What is tantalum?

Tantalum is mined in different parts of the planet, but most of the metal comes from South America and Australia.

In deposits it is often found with niobium, as well as thorium, uranium and other radioactive elements, so after mining it needs to be purified from impurities. In its pure form, tantalum is a shiny silvery metal with a blue tint. Tantalum is widely used in the production of capacitors, high power resistors and other electronic components. Tantalum deposits are rapidly depleting. Experts say there are approximately fifty years of metal reserves left to mine. This means that if new deposits rich in tantalum are not found in the coming years, in the near future we will be left without this trace element.

What is tantalum? Historical facts

Tantalum was first discovered in 1802 by the Swedish scientist A.G. Ekeberg in the composition of two minerals found in Sweden and Finland. The oxide of this element was very stable, and even a large amount of acid could not destroy its structure. The scientist formed the impression that the metal could not be saturated with acid. Ekeberg remembered the legend about King Tantalus, who was the son of Zeus and, as a result of punishment, could not quench his hunger and thirst. His suffering was called tantalum torment.

Likewise, the scientist, no matter how hard he tried, could not isolate pure metal from the oxide, so he compared his work with tantalum flour. He gave the name tantalum to the chemical element, and called the mineral that contained this metal tantalite. Only in 1903, the German chemist Bolton W. obtained the ductile metal tantalum in its pure form. Its industrial production began only in 1922. The first example of industrial production of tantalum was only the size of a match head. The United States was the first to produce it, and in 1942 a plant was launched to produce this metal.

Confusion with metals

The history of metal turned out to be very confusing. For a long time it was mistaken for niobium, and it took more than 30 years to prove otherwise. Until the beginning of the 19th century, both metals were not known to science. In 1801, Columbia was found in South America. A year later, in Sweden and Finland, Anders Ekeberg discovered a mineral with particles of an unknown metal, which he named tantalum in honor of the mythical character.

In 1809, William Wollaston compared two substances new to chemistry. Their properties were very similar, which is why the scientist concluded that they were all the same metal. His conclusions were confirmed by Friedrich Wöhler, and since then columbium and tantalum have been equated.

In the mid-40s of the 19th century, Heinrich Rose doubted the claims of his predecessors. He established that tantalum and columbium are separate elements. To emphasize the similarity of the metals, he renamed columbium niobium in honor of the legendary daughter of Tantalus. Later, Rose's conclusions were repeatedly confirmed, and he himself is often credited with the discovery of niobium.

Story

Tantalum was discovered in 1802 by the Swedish chemist A. G. Ekeberg in two minerals found in Finland and Sweden. However, it was not possible to isolate it in its pure form. Due to the difficulties of obtaining this element, it was named after the hero of ancient Greek mythology Tantalus.

Subsequently, tantalum and “Columbium” (niobium) were considered identical. It was only in 1844 that the German chemist Heinrich Rose proved that the mineral columbite-tantalite contains two different elements - niobium and tantalum.

Plastic metal tantalum was first obtained by the German scientist W. Bolton in 1903.

The first industrial stick of tantalum was obtained in 1922, and it was no larger than a match head. Then the element began to be used in current rectifiers and radio tubes. Active tantalum production began at the very end of the Second World War.

Description and properties of tantalum

In the periodic table, this metal occupies the 73rd position, designated Ta.

Under normal conditions it has a silvery color, similar in appearance to silver and some other noble metals. Due to oxidation in the air, it becomes covered with an oxide film, darkens, and becomes more like lead. At room temperature, oxidation occurs very slowly, so the metal retains its characteristic color for a long time. Active oxidation in air begins at temperatures above 280°C.

The metal reacts with halogens at low temperatures, but is immediately covered with a surface film, which protects it from further reactions throughout the entire volume.

The melting point is relatively high, 3017°C. It is much higher than that of many metals. For comparison:

- lead – 327°C;

- aluminum – 660°С;

- brass - up to 1000°C;

- gold – 1064°С;

- copper – 1083°С;

- iron – 1540°C.

Due to the highest strength of tantalum metal, it is used in many industries.

Among materials widely used in industry, tantalum is inferior in melting point to tungsten, for which this value is 3420°C.

The density of tantalum is 16,700 kg/m3; this metal is much denser than the common iron and copper, for which it is equal to 7870 and 8940 kg/m3, respectively. In terms of density, it can be compared with gold, whose density is 19320 kg/m3. Tantalum has high hardness. Despite its properties, it is a very ductile metal. The material can be rolled out to a thickness of 1 micron. Only gold has such plasticity.

The material is rolled without heating, which greatly simplifies its processing. Mechanical strength can be increased by cold hardening. At temperatures below – 196°C, the property of plasticity disappears and the metal becomes brittle.

Due to its magnetic properties, tantalum is classified as paramagnetic. The properties of a paramagnetic material manifest themselves well at temperatures below 3420°C, then the metal becomes ferromagnetic.

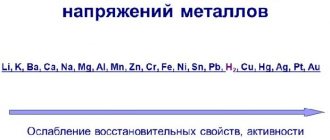

Tantalum has the highest resistance to aggressive environmental influences. It is not destroyed by nitric acid with a concentration of 70%. It is not affected by sulfuric acid heated to 150°C, but when the temperature of the acid increases to 200°C, the metal begins to slowly deteriorate.

This anti-corrosion resistance of the metal, which exceeds that of stainless steel, has made it indispensable in a number of production processes.

Electrolysis is used to separate precious metals from solutions and melts of their salts. But the cathodes on which noble metals are deposited are quickly destroyed. Replacing cathodes made of conventional metals with tantalum made the electrolysis process much more efficient and cheaper. This method is also used to isolate rare earth elements from ores.

Tantalum has high biological compatibility and is therefore widely used in medicine. Prostheses and implants made from it do not have a chemical effect on the body, do not oxidize, and therefore are not rejected by the body.

Tantalum cannot be considered a good conductor of electric current; its resistivity at 20°C is 0.13 Ohm*mm²/m, which is greater than that of iron (0.1 Ohm*mm²/m). But it has a relatively high transition temperature to the superconducting state, it is equal to 4.5 K. At higher temperatures, vanadium (5.3 K), lead (7.2 K) and its “twin” niobium (9.2 K) go into the state of superconductivity. This property of tantalum has made it in demand in the production of cryoton superconductors used in electronic computing technology. In radio electronics, capacitors with tantalum plates are used. They turned out to be the most effective, but they can work at low voltage values.

In the military industry, tantalum alloys are used to increase the penetrating power of projectiles.

For scientific and military purposes, radioactive isotopes are used to create gamma radiation sources. Radioactive isotopes are found in fossils, but they are found in much higher concentrations in the waste left over from nuclear reactors.

Tantalum is used in the construction of protection for nuclear reactors, since it is one of the few elements that is not destroyed by the action of cesium vapor.

Tantalum carbide is applied to the surface of the cutting tool to give it special strength. This tool is used for cutting and drilling particularly durable materials when drilling deep wells in hard rocks.

Due to its high strength, oxidation resistance and high melting point, tantalum is used in the production of aircraft and rocket engines.

Parts made of tantalum last tens of years longer in aggressive environments than those made of other materials with high corrosion resistance.

All physical characteristics of the material can be changed by introducing alloying additives into it.

Tantalum. Description and properties of tantalum metal

The metal Tantalum was discovered quite recently, namely in 1802. The Swedish chemist A.G. was lucky enough to discover this metal. Ekeberg. When studying two new minerals that were found in the Scandinavian countries, it turned out that in addition to the known elements, they also contained previously unstudied ones. The scientist was never able to isolate the metal from the mineral in its pure form, as great difficulties arose with this.

In this regard, the unexplored metal was named after a hero from the mythology of Ancient Greece, and on which the myth of Tantalus . After this, for more than 40 years, it was believed that tantalum and niobium were the same metal. However, one German chemist proved the difference between the metals, and after that another German isolated tantalum in its pure form, and this happened only in 1903.

Serial production of rolled products and tantalum products began only during the Second World War. Today this element is given the name “smart metal”, since rapidly developing electronics cannot do without it.

Description and properties of tantalum

Tantalum is a metal with high hardness and atomic density. In the periodic table of chemical elements, tantalum is located at position 73. In world practice, it is customary to denote this metal by a combination of two letters, namely Ta. At atmospheric pressure and room temperature, tantalum has a characteristic silvery-metallic color. The oxide film that forms on the surface of the metal will give it a leaden tint.

Tantalum is an inactive element at room temperature. Oxidation of the surface of this metal by air is possible only at temperatures above 280 degrees. Tantalum reacts with halogens at a temperature 30 degrees lower than with air. In this case, a protective film is formed on the surface, which prevents further penetration of oxidizing elements throughout the depth of the metal.

Tantalum is a chemical element with a fairly high melting point. So, it is 3290 K, and the boiling point reaches 5731 K. Despite the high density (16.7 g/cm3) and hardness, it is quite plastic. In terms of ductility, tantalum can be compared to gold. Pure metal is very easy and convenient to work with.

It is easy to machine, for example, it can be rolled out to a thickness of 1-10 microns. It should also be noted that tantalum is paramagnetic. An interesting feature of this metal begins to appear at a temperature of 800 degrees: tantalum absorbs 740 of its gas volumes.

There are already a number of facts in world practice that indicate the excellent durability of this metal in very aggressive environments. For example, it is known that tantalum is not damaged even by 70% nitric acid. Sulfuric acid up to 150 degrees also does not lead to corrosive destruction, but already at 200 degrees the metal will begin to dissolve at a rate of 0.006 mm/year.

Some production facts also indicate that tantalum is much more resistant than austenitic stainless steels. Therefore, there is a known case in which tantalum parts worked 20 years longer than stainless steel parts.

Another interesting fact is that tantalum is used for the catalytic separation of silver and gold. Cathodes are made from it, onto which the noble metal is in turn deposited, and then washed off with aqua regia. At the same time, the cathode and tantalum, due to its excellent resistance to acids, remain intact.

