Receipt

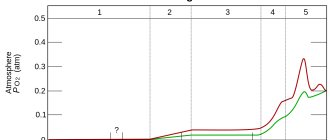

All methods for the industrial production of acetylene converge into two types: hydrolysis of calcium carbide and pyrolysis of various hydrocarbons. The latter requires less energy, but the purity of the product is quite low. The carbide method is the opposite.

The essence of pyrolysis is that methane, ethane or other light hydrocarbon, when heated to high temperatures (from 1000 °C), is converted into acetylene with the release of hydrogen. Heating can be carried out by electric discharge, plasma or combustion of part of the raw material. But the problem is that as a result of the pyrolysis reaction, not only acetylene can be formed, but also many different products that must subsequently be disposed of.

The carbide method is based on the reaction of calcium carbide with water. Calcium carbide is produced from its oxide by fusing with coke in electric furnaces. Hence the high energy consumption. But the purity of acetylene obtained in this way is extremely high (99.9%).

In the laboratory, acetylene can also be obtained by dehydrohalogenation of dihalogenated alkanes using an alcoholic alkali solution.

Method for producing acetylene from methane

The invention relates to a method for producing acetylene by oxidative pyrolysis of methane in the presence of an oxygen-containing gas and a catalyst heated to a temperature of 750-1200°C by passing an electric current through it. The method is characterized by the fact that oxides with a perovskite structure with the general formula Ba0.5Sr0.5Co0.8-xWxFe0.2O3-δ are used as a catalyst, where x=0-0.1; δ=0.4-0.6, molded in the form of tubes, methane is passed outside the catalyst tube, and oxygen-containing gas is passed inside the catalyst tube. The use of the present invention makes it possible to increase the stability of the catalyst and eliminate the formation of carbon deposits on its surface, which increases the yield of acetylene and ensures the explosion safety of the process. 1 tab., 7 pr., 1 ill.

The invention relates to the field of oil and gas chemistry, namely to processes for producing acetylene from methane.

The urgency of developing new methods for the synthesis of acetylene, a valuable petrochemical raw material, is caused by the need to involve natural gas in the raw material base for petrochemicals, which is due to the depletion of easily accessible oil reserves.

There are widely known methods for producing acetylene from methane by its oxidative pyrolysis - the process of burning methane in a torch under conditions of lack of oxygen. The process temperature is 1200-1400°C, the residence time of the components in the reaction zone is several milliseconds. A mandatory stage of the process is hardening of the products, which is their sharp cooling to a temperature below 300°C by introducing water or oil into the cooling medium flow, which is necessary to prevent the decomposition of the resulting acetylene into carbon and hydrogen (V.N. Antonov, A.S. Lapidus. Acetylene production. M.: Khimiya, 1970. - 415 pp.).

Most of the known methods for increasing the efficiency of the above methods involve optimizing the methane combustion process by improving burners (patent RU 2419599) or reactor devices (utility model patent RU 122089).

The general disadvantages of these methods are the low yield of the target product (acetylene), as well as the formation of soot aerosols as a result of the reaction, which creates certain difficulties in the process of compression and separation of the resulting gaseous products.

There are also known methods for carrying out the process of oxidative pyrolysis of methane, based on the use of solid catalysts at temperatures of 800-950°C. Oxides of iron, nickel, cadmium, zinc, manganese and silver supported on α-Al2O3 can be used as catalysts (GE Keller, MM Bhasin / Synthesis of Ethylene via Oxidative Coupling of Methane // Journal of Catalysis. 1982. V. 73 . P. 9-19), or the Bi2O3-MeO system, where Me is Mg, Ca, Sr, Ba (AC USSR No. 1216937). The degree of methane conversion in such processes does not exceed 20%, and the main conversion products are ethane and ethylene, while acetylene is obtained only in trace quantities.

The possibility of using perovskite-type oxides as catalysts for methane oxidation is also known (patent RU 2440292), however, the main direction of methane conversion on catalysts of this type is its deep oxidation with the formation of CO2 and H2O.

