The welding process involves high temperatures, open flames, and flammable gases. To avoid injury and loss of property from fires, it is necessary to adhere to fire safety rules when welding.

Fire safety during welding work is regulated by law. SNiPs and rules have been developed that not only professionals, but also novice welders must follow. Fire safety measures when carrying out welding work will help preserve your health and protect you from financial losses.

Rules for carrying out welding work indoors

Any gas-flame work cannot be carried out:

- Without the presence of a specialist, students of gas welders, employees of enterprises who have not undergone special training and have not received qualification certificates.

- Without a preliminary check of the operating condition of the devices, as well as if malfunctions or violations of operating rules were detected. The latter includes damage to equipment elements. In addition, work should not be carried out using devices with expired certification or with leaky connections.

- On structures, equipment elements, products that were recently painted with flammable primers or paints and varnishes.

- In protective clothing, protective gloves, contaminated with vegetable fats, oils, petroleum products and flammable liquids.

- In direct contact of cylinders with flammable gases, O2 with various types of electrical cables.

- On equipment bodies, containers, piping, communications, if they contain flammable, toxic materials or electric current passes through them. A similar rule applies to elements of construction projects made of lightweight metal structures insulated with combustible, difficult-to-burn materials.

It is possible to achieve safe welding work indoors through the precise implementation of organizational and technical measures specified in regulations:

- Before starting welding, it is necessary to prepare the surrounding area by clearing it of materials susceptible to combustion, including waste remaining after production and combustible debris. The required radius can be found in Appendix 3 to the “PPR in the Russian Federation”.

- The radius of the cleaned area directly depends on the height of the welding point from the floor/ground level. Thus, a radius of at least 5 m is cleared when working at floor level and 14 m when welding 10 m or more from the floor/ground surface. This approach is associated with the ability of drops of metal, hot scale, and cinders to fly away in different directions.

- Before welding various types of containers, sections of networks for pumping liquid flammable, combustible materials, all flammable and flammable liquids are drained from them.

- After emptying, the containers are washed, treated with hot steam, and ventilated. Next, the content of hazardous substances in the air is measured - this helps avoid explosions and fires during welding.

- For welding work in rooms with a high explosion and fire hazard category, they are ventilated in advance, uninterrupted operation of ventilation systems is ensured, and the presence of flammable gases and vapors is constantly monitored.

- All combustible structures that cannot be removed from the premises during the work and are located within the radius of the cleaning zone, for example, flooring, must be closed, curtained, covered with sheets and rolls of non-combustible materials. In this case, metal screens, fire-resistant fabrics/felts can be used, or water can be sprayed.

- It is allowed to fence the place where welding work is carried out indoors with a temporary solid non-flammable partition/screen with a height of at least 1.8 m, and the maximum gap to the floor is 50 mm. The latter is covered with a metal mesh with a maximum cell size of 1 mm

2.

- Before welding, close all doors, hatches in walls, partitions, and ceilings to prevent sparks, scale, and drops of molten metal from falling into the rooms in the immediate vicinity. Any construction, technological or installation openings must be protected with fireproof screens and shields.

- A mandatory preparatory stage is the registration and endorsement by the administration of the facility of a work permit for hot work in the form of Appendix 4 to the “PPR in the Russian Federation.”

- Fire extinguishers are installed in the immediate vicinity of the planned welding work site. The types, weight/volume of their charge are recorded in Appendix 1 to the “PPR in the Russian Federation”.

This is interesting: Escape stairs: types (types), requirements, tests

Fire safety rules when carrying out welding work

Those who weld at home need to have an understanding of fire safety. Technical regulations have been developed that set out fire safety rules when carrying out welding work.

Those who weld at home need to have an understanding of fire safety

A few important points to remember:

- Oxygen cylinders and reducers should not be allowed to come into contact with the power cable, the minimum distance is 50 cm;

- When arc welding, the workplace is cleared at a distance of at least 1 meter from the metal heating zone;

- when organizing the workplace, the height of the partition enclosing the welding zone is correctly maintained - at least 1.8 meters;

- You cannot replace gas hoses: acetylene with oxygen and vice versa;

- When performing a test run of electrical equipment, it is important to check the wiring;

- After performing welding work, you need to make sure that there is no smoke or a burning smell.

