Types and where to install

Lubricators are divided into:

A multi-point lubricator can serve several tool stations. Lubricators can have different inch inlet/outlet diameters, as well as oil flasks of different volumes.

Throughput depends on the inlet/outlet diameter, so the lubricator should be selected based on the amount of air consumed by the tool to ensure maximum efficiency for all operators. Most models have a special screw that allows you to adjust the intensity of oil supply.

Device price

The cost depends on several factors:

- Material of manufacture (steel, iron, brass, etc.).

- The volume of the container into which oil is poured for further distribution.

- Type of instalation.

- The number of points that the device can lubricate at a time.

- Capacity and maximum pressure.

- Manufacturer (domestic devices are 10-20% cheaper than their foreign counterparts).

As a rule, the least expensive option is to purchase a lubricator through an online store, where products for air tools are offered at discounted prices. In ordinary construction stores you can find the most popular devices that are used in conjunction with equipment for garages, workshops, construction compressor equipment, and are used for industrial and domestic purposes.

How to add oil?

Oil is poured into a stationary lubricator using a funnel through a hole located on the upper plane of the equipment. As a rule, the hole is closed with a plug for an internal hexagon. If the lubricator does not have a special hole, then the oil is poured into the removed flask and then installed back.

Connecting and operating pneumatic tools

A wide variety of different types of pneumatic equipment allows you to perform a wide range of different types of work both in large industries, in small auto repair shops, in various factories, and in domestic conditions.

Depending on the type of pneumatic tool, its performance characteristics and technical indicators, you can choose equipment for small jobs around the house - from minor repairs to garden work, as well as for use in large industry. To perform the work effectively, it is necessary to select the right equipment. In addition, the connection and use of pneumatic tools must be done correctly and taking into account the specifics of the work ahead. A pneumatic tool operates from a compressor system and therefore, first of all, it is necessary to choose the right compressor with the necessary characteristics - final pressure indicator, performance level and others.

So, after we have taken the necessary compressor suitable for working with the selected pneumatic equipment, it is necessary to correctly connect the pneumatic tool. Compliance with all the rules and requirements both for connecting equipment to the compressor unit and for working with the tool will not only allow you to competently and efficiently perform all the necessary work, but also eliminate the possibility of tool breakage and make the use of the entire pneumatic system as safe as possible.

Here you can familiarize yourself with the catalog of pneumatic tools sold by TekhMash Group of Companies LLC.

The first stage is preparation for work, which consists of competently organizing a system for supplying air under pressure to pneumatic equipment. This system, in addition to the compressor itself, consists of both basic elements, which include flexible hoses, and additional ones - lubricators, various filters, as well as oil and moisture separators. The air supplied by the compressor contains various impurities - dust, abrasive particles, water, and also oil in the case of an oil compressor. The entry of dust and other particles into the pneumatic mechanism can lead to premature failure of the equipment, and the presence of moisture, which is the result of condensation, or oil, can negatively affect the quality of the work performed. That is why it is necessary to prevent these impurities from entering the pneumatic system.

To clean compressed air from oil or moisture, a moisture separator is used, which is especially necessary in the case of long and intensive work. If pneumatic equipment is used in domestic conditions and for a short time, it is enough to drain the condensate from the receiver before starting work. Air is purified from dust and other particles by filters, which can be either built into the compressor or installed additionally to more effectively remove impurities. In this case, it is necessary to periodically clean the filters or replace them, which will prevent failure of the filtration system and the entry of contaminated air into the pneumatic system.

When operating a pneumatic tool, it is necessary to provide it with a special lubricant, which prevents friction of the working elements and their premature failure. To do this, a lubricator is installed to ensure a regular supply of lubricant to the pneumatic system. The presence of a lubricator and oil separator, as well as their correct installation, allows you to prevent damage to the working parts of pneumatic equipment, while receiving purified compressed air.

The direct connection of pneumatic equipment to the compressor occurs using special hoses - in the case of using the equipment in domestic conditions. If the work is carried out in any production, first of all, a plastic or metal pipeline is installed, to which pneumatic equipment is then connected using splitters.