The closest to the proposed method is the method of producing acetylene from methane (patent RU 2409542, prototype), according to which acetylene is produced by passing a mixture of methane-oxygen-inert gas over a heated catalyst. As a catalyst, it is proposed to use a fechral alloy treated in air at 900-1100°C in the form of spirals, tapes, rods and other forms. The catalyst is heated by passing an electric current through it to temperatures of 700-1200°C, and the methane/oxygen ratio is changed in the range of 5:1-15:1. Since the gas mixture is supplied cold, the breakthrough of part of the cold gas leads to a sharp cooling of the reaction products formed upon contact with high-temperature fechral, i.e. to hardening the products of oxidative pyrolysis and increasing the yield of C2+ hydrocarbons, primarily acetylene. The described method makes it possible to obtain C2+ hydrocarbons with a maximum yield of 25.5 wt. % with a methane conversion rate of 56.4%. The described method has significant disadvantages, the main one of which is the formation of carbon on the surface of the catalyst during oxidative pyrolysis. This leads to rapid (within minutes) deactivation of the catalyst, as well as destruction of the catalyst as a result of carbon corrosion and the inability to reuse it in the catalytic cycle. Another disadvantage is the use of air-methane mixtures as raw materials, which can be explosive at a certain ratio of components.

The purpose of this invention is to increase the efficiency of the acetylene synthesis process, namely: increasing the stability of the catalyst and eliminating the formation of carbon deposits on its surface, increasing the yield of acetylene, as well as ensuring the explosion safety of the process.

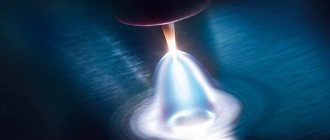

To achieve this goal, a method is proposed for producing acetylene by oxidative pyrolysis of methane in the presence of an oxygen-containing gas using a membrane-catalytic material that has both electronic conductivity and selective oxygen permeability.

Oxides with a perovskite structure with the general formula Ba0.5Sr0.5Co0.8-xWxFe0.2O3-δ, where x=0-0.1; δ=0.4-0.6, molded in the form of tubes. The method is implemented by passing oxygen-containing gas through the internal space of the tube, and methane - outside the tube, resulting in the diffusion of oxygen through the wall of the tube from the oxygen-containing gas flow into the methane flow. In this case, the tube is heated by passing an electric current through it to a temperature of 750-1200°C.

The drawing shows an installation diagram for implementing the method. The installation consists of a reactor 1, a catalyst molded in the form of a tube 2, an alternating current source 3 and an inductive reactance 4.

The installation works as follows. Methane is fed into reactor 1, in the lower part of which there is a catalyst molded in the form of a tube 2, into the internal space of which oxygen-containing gas is supplied. To carry out heating, the ends of the catalyst tube are connected to an electrical circuit consisting of an alternating current source 3 and an inductive reactance 4, which is used to regulate the current strength.

The process is carried out at temperatures of 750-1200°C. Oxygen enters the reactor, diffusing through the walls of the catalyst tube, and is instantly consumed. This prevents the formation of explosive mixtures. The methane/oxygen ratio is adjusted by changing the flow rate of the corresponding gases.

The essence of the invention is illustrated by the following examples.

Example 1. The process of oxidative conversion of methane is carried out in a reactor made of a quartz tube with an internal diameter of 15 mm. The process temperature is 750°C, methane is supplied to the reactor at a flow rate of 100 cm3/min, air is supplied to the internal space of the perovskite tube at a flow rate of 33 cm3/min, the methane/oxygen ratio is 15/1. The composition of the starting materials and gaseous products of the process is determined by gas chromatography. For this purpose, a two-channel chromatograph “Chromos GC-1000” is used, equipped with a packed column with a “Poropak-Q” sorbent and a katharometer, as well as an HP Pona capillary column and a flame ionization detector. The quantitative composition of the sample is determined by the internal standard method, which uses air nitrogen.

Methane conversion is carried out within three hours, while the process indicators remain stable.

Example 2. Similar to example 1, but the process temperature is 900°C. The process indicators are shown in the table.

Example 3. Similar to example 1, but the process temperature is 1000°C. The process indicators are shown in the table.

Example 4. Similar to example 1, but the process temperature is 1100°C. The process indicators are shown in the table.

Example 5. Similar to example 1, but the process temperature is 1200°C. The process indicators are shown in the table.

Example 6 (based on the prototype). A spiral of fechral wire with a diameter of 0.5 mm is used as a catalyst. The process temperature is 750°C. After 1 hour of operation, the catalyst becomes covered with a coating of carbon deposits, which leads to a drop in activity. The process indicators are shown in the table.

