The high, constantly growing demand for metal structures makes their production a profitable and profitable business that requires large investments. A business plan for the production of metal structures is usually based on attracting third-party investments that will pay for themselves in the next 5 years. Startup capital for a startup runs into hundreds of thousands of dollars, so the business plan must be carefully thought out.

The high demand for metal structures in various industries is justified by the characteristics of the products: durability, strength, high wear resistance. The ease of installation of structures and structures makes their purchase profitable.

Product description

Metal structures are divided into:

- solid;

- collapsible;

- mixed.

The last two categories are convenient for the buyer in that no special skills are required during assembly; installation can be done on your own.

Depending on the area of use and the role assigned to the metal structure, the following are distinguished:

- Sheet (made from sheet steel or sheet alloys based on aluminum). They are used for the production of containers, pipelines, chimneys, and other elements of buildings and structures.

- Long-span (frames and arches).

- Pavements, for the construction of road and railway bridges, suspension bridges and pedestrian crossings.

- Crane structures, support and suspension crane designs.

The production of one or more types of metal structures involves the purchase of the necessary equipment. Before making a choice, you need to carefully study the market, supply and demand, and, if possible, occupy one of the free (or least occupied) niches.

Market analysis

Potential of consumers of construction organizations' services

When planning a business, you need to decide on potential clients. These include:

- large organizations with government funding, specializing in the construction of houses, bridges, buildings;

- private firms involved in construction, providing intermediary services to third parties;

- private individuals purchasing metal structures for their own needs.

Negotiations on the supply of products must be carried out long before the workshop begins its activities; working at a “warehouse” in a business related to the production of metal structures will lead to ruin and debt. When analyzing a possible sales market, you need to take into account the direction of activity of competitors, offer either metal structures of a different type, or work in a different price segment, or offer high-quality products at an adequate price.

The modern market is focused on generating income through turnover.

Business development and key mistakes

The company expanded, acquired its regular clientele, many clients came thanks to word of mouth. In 2011, I opened a small office near the city center. My staff was replenished with a manager who took calls and conducted preliminary consultations on the company’s services and pricing policy. I also hired a part-time designer to help me with particularly difficult orders. We completed 5-15 orders per month, my net profit fluctuated between 180,000-250,000 rubles.

There was a strong decline in 2012 and 2013. I became interested in the new construction industry and took the risk of buying a plot for the construction of 2 townhouses, with further sale. A lot of finances were taken out of the company's turnover. But the biggest mistake was the belief that my business of manufacturing and installing metal structures could already do without my constant supervision.

Old advertising models did not bring in new customers. The workers went on binges without finishing the projects. I found myself close to bankruptcy. There were loans, the sale of a personal car and an ill-fated plot of land with unfinished townhouses. It was only recently, in 2015, that I started making a profit again. So far this is no more than 150,000 rubles per month, but I am confident in the further development of my company and in my own abilities. I run advertising mainly on the Internet. I try not to give advances to workers until the completion of the project, so as not to look for them later through bosom buddies.

Room

The purchase or rental of premises is not limited to the workshop in which the machines will be located. The complex must include a warehouse for storing raw materials and finished products. Ideally, finished products are not stored, but are immediately sent to the customer.

The workshop is divided into:

- preparatory stage;

- processing;

- assembly;

- coloring

The size of the workshop directly depends on the scale of production: for the manufacture of gratings, fences, and fences, a small garage provided with electricity is suitable. And for a large production workshop you will need a room with an area of three hundred square meters. Rental prices vary greatly in different regions. In a small town you can rent a workshop with a payment starting from 100 rubles. per square meter, there is no upper limit on the price.

The workshop must be equipped with ventilation, lighting and heating. A thrifty owner will first take care of installing an alarm system.

Equipment

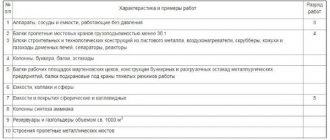

The chosen specialization makes its own adjustments, but the standard set includes automatic sheet metal processing machines, plasma and thermal cutting machines, hydraulic press shears, drilling machines, cantilever shelving and racks, painting equipment, and work tools.

The purchase of equipment will cost about 6 million rubles and depends on the number of machines purchased and the country of origin.

Delivery of raw materials to the warehouse, and finished products to the customer will be faster and more efficient if you have your own freight transport.

Staff

To produce quality goods and expand the business, qualified workers will be required:

- manager;

- warehouse manager, who controls the acceptance of raw materials and the release of goods, the purchase of necessary materials;

- for round-the-clock shift work, qualified and experienced specialists in working with metal are needed, as well as technologists and shift foreman;

- cleaner;

- accountant;

- Sales Manager;

- driver (if you have your own transport);

- watchmen (guards).