To connect flexible hoses through which compressed air is supplied from the source to pneumatic equipment, with a compressor, pneumatic tools and other parts of the pneumatic route, special nipples, fittings and adapters are used, which allow the fastening to be performed as efficiently as possible.

When connecting and using pneumatic tools, you must comply with some safety requirements:

Using a pneumatic tool provides many advantages, including convenience and ease of operation, the ability to work in almost any conditions, a wide range of work, and much more. In addition, the correct connection and use of pneumatic tools allows you to perform the necessary work as efficiently and quickly as possible. That is why pneumatic tools are used in many fields of activity - in construction and during repair and finishing work, in metalworking and mechanical engineering, mining and many other industries. In addition, such tools are especially popular in small businesses, service stations and private use.

Source

Lubricator for pneumatic tools. A small detail that works correctly

When working with any pneumatic equipment, it is necessary to ensure that purified air, which is enriched with oil particles, is supplied to the system.

A filter copes with the first task, but for the second, a lubricator for pneumatic tools is needed. With this device, the air flow is diluted with oil during the spraying process, and this greatly extends the service life of all equipment and reduces wear rates. This is especially important for those who are forced to regularly resort to the use of pneumatic devices (workshop employees, service stations, construction crews, etc.). Modern lubricators have an autonomous design; their system allows you to calibrate the supply of lubricants during operation;

thus, the pneumatic tool receives the required amount of fluid. During operation, you can control the oil level in the refill container. During operation, it is important to use the types of consumables recommended by the manufacturer: the use of low-quality or simply unsuitable oil leads to malfunctions not only of the equipment, but also of the lubricator itself.

Advantages of lubricators

After it has become clear what a lubricator for pneumatic tools is, you should understand the remaining nuances. The most important thing is the advantages:

- Due to the fact that all actions carried out must meet certain requirements and conditions, additional installation of a lubricant is required. It will reduce equipment wear and increase its operation.

- Lubricant enters the products automatically. This means that workers no longer need to waste their time pouring oil into the tool.

- Minimize the risk of operational downtime, which is a very common cause of various types of breakdowns.

- Most of the mechanisms produced are universal and compact. It is installed almost everywhere.

- People will no longer have to wonder what caused the breakdown of oil equipment if a lubricator is installed.

How to choose a lubricator for pneumatic tools?

Such designs should be purchased based on the characteristics of operation and the tasks to be solved. Key features to pay attention to:

If you have doubts when making a choice, it is better to consult with a specialist who can advise which device is most suitable for specific pneumatic equipment. After purchasing a lubricator, it is important to use the required brand of oil, which has the appropriate parameters (viscosity, alkalinity, etc.). It is necessary to check that water does not get inside, which causes corrosion of the housing, and periodically monitor the oil level.

How and with what frequency should pneumatic tools be lubricated?

However, there is another way - to install a mini-lubricator or air preparation unit on the device. For pneumatic tools, it is recommended to use special oil with special additives, because any other industrial oils have a negative effect on the rubber parts of the tool.

In addition to oil sprayers, there are other systems for lubricating compressed air with oil mist. The oil mist thus obtained has a high degree of homogeneity with a particle size of 0.3-2 µm. This significantly reduces oil consumption and also supplies lubricated air to devices located at a distance of up to 500 m.

Mobil Almo oil is a highly purified mineral oil based on paraffin and contains emulsifiers, anti-wear, adhesive and anti-corrosion additives. The product is designed to protect against aging and corrosion in hammer drills and other pneumatic tools.

Meets all tests and specifications developed for oils used in severe mining applications. It is approved by Ingersoll Rand Company, Joy Manufacturing Company and other companies.

For Camozzi industrial pneumatics, lubrication is not necessary, because... During manufacturing, a grease is added that is designed for the entire service life of the product. But if you do not use oil-moisture separator filters, then this substance is washed out over time by moisture in the air. If additional lubricant (lubrication) is already supplied to the system, then its supply cannot be stopped, because this lubricant also washes away the grease. The maximum amount of oil supply is 1 drop per minute for machines with medium speed. Recommended oil viscosity is 32 cSt at 40 degrees. Celsius.