Example 7. Similar to example 6, but the process temperature is 1170°C. After 1.2 hours of operation, the spiral burns out due to the effects of carbon corrosion. The process indicators are shown in the table.

As can be seen from the table data, the proposed method makes it possible to obtain acetylene with a yield of 26.6%, the degree of methane conversion is 58.1%, while the time of stable operation of the catalyst is 3 hours or more. An additional advantage is the ability to separate oxygen-containing gas and methane flows, which reduces the explosion hazard of the method.

Thus, the proposed method makes it possible to increase the efficiency of the process of acetylene synthesis from methane compared to existing methods.

A method for producing acetylene by oxidative pyrolysis of methane in the presence of an oxygen-containing gas and a catalyst heated to a temperature of 750-1200°C by passing an electric current through it, characterized in that oxides with a perovskite structure with the general formula Ba0.5Sr0.5Co0.8 are used as a catalyst -xWxFe0.2O3-δ, where x=0-0.1; δ=0.4-0.6, molded in the form of tubes, methane is passed outside the catalyst tube, and oxygen-containing gas is passed inside the catalyst tube.

Chemical properties of acetylene

Based on the triple bond of acetylene, it will be characterized by addition reactions and polymerization reactions. Hydrogen atoms in an acetylene molecule can be replaced by other atoms or groups. Therefore, we can say that acetylene exhibits acidic properties. Let's look at the chemical properties of acetylene based on specific reactions.

- Hydrogenation. It is carried out at high temperature and in the presence of a catalyst (Ni, Pt, Pd). On a palladium catalyst, incomplete hydrogenation is possible.

- Halogenation. It can be either partial or complete. Goes easily even without catalysts or heat. In the light, chlorination occurs explosively. In this case, acetylene completely decomposes to carbon.

- Addition to acetic acid and ethyl alcohol. Reactions take place only in the presence of catalysts.

- Addition of hydrocyanic acid.

- Interaction of acetylene with metal-organic compounds.

- Interaction with sodium metal. A temperature of 150 °C or preliminary dissolution of sodium in ammonia is required.

2CH≡CH + 2Na → 2CH≡CNa + H2

- Interaction with complex salts of copper and silver.

- Interaction with sodium amide.

- Dimerization. In this reaction, two acetylene molecules combine into one. A catalyst is required - a monovalent copper salt.

- Trimerization. In this reaction, three acetylene molecules form benzene. Requires heating to 70 °C, pressure and a catalyst.

- Tetramerization. As a result of the reaction, an eight-membered ring is obtained - cyclooctatetraene. This reaction also requires little heat, pressure and an appropriate catalyst. Typically these are complex compounds of divalent nickel.

These are not all the chemical properties of acetylene.

Application of acetylene

Acetylene is used in all processes of gas-flame processing of metals (gas welding and gas cutting), due to the high flame temperature, which cannot be achieved when using other combustibles.

For soldering, cutting, surfacing, flame hardening, metallization, gas press welding, welding of non-ferrous metals and alloys, acetylene substitute gases are successfully used:

- propane-butane mixtures

- city gas

- natural gases

- hydrogen

- gasoline vapor

- kerosene vapor

- MAF

- and etc.

In terms of chemical composition, all of them, with the exception of hydrogen, are either compounds or mixtures of various hydrocarbons.

The correct selection and use of substitute gases allows you to achieve high quality welding and cutting, and when gas cutting metals of small thickness, it gives a higher cutting cleanliness.

Gas welding is possible provided that the flame temperature is twice the melting point of the metal being welded. Therefore, substitute gases whose flame temperature is lower than that of acetylene are used for welding metals with a melting point lower than that of steels

For gas cutting, the choice of flammable gas is based on its calorific value, but it must be taken into account that the gas, when burned in a mixture with oxygen, must form a flame with a temperature of at least 2000°C.

The influence of impurities in acetylene on the quality of the weld

Let's look at some more features of the use of acetylene in gas welding - the influence of impurities on the quality of the weld. The following impurities have a harmful effect:

- hydrogen sulfide

- hydrogen phosphide

The above impurities are necessarily removed from acetylene, not only because of the effect on the quality of the weld, but also because of the detrimental effect on the respiratory system and vision of the welder (see the article Explosion hazard, toxicity and self-ignition of acetylene).

