Pneumatic impact wrenches have a number of advantages over other types of this tool, including durability, reliability, safety during operation, as well as immunity to prolonged loads and the ability to cope with even the most complex fasteners. For this reason, air tools are chosen for workshops, auto repair shops and service centers.

How to choose a pneumatic impact wrench

When choosing a pneumatic impact wrench, you need to clearly define the purpose of its use.

Angular or straight?

An angle wrench is suitable for working with fasteners from the side. In this case, the tool body acts as a force arm. It is easier to hold in your hands when working with heavy fasteners. Models with a straight stem are cheaper, more familiar and structurally simpler.

Torque

This parameter determines the power of the pneumatic tool. The higher the torque, the more complex fasteners it can handle. For the simplest impact wrenches, a torque of 80-100 Nm will be enough to work. Models designed to work with truck fasteners are required to produce thousands of newton meters. Peak performance is only required for unscrewing to get the nut out of place. When screwing, huge efforts are not required. On the contrary, an overtightened bolt ends up easily bursting across and the thread breaks off. And if such troubles do not occur, more power will be required to unscrew it next time.

Idle speed

It is believed that the idle speed of the spindle is determined by the power of the pneumatic impact wrench. In fact, the speed only indicates design features. Thus, a powerful tool is capable of delivering up to 7 thousand rpm, but for cargo models it is not speed that is important, but force. For this reason, they have a high air flow, but the idle speed is about 3 thousand rpm.

Operating pressure and air flow

Air consumption is directly proportional to the power of the tool; it can be different at the same operating pressure in the pneumatic system. For example, with a standard pressure of 6.3 atmospheres, medium-power models consume about 150 liters of air per minute. This figure for “strong men” can exceed 800 liters.

It is advisable that the pneumatic system be equipped with a compressed air preparation unit. This will significantly extend the working life of the impact wrench, and the operator will only need to control the output pressure and the presence of lubricant.

Compressor

The parameters of the impact wrench must correspond to the technical characteristics of the compressor. The passport for the instrument always indicates the recommended requirements for the pneumatic system. The model is selected so that the compressor is capable of providing normal operating pressure at the declared flow rate.

Landing size of the spindle (chuck, square shank)

The power of the impact wrench determines the seat size of the shank, which is usually indicated in inches. The following standards exist: 1, ½, ¾ inches, and less common options. The more powerful the tool, the larger the spindle diameter. This is natural, because a square of small cross-section with high power simply will not withstand the load. It is important to note here that it will be difficult to find heads for a non-standard shank; you will have to additionally purchase an adapter.

Impact mechanism

Due to the jerks when unscrewing, the fastener yields faster. In addition, half of the nuts simply cannot be unscrewed with a hammerless tool. Therefore, when choosing, preference is always given to impact wrenches.

The ability to adjust the tightening force and the presence of reverse

Almost all modern models are equipped with a reverse switch. This function allows you to both tighten fasteners with high force and unscrew old bolts. But there are also models without reverse on the market. Their spindle rotates only in one direction.

The torque adjustment function is also common, but this is the first thing that fails in low-quality models. It allows you to set the maximum force that will be applied to the fastener. The accuracy of torque setting, even with an expensive tool from branded manufacturers, does not exceed 10%. If the error needs to be reduced to zero, it is better to use a torque wrench.

Dimensions, weight and ergonomics

The weight of the tool is reduced due to the use of light alloys of increased strength. There are models on the market with a plastic body, but their quality is initially questionable.

It is impossible to work with a heavy tool with one hand, not only because of the weight, but also because of the high torque. Therefore, such models are equipped with an additional handle.

For ease of operation, pneumatic impact wrenches are equipped with rubberized linings on the body and handles, as well as a rotating nozzle for air removal. The tool is used at various angles, and the escaping air stream directed into the ground raises dust. Debris gets into your eyes and lungs. Being able to adjust the direction of the air nozzle would be an added bonus.

How to choose a pneumatic impact wrench? Find out!

Each model has many different benefits and amenities to consider before making a purchase.

Below is a list of features you should rely on when choosing a wrench.

- The presence of a striking mechanism;

- Maximum torque;

- Connecting square size;

- Air flow and operating pressure;

- Rotation speed of the working shaft (spindle);

- Features of the case (material, type, size, additional handle);

- Working shaft length;

- Power adjustment;

- Weight;

- Ergonomics and reverse switch;

- Equipment;

- Warranty, service center and availability of spare parts;

- Country of Origin;

- Price.

Having listed all the parameters that you need to pay attention to, we will try to talk about each in more detail in order to decide which pneumatic impact wrench to choose in a particular case to solve the problem.

Presence of impact mechanism

As a rule, all pistol and straight impact wrenches have an impact mechanism. Due to the shock-rotating action of the working shaft, even the most rusty and “stuck” threaded connections are unscrewed.

In most cases, air ratchets are considered non-impact impact wrenches, although some models may have an impact mechanism. They have an angular design, where the spindle is located at a right angle (perpendicular) to the body. Pneumatic ratchets develop low torque values and are used to work with small fasteners. They are relevant for use in hard-to-reach places, for example, in the engine compartment of a car.

Maximum torque

Having enough torque to remove fasteners is the most important factor when selecting an air impact wrench. Removing bolts and fasteners of various sizes requires a certain amount of torque, which varies from case to case. Knowing the recommended parameters in your field of activity, you can easily select the necessary model.

Below in the table you will find the most suitable parameters for choosing a pneumatic impact wrench for unscrewing different bolts and nuts.

For frequent or professional use, we recommend choosing a more powerful model (yellow in the table).

If the air impact wrench cannot loosen the bolt or nut within 5 seconds, then you need to use a more powerful tool or apply penetrating lubricant to the threaded connection and try to unscrew the fastener again.

Connection square size

This parameter is closely related to the torque characteristic. The higher the torque, the larger the size of the connecting square the pneumatic impact wrench will have. The size of the tool's connecting square must correspond to the size of the square of the impact sockets, extensions and other fitting tools that you use. In some cases, it is possible to use adapters.

The most common are 1/2" square drive impact wrenches, which are suitable for most applications.

Best Air Impact Wrench

The Ingersoll RAND 631L model is the best in functionality. It is intended for use in workshops, production shops and automotive services. This impact wrench easily handles highly loaded joints due to its impressive torque and powerful impact mechanism. An additional handle provides comfortable holding of the tool.

The Ingersoll RAND 631L is equipped with a 4-stage power regulator and can handle fasteners up to M42 in size. For ease of operation, it has a pistol-type main handle of a closed design.

Characteristics

- cartridge – 1 inch;

- pressure – 6.2 atm.;

- torque - 4.3 kNm;

- air flow – 426 liters per minute;

- rotation speed – 3.5 thousand revolutions per minute;

- weight – 16.6 kg.

pros

- large working resource;

- durable body;

- possibility of long-term work;

- high torque;

- good air flow.

Minuses

- The package includes only an additional handle;

- high price.

Compressor for pneumatic impact wrench

The most important piece of equipment needed to operate a pneumatic tool is an air compressor. This device, using a motor, pumps air into itself and directs it through a special hose into the tool. Let's look at how to choose a compressor for a wrench to suit all your needs.

- Pressure

. The force of compressed air output, and therefore the performance of the tool, depends on this characteristic. For most medium-sized impact wrenches, a low-pressure compressor delivering at least 6.3 atmospheres is sufficient. - Maximum performance

. An important indicator on which the speed of operation of the tool depends. If a pneumatic impact wrench indicates a flow rate of 360 liters per minute, but the compressor pumps only 330 during the same time, you can forget about uninterrupted operation in such a combination. The compressor's performance must be higher than the impact driver's needs. - Receiver volume

. A rather controversial indicator that determines the battery life of a tool in the absence of constant air pumping. Compressors with a small volume of air (50 liters) quickly lose pressure and for continuous operation of the tool, they must constantly pump air. With more impressive volumes (100-200 liters), the equipment can rest a little, despite the continued operation of the pneumatics. For convenient work in the home workshop, the compressor for the impact wrench will have 100 liters. - Connection type

. To deliver compressed air to the gearbox of a pneumatic impact wrench, a special sealed hose is required that can withstand the applied pressure. Before purchasing such a hose, you should find out what size fitting it fits (1/4, 1/2 or 3/4). The manufacturer indicates this data on the instrument itself, in the documentation or on the box.

article from the Rating section

- 40

Pneumatic tools Locksmith tools

Save this page on your social media. network and return to it at any time.

ADD A COMMENT

Best cargo pneumatic impact wrench

The powerful pneumatic impact wrench Rossvik RT-5880 is designed for tire mounting work on trucks of any tonnage. It has an extended spindle, which allows it to be used with a deep rim. The tool is equipped with an impact mechanism, reverse and a system for pre-setting the tightening torque. An impressive torque of 3.8 kNm requires an air flow of 1.3 thousand l/min.

In addition to truck tire fitting, the tool can be used in production and construction sites.

Characteristics

- cartridge – 1 inch;

- pressure – 6.3 atm.;

- torque – 3800 Nm;

- air consumption – 1.3 thousand liters per minute;

- rotation speed – 3.5 thousand revolutions per minute;

- weight – 17.3 kg.

pros

- high torque;

- ability to work with nuts with a diameter of up to 45 mm;

- high quality impact mechanism.