The use of oil sprayers (lubricators) is necessary in cases where mechanisms are used in extreme conditions with a high frequency of operation - more than 40 times per minute, or with a high speed of movement - more than 1 m/s.

Lubricator for lubrication of pneumatic tools

A pneumatically driven tool, like any other, needs lubrication. As a rule, it is carried out using microdroplets of lubricants sprayed into the supplied compressed air. To create such an oil-air mixture, special lubricators are used. A portable microlubricator can be installed in a hose break or directly on a pneumatic tool. Stationary enrichment devices, designed to supply many consumers at the same time, are mounted on the wall next to the compressor.

The cost of the tool and what affects it

Once a specific model has already been selected, employees must choose the most relevant cost that will pay for itself quickly. Need a cheap product? It is better to look for a product with low-quality materials. But you have to be careful. If moisture gets on low-quality metal, it can cause corrosion.

Video: Review from the master

Do you need a brand from a domestic manufacturer? There are many suppliers on the Internet who install their devices at a lower cost than foreign companies.

Also, in simple construction stores it is easy to find a special device that meets the necessary standards.

What is a lubricator

A lubricator, or oil sprayer, is a device for creating a suspension of oil droplets in the compressed air supplied to drive pneumatic tools.

Not all compressed air consumers need to supply the oil-air mixture through a hose. It will render them unusable or interfere with normal functioning. For them, on the contrary, it is necessary to pass the air flow through an oil separator, which absorbs droplets of oil that enter it in the cylinders of a piston compressor. These are consumers such as:

But for pneumatic impact wrenches, hammers, scissors, scrapers - all consumers containing moving parts and converting the energy of compressed air into mechanical energy of rotation or reciprocating motion.

Features of pneumatic tools, their types, classification and characteristics

Pneumatic tools are devices that operate on compressed air for manual industrial use. Such devices are equipped with motors, which can be piston or rotary, and the air supply to them is provided by a compressor. In this case, the functioning of the compressor comes from the operation of engines using energy sources such as electricity, gasoline and diesel fuel.

In this regard, we can say that the operation of a pneumatic tool necessarily correlates with the use of additional equipment. Previously, such a tool was used exclusively in industrial areas: metal processing, road construction, mechanical engineering, etc. Now the situation has changed radically, since pneumatic tools began to be actively used not only in the construction of private houses, but also in everyday life. For example, you can use it to:

- construction and repair work;

- cutting and drilling;

- installation and dismantling;

- destruction of materials of varying degrees of strength;

- cleaning seams.

Design and principle of operation

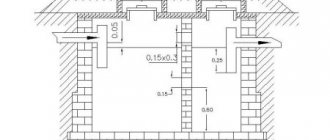

The design of the microlubricator is very simple. This is a metal cylinder mounted on the inlet pipe of a pneumatic tool on a threaded connection. Inside there is an oil container and a mixing chamber. The lubricant enters the chamber from a container connected by a pipe. The air flow passing through the chamber picks up its droplets and mixes them into an oil-air mixture. Next, air enriched with lubricant enters the inlet pipe of the pneumatic tool, lubricating it.

The stationary lubricator is somewhat more complicated, but its operating principle is the same.

IMPORTANT! The lubricator must be installed AFTER the moisture separator so that condensate and water vapor contained in the air mixture do not reach its inlet.

When designing air lines, one must take into account the limitation: the distance from the lubricator to the consumer should not exceed 8-10 m. Otherwise, the uniformity of mixing of the oil-air mixture will decrease, and droplets will begin to settle on the walls of the hose. The tool will not receive full lubricant. If longer hoses are required, it is better to install portable oil sprayers on the inlet pipes of air tools.

Why do you need a lubricator?

Compressed air is used to operate pneumatic tools, which are used in many production and repair areas. But the air leaving the compressor equipment is not ready for use without proper preparation. Condensation, oil and other contaminants in compressed air can cause significant damage to the instrument, significantly reducing its service life. Therefore, before feeding the air into the tool, it is necessary to clean it and add lubricant by installing a moisture separator and lubricator or a modular group in the pneumatic line, which provides comprehensive preparation.