Safety requirements for premises, materials and equipment

Normally, welding should be carried out in places designated for this purpose with special equipment and ventilation. When such work has to be carried out in closed containers or rooms, it is important for the specialist to protect the respiratory system with the help of additional means. Safety precautions when welding using gas equipment indoors require that the cylinders be kept separately, and each workplace be isolated with screens.

Recommended reading

- Cutting copper with a laser: advantages and disadvantages of technology

- Types of metal cutting: industrial applications

- Metalworking according to drawings: convenient and profitable

Another important parameter is illumination, so it is necessary to ensure sufficient access to light.

Don’t forget to carry out equipment maintenance on time; the preventive maintenance schedule included in the instructions will help you with this.

All safety standards can only be observed in specialized workshops, where welding is recommended. To do this, the elements of the structure to be welded are laid on flat, clean surfaces that are not capable of conducting current, or they are connected to each other using clamps or magnetic squares. Remember that it is important to first clean any equipment used during the work process from dirt and adhering particles. In addition, only tools made of materials that are not subject to ignition are suitable for welding.

Requirements for premises for gas welding work

Welding work involving the use of flammable and explosive gases is carried out in a room specially designed for these purposes. They must fully comply with the workflow.

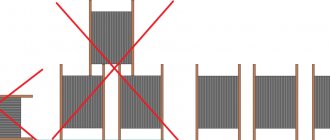

The workplace should not be less than 4 square meters. m. This value does not apply to the placement of welding equipment. There must be a passage at least a meter wide between welding stations.

The height of the work room should not be less than 3 meters, and there should be no protrusions above the workplace. The room must be well lit and heated: the lighting level cannot be less than 80 lux. Also, the room must have good ventilation and a volume of at least 300 cubic meters. m.

In the process of performing gas-flame work in compartments, pits and tanks in which accumulations of harmful poisonous gases are allowed, supply and exhaust measures must be in place.

Before you start welding indoors, you need to ventilate the room to remove any accumulation of gases.

The welder's workplace must always be kept clean, and the functionality of the tools must be checked regularly.

At the welding station, the presence of wood that has not been previously treated with a special compound, rags, plastic and other flammable items is unacceptable. There cannot be any containers with fuel near the welder’s workplace.

Fire extinguishing means must be present at the place where gas welding work is carried out. Other fire safety rules must also be observed. Acetylene can only be extinguished with dry sand; extinguishing with water is unacceptable.

It is not allowed to install gas welding equipment in rooms with high temperatures (for example, in forges, boiler rooms).

If welding work is carried out in a room in which other people work, then protection is installed around the perimeter.

Causes of fires

Negligence is the main cause of industrial fires

There are two hazards to consider: equipment and human factors. A person who picks up a welding machine must understand that it is necessary to follow certain fire safety rules. Reasons for human character:

- cluttering of the 5-meter working area with flammable materials and liquids;

- carrying out work in an unprepared space;

- inept handling of the tool;

- the use of blowtorches to heat metal;

- negligent inspection of equipment before work.

Possible technical reasons:

- unstable voltage;

- faulty equipment;

- wide zone of hot metal splashing;

- unreliable electrical wiring;

- lack of fuses in the power supply system;

- corrosion damage to the welding holder;

- violation of the rules for transporting gas cylinders, heating them in the sun;

- water seal malfunction;

- oiling of the oxygen cylinder fitting;

- increased working gas pressure.

Safety precautions for gas welding: general information

Safety precautions when performing gas welding apply to:

- On the behavior of the specialist responsible for welding work.

- To organize a work space for performing work.

- On the equipment used.

- At the end of gas welding work.

The main sources of danger during gas cutting and welding can be:

- Explosions of oxygen cylinders when they are opened if there is oil on the cylinder fitting or reducer.

- Careless handling of the torch of a gas welding machine can cause a fire in the welder’s clothes or hair , or a fire in the room.

- Eye burn if the welder did not use light filters.