Applications of tantalum

Long ago, this metal was used to produce filaments in incandescent lamps. Today, tantalum and tantalum alloys are used in the following industries and products:

— when smelting heat-resistant and corrosion-resistant alloys (for example, aircraft engine parts);

— in the chemical industry to create corrosion-resistant equipment;

— in metallurgical production for the production of rare earth metals;

— during the construction of nuclear reactors (tantalum is the most resistant metal to cesium vapor);

— due to its high biocompatibility, tantalum is used for the manufacture of medical implants and prostheses;

- for the production of superconductors - cryotrons (these are elements of computer technology);

- used in the military industry for the manufacture of shells. The use of this metal increases the penetrating power of ammunition;

- more efficient low voltage capacitors are made from tantalum;

- Tantalum has recently become firmly established in the jewelry business. This is due to the ability of the metal to form strong oxide films on the surface, which can be of various colors and shades;

— a large number of modifications of tantalum accumulate in nuclear reactors. For laboratory or military purposes, this modification of the metal can be used as a source of gamma radiation;

— this metal is used as the main one (after platinum) for the manufacture of mass standards, which have increased accuracy;

— some tantalum intermetallic compounds have very high hardness and strength, as well as increased resistance to oxidation. These compounds are used in the aviation and space industries;

— tantalum carbides are used for the manufacture of cutting tools with increased red resistance. The tool is obtained by sintering a mixture of carbide powders. These tools are used in very difficult conditions, for example, during percussion drilling;

— pentavalent tantalum oxide is necessary for welding glass in nuclear technology.

Tantalum deposits and mining

Tantalum is a rare metal. Its amount in the earth's crust is only 0.0002%. This amount includes two modifications of the metal: stable and radioactive. This rare metal occurs in the form of its own compounds and is part of many minerals. If tantalum is included in a mineral, it will always be together with niobium.

deposits of tantalum compounds and minerals in many countries. The largest deposit of this element in Europe is located in France. On the African continent, Egypt has the most tantalum. China and Thailand also have high reserves of this metal. Smaller deposits are located in the CIS, Nigeria, Canada, Australia and other countries. However, the largest deposits discovered to date are in Australia.

About 420 tons of tantalum are mined annually in the world. The main processing plants for this metal are located in the USA and Germany. It is worth noting that the international community is declaring the need to increase the production of this rare metal. Such statements are primarily related to the increase in the production of electronics, in which this element is intensively used.

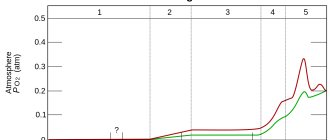

Thus, the number of developed fields increases every year. For example, to the main world developing fields, more places were added in Brazil, the USA and South Africa. However, it is worth noting the fact that in the last 10 years, there has been an intensive decline in tantalum production . The lowest production figure in the 21st century occurred in 2010.

Tantalum price

The cost of tantalum has fluctuated greatly over the past 15 years. So, in 2002-2003 to buy tantalum at the lowest price. This year the price of tantalum fluctuated from 340 to 375 dollars per kilogram. In Russia today you can buy tantalum, the price of which is 2950 rubles per kilogram.

Physical properties

Tantalum has a high melting point - 3290 K (3017 °C); boils at 5731 K (5458 °C). The density of tantalum is 16.65 g/cm³. Despite its hardness, it is as flexible as gold. Pure tantalum lends itself well to machining, is easily stamped, rolled into wire and thin sheets a hundredths of a millimeter thick. Tantalum is an excellent getter (gas absorber); at 800 °C it is capable of absorbing 740 volumes of gas. The crystal lattice is cubic, body-centered. Has paramagnetic properties.

At temperatures below 4.45 K it goes into a superconducting state.

Isotopes

Known isotopes of tantalum with mass numbers from 155 to 190 (number of protons 73, neutrons from 82 to 117), and more than 30 nuclear isomers.

Natural tantalum consists of a mixture of a stable isotope and a stable isomer: 181Ta (99.9877%) and 180mTa (0.0123%). The latter is an extremely stable isomer (excited state) of the 180Ta isotope, with a half-life of just over 8 hours.

Tantalum – element 73 of the periodic table

Tantalum (named after the hero of ancient Greek mythology Tantalus, condemned to eternal unquenchable thirst; so named because of the difficulty of obtaining it in its pure form; lat. Tantalum) Ta, chemical element V gr. periodic table, atomic number 73, atomic mass 180.9479. There are two isotopes in nature: stabil. 181Ta (99.9877%) and radioactive 180Ta (0.0123%, b-emitters, T1/2 1•1013 years). The cross-section of thermal neutron capture is 2.13•10-27 m2. The configuration of the outer electron shells of the atom is 5s25р65d36s2; oxidation state +5, much less often + 4, +3 and +2; ionization energies Ta0 : Ta+ : Ta2+ 7.89 and 16.2 eV, respectively; Pauling electronegativity 1.5; atomic radius 0.146 nm, ionic radii, nm (coordination numbers are indicated in parentheses): Ta3+ 0.086(6), Ta4+ 0.082(6), Ta5+ 0.078 (6), 0.083 (7), 0.088(8).