More details about the preparation of compressed air are described in a separate article.

In most pneumatic tools, for example, pneumatic impact wrenches, pneumatic ratchets, pneumatic chisels, pneumatic screwdrivers, and so on, compressed air is used to start the drive (motor). Therefore, in addition to air purification, a special oil must be supplied to the air flow, which provides lubrication of the rubbing internal mechanisms.

Varieties

Lubricators offered for pneumatic tools can be classified into several categories

First of all, by design:

Based on tank volume:

According to the material from which the tank and mixing chamber are made:

By connecting size, inches.

There is special equipment for large production complexes for large thread sizes. There are also devices with external and internal threads. It is necessary to pay attention to these nuances when configuring the equipment.

Nailer care and lubrication

They are quite simple and consist of removing contaminants that periodically accumulate on working parts and careful handling. The tool must not be thrown. You need to make sure that no water gets into it. In short, mechanical deformation and damage must be avoided.

Everything said above can be attributed to any devices. As for the pneumatic nailer, it is also necessary to add that this type of tool needs to be lubricated. This is done according to the manufacturer's instructions. Most often, this procedure involves placing a few (2-3) drops of oil into the connecting fitting before starting work. This manipulation must be repeated in the middle of the working day if the tool is actively used.

If there is a long break in work, it is recommended to drop the same 3 drops into the nailer and take several shots to distribute the oil evenly. This will protect the inner surface from corrosion.

Criterias of choice

When choosing a device, you must be guided, first of all, by what work the equipment is required for and what its volume is. The purchase of equipment must, among other things, also be economically justified.

The following parameters are key:

If you do not have sufficient skills in handling pneumatic tools and organizing air lines, it is better to engage an experienced expert for consultation.

It is imperative to install a water vapor separator BEFORE the lubricator or distribution unit. Moisture entering the device will significantly reduce its performance. The quality of lubrication of pneumatic tools and its performance will also decrease. Prolonged operation in this mode will lead to breakdown and costly repairs.

During work, you should systematically check the oil level in the reservoir and replenish it in a timely manner. It is better to do this before starting work, so that you do not have to be interrupted in the middle of the working day.

Operating principle of an oil sprayer (lubricator)

The oil sprayer (lubricator) must be supplied with air pre-cleaned from compressor oil and moisture. The figure shows the design of the oil sprayer. If air is supplied to the oil sprayer (lubricator), but there is no air consumption, then equal pressure is established in cavities A and B. The oil sprayer (lubricator) does not work and no oil is sprayed. With the advent of air flow in the oil sprayer, two air flows are formed. The main flow from the inlet, bending membrane 6, passes through the windows and goes directly to the outlet of the oil sprayer. The rest of the flow passes through hole 7, flows around nozzle 8 and, thanks to the suction action of the main flow, also enters the outlet. When flowing around nozzle 8, the auxiliary flow sucks air through it from cavity A, reducing the pressure in it. Under the influence of the higher pressure of cavity B (the pressure in this cavity is equal to the main one), oil from glass 1 rises through tube 9, passes through check valve 5 and from inlet 10 drops fall into the conical hole of nozzle 8. The frequency of drops falling when air flows through the oil sprayer is regulated throttle 4 installed on the communication line between cavities A and B. The frequency of drops falling is also affected by the air flow through the oil nozzle and the oil level in the glass. To reduce the influence of compressed air consumption on the intensity of falling oil droplets, a flexible membrane 6 is used, which automatically adjusts the flow area through the oil sprayer, thereby maintaining the required air flow rate in hole 7. When droplets fall from nozzle 8, the oil is initially sprayed, and the air is drops of oil are carried to the outlet of the oil atomizer, where they meet the main air flow, this leads to re-atomization of the oil, which makes it possible to obtain the smallest drops of oil suspended in the air. If there is no air flow through the oil sprayer, the pressure in cavities A and B is equalized, and the fall of oil drops from nozzle 10 stops. In this case, the ball check valve 5 prevents the oil level from decreasing in pipeline 9 (due to pressure equalization in cavities A and B), due to which the supply of oil for spraying begins immediately after air flow through the oil sprayer occurs.