Hydrogen sulfide , when burned, forms sulfuric acid, which, when transferred to the weld metal, causes red brittleness. It has been established that the presence of hydrogen sulfide up to 0.007% does not have a harmful effect on the strength of the weld.

Determining the presence of hydrogen sulfide in acetylene is quite easy; you need to hold filter paper soaked in a solution of mercury chloride under a stream of acetylene. In the presence of hydrogen sulfide, the paper will turn white.

The process of purifying hydrogen sulfide is also quite simple - you need to pass acetylene through water, as a result of which hydrogen sulfide will dissolve in water.

Phosphorous hydrogen, when burned, forms phosphoric acid, which, when transferred to the weld metal, causes cold brittleness. It has been established that the presence of hydrogen phosphide up to 0.027% does not have a harmful effect on the strength of the weld.

To determine the presence of hydrogen phosphide, you need to place a piece of filter paper soaked in a ten percent solution of silver nitrate under a stream of acetylene. With a content of hydrogen phosphide of 0.01%, the paper takes on a distinct light yellow color; with a content of more than 0.02%, the paper darkens.

Chemical purification of acetylene from hydrogen phosphide is carried out by passing it through a special cleaning mass - geratol. Geratol is a yellow mass, which, as a result of interaction with hydrogen phosphide, becomes green.

Application of acetylene in the chemical industry

In addition to gas-flame processing, acetylene is used in the chemical industry as the main starting material for the production of a number of important products of organic synthesis: synthetic rubber, plastics, solvents, acetic acid, etc. Next, we will look at how acetylene is used to obtain certain chemical compounds .

Acetaldehyde

The product of the addition of water to acetylene is acetaldehyde. This synthesis was first carried out by M. G. Kucherov in 1881. The reaction proceeds according to the equation:

HC = CH + H2O? CH3 - CHO

The reaction is carried out by passing acetylene through a sulfate solution of mercuric oxide salt at a temperature of 70-80°C.

The use of this reaction was the beginning of the industrial synthesis of organic substances using acetylene as the starting product.

Acetone

When passing a mixture of acetylene and water vapor in a ratio of approximately 1:10 at a temperature of 430-450°C over a zinc-vanadium catalyst, acetone is formed according to the equation:

2C2H2 + 3H2O ? CH3-CO-CH3 + CO2 + H2O

This process has found application on an industrial scale.

Vinyl chloride

When acetylene reacts with hydrogen chloride at 200°C over a catalyst consisting of mercury dichloride supported on activated carbon, vinyl chloride is formed according to the equation:

C2H2 + HCl ? CH2 = CHCl

Vinyl acetate

With acetic acid, also in the presence of mercury salts, acetylene forms vinyl acetate:

C2H3 + CH3COOH ? CH2 = CH-OCO-CH3

Vinyl chloride and vinyl acetate are widely used in the production of plastics.

Application

The structural formula of acetylene shows us a fairly strong bond between carbon atoms. When it ruptures, for example during combustion, a lot of energy is released. For this reason, the acetylene flame has a record high temperature - about 4000 °C. It is used in torches for welding and cutting metal, as well as in rocket engines.

Read also: Which machine is impossible to process metal

The acetylene combustion flame also has a very high brightness, so it is often used in lighting devices. It is also used in explosives. True, it is not acetylene itself that is used, but its salts.

As can be seen from its varied chemical properties, acetylene can be used as a raw material for the synthesis of other important substances: solvents, varnishes, polymers, synthetic fibers, plastics, organic glass, explosives and acetic acid.

Molecular formula of acetylene

Ethine is the simplest member of its homologous series; its composition and structure are reflected by the formulas:

- C2H2 is the molecular notation for the composition of ethyne, which gives the idea that the substance is formed by two carbon atoms and the same number of hydrogen atoms. Using this formula, you can calculate the molecular and molar mass of a compound. Mr (C2H2) = 26 a. e.m., M (C2H2) = 26.04 g/mol.

- H:S:::S:H is the electron dot formula of acetylene. Such images, called “Lewis structures,” reflect the electronic structure of the molecule. When writing, you must follow the rules: the hydrogen atom, when forming a chemical bond, tends to have the configuration of the helium valence shell, other elements - an octet of outer electrons. Each colon represents a shared or lone pair of electrons in the outer energy level.