The tantalum content in the earth's crust is 2.5•10-4% by mass. Usually found in nature together with Nb. It is part of several dozen minerals, which are tantalum-niobates or titanium-tantalum-niobates. The most important of them are columbite-tantalite and pyrochlore (see Niobium), a microlite-temperature variety of pyrochlore containing 55-74% Ta2O5. TANTALUM is also contained in cassiterite (see Tin), during the processing of which TANTALUM goes into slag and is reduced. melts (11-15%, sometimes up to 30% Ta2O5). TANTALUM deposits are found in Nigeria, Canada, Brazil, the CIS, Australia, Zaire, Malaysia, Mozambique and Thailand. The total world reserves of TANTALUM in 1980 were estimated at 254 thousand tons, in industrial quantities. deposits - about 65.3 thousand tons.

Physico-chemical characteristics

Tantalum is a refractory metal, but its ductility rivals gold.

Being clean, it is easy to process. Gas impurities destroy the crystalline structure, negating this property.

Heavy, hard metal of gray color – tantalum

The metal has average electrical conductivity, but it becomes a superconductor at lower temperatures than others.

Chemical properties appear at high temperatures:

- Oxidizes if the air is hotter than 280°C. The result is a rainbow-colored oxide film that protects against further transformation.

- Pure metal is indifferent to the effects of aggressive environments (except for alkaline melt).

The chemical resistance of tantalum is similar to glass.

| Properties of the atom | |

| Name, symbol, number | Tantalum / Tantalum (Ta), 73 |

| Atomic mass (molar mass) | 180.94788(2) a. e.m. (g/mol) |

| Electronic configuration | [Xe] 4f14 5d3 6s2 |

| Electrons by shell | 2, 8, 18, 32, 11, 2 |

| Atomic radius | 149 pm |

| Chemical properties | |

| Covalent radius | 134 pm |

| Ion radius | (+5e) 68 pm |

| Electronegativity | 1.5 (Pauling scale) |

| Electrode potential | −1,12 |

| Oxidation states | 5 |

| Ionization energy (first electron) | 760.1 (7.88) kJ/mol (eV) |

| Thermodynamic properties of a simple substance | |

| Density (at normal conditions) | 16.65 g/cm³ |

| Melting temperature | 3290 K (3017 °C) |

| Boiling temperature | 5731 K (5458 °C) |

| Ud. heat of fusion | 24.7 kJ/mol |

| Ud. heat of vaporization | 758 kJ/mol |

| Molar heat capacity | 25.39 J/(K mol) |

| Molar volume | 10.9 cm³/mol |

| Crystal lattice of a simple substance | |

| Lattice structure | cubic, body-centered |

| Lattice parameters | 3.310 Å |

| Debye temperature | 225.00 K |

| Other characteristics | |

| Thermal conductivity | (300 K) 57.5 W/(mK) |

| CAS number | 7440-25-7 |

Insoluble in acids (except for hydrofluoric nitrogen mixture), including aqua regia. Powdered tantalum interacts with fluoride and the reaction ends with an explosion.

Occurrence in nature and production of tantalum

Tantalum, as a chemical element, is very rare in nature, making up only 0.0002% of the earth's crust. It is very rarely found in its pure form, most often in the composition of various minerals, in proximity to another metal - niobium.

Deposits of this element are found in many countries. Large deposits are found in France, Egypt, China and Thailand. But the largest deposits of this element are in Australia. Tantalum is mined in quantities of more than 400 tons annually. At the same time, the need for its use is constantly growing, which is associated with an increase in the volume of electrical equipment produced using this metal. Based on this, there is a constant development of new deposits.

In our country, tantalum production is concentrated at the Solikamsk magnesium plant. The metal is obtained after processing loparite concentrates. In other countries, other minerals are also used, such as rutile, struverite, tantalite and columbite.

The largest producers of this metal in the world are the USA, Japan and China. The number of global manufacturers does not exceed 40 firms. Cost - from 1000 dollars per kg.

Properties of tantalum

Tantalum belongs to the category of metals. It has a silvery-white tint. It is somewhat reminiscent of lead in appearance because it has a strong oxide film on it.

This metal belongs to the category of the most rarely found in nature. To date, only twenty tantalum minerals are known. However, there are sixty more minerals that contain this metal. Along with it, niobium is necessarily present in such minerals. It has similar chemical properties.

Tantalum deposits

Tantalum ores are very rare.

However, the largest of them are located in countries such as:

- Egypt,

- France,

- China,

- Thailand,

- Australia,

- Mozambique.

The world's largest tantalum ore is located in Greenbush in Australia.

Tantalum has a high melting point. It is more than three thousand degrees Celsius. The boiling point of this metal exceeds five thousand degrees Celsius. The properties of tantalum are also represented by other characteristics. This substance has a fairly solid structure. However, the metal has a high level of ductility. In this parameter it is comparable to gold. It is excellent for machining products. Thanks to it, you can create the finest types of wire or sheets for finishing products.

Tantalum belongs to the category of low-active metals. Its oxidation rate under the influence of air is quite low. In air, it undergoes oxidation only if its temperature reaches 250 degrees Celsius.

Table. Characteristics of mica capacitors based on polycarbonate, polystyrene and tantalum.

| Capacitor parameter | Capacitor type | ||

| Polycarbonate based | Based on polystyrene | Tantalum based | |

| Capacitor capacitance range | 10 nF to 10 µF | 10 pF to 10 nF | 100 nF to 100 µF |

| Accuracy (possible spread of capacitor capacitance values), % | ± 20 | ± 2,5 | ± 20 |

| Operating voltage of capacitors, V | 63 — 630 | 160 | 6,3 — 35 |

| Capacitor Stability | Excellent | good | Sufficient |

| Range of changes in ambient temperature, °C | -55 to +100 | -40 to +70 | -55 to +85 |

Deposits and production

The proportion of tantalum in the earth's crust is 0.0002%, which makes it a rare metal. In nature, it is very dispersed and is present only in the form of two isotopes: tantalum 181 and tantalum 180. The latter is radioactive and has a half-life of 1015 years.

The metal has 20 of its own minerals (woginite, loparite, columbite-tantalite), and about 60 in which it is often contained. Its constant companion is niobium; it is present in all rocks containing tantalum. But they rarely turn out to be suitable for industrial development. The most commonly used mineral is columbite-tantalite.

Tantalum production is not always a profitable business. The largest deposits of the metal are located in Brazil, Australia, Nigeria, USA, France, and Egypt. They are also found in Mozambique, Thailand, the Democratic Republic of Congo, and Russia.

In some African countries, metal mining occurs using artisanal methods. Armed conflicts often occur over the ownership of lands with deposits of expensive minerals. Since the demand for tantalum is only increasing, it also periodically finds itself at the center of these events. In particular, the Republic of Congo has become famous for its “tantalum wars” in recent decades. In 2021, a kilogram of metal on the world market is valued at approximately $320.

Being in nature

Tantalum is a rare metal; it accounts for 0.0002% of the earth's crust. About 20 of tantalum's own minerals are known - the columbite-tantalite series, wodginite, loparite, manganotantalit and others, as well as more than 60 minerals containing tantalum. All of them are associated with endogenous mineral formation. In minerals, tantalum is always found together with niobium due to the similarity of their physical and chemical properties. Tantalum is a typically trace element, as it is isomorphic with many chemical elements. Tantalum deposits are confined to granitic pegmatites, carbonatites and alkaline layered intrusions.

Features of tantalum mining

Ta occurs naturally in the mineral columbite-tantalite, which is found in tantalum deposits in Australia, Brazil, Mozambique, Thailand, Portugal, Nigeria, Zaire and Canada. Separation of Ta from niobium requires either electrolysis, reduction of potassium fluorotantalate with sodium, or interaction of carbide with oxide.

Over the past 15 years, the source of Ta production has changed. This is because it was primarily located in Australia, but is mined primarily in Rwanda and DR Congo, raising concerns about its status as a conflict mineral in war-torn countries. The Dodd-Frank Act means companies must trace the source of these minerals and only use accredited resources. Minerals used to finance armed insurgencies and violence are found throughout the world. These include tin, tungsten and tantalum, which are found in many highly popular products such as smartphones and laptops.

Tantalum is found in hard rock deposits such as granites, carbonites and pegmatites - an igneous rock consisting of coarse granite. It is not one of the most widespread metals on the planet, and its extraction is difficult. That comes from the processing and refining of tantalite - this is the general name for any mineral ore containing it.

Most tantalum mines are in open pits, some are underground. The Ta mining process involves blasting, crushing and transporting the resulting ore. The ore is then concentrated at or near the mine site to increase the percentage by weight of tantalum and niobium oxide. The material is concentrated using wet gravity, electrostatics and electromagnetism methods.

The tantalum concentrate is transported to a processor for chemical processing. It is then treated with a mixture of hydrofluoric and sulfuric acids at high temperatures. This causes Ta and niobium to dissolve as fluorides. The concentrate is transferred into a liquid solution. The suspension is filtered and further processed by solvent extraction.

The use of methyl isobutyl ketone (MIBK) or liquid ion exchange using an amine extractant in kerosene produces highly purified solutions of tantalum and niobium. Finally, tantalum oxide is reduced by molten sodium to form Ta metal.

Tantalum mining

Thanks to exploration work, new deposits of the metal tantalum were found

The earth's crust contains about 0.0002% tantalum, so it is classified as a rare element. But almost all countries have deposits of its compounds. In Europe, the largest and richest deposits are in France, and there are small deposits in most countries of the former USSR. Among African countries, Egypt has the largest reserves of raw materials. But the largest and richest deposits known and developed to date are located in Australia.

The element is found in the form of its own salts, or it is part of other minerals. In the second case, it is necessarily accompanied by niobium. Minerals can be stable or radioactive.

The extraction of this metal is 420 tons per year. The leading countries in production and processing are the USA and Germany.

Due to the global crisis, the demand for tantalum decreased slightly, but since 2010 it has increased again. Recently, active exploration work has been carried out. Thanks to them, new deposits were discovered in the USA, Brazil, and South Africa.

Characteristics and properties of metal

Ta is a heavy blue-gray metal element with a melting point of 3017 C. It has excellent corrosion resistance, good ductility and is resistant to most acids. In electronics it forms the basis of high-performance capacitors, and in chemical manufacturing where, when alloyed with iron, it provides excellent corrosion resistance to metals used in corrosive environments such as oil and gas pipelines. The properties of tantalum in aluminum alloys prevent oxidation, allowing lighter components to be used safely. Due to its high melting point, it is used to cement tungsten carbide in machine tools and in alloys for jet engine turbine blades.

Chemical properties:

- Atomic number: 73;

- atomic weight: 180.94788;

- melting point: 3290 K (3017 C or 5463 F);

- boiling point: 5731 K (5458 C or 9856 F);

- density: 16.4 grams / cm3;

- phase at room temperature: solid;

- classification of elements: metal;

- period number: 6;

- group number: 5;

- group name: no.

Tantalum ingot

Technical features of tantalum

First of all, it is worth understanding that tantalum is a gray metal with a shiny tint that can be easily processed mechanically.

Among the features of the metal, it is worth noting a number of the following important aspects:

- serial number in the periodic table – 73;

- atomic weight – 180;

- the density of the substance is 60 g/cm3;

- melting point – 3015 0С;

- The boiling point of the substance is 5300 0C.

Metal properties

Due to these characteristics, tantalum undoubtedly has the following advantageous properties:

- Tantalum is a refractory metal, and, as a result, the element has the following properties:

- small linear expansion rate;

- good level of thermal conductivity;

- high mechanical strength and ductility.

- Has excellent anti-corrosion qualities. It is worth noting that tantalum under normal conditions is practically inert to sea water, but if it is saturated with oxygen, then the metal in this case only tarnishes.

- Tantalum has good resistance to the following types of salts:

- iron and copper chlorides;

- nitrates;

- sulfates;

- salts of organic acids, however, provided that they do not contain fluorine or fluorides.

- Tantalum begins to lose its strength characteristics when it reacts with fluorine. It is also worth considering the fact that tantalum does not react chemically with bromine, iodine and liquid chlorine unless a temperature of 150 0C is reached.

- Tantalum is quite resistant to the effects of liquid metals with a low melting point.

- Tantalum has excellent stability characteristics in air at temperatures up to 400 0C, while a protective oxide film appears during storage or processing.

- Tantalum melted by the electron beam method has an increased plasticity property, which, when the metal is deformed, allows for a greater degree of compression.

- It converts well into sheet metal, which lends itself well to forging.

- It lends itself well to processing during cold deformation. However, you need to understand that this metal should not be deformed in a hot state, since when heated, tantalum begins to absorb nitrogen, carbon dioxide, oxygen, and, as a result, the material becomes quite brittle.

- One of the main operations in tantalum processing is cutting the material on high-speed equipment.

As for the connection of tantalum parts, it can be done in the following ways:

- welding;

- soldering;

- connection using rivets.

Here it is worth taking into account the fact that the last two methods are used quite rarely, so the quality of tantalum welded joints always remains at a high level.

Alloys

Most people buy pure tantalum, but alloys are also available.

They include hafnium, niobium, tungsten, and molybdenum. Such alloys are similar in structure to niobium single-phase alloys.

The most popular alloy in industry is tungsten alloy (TV-5, TV-10, TV-15).

Alloys of tantalum carbides (chemical formula Ta4HfC5) and tungsten are indispensable for drilling the hardest rocks.

Tantalum beryllide is in high demand in the aerospace industry.

Tantalum grades

In most cases, the material is distributed in its pure form, however, alloys with other metals are also found.

- HDTV – high purity tantalum, Ta content is 99.9%.

- T – pure tantalum with 99.37% Ta and 0.5% Nb.

- TV is an alloy of Ta and W.

Tantalum deposits and mining

What is tantalum? This is a very rare metal. In its pure form it is practically not observed. It can be found in minerals and in the form of its own compounds. In minerals it is always found together with niobium, which is very similar in properties to tantalum. Deposits with tantalum compounds and minerals are located in many countries around the world.

The largest is located in France. Reserves of this metal are high in China and Thailand. In the CIS countries the deposits are much smaller. About 420 tons of tantalum are produced annually in the world. The main plants that process metal are located in Germany and the USA. Due to the rapid development of electronics, in which the use of tantalum is not the least important, there is a shortage of this rare metal, which leads to the search for new deposits.

Advantages and disadvantages

| Advantages | Flaws |

| Exceptionally resistant to corrosion in chemically aggressive environments | Rare earth metal (to obtain a ton of tantalum con up to 3000 tons of minerals). |

| Excellent gas absorber | |

| High melting point | |

| Excellent compatibility with biological tissues | High price |

| The metal is ductile, durable and hard |

Minerals, production

Our element is a rare metal, found in nature in the form of tantalum ore (general formula (Fe,Mn) [(Nb,Ta)O3]2.

The preliminary stage for any method is obtaining concentrates from ore.

There are several ways to obtain a pure product:

- Carbothermic method.

- Na-thermal reduction from fluorides.

- Al-thermal method.

- By electrolysis method.

Informative: tantalum and niobium are always nearby, in all minerals and ores; they are difficult to distinguish. The difficulty of production lies in the separation of these metals.

Product types:

- powder;

- wire;

- rods;

- foil;

- sheets.

Informative: niobium is always present in industrial tantalum.

Tantalum based alloys

Due to its special physical properties, this metal in its pure form is very often used in industry. However, to increase strength and resistance to high temperatures, alloys based on it can be used and appropriate alloying components can be added.

Tantalum alloys can remain solid at temperatures of about 1700 degrees. This is necessary when using tantalum compounds in the energy sector, chemical industry, production of high-precision instruments and metallurgy. Very often, various alloys are used in the construction of space rockets.

The type of alloying components used depends on the final properties required. To improve the quality of work, elements are used that give the alloy improved ductility properties.

It should be noted that very often tantalum in alloys is used not as a base, but as an alloying component. Its addition to various materials allows for increased resistance to high temperatures and corrosion.

Tantalum capacitor circuit

Tantalum capacitors

Tantalum TAV-10 is a widely used alloy based on this metal. It is produced with the addition of tungsten, the amount of which is about 10%. This results in a material with improved heat resistance. It is used for the production of heating elements and for medical purposes, since its components do not irritate human skin.

Physical properties of tantalum

What is tantalum? It is a silver-white metal. The durable oxide film on it gives it a similar appearance to lead. The metal has high strength and hardness and at the same time ductility. In terms of its ductility, it is compared to gold.

In its pure form, it is perfectly subject to mechanical processing. It is easy to stamp and rolls out into a very thin layer up to 0.04 mm. It produces high-quality wire. Tantalum, what is it? It is a refractory metal, the melting point of which is approximately 3000 degrees. Only tungsten and rhenium surpass it in this property. One of its specific qualities is its high thermal conductivity. Even the oxide film that forms on it does not reduce this property.

Areas of application

Tantalum is an important material for the development of high technologies. Today the metal is used in electronics to create capacitors. They can be made very small, which is convenient for the production of gadgets. Therefore, tantalum capacitors are present in almost all smartphones, laptops and tablets.

The internal resistivity of the metal is almost like that of steel, so the use of tantalum is logical where high temperatures are needed. It is used in various heating elements, for example, for high-temperature furnaces.

In addition, the metal is useful for making lenses. Adding its oxide to glass improves their optical qualities. Heat-resistant alloys that are resistant to corrosion are made from tantalum with the addition of titanium. Its carbide is used to make tools for cutting metals.

It is also suitable for the production of dies, laboratory glassware, and aerospace equipment. Recently, tantalum has increasingly gained fame as a jewelry metal and is used to make jewelry.

Pipe products

Nuclear energy is a separate industry that uses tantalum tubes and heat exchangers. Possessing high heat resistance and a low neutron capture cross section, the element has long occupied the main share in the structural material of nuclear installations.

Heat exchanger made of tantalum pipes at one of the nuclear power plants

Today, tantalum is being replaced from this industry by niobium. However, it is unlikely that it will be possible to hand over tantalum products written off from the nuclear energy sector due to a set of obstacles:

- prohibition on sale;

- inability to obtain this type of secondary metal;

- health hazard.

On the contrary, the exceptional inertness of tantalum with respect to acids finds use for the rare metal for chemical and laboratory purposes. Coils, lines for supplying hydrochloric acid, and stirrers are made from tantalum tubes. Some types of laboratory glassware are also made from this material. Despite the long service life, which pays off the high cost of tantalum products, products wear out over time and must be replaced. Some of the discarded pipe products manage to leak to scrap metal collection points.

Tantalum products

It remains to add that not all pipes are made from the TVCh grade of high-purity tantalum. A significant percentage of these products are made from an alloy of this metal with tungsten. Brands of these heat-resistant compounds TV-5 (10.15) contain tantalum at the level of 95 - 85%.

Mining and production of tantalum

Tantalum is classified as a rare metal. In nature, it exists in the form of isotopes - stable and radioactive. At the moment, about twenty tantalum minerals and about sixty minerals that contain this metal are isolated. The largest tantalum deposit was discovered in Australia. This mineral is also mined in China, France, CIS countries, Brazil, and Canada. The Murmansk region produces the bulk of tantalum, which was discovered in deposits of the Russian Federation.

Tantalum has a rather complex production technology. To obtain it, more than three thousand tons of ore are processed, due to which the metal has a very high cost, exceeding $4,500 per kilogram.

Tantalum in medicine

The metal is used in surgery to restore the body. Thin tantalum plates are inserted into the skull to bridge cracks or breaks. Strong wire made of this metal is used to fasten bones and sew organ tissues with it.

It is used for dentures. For example, a metal mesh is used for eyeballs, and plates can be used to replace ears, by transplanting skin from other parts of the body onto them. Tantalum threads are truly used for jewelry: they are used to sew together the finest nerve fibers, tendons, and blood vessels.

The use of tantalum in medicine is due to its unique properties. Metal is perfectly compatible with living tissue. It does not oxidize in the body, does not cause irritation or rejection.

Applications of tantalum

Initially, in industry, this metal was used only to create thin wire for the production of well-known incandescent lamps. Today, tantalum is used quite widely. It is used for the production of industrial and household items, and in the creation of new types of weapons in the military industry.

A metal such as tantalum is indispensable in the production of objects and equipment that are resistant to corrosion. In addition, many of these products have a high level of heat resistance.

In the medical industry, the use of tantalum has long been considered the norm. Foil and wire made from this unique material are used to restore the activity of tissues and nerves of patients. They are also actively used to stitch the victim.

Due to the strength of tantalum, it began to be used for the production of spacecraft. Tantalum beryllide has excellent resistance to oxidation in air.

This metal has found its application in the metallurgical industry. It is used to produce hard alloys for metalworking. A mixture of tantalum and tungsten carbides is used to create hard alloys that can be used to drill holes in the most durable materials, such as stones and composites.

This material has gained wide popularity in the military industry. With its help, ammunition is created that has a high level of durability. They are almost impossible to break through. The metal is used in laboratories at the Ministry of Internal Affairs to create nuclear weapons.

Main types of tantalum scrap metal

Focusing on the element as a source of secondary rare metal, we can identify several types of tantalum-containing waste:

- lump scrap, includes rods, sheets, tubes, wire, etc.;

This is what tantalum looks like - a dark metallic color, the photo shows a tantalum sheet

- alloys with other rare metals;

- capacitors.

Additionally, the element is contained in tungsten-titanium-tantalum alloys, but its content within the compound does not exceed 14%. Another potential source for detecting tantalum is dust waste. They are formed when working with carbide materials:

- processing of plates with diamond tools;

- production of mixtures.

For the first case, the percentage concentration of tantalum is 2 – 6%, in the second option it is no more than 1.5. It should be added that such dusty waste is accepted as tungsten scrap, so handing over tantalum in this way is extremely problematic.

Refractory metals and alloys

We offer rolled products and products from a wide range of refractory metals and alloys. Starting from rolled products (rod, sheet, wire, pipe, foil), ending with products of the most complex configuration, including according to customer drawings (crucibles, electrodes, boats, evaporators, targets, heaters and much more).

Foundry modifiers

Our company specializes, first of all, in the supply of high-quality casting modifiers based on ferrosilicon, which are an integral part of the after-furnace processing of molten cast iron. Additions of such modifiers change the properties of the melt and make it possible to obtain the necessary structures and properties of castings.

Tantalum prices

Most of the tantalum, up to 60%, is consumed by the electronics industry. Its use on heat-resistant alloys is about 20%. Prices for this rare metal can change quickly. Demand for it either recovers or falls again. Analysts predict that supply and demand will fluctuate in the coming years, mainly depending on economic factors.

The approximate price of tantalum per 1 kg in rubles on the Russian market is:

- sheet – 65,660;

- in rods – 73,030;

- wire – 73,700.

Prospects

More and more people are beginning to use this smart metal in the medical industry for the needs of reconstructive surgery. It is used to make implants. Tantalum yarn is used to replace muscle tissue, wire is used to fasten bones, and threads are used for suturing. Due to the major re-equipment of the world's airlines, the use of tantalum for aircraft manufacturing will continue to grow. Alloys in the aviation industry are used for aircraft engines. In addition, tantalum continues to be actively used for the production of computer equipment: processors, printers.

The demand for this metal in the chemical industry is not decreasing either. It is widely used for the production of chlorine, hydrogen peroxide, and many acids. Chemical engineering widely uses it in the manufacture of equipment in contact with aggressive environments. The metallurgical industry remains the most serious consumer of tantalum alloys. The demand for it is also growing in nuclear energy, where thermal conductivity in combination with the ductility and hardness of tantalum is mainly used.

Sources

- https://aggeil.ru/kolco/kolco-iz-tantala-polnoe-rukovodstvo/

- https://FB.ru/article/362045/svoystva-i-primenenie-tantala

- https://ometallah.com/svojstva/tantal-harakteristiki.html

- https://chem.ru/tantal.html

- https://calcsbox.com/post/tantalum.html

- https://k-tree.ru/tools/chemistry/periodic.php?element=Ta

- https://stankiexpert.ru/spravochnik/materialovedenie/tantal.html

- https://1nerudnyi.ru/tantal-metall-01/

- https://TheMineral.ru/metally/tantal

- https://www.metotech.ru/tantal-opisanie.htm

- https://xlom.ru/vidy-metalloloma/lom-tantala-vidy-loma-stoimost-na-rynke

- https://ergarda.com/tugoplavkie-metally-i-splavy/tantal/tantalovye-izdeliya.html

- https://FB.ru/article/361943/chto-takoe-tantal-osobennosti-izdeliya-svoystva-i-primenenie

Applications of tantalum

The metal has received a wide range of uses. At the initial stage of production, it was used mainly to produce wire for incandescent lamps. Nowadays, a wide range of products are produced using metal and its alloys. The most popular and highly in demand include equipment for the chemical industry and heat exchangers for nuclear energy systems. Tantalum wire is actively used in cryotrons.

The metal has found wide application in modern medicine. Here it is used to produce wire, foil and sheets intended for fastening tissues and nerves and producing prostheses.

Tantalum is in quite high demand in the manufacture of jewelry. In this area, its ability to form a durable oxide film, which has an iridescent appearance, has been appreciated. The metal is used in the nuclear and military industries, where it is used to produce weapons. Along with hafnium, it can serve as an ideal source of gamma radiation. In the production of aerospace equipment, titanium berylide is used, which is famous for its excellent hardness and resistance to negative environmental factors.

In the future, the scope of application of this metal will expand even more, as it has excellent chemical and physical properties.