Prices (price list) for oil sprayers - lubricators from 03/01/2013.

| Model | Crepe- | Max.input pressure, | Operating pressure, | Consumption | temperature , | Connecting thread | Weight, | Price, |

| SA-L20-08 | Vertical | 15 | 10 | 400 — 800 | 0 — 60 | G1/4″ | 0,20 | 462,00 |

| SA-L30-10 | Vertical | 15 | 10 | 800 — 1500 | 0 — 60 | G3/8″ | 0,24 | 658,00 |

| SA-L40-15 | Vertical | 15 | 10 | 1500 — 2500 | 0 — 60 | G1/2″ | 0,47 | 868,00 |

| SA-L40-20 | Vertical | 15 | 10 | 1500 — 2500 | 0 — 60 | G3/4″ | 0,47 | 952,00 |

| SA-L50-20 | Vertical | 15 | 10 | 2500 — 4000 | 0 — 60 | G3/4″ | 1,06 | 1414,00 |

| SA-L50-25 | Vertical | 15 | 10 | 2500 — 4000 | 0 — 60 | G1″ | 1,06 | 1414,00 |

The oil sprayer (lubricator) must be located as close as possible to the mechanisms being lubricated. In this case, the presence of kinks or sharp turns in the pipeline in the area from the oil sprayer to the lubricated mechanism is not allowed. When passing sharp turns, oil droplets in the pipeline are subject to centrifugal force, pressing them against the outer wall of the pipeline - this causes oil to settle on the walls of the pipeline and, as a result, a decrease in the amount of oil entering the lubricated mechanism. The range we offer includes two series of oil sprayers: L and LM series. Oil sprayers (lubricators) of the LM series are used to lubricate mechanisms with low air consumption up to 600 l/min. Filling of oil into oil sprayers of this series is carried out with the inlet pressure turned off. Oil sprayers (lubricators) of the L series are specially designed to work in harsh conditions on continuous operation mechanisms with high air flow rates of up to 12,000 Nl/min. Recommendations for choosing oil sprayers To select an oil sprayer, the company's catalog presents graphs showing the pressure drop across the oil sprayer (lubricator) depending on the inlet pressure and air flow through the oil sprayer (lubricator). For the oil sprayer (lubricator) to operate effectively, it must be selected in such a way that the pressure drop across it at the planned flow rate is 0.2-0.5 Bar. When the pressure drops below 0.2 Bar, it is necessary to select an oil sprayer (lubricator) with a smaller connection size and, conversely, select an oil sprayer (lubricator) with a larger connection size for a large pressure drop.

How to add oil

Before adding lubricant, you must disconnect the tool from the line and make sure that there is no residual pressure in its working parts. To do this, press the power button several times and allow the air to escape from the tool. Next, you need to open the lid and carefully, using a funnel, add lubricant from a small container. It is strictly not recommended to add silt from large canisters; spilling some of the oil and subsequent cleanup is almost inevitable. Many equipment and lubricant manufacturers include special measuring vessels with a spout in the delivery package. They are made of transparent plastic and allow you to measure the required amount at one time and carefully and without loss pour it into the container.

Sometimes novice users ask questions: is it possible to lubricate pneumatic tools without a portable lubricator? The answer is simple: only if a stationary lubricator is used.

Hose selection

The most tensile strength reinforced oil and petrol resistant rubber hoses. These are difficult to damage even with a car wheel, but they also have the highest price. Hybrid-polymer models with good performance characteristics are more accessible.

First of all, you should decide on the cross-section of the hose, which is selected in accordance with the recommendations of the tool manufacturer. In general, it is recommended to choose hoses with a diameter of 10 and 12 mm to avoid bottlenecks later. Two models with the same cross-section may have different strength and operating pressure characteristics, so it is worth checking these parameters for each position separately.

When operating a pneumatic line in a car service center, it is useful to use the most flexible hoses, because the “oak” line will cling to everything, break easier and be difficult to move around the room. The bendability parameter in the product characteristics is responsible for this property.

