Purpose of seam sealants

Welded seams require additional protection so that the metal structure lasts longer and negative processes do not occur on the material, for example, corrosion does not appear. The purposes of sealants are as follows:

- Waterproofing layer for seams or base;

- Closing cracks and gaps;

- Repair work on planes with flaws and cracks.

The products differ in the level of shrinkage following curing. Having treated the metal with the composition, there is no need to be afraid that vibration effects will affect the integrity of the seam; the layer can stretch and bend. The product is used for pipelines, heating systems, in parts of various devices and for other items, depending on the chosen type.

When welding channels, high-quality electrodes are used. In this case, the drawings should be carried out in accordance with the ESKD, after which additional processing of the seams is also sometimes used.

Welds require additional protection to ensure that the metal structure lasts longer.

https://youtu.be/

Criteria for choosing joint sealant

Various types of sealants are created for cars: for the body, pipe joints, hatches. The differences between the compositions lie in the degree of heat-resistant, elastic properties, and durability of the processing result. The most effective are considered to be professional types, which are sold in large volumes, and it is advisable to take them for auto repair shops when a lot of similar work is carried out.

For independent one-time processing of welding seams, it is advisable to purchase small tubes of 40-200 grams. If you take a similar type, then it is advisable to leave the choice on an aluminum tube; the container allows you to maintain the technical characteristics without changing the entire shelf life.

The plastic option is cheaper, then you should use a sealant if its shelf life lasts at least six months.

There are options for sealants on sale, with a provided tip, which can be used to fill welding seams and corners conveniently. Body sealant in cartridges can only be applied using a special gun.

The differences between the compositions lie in the degree of heat-resistant, elastic properties, and durability of the processing result.

Moskvich 2141 BTR-2, Vozrozhdenie › Logbook › Day 36. Guide to protecting welds

For the last stage of welding work (welding the false thresholds from the inside of the cabin), it is necessary to process the half-threshold joint that will be forever closed by the cavity of the false threshold.

Therefore, instructions on how to protect welding seams according to science

We see a seam from a week ago.

Therefore, I use a brush attachment on a grinder and clean off all the oxide. Then I blow the seam with a vacuum cleaner (hose on the exhaust). It's faster than dragging the blower from the compressor)

I blow it again until the solvent dries and cover it with reactive (tapping) primer. I blew it out with a paint spray, although you can use a brush (but it will take up much more soil)

Then I heat the hand (suture) sealant in a water bath. We use a good one, dear. The cheap one will fall off in 4-5 years like a factory one from Moscow. Then I apply it to the seam with a brush.

It turns out like this:

Next you need to dry it, follow the instructions for drying time. It's cold in my garage, so I leave it to dry overnight.

In the morning you need to cover the resulting

After this procedure, processing of the weld seam is completed. The seam becomes almost eternal and will last the entire service life of the car.

Moskvich 2141 1992, petrol engine 1.5 l., 72 l. p., front drive, manual transmission — body repair

Cars for sale

Moskvich 2141, 1990

Moskvich 2141, 1998

Moskvich 2141, 1993

Moskvich 2141, 1997

Comments 51

Well, how is the seam doing after 6 years?)

Why is epoxy primer applied over joint compound and not vice versa?

I have the same question :)

So, how are the stitches holding up after 4 years?)

I support it, it’s also interesting!

In Steam Punk style)

PLEASE TELL ME, THE FRONT SIDE NEEDS TO BE WELDED... ACCORDING TO THE IDEA THERE WILL BE NO SEALANT, THERE WILL BE A WHOLE SEAM (WELDING THE ARCH) WHAT IS THE BETTER PROTECTION? ALL I FOUND WAS PASTE WITH TIN FOR TINNING. THEY Suggest THAT YOU CAN PROCESS A PASTE FOR SOLDERING FOOD PIPES, IT'S WITH SILVER... I WANT THE SEAM NOT TO RUST ANYMORE... IS THIS POSSIBLE?

it won’t even work with a spatula if you protect the cooked food from the inside from moisture and air

As I understand it, if the metal is tinned on all sides and closed, then everything will be fine?

the weld seam is where the threshold (stiffening rib) is, if it suddenly gets jammed, is it worth bothering with repairs or is it easier to treat with chemicals?

success and not a nail or a rod!

Tell me, what did you use to treat the external welds?

Types of seam sealants

Sealing of areas should be carried out with a high-quality composition intended for the selected area. Therefore, the choice of sealant must be made correctly, in order for the coating to be reliable, you should understand the differences between the popular types of compounds.