How to open a metalworking business from scratch: main steps

Creating a business plan will be a necessary step in creating any type of business. It requires planning both the main stages of opening an enterprise and its further activities, calculating initial investments and regular investments, and also correlating the data obtained with the projected profit. Based on such calculations, the profitability of the future company is determined and it is predicted how long it will take to recoup costs and begin to generate stable profits. Depending on the region, the specifics and volume of work that the enterprise will perform, profitability indicators may differ. But on average, experienced businessmen give a figure of about 20%, which, taking into account the considerable investment in opening a company, implies a payback period of 2 years.

On video: An example of a home business in metal processing

A suitable room for metalworking will be one of the important expenses. If an entrepreneur does not have a suitable workshop, it is necessary to buy or rent a premises measuring 30 square meters. m or more. The workshop premises must comply with fire safety and sanitary standards, in confirmation of which it is necessary to obtain appropriate permits from regulatory services.

In addition to the workshop itself, it is also necessary to equip office and storage space. If at the first stage of the company’s work it is possible to do without an office, then with its expansion it will be necessary to hire administrative department employees who will establish contacts with potential clients, sign contracts with suppliers of equipment and consumables; both the manager and his deputy will need jobs. The warehouse, for which part of the production workshop can be allocated, should already have finished products, as well as raw materials and consumables.

On video: Plasma processing of metals

An advertising campaign for a metalworking enterprise should be drawn up taking into account the fact that the target audience of this industry is quite limited. As a rule, the main customers and buyers of products will be companies of various levels, less often - individuals. Taking this feature into account, you should choose suitable advertising methods.

The most important thing for promoting an enterprise will be the creation of the company’s own website. This resource should be informative and user-friendly, providing all the information that may be of interest to potential clients; for this purpose, its development and maintenance is entrusted to professionals. It is desirable that the company’s official website be optimized for basic search queries, which will enable future buyers to see it in the first lines of search engines.

Metal processing as a business: how to make money on artistic forging and more

Other types of advertising on the Internet, as well as placement of information in the media and thematic print publications, will also be relevant. Outdoor advertising, posting notices and distributing leaflets and business cards of the enterprise can be auxiliary methods.

The amount and specifics of equipment that you need to purchase before opening a metalworking business will depend on the selected industries. Thus, just starting work, the company will most likely engage in the simplest and least expensive types of work. Therefore, first of all, you need to purchase high-quality metalworking tools and several machines, primarily equipment for cutting metal. At the first stage, you can even purchase used machines, which will significantly reduce your investment.

As the scope of work expands, the variety of equipment will be significantly greater. So, you will need to purchase rotary lathes, lathes, milling and grinding machines. To perform grinding of parts you will need presses - crank and hydraulic, be sure to purchase several sets of tools. It would be good if each machine was presented in several varieties and in sufficient quantities - this would allow a large volume of work to be carried out with an increase in orders. If you start a business with a simpler activity - metal turning, then according to rough estimates, the amount required for the purchase of equipment will be up to 60 thousand rubles, of which about 45 thousand must be spent on purchasing a lathe. Equipment for processing metal under pressure will require at least 15 thousand rubles. Therefore, when determining the profile of future production, it is imperative to take into account financial aspects.

Metal processing business in your city from scratch: how to start

When purchasing metalworking equipment, you should pay attention to the quality of the product offered. Thus, often expensive imported equipment turns out to be of higher quality and has a long service life. However, in the first stages it makes sense to use high-quality, but used equipment, which will save money.

The staff of the enterprise will depend on production volumes and the specifics of the company’s offerings. So, in most cases, you will need experienced turners, milling operators, mechanics, grinders, mechanics, machine operators, at least one technologist, as well as customer and supplier managers, accountants, deputy managers and technical workers.

The choice of name plays an important role; you should not chase complex abbreviations or overuse abbreviations that are difficult to remember and do not tell the client anything. A succinct, clear name related to the company’s activities will be easy to remember and will facilitate the implementation of an advertising campaign.

Modern realities confirm that an organization aimed at development and making a profit must have its own website, providing potential and actual customers with up-to-date information, answers to popular questions, photographs and descriptions of products.

To help the site - contextual advertising, partnerships with friendly organizations (information on their websites), outdoor advertising, advertising in the media.

Approximate investments

At the initial stage of production development, the business plan includes costs for:

- paperwork and registration (self-registration of an individual entrepreneur will cost 800 rubles - payment of state duty, for an LLC - 4 thousand rubles);

- rent or purchase of a building (from 100 rubles per square meter);

- purchase of equipment, tools (from $100 thousand, imported - more expensive than domestic);

- purchase of raw materials and materials.

Monthly expenses include utility bills, depreciation and maintenance of machines, transport, employee salaries, and taxes.

Investments in business

Naturally, you must first register your business. It will take about 50 thousand rubles to collect documentation for this particular type of business. This is not the smallest investment in the production of metal structures.

Next you will need a room. The workshop cannot be less than 250 square meters. This area is necessary to accommodate all the machines, apparatus, as well as various utility rooms. Building a new plant costs differently in different areas. On average, you can meet 600-900 thousand rubles. This indicator is very conditional.

You need to think about finding employees in advance. You will need a staff of at least 30 people. Workers must be professionals in their field, have extensive experience and seniority.

The biggest investment item in the business is equipment for the production of metal structures. You can order it from both domestic and foreign companies. The first option is cheaper, but the quality is only slightly inferior to the second. You will have to invest no less than 6-7 million rubles. That's why it's worth considering attracting outside investment.

This applies only to large and massive enterprises, in particular, the production of building metal structures. It is difficult and sometimes completely impossible to produce this type of product in a small factory. That is why, before organizing production, you need to decide what you will sell.

And of course, you cannot do without the material from which this or that part or structure will ultimately be made. You can also purchase material at a low price at scrap metal collection points. Sellers usually provide substantial discounts for bulk purchases. This applies mostly to private locations, because state-owned enterprises rarely sell wholesale quantities of material.

In total, initial payments include:

- documentation,

- room,

- equipment,

- advertising,

- material.

Despite the fact that the supply market is not very large, competition exists. In order for the buyer to notice you, you need to spend money on advertising. This can be either a television commercial or information on the radio. Ideally, have your own website on the Internet, where not only services and prices will be described, but there will also be photographs of the finished product.

An additional expense item may be your own vehicle fleet. If you plan to deliver your products to customers yourself for a certain price, then you cannot do without technology.

The production of light metal structures is quite viable even in a small area. If you are going to sell forged gratings, fences and other small structures, then you can do this on your personal plot, for example. Then the costs will only cost you the construction of a premises, registration of an individual entrepreneur, purchase of a welding machine and a couple of special non-production machines. At the same time, finding clients is quite easy. You can contact offices providing funeral services, as well as small sales companies, with an offer of cooperation. Advertising can be launched on the Internet. You may need a Gazelle-type car from your own equipment.

Whatever kind of production you start - large-scale or small-scale, you need to draw up your own business project, as well as calculate investments (taking into account all the features of your region), study the market and evaluate your strengths.

In order not to work at a loss by creating unclaimed standard structures, it is worth setting up the production of metal structures to order. This option will allow you to work at a good pace, increasing your profits. This type of work is universal for this type of business (be it a large plant or a small private enterprise).

Pros and cons of business

The advantages of business include:

- demand for products;

- high profitability;

- the opportunity to work to order without fear of “hungry” periods.

Minuses:

- high competition;

- long payback period for investments;

- huge starting capital;

- need for qualified specialists.

When choosing the production of metal structures as a source of income, you need to be prepared for market overcrowding and sales problems. Initial capital contributed by several investors requires the opening of a legal entity. However, working with specific customers, searching for unfilled niches, and quickly responding to changing demand will bear fruit.

The production of metal structures is a future-oriented business; the winner is the one who can quickly and flexibly adapt to the needs of the market, and beat competitors in price, range and quality.

How I decided to open my own business in the field of installation

In 2008, the global financial crisis began, and I, Maxim Solovyov, opened my own small construction business. At that time I was 22 years old, I was a part-time student at the Krasnodar Polytechnic University and worked part-time as a metal structure installer. In Krasnodar, a rapidly developing southern region, construction, even in conditions of fierce competition, is always in demand.

So, I made a decision, and my theoretical knowledge of construction and practical experience as an installer helped me with this. The company specialized in the manufacture and installation of metal structures, canopies and canopies made of polycarbonate. I decided to focus on the ratio of price and quality. At low, compared to average, prices, I offered decent quality with a guarantee.

Metal gates

I didn’t have a business plan as such, nor did I have any money set aside. But there was a great desire and a lot of ambition. I figured out the initial capital thanks to my grandmother, who believed in me. I borrowed 50,000 rubles from her, this amount was enough to buy the most necessary construction tools, open an individual business and rent a small part of the construction workshop.

Material on the topic : How to make money by installing plastic windows and entrance doors.

My profit from each completed job is about 20% salary, plus whatever I can save from the amounts specified in the order estimate. My initial goal was to earn at least 50,000 rubles a month (at that time the salary was much higher than average). To do this, I needed to fulfill orders worth approximately 350-500 thousand rubles monthly. I won’t say that everything always went smoothly, there were empty months, and there were times when we couldn’t complete one order in two months. But my monthly profit did not fall below 50,000, but on average amounted to 70-100 thousand rubles - and this is only the first year and a half.