As for the form, there are three options:

Regardless of the shape and material of manufacture, it is not recommended to use hoses longer than 15 m, as this leads to loss of power.

What kind of oil to fill

Sometimes when purchasing lubricant lubricant there is a temptation to save money. Purchasing cheap oils of obscure origin from little-known manufacturers seems like savings only at first glance. Such a replacement will inevitably lead to disruptions in the operation of the oil evaporator, uneven saturation of the air flow with lubricant, deterioration of the lubrication conditions of the pneumatic tool, a decrease in its service life and failure.

You need to use exactly the oil that is recommended in the instructions for the tool, or oil from the list of analogues approved by the manufacturer for use.

Separately, it is necessary to ensure the cleanliness of the lubricant, the absence of chemical contaminants and mechanical inclusions. Such “additives” will damage the tool even faster.

Source

What kind of oil to pour into the lubricator. Oil for pneumatic systems (pneumatic tools). Inspections and repairs

For Camozzi industrial pneumatics, lubrication is not necessary, because... During manufacturing, a grease is added that is designed for the entire service life of the product. But if you do not use oil-moisture separator filters, then this substance is washed out over time by moisture in the air. If additional lubricant (lubrication) is already supplied to the system, then its supply cannot be stopped, because this lubricant also washes away the grease. The maximum amount of oil supply is 1 drop per minute for machines with medium speed. Recommended oil viscosity is 32 cSt at 40 degrees. Celsius.

The use of oil sprayers (lubricators) is necessary in cases where mechanisms are used in extreme conditions with a high frequency of operation - more than 40 times per minute, or with a high speed of movement - more than 1 m/s.

Pneumatic tools.

Each instrument on each air duct must be equipped with an air preparation unit, which consists of an oil and moisture separator, a pressure regulator, and an oil sprayer (lubricator). Installation should be carried out as close as possible to the instrument (up to 5 meters) and above it vertically. If there is no air preparation unit, lubricant can be directly poured into the lubrication hole on the tool, at least every half hour of operation. To lubricate pneumatic tools, use pneumatic oil with a viscosity of ISO VG 32 or VG 40.

Moisture in the air is detrimental to the rubbing mechanisms in the tool; it washes away the lubricant and causes corrosion of metal parts.

The use of compressor, engine, and transmission oil is strictly prohibited.

In the warehouses of our organization we always have oil for pneumatic systems and oil for pneumatic tools.

Oil sprayers (lubricators) are supplied with connecting dimensions ranging from M5 - G1″.

Working medium - air; design - two-chamber with a sprayer and regulator; materials - aluminum, technopolymer, NBR; recommended oil is Turbine No. 1 (ISO Vg32).

Typically, pneumatic equipment is used without an oil sprayer (lubricator), since it contains a grease designed for a lifetime. If drives are used in extreme conditions, for example, high frequency (up to 40 or more times per minute) actuation and movement speed (1 m/sec or more) or there is a need for high smoothness of movement, it is necessary to use air with atomized oil. Our company offers oil sprayers with a single spray of oil, which provide oil particles from 0.01 to 0.003 mm.

Device installation and configuration

Lubricator installation kit includes:

- liquid container with dosing device;

- bracket with a set of fasteners;

- connecting tubes;

- clamps, adapters, fittings.

The FLASHLUBE kit already includes a 500 ml container of oil.

Installation

The installation process involves selecting a suitable location under the hood of the car, where several points need to be taken into account:

- Before proceeding with installation, you must remove the battery terminal;

- the vessel must be mounted at a sufficient distance from the heated elements of the engine;

- the adjusting screw must be freely accessible;

- the tank must be mounted strictly vertically;

- the liquid level scale should be clearly visible;

- It is advisable to place the container below the vacuum system of the motor.

Lubricator installation diagram

Then mount the bracket and install the dropper. Then determine the insertion location of the supply fitting. For injection cars, the optimal point will be at a distance of 70-120 mm after the throttle valve. On carburetor engines, it is advisable to place the fitting directly behind the throttle valve.

If there are no standard holes for tapping, you need to drill a hole of a suitable diameter, then cut the thread and screw in the fitting. In this case, it would be good to use a sealant for threaded connections, and also to minimize the entry of chips into the intake tract.