Sealing of areas should be carried out with a high-quality composition intended for the selected area.

Silicone

They are considered a good option for home use due to their ease of application. They are quick-drying, handle weld seams firmly and provide long-term protection.

The silicone layer does not allow water to pass through at all and can withstand changes in temperature. If the air humidity is high, then curing will take place in 10-15 minutes.

They are considered a good option for home use due to their ease of application.

Acrylic

Acrylic-based solutions have a high level of adhesion, however, vibration exposure can lead to disruption of integrity, since the elastic property is average.

Therefore, it is optimal to use them for porous bases, stable joints and seam areas. Painting the layer is acceptable.

Acrylic-based solutions have a high level of adhesion, but vibration exposure can lead to damage to integrity.

Polyurethane

The name of this type includes the main component of the composition, polyurethane. It is considered one of the most popular types; there are many similar options on sale. There are forms that are sprayed, for distribution with a brush, in the form of a paste. The following features are noted:

- Ease of use;

- Do not spread, even if applied to a vertical base;

- High degree of flexible, elastic, heat-resistant, moisture-resistant properties;

- Able to withstand increased mechanical loads.

High degree of flexible, elastic, heat-resistant, moisture-resistant properties.

Bituminous

Externally they are a dark paste. They are created with the addition of bitumen, modifying substances and fillers to increase the speed of adhesion. They are distinguished by the fact that they do not require careful preparation of the base; they are applicable for any base. Withstands high humidity and water.

They are distinguished by the fact that they do not require careful preparation of the base; they are applicable for any base.

What types of sealants are there?

All sealants for metal seams on automobile body parts can be divided into two categories - by composition and by application method. The method of application largely determines not only the ease of use, but also whether the product belongs to the professional class.

Division of sealants by composition

The mentioned products can be divided into the following five groups - acrylic, anaerobic, silicone, polyurethane, bitumen. We will describe them in the given order.

Acrylic compounds

They are based on polymer compositions. Such sealants have good adhesion, but their elasticity can be described as average. Accordingly, under strong mechanical loads and/or vibration, there is a risk that they will simply delaminate on their own and lose their properties. Accordingly, they are best used on rough surfaces (most seams are like this) and on stable mechanical components. Their strength is quite good. Acrylic sealants can be either varnished or painted.

Sealants for body seams according to application method

On the packaging of any sealant there is an indication of how it will need to be applied. This can also be understood by its container; usually the external shape shows an approximate procedure for distributing the solution.

On the packaging of any sealant there is an indication of how it will need to be applied.

Sprayable Sealants

Typically, these types include polymeric substances. They are one-component products; they use a lot of dry elements, due to this the layer quickly hardens from moisture and the connection is highly durable.

The surface must be treated using special guns; this facilitates comfortable distribution in the area of the bottom, engine part, and trunk of the car.

The layer hardens quickly due to moisture and the connection is highly durable.

Brush applied

Such products may be based on a nitro-rubber or silicone component; the composition is sold in cans of 1 kg or more. The substance can be used to cover seams that were welded in the area of the trunk, wheel arches, flavors, glued jumpers, and pallets.

As standard they come in white or black, drying lasts about 10 minutes. After this, it is allowed to apply paint and varnish material to obtain the desired tone.

The substance can be used to cover seams that were welded in the area of the trunk, wheel arches, flavors, glued jumpers, and pallets.

Sealant tape

Automotive parts must be sealed in an even layer, but due to lack of practice, beginners cannot always do this easily. Then you can choose tape sealant to simplify the process.

The tape on one side has an adhesive base, it can be glued to any area due to its flexibility, painting is possible immediately after gluing, drying is not required in this case.

The tape on one side has an adhesive base, it can be glued to any area due to its flexibility.

Extruded sealants

Such products are packaged in tubes from which they are squeezed onto the seam. There are options that can be distributed manually, others can only be squeezed out using a special tool.

The gun allows for the most convenient application and makes it easier to create an even layer. As a standard, they are chosen to cover seam areas on the hood, doors, trunk, and engine compartment.

The gun allows for the most convenient application and makes it easier to create an even layer.

How to choose joint sealant

Sealants must create reliable waterproofing and effectively protect the surface from corrosion. When choosing a product, you should pay attention to the presence of the following properties:

- Long service life;

- Elasticity of the layer; parts in cars are usually subject to vibration, so the layer must stretch elastically so as not to change its structure;

- High level of adhesion so that adhesion to the base is reliable and durable;

- Resistance to harmful environmental factors;

- Acceptability of layer coloring.