- Explosion of an acetylene generator from a backfire if the water seal does not work.

- Poisoning by harmful gases due to insufficient ventilation (when working indoors).

Before starting welding work, all workers must undergo safety training and sign for completion in a special journal.

Measures aimed at preventing potentially dangerous situations

- Organizational. Training personnel in fire safety rules, familiarization with the necessary instructions on labor protection and fire safety techniques, conducting training evacuations in case of fire, successfully passing state fire supervision inspections, audits, fire prevention measures.

- Regime. Smoking ban in unauthorized places.

- Technical. Compliance with the rules for installing welding equipment, ventilation, grounding, etc.

- Operational. Compliance with the rules for using welding and other equipment.

During construction and installation work, there are the following types of equipment for fire protection.

- Fire trucks

- Fire extinguishing installations

- Fire alarm

- Fire extinguishers

- Fire equipment

- Manual equipment

- Rescue devices

Types of fire extinguishers

- Gas

- Foam

- Powder

Gas fire extinguishers are divided into carbon dioxide and carbon dioxide-bromoethyl. Carbon dioxide is used as a fire extinguishing agent. Foam fire extinguishers are used to extinguish fires that have just begun, solid objects, and flammable substances. Their use is unacceptable for extinguishing electrical networks, as well as when extinguishing alkali metals (the interaction of these metals with water from foam will only intensify the fire). Powder fire extinguishers are available with powder for general purposes to extinguish fires of categories A, B, C, E, as well as for categories B, C, E.

The fire safety instructions must contain the following information

- List of names of operations related to hot work.

- List of persons permitted to perform hot work.

- The procedure for obtaining access to hot work, responsibility for violating this procedure.

- Stages of hot work.

- List of prohibitions when carrying out gas welding work.

- List of actions that are not permitted in places during welding work.

- Actions of the work performer in case of fire.

Let's look at the basic fire safety rules using the example of construction work.

- Before starting welding of vessels that previously contained explosive, flammable substances, gases, they must be thoroughly cleaned, washed, and dried.

- Do not weld newly painted parts until they are completely dry.

- When welding, do not use gloves smeared with oil, gasoline or other flammable substances.

- Do not allow electrical wiring to come into contact with gas cylinders.

- The person responsible for safety must check that all rules are followed before, during and after welding work.

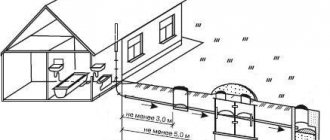

- Acetylene generators are installed at a distance of 10 meters from the place where welding is directly carried out.

- When using an acetylene generator, be sure to post signs with the warnings “NO SMOKING” and “NO TRESPASS ENTRY.”

- Calcium carbide must be modified after welding with an acetylene generator. Lime from the generator must be placed in a special container or in a special pit. There are open sludge pits and closed ones. In open ones, special railings must be installed, in closed ones there must be fireproof partitions, ventilation and hatches for removing silt.

- Gas-conducting hoses must be secured with special clamps or wire.

- Gas cylinders must be stored and transported only with special safety caps, and sudden shocks must not be allowed.

- To open the calcium carbide drum, special tools are used: a chisel with a hammer or a knife. Already open drums must be closed with a lid with a special requirement for the height of the side of the lid, it must be at least 50 mm.

- The container with calcium carbide should be stored vertically in well-ventilated areas. These should not be basements or low rooms.

Calcium carbide

- Electric welding work is carried out in rooms with good ventilation.

- Floors and walls in rooms where electric welding is carried out must be made of non-flammable materials.

- Welding equipment at the welding site must be provided with fuses.

- Conducting wires must be insulated and flexible. Do not use bare, uninsulated wires. The wire must be capable of carrying the required current.

- Electrical wiring of welding devices should be located at a distance of at least half a meter from oxygen pipelines, and at least one meter from gas wiring. This distance can be halved if the gas wire is located in a special protective metal pipe.

- The electric holder for manual welding should be lightweight. Its design must ensure prompt replacement of electrodes and prevent short circuits. The handle of the electric holder must be made of non-flammable material.

- Electrodes for welding must comply with the GOST standard and be factory-made.

- Remains of electrodes after welding must be thrown into a special metal bag.

- The welding machine must be grounded, the generator and transformer, if work is performed outdoors, must be located in places protected from moisture, as well as under canopies made of non-flammable materials.

- The welding device must be cleaned and repaired regularly.

- Do not allow the torch to be left while the arc is burning.

- When soldering, the work site must be cleared of flammable substances.

- Blowtorches should be checked monthly for serviceability and pressure tested once a year.

- You cannot use gasoline for a kerosene lamp, you cannot mix gasoline with kerosene; pour more kerosene into the lamp than three-quarters of the volume.

What are the hazards of hot work?

- open fire (arc welding, gas torch)

- pieces of metal flying off. When sparks enter cracks or open holes, a “hidden” fire can occur. It lasts from several hours to a day. high temperature of things prepared for welding.

What happens if you violate safety rules? Fire (defective wiring dangerous to humans, flammable gases and mixtures that are close to the epicenter of the fire) or explosion (be especially careful when operating gas cylinders).

Common causes of fires:

- Faulty equipment (damage to wires, cables, etc.) that did not pass the scheduled inspection.

- The work uses equipment whose expiration date has long expired.

- Corrosion of electrical devices.

- Human errors (violation of the Rules, smoking break at the work site, improper storage of cylinders)

It is important to remember that only those employees who have been instructed and confirmed their knowledge of eliminating a possible fire are allowed to perform hot work.

There are two types of jobs for welders: permanent (including short breaks) and temporary (repair work).

The legislation regulates the field of fire safety, including hot work. Where can I get acquainted with the prescribed acts?

- Federal Law “On Fire Safety” dated December 21, 1994 N 69-FZ

- Federal Law “On Voluntary Fire Protection” dated 05/06/2011 N 100-FZ

- Federal Law “Technical Regulations on Fire Safety Requirements” dated July 22, 2008 N 123-FZ

Remember that different areas of production have their own fire safety rules. It is better to look for these standards additionally.

Requirements for storing materials and equipment for welding indoors

In addition to safety precautions, it is important to strictly follow the standards for the maintenance and use of welding materials and equipment.

The following are the basic requirements for equipment and components:

- Only a separate dry room, treated from pests and rodents, is suitable for storing welding products. The fact is that damp or leaky hoses can cause explosions and fires when working with gases or fire. The ideal conditions for maintaining such devices are considered to be a temperature of +15 °C and a humidity of 40%. Compliance with the requirements for the premises is considered mandatory, since they are included in the labor protection conditions during welding.

- Electrodes should be kept in a dry, cool place. High humidity causes them to become damp, which means they cannot provide an arc for work. If the maintenance rules have been violated and the electrodes have absorbed excess moisture, they can be carefully dried in the oven.

- Generators are installed as reliably as possible - they should not fall, wobble, or touch other equipment located nearby. The use of generators without a water seal is strictly prohibited. The device must be positioned vertically and not have any malfunctions. According to safety regulations, working at temperatures below 0 °C requires monitoring the water condition. If it turns into ice, do not start welding until the hose and water jam are warmed up.

- Only hoses with a length of 20 m or more can be used. During installation, work with 40-meter hoses is allowed.

Under no circumstances is it allowed to connect various devices to simultaneously connect a number of burners at once. To be used during welding work, the hose must be in good condition and not damaged. During the gas welding process, the locations of the hoses intended for supplying oxygen and acetylene cannot be changed. To secure them tightly, clamps or wire are used. The hoses are maintained in accordance with the storage standards for welding materials; they must be folded into rings, avoiding fractures and crushing. - Cylinders require the most careful handling. When removing the metal cap, make sure that there is no mechanical damage to the valve and fitting. Safety precautions prohibit knocking out the cap using impact tools, as such actions can lead to the formation of a spark.

When unscrewing the valve, do not allow the gas flow to reach nearby workers. The cylinders are installed vertically, placed on a flat surface, or stands secured with clamps can be used. The cylinder cannot be located less than 5 m from the flame source. A distance of at least 1 m must be maintained between it and the heating device.