When purchasing a kit with automatic control of liquid supply, it is necessary to install the electronic unit no further than 30 cm from the container, and it is important to take into account possible thermal loads. Then stretch and secure the wires to the reservoir, and also mount an LED to indicate the liquid level in the car on the dashboard

Then, according to the diagram, connect the connectors. Power can be taken from the gas injectors or the gas valve.

Adjustment

Dropper for HBO with mechanical feed adjustment

The procedure for setting up a dropper with mechanical feed adjustment comes down to setting the liquid flow rate. To do this, you need to fill the lubricator container with 400-450 ml of oil. Then, with the internal combustion engine running steadily at idle, using the adjustment screw, adjust the fluid flow rate to approximately 10-12 drops per minute. If the setting is done correctly, 1 ml of additive should be consumed per 1 liter of fuel.

To adjust the automatic feed, you need to use a flat screwdriver on the electronic control unit to turn the adjuster screw. The screw arrow should be turned in the direction of the number (from 1 to 9) of the corresponding engine power (kW or hp), according to the table.

Video on installing the LPG lubricator (in English):

Advantages of a mini-lubricator

The use of an oil sprayer is a prerequisite for the operation of pneumatic tools. Manufacturers in the user manual must indicate a list of recommended and compatible brands of lubricants.

The use of devices has the following advantages:

Automation of lubricant supply to pneumatic equipment. This saves working time spent on equipment maintenance. You just need to monitor the level of lubricant in the container. A high-quality oil-air mixture significantly reduces wear on the moving parts of pneumatic tools and increases its performance. In addition, the service life of equipment is significantly extended and non-productive costs for its repair are reduced. Reduced resource losses that occur during breakdowns and production stops

This is especially important for enterprises operating in continuous cycle conditions. Current designs of mini-lubricators are very compact and do not create interference or inconvenience when working with the tool throughout the entire shift. Multipoint devices allow simultaneous supply of up to 8 different consumers. For each, an individual mode of saturating the mixture with lubricant can be set.

Old models had a drawback - large weight and dimensions, which interfered with the worker’s movements and caused increased fatigue during prolonged work.

Linear lubricator for pneumatic tools, JONNESWAY, JA-7253

Linear lubricator for pneumatic tools, JONNESWAY, JA-7253

with delivery throughout Russia: Moscow, St. Petersburg, Rostov-on-Don, Nizhny Novgorod, Samara, Chelyabinsk, Yekaterinburg, Novosibirsk and other cities. A

- Abakan

- Azov

- Alexandrov

- Aleksin

- Almetyevsk

- Anapa

- Angarsk

- Anzhero-Sudzhensk

- Apatity

- Arzamas

- Armavir

- Arsenyev

- Artyom

- Arkhangelsk

- Asbestos

- Astrakhan

- Achinsk

B

- Balakovo

- Balakhna

- Balashikha

- Balashov

- Barnaul

- Bataysk

- Belgorod

- Belebey

- Belovo

- Belogorsk

- Beloretsk

- Belorechensk

- Berdsk

- Berezniki

- Berezovsky

- Biysk

- Birobidzhan

- Blagoveshchensk

- Bor

- Borisoglebsk

- Borovichi

- Bratsk

- Bryansk

- Bugulma

- Budennovsk

- Buzuluk

- Buynaksk

IN

- Velikie Luki

- Velikiy Novgorod

- Upper Pyshma

- Vidnoe

- Vladivostok

- Vladikavkaz

- Vladimir

- Volgograd

- Volgodonsk

- Volzhsk

- Volzhsky

- Vologda

- Volsk

- Vorkuta

- Voronezh

- Voskresensk

- Votkinsk

- Vsevolozhsk

- Vyborg

- Vyksa

- Vyazma

G

- Gatchina

- Gelendzhik

- Georgievsk

- Glazov

- Gorno-Altaisk

- Grozny

- Gubkin

- Gudermes

- Gukovo

- Gus-Khrustalny

D

Recirculation Air System Methods

- Derbent

- Dzerzhinsk

- