of welded joint

Lack of penetration

. Lack of penetration is a local lack of fusion of the deposited metal with the base metal, or between the weld layers. This defect also includes non-filling of the seam section. Lack of penetration significantly reduces the strength of the seam and can cause structural failure.

Failure to fill and lack of penetration of the seam

The defect occurs due to low welding current, improper edge preparation, excessively high welding speed, the presence of foreign substances (scale, rust, slag) and contamination on the edges of the parts being welded. When correcting, you need to cut out the area of lack of penetration and weld it.

Craters

. These are defects in the form of a depression resulting from a break in the welding arc. Craters reduce the strength of the weld due to a decrease in its cross-section. They may contain shrinkage looseness that contributes to the formation of cracks. Craters must be cut down to the base metal and welded.

Weld crater

Fistulas

. Fistulas are suture defects in the form of a cavity. Like craters, they reduce the strength of the weld and promote the development of cracks. The usual method of correction is cutting out the defective area and welding it.

Fistula welds

Foreign inclusions

. Inclusions can consist of various substances - slag, tungsten, metal oxides, etc. Slag inclusions are formed when the slag does not have time to float to the surface of the metal and remains inside it. This happens when the welding mode is incorrect (excessive speed, for example), poor stripping of the metal being welded or the previous layer during multilayer welding.

Foreign inclusions in the welded joint

Tungsten inclusions occur during welding with a tungsten electrode, while oxide inclusions occur due to poor solubility of oxides and excessively rapid cooling.

All types of inclusions reduce the cross-section of the seam and form a focus of stress concentration, thereby reducing the strength of the joint. The defect is eliminated by cutting and brewing.

Porosity

. Porosity is cavities filled with gases. They arise due to intense gas formation inside the metal, in which gas bubbles remain in the metal after it has solidified. Pore sizes can be microscopic or reach several millimeters. Often a whole cluster of pores appears in combination with fistulas and conchas.

Porosity in the weld

The occurrence of pores is facilitated by the presence of contaminants and foreign substances on the surface of the metal being welded, high carbon content in the filler material and base metal, too high welding speed, due to which the gases do not have time to escape, and increased humidity of the electrodes. Like other defects, porosity will reduce the strength of the weld. The area with it must be cut down to the base metal and welded.

Overheating and burning of metal

. Burnout and overheating occur due to excessively high welding current or low welding speed. When overheated, the size of the metal grains in the weld and heat-affected zone increases, as a result of which the strength characteristics of the welded joint, mainly impact strength, decrease. Overheating is eliminated by heat treatment of the product.

Overburning is a more dangerous defect than overheating. Burnt metal becomes brittle due to the presence of oxidized grains that have little mutual adhesion. The reasons for burnout are the same as overheating, and in addition there is also insufficient protection of the molten metal from nitrogen and oxygen in the air. The burnt metal must be completely cut out and the area welded again.

Burnt weld metal