Minuses

- weight;

- huge air consumption.

The best professional pneumatic impact wrench

The Metabo DSSW 2440-1 model is a professional-class pneumatic impact wrench. Used to work with the heaviest fasteners. Loosening and tightening of truck nuts with deep rims is possible thanks to the extended spindle. Comfortable work is ensured by two arc-shaped handles. The weight of the device does not allow it to be used with one hand, but this is not surprising, because the torque reaches 2440 Nm. It is really difficult to maintain such power. The double impact system allows you to unscrew soured nuts up to M38 in size.

Metabo DSSW 2440-1” is one of the most powerful impact wrenches. In addition to oil, the kit includes a hose clamp and a 10mm ferrule, as well as 2 ½” push-in nipples.

Characteristics

- cartridge – 1 inch;

- pressure – 6.2 bar;

- torque – 2440 Nm;

- air flow – 780 liters per minute;

- rotation speed – 6 thousand revolutions per minute;

- weight – 7.3 kg.

pros

- ability to work with fasteners up to M38;

- Double punch;

- high rpm;

- long drive spindle;

- oil included.

Minuses

- dimensions and weight;

- high air consumption;

- price;

- it is possible to hold the instrument only with both hands;

- It is possible for the heads to fall off when holding the tool in the lower position.

Rating of the 4 best pneumatic impact wrenches

Best Straight Air Impact Wrench for Trucks

Metabo DSSW 2440-1

Metabo DSSW 2440-1 is a reliable, powerful air impact wrench designed to service the heaviest trucks. The tool sells for RUB 57,999. Users note the following advantages of the equipment:

- the presence of a large arc handle for comfortable ergonomic work;

- the presence of an extended drive spindle for more convenient and faster work with deep rims;

- double impact mechanism;

- ergonomic straight body.

The pneumatic impact wrench is comfortable to hold in your hand and despite its rather heavy weight of 7.3 kg, it can be used quite quickly.

Price: RUB 57,999

Metabo DSSW 2440-1

The best pneumatic impact wrench for tire service

Licota PAW-06025-8

Licota PAW-06025-8 is a lightweight industrial pistol-type impact screwdriver priced at RUB 35,990 that will help solve all problems with tightening and unscrewing (due to the presence of reverse) nuts. The industrial model with downward air outlet is designed for high loads. Its small size and weight of only 4 kg allow you to hold the instrument for a long time in your hands without overexertion.

Price: RUB 35,990

pneumatic impact wrench Licota

The best non-impact air impact wrench

TOPTUL KAAJ2480

The TOPTUL KAAJ2480 is a very inexpensive tool with a pistol design. Impactless impact wrench for RUB 23,640. A lightweight, compact tool with an impact mechanism that can work in hard-to-reach places. To ensure that the tool lasts longer, the body is made of high-quality composite materials. A comfortable ergonomic handle provides a tight grip.

The impact wrench can be used both professionally and in home workshops. Light weight - only 2.3 kg - allows you to work with the tool for a long time in the most inconvenient places.

Price: RUB 23,640

impact wrench TOPTUL

Best Air Impact Wrench

Fubag IW720(100193)

Fubag IW720 (100193) is a pneumatic impact wrench with an impact mechanism for household work with hard joints. Using an air fitting, the tool is connected to the compressor. Great torque. Thanks to the adjustable tightening torque, you can work with equipment of different sizes. The tool is controlled using a wide, convenient start key. The kit includes equipment, a durable thick case and a set of heads. The cost of the tool is only 3,500 ₽. What are the advantages of the tool:

- high tightening torque;

- the blow will help when unscrewing rusted nuts;

- Thanks to the use of high-quality materials in manufacturing, the tool is durable and resistant to wear;

- can be used in conditions of high humidity;

- the tightening torque is adjustable;

- there is a reverse;

- low fire and explosion hazard during the working process due to the fact that the tool operates on compressed air;

- good equipment;

- inexpensive price accessible to everyone.

Price: RUB 3,449

Fubag IW720(100193)

Best Angle Pneumatic Impact Wrench

The pneumatic model SUMAKE ST-5553 is designed for unscrewing and tightening fasteners up to 10M in size at a professional level. The straight shape of the angle tool handle allows you to work in confined spaces. This impact wrench is designed for long-term operation under conditions of conveyor assembly of units. The main difference from the impact options is the high precision of working with fasteners with multiple repetitions of operations.

Quick loosening of fasteners is possible due to the reverse function; the pneumatic motor has increased resistance to excessive loads. The air flow is 400 liters per minute, which is a very impressive figure for a device of such compact size and light weight. But this parameter is offset by efficiency.

Characteristics

- cartridge - ½ inch;

- pressure – 6.5 atm.;

- torque – 61 Nm;

- air flow – 400 liters per minute;

- rotation speed – 150 rpm;

- weight – 1.2 kg.

pros

- convenient start button;

- ergonomic handle;

- presence of reverse;

- resistance to prolonged high loads;

- light weight.

Minuses

- high air consumption;

- the air is diverted towards the square, raising dust during operation.

Best Air Impact Wrench with Adjustment

The FUBAG IW-720 impact pneumatic impact wrench has high performance and high torque. Its compact design has a reverse function, which allows you not only to unscrew large soured nuts, but also to tighten them. The main purpose of this model is to work with wheel nuts of trucks and passenger vehicles.

The impact wrench has a 4-speed speed switch and operates in both directions of spindle rotation. For operation, an air hose with a diameter of 6x8 mm is required. The tool has high fire safety due to the ability to operate on compressed air. Compact dimensions due to the lack of an engine. This is an excellent choice for auto repair shops and various service centers equipped with an air line.

Characteristics

- cartridge - ½ inch;

- pressure – 6.3 atm.;

- torque – 720 Nm;

- air consumption – 226 liters per minute;

- rotation speed – 8 thousand revolutions per minute;

- weight – 2.8 kg.

pros

- high power for this category;

- price;

- compactness;

- Convenient torque adjustment.

Minuses

- hard reverse switch;

- equipment.

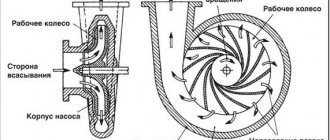

Operating principle of a pneumatic impact wrench

The pneumatic impact wrench is connected through a fitting to an air compressor, the pressure of which should not exceed the value specified in the operating instructions for the device. When the trigger is pressed, compressed air entering the rotor blades causes it to rotate. Through the frame and hammers, the rotation of the rotor is transmitted to the stop and the nut or bolt is unscrewed or screwed into its seat. If a lot of force is required to turn the nut, the stop does not rotate, and the hammers, while turning, are deflected back and engage with the stop. During the next revolution, the hammers gain inertia and, approaching the engagement, hit the stop in the direction of rotation. The blows are repeated until the nut begins to turn. Thus, the impact wrench allows you to quickly and easily unscrew and tighten tight bolts and nuts. Due to its light weight (no more than 2.6 kg), the tool can be held with one hand.

Pneumatic impact wrench device

By switching the air supply channels to the rotor blades, you can change the direction of its rotation, which allows you to use the impact wrench both for tightening and unscrewing bolts and nuts. Reversing the direction of rotation is achieved by simply turning the switch knob to the desired position.

Best Reversible Pneumatic Impact Wrench

The powerful ROTAKE RT-5563 pneumatic impact wrench is a professional-class tool, used for metalworking work with light and heavy equipment, including special-purpose vehicles. The body is made of steel and aluminum alloy. For more convenient use of the tool, a short shaft and an additional handle are installed. Used in conjunction with a pneumatic line having an air preparation unit.

The ROTAKE RT-5563 pistol impact wrench consumes up to 340 liters of air per minute, but such a high consumption is fully compensated by the functionality of the tool. The built-in impact mechanism and relatively large weight allow you to cope even with large stuck nuts.

Characteristics

- shank – 1 inch;

- pressure – 6.3 bar;

- torque - 1898 Nm;

- air flow – 340 liters per minute;

- rotation speed – 4500 rpm;

- weight – 7 kg.

pros

- presence of reverse;

- additional handle.

Minuses

- air flow;

- weight.

Best Air Impact Wrench with Socket Set

The corner model Metabo DRS 68 Set 1/2″ is perfect for working with fasteners in hard-to-reach places. The head height is 55 mm, and the kit includes a cardan shaft for working at angles up to 45° and a 10 cm extension. There is a reverse switch on top of the cartridge, which allows you to activate it at the right time. To adjust the twisting force, there is a regulator at the end of the handle. The start key has a bracket-like shape and starts the impact wrench when pressed.

The body of the impact wrench has a rubber coating, which, together with the ergonomic handle, makes it comfortable to use. On the side of the frame there is a rotating pipeline that exhausts air.

Characteristics

- cartridge - ½ inch;

- pressure – 6.2 atm.;

- torque – 68 Nm;

- air flow – 220 liters per minute;

- rotation speed – 175 rpm;

- weight – 1.2 kg.

pros

- set of 10-27 mm heads (7 pieces);

- transport case;

- convenient start key;

- work resource;

- small dimensions and weight;

- speed controller.