- H—C≡C—H is the structural formula of acetylene, reflecting the order and multiplicity of bonds between atoms. One dash replaces one pair of electrons.

Safety

As already mentioned, acetylene is a flammable substance. With oxygen or air it is capable of forming extremely flammable mixtures. A single spark from static electricity, heating up to 500 °C or slight pressure is enough to cause an explosion. At a temperature of 335 °C, pure acetylene spontaneously ignites.

Because of this, acetylene is stored in pressure cylinders that are filled with a porous substance (pumice, activated carbon, asbestos). In this way, acetylene is distributed throughout the pores, reducing the risk of explosion. Often these pores are impregnated with acetone, which results in the formation of an acetylene solution. Sometimes acetylene is diluted with other, more inert gases (nitrogen, methane, propane).

This gas also has a toxic effect. When it is inhaled, intoxication of the body will begin. Signs of poisoning are nausea, vomiting, tinnitus, and dizziness. Large concentrations can even lead to loss of consciousness.

1) acetylene of this series of hydrocarbons is of great practical importance;

2) unlike methane and ethylene, acetylene burns with a bright flame.

Examples of acetylene combustion: welding work on construction sites, workshops, factories.

In all these cases, no soot formation is visible.

In this case: a) carbon particles become very hot in the middle part of the flame; b) give it brightness; c) eventually burn out completely.

When welding, oxygen is used instead of air. In this case, complete combustion of acetylene is achieved, the flame temperature increases to 3000 °C. Mixtures of acetylene with air and oxygen are explosive;

3) the π bond is inferior in strength to the main δ bond;

4) addition and oxidation reactions can take place at the site of π bonds.

of potassium permanganate is poured into a cylinder filled with acetylene the solution will quickly become discolored;

5) acetylene, like ethylene, is easily oxidized;

6) of the addition reactions for acetylene, interaction with bromine is typical.

Two stages of the addition reaction when acetylene reacts with bromine:

1) first, bromine joins at the site of one π-bond and 1,2-dibromoethene is formed: CH = CH + Br2 → BrCH=CHBr;

2) then a second bromine molecule is added at the second π-bond, the reaction product is 1,1,2,2-tetrabromoethane: BrCH=CHBr + Br2 → Br2CH–CHBr2;

3) in the presence of a catalyst (platinum, nickel), hydrogen can join acetylene.

In this case, acetylene first turns into ethylene and then into ethane:

4) when hydrogen chloride is added to one of the π bonds, the gaseous substance chloroethene (vinyl chloride) is formed. The catalyst for this reaction is mercuric chloride:

5) addition of water (hydration) occurs in the presence of a Hg 2+ catalyst in an acidic medium (reaction of M.G. Kucherov). In this case, acetylene forms acetaldehyde, and its homologues form the corresponding ketones:

Date added: 2015-09-29; ; ORDER A WORK WRITING

How to get acetylene

It is very difficult to obtain acetylene from methane at home. The simplest method for isolating this gas is the reaction of water with calcium carbide. Many of you probably remember throwing pieces of this substance into puddles and what the reaction was. At the same time, a violent hissing was noted. As for the calcium carbide, it gradually melted, forming a large amount of foam. Such a reaction can be written as follows:

CaC2+2H2O=C2H2+Ca(OH)2.

Many people use technical calcium carbide, which contains a large amount of impurities. As a result, when reacting with water, the substance emits an unpleasant odor. It occurs due to the formation of a small amount of toxic gas vapors together with acetylene. Most often this is phosphine, hydrogen sulfide, and so on. This method is considered the most common, since acetylene can only be obtained from methane using special equipment.

Definition of alkynes, formula, basic chemical properties

Alkynes (hydrocarbons of the acetylene series)

are chemical substances from the group of aliphatic hydrocarbons that contain one triple bond -C≡C-.

The general formula of alkynes is СnH2n-2.

The simplest representative of the alkyne series is acetylene (ethyne) C2H2.

According to the IUPAC substitutive nomenclature, the names of acetylene hydrocarbons are formed from the name of the corresponding alkane, and the suffix -an should be replaced with -in (-in) indicating the position of the triple bond in the chain of carbon atoms.

The numbering of carbon atoms begins from the end to which the triple bond is closest, for example, CH3CH (CH 3) C≡CH3 - 4-methylpentine-2.

Read also: Welding connecting cable price

According to rational nomenclature, hydrocarbons of the acetylene series or alkynes are called acetylene derivatives, in the empirical formula of which hydrogen atoms are replaced by radicals: HC≡C-CH 2 CH 3 - ethyl acetylene.

The isomerism of acetylene hydrocarbons is associated with the position of the triple bond and the branching of the carbon chain. Alkynes C2-C4 are gases, C5-C16 are liquids, and starting from C17 they are solid substances.

Alkynes. General formula. Acetylene

Alkyne hydrocarbons, or acetylene hydrocarbons, are acyclic and unsaturated. The chain of carbon atoms is not closed; it contains simple and multiple bonds. The composition of alkynes is reflected by the summary formula CnH2n– 2. The molecules of substances of this class contain one or more triple bonds. Acetylene compounds are unsaturated. This means that only one valency of carbon is realized by hydrogen. The remaining three bonds are used when interacting with other carbon atoms.

The first and most famous representative of alkynes is acetylene, or ethyn. The trivial name of the substance comes from the Latin word “acetum” - “vinegar” and the Greek word “hyle” - “wood”. The ancestor of the homologous series was discovered in 1836 in chemical experiments; later the substance was synthesized from coal and hydrogen by E. Davy and M. Berthelot (1862). At normal temperature and normal atmospheric pressure, acetylene is in a gaseous state. It is a colorless, odorless gas, slightly soluble in water. Ethyne dissolves more easily in ethanol and acetone.

Chemical properties of alkynes

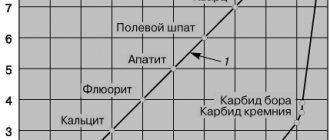

The chemical properties of acetylene hydrocarbons are determined by the presence of a triple bond in the structure of their substance. The acetylene (alkyne) group -C≡C-H or -C≡C-R has a linear structure, the carbon atoms are sp-hybridized. They are connected by one σ- and two π-bonds, with their maximum densities located in two mutually perpendicular areas, forming a cylindrical cloud of π-electron density. The distance -С≡С- is 1.1205 nm, the energy of the triple bond is 836 kJ/mol. Due to the structural features of the triple bond, alkynes are characterized by oxidation, addition, polymerization, isomerization, and substitution reactions. Acetylene hydrocarbons add halogens directly to the -C≡C- bond, and hydrogen halides – in the presence of catalysts (for example, HgCl2, CuCl), forming dihalides and tetrahalides.

These reactions are used in the production of trichlorethylene, tetrachlorethylene, vinyl chloride and other chlorine derivatives. Hydrogenation of alkynes with sodium in liquid NH3 leads to trans-alkenes, and hydrogen over Pd/C to cis-alkenes. Water adds in the presence of Hg2+ salts to form acetaldehyde for acetylene and ketones for all other alkynes (Kucherov reaction). Direct hydration of acetylene is possible by passing it in a mixture with water vapor at T = 300-400 ° C over heavy metal phosphates. The acetylene hydration reaction is used industrially to produce acetaldehyde and its further transformation products - acetone, acetic acid, alcohol, etc. Alcohols react with acetylene hydrocarbons in the presence of ROH, BF3 or HgO, alkali metal alkoxides, copper salts at a temperature of 150-200 ° C.

The reaction products are vinyl esters, which are used in the production of polymers, emulsifiers, lubricants, etc. Similar to acetylene hydrocarbons, carboxylic acids are also added (in this case, HgSO4, Cd or Zn acetates on activated carbon are used as a catalyst), acid amides, amines, thiols and others to form vinyl compounds, for example:

Vinyl acetate is widely used to produce the polymer polyvinyl acetate (PVA). By adding cyanide acid to acetylene or by reacting with CO and alcohols, NH3, as well as amines in the presence of Ni (CO) 4 as a catalyst under pressure, nitrile, amides or esters of acrylic acid are obtained, which are used in the synthesis of polymers:

Acetylene hydrocarbons in the presence of alkaline catalysts add ketones and aldehydes (Favorsky reaction):

An important practical role is played by the interaction reaction in the presence of Cu acetylenides of acetylene with formaldehyde (Reppe reaction):

Under the action of alkali metals, the triple bond in alkynes moves through the stage of formation of intermediates but not to the end of the molecule. And in the presence of alcoholic solutions of alkali, on the contrary, the triple bond moves to the middle of the molecule:

Read also: Container for cyclone filter

Alkynes with finite triple bonds

(RC≡CH) have high acidity for hydrocarbons (for acetylene pKa≈25) and form, under the action of alkali, alkaline earth metals, metal amides, metal derivatives, the so-called acetylenides MC≡CR, which react vigorously with water, regenerating acetylene hydrocarbons.

Magnesium halogen derivatives of acetylene hydrocarbons (Jocic reagents) are easily formed from organomagnesium compounds. Na, Mg, Li acetylenides are used in organic synthesis to introduce an acetylene group into the molecule, for example:

Disubstituted acetylenides Cu2C2 and Ag2C2 are synthesized by treating acetylene with ammonia solutions of Cu(I) and Ag salts, respectively. The formation of red-brown Cu2C2 is used to identify acetylene and its homologues with a terminal triple bond. Heavy metal acetylenides in dry form are unstable compounds that explode when subjected to shock. During the combustion of acetylene, with access to pure oxygen, a significant amount of heat is released (with the flame temperature reaching 3000 degrees C), which makes it possible to use acetylene for the purpose of autogenous cutting and welding of metals. Oxidizing agents KMnO4 (in a neutral or alkaline environment), K2Cr2O7, RuO4, SeO2, CrO3 in an acidic environment, ozone lead to the cleavage of the triple bond with the synthesis of carboxylic acids. In some cases, oxidation to α-diketones is possible. With a terminal triple bond, alkynes form carboxylic acid and CO2 under these conditions.

Methods for extracting acetylene in industry:

- decomposition of calcium carbide in water:

- electrocracking of methane (natural gas with impurities) in electric arc furnaces: Temperature 1600 ° C, normal pressure, the mixture of gases is sharply cooled with water;

- partial oxidation (thermal-oxidative cracking) of natural gas due to the heat released during partial combustion of methane:

- natural gas pyrolysis process.

Acetylene hydrocarbons are obtained

in laboratory conditions as a result of the action of an alcohol solution of alkali (KOH - alcohol solution) on 1,1- or 1,2-dihalogen derivatives of hydrocarbons:

- alkylation of sodium acetylenides, electrolysis of dibasic unsaturated acids.

Alkynes, in particular polyacetylene

, found in nature in many plants, fungi (Bas >

Alkynes (acetylene hydrocarbons) have a narcotic effect, which increases with increasing molecular weight of the substance.

Long-term work of specialists with acetylene in industrial conditions can lead to functional disorders of the nervous system. High concentrations of acetylene with low oxygen levels lead to pulmonary edema and loss of consciousness.

Features of chemical bonds in acetylene

The ethin molecule has a linear shape, which is successfully reflected by the chemical formula of acetylene - H—C≡C—H. The carbon and hydrogen atoms are located along the same straight line, and 3 σ- and 2 π-bonds arise between them. Free movement, rotation along the C-C axis is impossible, this is prevented by the presence of multiple bonds. Other features of the triple bond:

- the number of pairs of electrons connecting two carbon atoms is 3;

- length - 0.120 nm;

- rupture energy - 836 kJ/mol.

For comparison: in ethane and ethylene molecules, the length of single and double chemical bonds is 1.54 and 1.34 nm, respectively, the energy of C-C cleavage is 348 kJ/mol, C=C is 614 kJ/mol.

Application of alkynes (acetylene hydrocarbons) in medicine

Acetylene

– one of the basic raw materials for the organic synthesis industry.

By condensing acetylene with pyrrolidone, N-vinylpyrrolidone is obtained, which easily polymerizes with the synthesis of polyvinylpyrrolidone (PVP):

Polymer compounds based on vinylpyrrolidone have found widespread use in medical practice as substances in the production of drugs, and many of them are themselves medicinal. For example, low molecular weight polyvinylpyrrolidone (12000-13000 molecular weight) forms colloidal solutions in water and is used in the process of preparing hemodesis (blood substitute), medium molecular weight polyvinylpyrrolidone (with a molecular weight of 35000-40000) is used in pharmacy as a binder for the manufacture of tablets.

By copolymerizing vinylpyrrolidone, acrylamide and ethyl acrylate, a biosoluble polymer is obtained that provides extended action of drugs (prolonging the effect), for example, medicinal films for the eyes.