Products created in accordance with GOST are of good quality.

Sealants must create reliable waterproofing and effectively protect the surface from corrosion.

How to properly remove sealant

If the composition is applied incorrectly or if there is old sealant, the seam must be removed and the work done again. To clean hidden seams, use a mechanical method - remove a layer of material with a sharp spatula, knife, pumice stone, or sandpaper. To make sure you don’t scratch the base, you can use a chemical method - moisten the sealant with white spirit, and then use a knife to separate the softened compound. After preparing the base, you can apply a new layer of sealant, following the manufacturer's instructions.

Sealant application technology

The use of sealant for a car has certain requirements. You need to know the operating rules described below:

- First, the base must be cleaned of all types of contaminants, including removing rust and degreasing the base;

- To increase the degree of adhesion, stripping is carried out with red Scotch Brite;

- A primer solution for metal surfaces is applied when such a step is indicated in the instructions for the sealant;

- Prepare the composition, place the tube in the gun, open the tape, or prepare a brush or spatula for applying the product;

- The product is distributed at the same speed and preferably in one go, so that the seam comes out optimally even.

The excess part of the layer is removed immediately with a spatula or simply with a gloved finger. If the layer is excessively sticky, sprinkling with water will reduce the problem. The layer can be painted after the time indicated on the packaging.

The product is distributed at the same speed and preferably in one go, so that the seam comes out optimally even.

Rating of popular body sealants

The answer to the question that many car enthusiasts are interested in, which car seam sealant to buy, will be the following approximate answer - the most suitable one in terms of parameters. A list of the most popular sealants for body seams, compiled based on reviews and tests from the Internet. If you have used other means, write about it in the comments.

Merbenit XS55

Merbenit XS55 is positioned as a one-component high-strength adhesive-sealant designed for gluing parts with different thermal coefficients of thermal expansion. Operating temperature range - from -40°C to +90°C, application temperature - from +5°C to +40°C. The average value of the breaking load is 909.1 Newton, the average value of the breaking stress is 2.865 MPa.

Merbenit sealant is odorless, perfectly protects the surface from corrosion and ultraviolet radiation, withstands shock and vibration, has excellent adhesion, and is resistant to process fluids (oils and fuels). The sealant can be painted using the powder method, including when it has not yet hardened. Available for sale in three colors - white, gray, black.

Reviews of Merbenit XS55 body sealant are mostly positive. Sold in a 290 ml cartridge. As of summer 2021, the price of one such package is about 800 Russian rubles.

Body 999

Body 999 body sealant is a one-component composition based on rubber and various synthetic resins. Can be used for gluing body parts, filling voids, sealing welds and simply metal surfaces. It perfectly combines high strength and elasticity, so it does not lose its properties under the influence of vibration. Has excellent adhesion. After drying, the “Body” sealant can be painted using any methods and paints. Drying time at a temperature of +20°C...+25°C is about two hours. One of the features worth noting is that it cannot be used on open surfaces exposed to sunlight, since this sealant is destroyed by ultraviolet radiation.

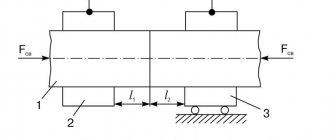

Heat treatment of welded joints

Welding involves a high-temperature effect on the metal, which leads to disruption of its structure; the material becomes thinner, so after welding it is required to additionally strengthen it with protective agents. In this case, heat treatment of welded joints may be resorted to. The type of exposure scheme depends on the type of metal and operating conditions.

After welding, it is necessary to further strengthen it with protective agents.

There are a variety of sealants for cars, this makes it possible to choose a convenient type for use. When choosing a product, take into account the area of application and the type of metal base.

Causes of corrosion on a car

All vehicles without exception are subject to this, regardless of which manufacturer they were produced by. To a lesser extent, it affects cars produced in a single copy on a personal order. As a rule, they are subjected to anti-corrosion treatment at the first stages of production. But even such measures are not able to completely rid the vehicle of this harmful phenomenon. With further operation of the car, especially in large cities and metropolitan areas, the process of destruction of metal by rust receives favorable conditions for its development. The acceleration of corrosion is facilitated by small scratches and chips that a car can receive when driving on a poor quality road.

The vapors of reagents that are used to treat roads to prevent icy conditions help rust develop even more.