By strictly following the standards for the use of welding materials, you ensure your own safety during welding work indoors.

This is interesting: Fire safety at school

What must a fire safety instruction include?

Any fire safety instructions for welding must contain:

- List of operations that are included in hot work

- The number and names of employees who have been trained and allowed to work on site.

- Instructions for obtaining access and a list of those responsible for violations.

- Stages of permissible actions on the site and a list of prohibitions.

- Procedure in case of fire.

Examples always speak much better than words. Let's look at the scope of construction work:

- Weld vessels that previously contained explosive or flammable substances only after cleaning and rinsing.

- Dry painted parts before starting welding.

- Never use gloves contaminated with oil or gasoline.

- Keep gas cylinders away from electrical wiring.

- Follow the Rules before, during and after completion of work.

- It is better to install acetylene generators at a distance of 10 meters from the work site.

- Hang up signs with reminders “NO SMOKING” and “NO TRESPASSING.”

- After welding, place calcium carbide in a container prepared for it.

- Secure gas hoses with wire or clamps.

- When transporting gas cylinders, avoid sudden jolts.

- To open the calcium carbide drum, use a chisel with a hammer or a knife. The edge of the lid must be at least 50 mm.

- Store the container with calcium carbide in an upright position in well-ventilated areas (starting from the 1st floor).

- Work in an area with good ventilation.

- Install fuses on the welding equipment.

- Do not use bare or uninsulated wires.

- Check the electrode holder for manual welding. Main parameters: weight - light, handle consists of non-flammable material, complies with GOST, manufactured at the factory.

- Throw away any remaining electrodes in a metal bag.

- Ground the welding machine, and place the generator and transformer in places protected from moisture.

- Clean welding devices regularly.

Why should you contact us?

We treat all clients with respect and carry out tasks of any size equally scrupulously.

Our production facilities allow us to process various materials:

- non-ferrous metals;

- cast iron;

- stainless steel.

When completing an order, our specialists use all known methods of metal machining. Modern equipment of the latest generation makes it possible to achieve maximum compliance with the original drawings.

In order to bring the workpiece closer to the sketch submitted by the customer, our specialists use universal equipment designed for jewelry sharpening of tools for particularly complex operations. In our production workshops, metal becomes a plastic material from which any workpiece can be made.

The advantage of contacting our specialists is their compliance with GOST and all technological standards. Strict quality control is carried out at every stage of work, so we guarantee our customers a conscientiously completed product.

Thanks to the experience of our craftsmen, the output is an exemplary product that meets the most demanding requirements. At the same time, we start from a strong material base and focus on innovative technological developments.

We work with customers from all regions of Russia. If you want to place an order for metalworking, our managers are ready to listen to all the conditions. If necessary, the client is provided with free specialized consultation.

Articles on topics: Metal products, Metalworking, Welding, Laser cutting, Metal structures, Plasma cutting, Metal bending, Cabinets, Properties of metals, Mechanical processing, Painting

Types of fire extinguishers

Fire safety requirements imply fire extinguishing means. Fire extinguishers are powder or carbon dioxide. If electrical wiring catches fire, do not use water or liquid foam to avoid short circuits and electric shock.

Powder fire extinguishers are universal, suitable for all classes of fires; for welding they are chosen with the “D” marking. The powder component contains potassium, sodium, and phosphorus salts. White soot, talc, nepheline, and silicon compounds are used as disintegrants. Various modifications of fire extinguishers are available:

gas generators;

Carbon dioxide is distinguished by its ability to lower the temperature when gas is released. They are reliable for gas welding and quickly neutralize oxygen. Carbon dioxide is in cylinders in a liquid state, under pressure.

Fire extinguishers are powder or carbon dioxide.

Oil, Gas and Energy

10.3.1. During gas welding work, it is necessary to take measures to prevent the possibility of oil, petroleum and petroleum products getting on oxygen cylinders, hoses, burners, as well as the acetylene generator.

10.3.2. Work using open flames (welding, forging, etc.) and storing flammable and lubricating materials at a distance of at least 10 m from oxygen cylinders is prohibited.

10.3.3. In the premises of acetylene plants, where stationary generators with a capacity of up to 5 m2/h are installed, in the absence of a special intermediate warehouse, it is allowed to store calcium carbide in drums in an amount of no more than 200 kg. In this case, only one drum is allowed to be open.

10.3.4. For temporary welding work, the installation of mobile acetylene generators is permitted outside fire and explosion hazard areas and premises. Generators can be installed temporarily in industrial premises only if the premises are well ventilated. A portable acetylene generator must be installed at a distance of at least 10 m from the place where welding work is carried out, from sources of open fire and highly heated objects.

10.3.5. It is allowed to have no more than two oxygen cylinders at the gas welding work site. Cylinders filled with oxygen and emptied after the cessation of temporary hot work must be removed.

10.3.6. After charging the acetylene generator with calcium carbide, the air from the gas holder and hoses must be displaced by gas before igniting the burner.

10.3.7. Welding work is prohibited when the hydraulic seal of the acetylene generator is faulty or not filled with water.

10.3.8. Before starting gas welding work, the serviceability of the hoses and their attachment to the burners must be checked.

The use of gas-permeable hoses, as well as the replacement of acetylene hoses with oxygen ones and vice versa, are not allowed. During gas welding work, gas hoses must be protected from high temperatures and mechanical damage.

10.3.9. When welding, do not allow the torch to overheat. In case of overheating, you should periodically stop working and cool the burner by immersing it in water.

10.3.10. Spent calcium carbide from the acetylene generator must be removed into sludge pits, which must be located in specially designated areas: the location of the sludge pits must be agreed upon with the fire department.

Sludge pits should be fenced within a radius of 10 m.

When gas welding it is prohibited:

— Perform welding work with faulty equipment and hoses; warm frozen generators, their parts, gearboxes, valves, pipelines and other parts of welding installations with open fire or hot objects (warming can only be done with hot water or steam);

— Repair the valves of gas cylinders before releasing the gas contained in them and purging them; the gas should only be released outdoors, away from open fire;

— Smoking and using open fire at a distance of no closer than 10 m from an acetylene generator, oxygen cylinders, hoses, gas pipelines and sludge pits;

— Leave cylinders with compressed and liquefied gases in the sun without shelter;

— Leave acetylene generators after completion of welding work uncleaned from calcium carbide and sludge residues, and rotors, boxes and other parts of the generator unwashed;

— Blow the hoses with oxygen towards the generator;

— Increase the pressure in the acetylene generator by placing objects on the bell;

— install acetylene generators in operating boiler rooms and hot shops, as well as near air intake by compressors, blowers and fans.

Benzene, kerosene and oxygen cutting

10.4.1. When gas cutting with liquid fuel, before filling the tank, you should make sure that it is in good working order.

The tank must be filled with fuel to no more than ¾ capacity.

10.4.2. The fuel tank should be located no closer than 5 m from oxygen cylinders and sources of open fire and no closer than 3 m from the cutter’s workplace. In this case, the tank must be located so that it is not exposed to flames or sparks during operation.

10.4.3. The fuel tank must be in good working order and sealed. The tank must have pressure gauges, as well as a safety valve that does not allow the pressure in the tank to increase above 0.5 MPa. Tanks that have not been tested with water to a pressure of 1 MPa, that have a leak of flammable liquid or a faulty pump are not allowed for operation.

10.4.4. It is prohibited to warm up or vaporize the cutter by igniting a flammable liquid poured into the workplace. For this purpose, blowtorches or alcohol lamps or alcohol lamps should be used.

10.4.5. When cutting metal using a gasoline, kerosene or oxygen cutter, the following is prohibited:

— carry out cutting when the air pressure in the fuel tank exceeds the operating pressure of oxygen in the cutter;

— use oxygen hoses to supply fuel to the cutter;

- use fuel that is contaminated or mixed with water;

- direct the flame and place the burner on combustible objects;

— store a supply of fuel at the gas cutting site;

— approach the tank for pumping air with a lit cutting torch.

10.4.6. Fuel in quantities not exceeding the replacement requirement should be stored in hermetically sealed, serviceable and unbreakable special containers at a distance of at least 10 m from the hot work site.

Optimal placement of shelving in a warehouse: some useful tips

Organizing the optimal placement of shelving in a warehouse is not an easy task, and in most cases only professionals can handle it. Too much has to be taken into account here: the parameters of the premises, the characteristics of the stored products, and numerous safety requirements. On the other hand, the correct arrangement of shelving allows you to easily find the right product, quickly perform loading and unloading operations, and optimize the work of employees. And the less staff labor costs, the more profitable it is for the business. This law has not yet been repealed.

Popular materials for making gates: advantages and disadvantages

The materials used to make gates directly affect the durability of the entire structure. Today, every owner of a summer house, private house or personal garage is not only puzzled by the issue of property safety, but also dreams of installing the most durable gates so that they last a long time. Depending on the chosen material, there are special subtleties in the manufacture of gates and their installation. In addition, the raw materials for their production endow the design with its own advantages and disadvantages. What should you choose? Our article will help you decide.

Manufacturing of metal tables: review of designs and technology

Manufacturing metal tables allows you to get reliable and durable furniture that will last for many years. It is a mistake to believe that such items are devoid of grace and elegance, and that they are suitable, at best, as garden furniture. On the contrary, metal products can decorate both the expensive interior of a mansion and perform utilitarian functions in a workshop. The process of making a metal table itself is also not so simple: it is necessary to calculate the dimensions of the structure, decide on its design and load-bearing elements. In our article we will describe this process in detail, and also provide rules for choosing ready-made metal tables and talk in detail about their modifications.

Auxiliary welding equipment: types and description

Auxiliary welding equipment is designed to provide convenience and speed in performing non-standard work or to facilitate manipulation in difficult production or weather conditions. The composition of such devices, mechanisms and tools depends entirely on the tasks assigned. For example, for an automatic welding line these will be stationary installations, for manual welding - much smaller devices. Regardless of what type of equipment we are talking about, each of them must ensure that the finished product meets quality requirements, and the work process itself - according to security. In our article we will talk about these standards, and also list the types of auxiliary welding equipment.

Causes of fires and basic fire safety rules

When building ships, various flammable materials are used in large quantities, which can cause a fire.

The main cause of fires in assembly and welding shops and on ships is violation of fire safety rules during welding and gas-cutting operations. As is known, during electric welding and gas cutting, sparks and drops of molten metal are formed. If they come into contact with flammable materials or in areas containing flammable or explosive gases or vapors, they may cause a fire or explosion. The causes of fire during electric welding and gas cutting operations are:

— ignition of flammable materials located on the opposite side of structures that are subjected to welding or gas cutting; — leakage of flammable gases (for example, acetylene) through faulty pipelines, fittings, hoses and tools; — faults in electrical wiring, electrical appliances and electric welding wires. Fires can occur as a result of careless handling of fire, the location of flammable materials in close proximity to fire sources, improper handling of flammable liquids (kerosene, gasoline), smoking in unauthorized places, self-ignition of oily rags and protective clothing.

Every worker should know that a fire is easier to prevent than to extinguish. Therefore, when working in the workshops of shipyards, as well as on ships, fire safety rules must be strictly observed.

One of them is keeping the work area clean. It is imperative to remove flammable materials, especially in areas where open flames are used.

All workplaces must be equipped with fire extinguishing equipment.

Before starting electric welding and gas cutting work, it is necessary to clear the workplace of flammable materials and remove these materials from the opposite side of the structure. When welding on wooden scaffolding and scaffolding, you should be especially careful and have fire extinguishing equipment (for example, a bucket of water) ready. After completion of electric welding, welding stations must be disconnected from power sources.

Cylinders with flammable gases must have a person on duty who monitors the serviceability of equipment and hoses.

When working on assembly and assembly-welding mechanisms that have hydraulic systems, oil leaks must not be allowed, as this can lead to fires.

After finishing work (even during a lunch break), you should disconnect the mechanism from the power supply.

Before performing assembly, welding, gas cutting and other work on structures enclosing rooms that contained petroleum products or other flammable materials, the rooms must be steamed and ventilated. Tanks containing kerosene or gasoline must also be checked for the absence of explosive gases and vapors. Work in these rooms and tanks is only possible with special permission from fire department workers.

After completing welding and gas cutting work, it is necessary to carefully inspect the area in which the work was carried out in order to prevent possible fires.

If a fire occurs in a workshop or on a ship under construction, you should immediately call the fire brigade by telephone or using a special fire signal. Before the fire brigade arrives, it is necessary to take all possible measures to ensure the safety of people, save equipment and property from the fire, and begin to extinguish the fire using all available means.

A worker must extinguish a small fire independently using the means available at the workplace (a bucket of water, boxes of sand, fire extinguishers, fire hoses). It should be remembered that burning electrical wiring, electrical machines and energized devices cannot be extinguished with water and foam fire extinguishers, this can lead to electric shock. In such cases, you must immediately turn off the power to the wiring, machine or apparatus, and then begin to extinguish the fire.

Narrow metal shelving for warehouse, office and home

Thanks to their durable frame, reliable fastenings and the ability to store a wide variety of items and documents, metal racks find their use in many areas. Due to their obvious advantages, they are used as retail, warehouse, and office storage systems, and are also installed in workshops and even in homes. A narrow metal rack will fit perfectly into the interior of a modern apartment. It can be used on balconies and even in the bathroom, where wooden cabinets cannot last long. The different types of racks and the features of their choice are described below.

Welded gate for a fence: simple and practical

A welded fence gate is the most practical option for creating an entrance to a site. The manufacture and installation of such a product takes little time, the whole thing is inexpensive, and in terms of strength, durability and performance qualities it is not inferior to more expensive solutions. Before manufacturing a welded gate, it is necessary to decide on the material of the load-bearing supports, the front cladding, the type of structure, and sketch out its plan , understand the installation steps. Read about this and much more in our material.

Brief information about acetylene, propane, gasoline, kerosene, oxygen

Acetylene, propane, butane are flammable gases. Flammability limits in air by volume: acetylene - lower -2.2%, upper - 81%, propane - 2 - 9.5%, butane - 1.5 - 8.5%

Gasoline is a flammable liquid with a flash point of up to 28 degrees. C. (A-72 flash point minus 27 degrees C, AI - 92 T flash point - minus 32 degrees C)

Kerosene is a flammable liquid with a flash point of more than 28 degrees. C (KO-20 T vsp. –55 degrees C, KO – 25 T vp. – 40 degrees C). Concentration limits of flame propagation (ignition): gasoline vapors - lower - 0.7%, upper - 6%; kerosene vapor – 1-1.3%.

Oxygen is a colorless, odorless and tasteless gas, heavier than air. Oxygen is not flammable, but is the main gas that supports combustion of substances. Highly active, combines with most elements. Oxygen forms explosive mixtures with flammable gases. Do not allow oils (fats) or oxygen cylinder fittings to come into contact with oily materials during their storage and transportation.

Industrial painting of metal products: preparation, process, choice of coating

When industrially painting metal products, it is necessary to comply with certain requirements for each stage, from surface preparation to the choice of coating and method of its application. If in everyday life you can afford certain shortcomings when painting with your own hands, then with the industrial method the product must meet strict quality criteria. Despite the high demands on the result, industrial painting is not so complicated. In our article we will look at the types of paints for this process, describe the preparation of the surface to be painted, understand coating technologies and give recommendations on the choice of composition.

Manufacturing of metal cabinets for locker rooms: types, production stages, selection criteria

The production of metal cabinets for locker rooms begins with processing the requirements and wishes of the customer, if this is not a standard model, but an individual sketch for the dimensions and interior of a particular room. Next, the production process moves into the technical plane: preparation of the frame, work with sheet metal, grinding, painting, assembly. The fact of acceptance of the work result is also important. To do this, you should prepare criteria for evaluating cabinets. From our material you will learn about the advantages of installing metal cabinets in locker rooms, the stages of their production and the rules for choosing finished products.

Express order cost calculation

Find out the preliminary cost of your order by sending us the necessary information:

Request a call

Find out the preliminary cost of your order by sending us the necessary information: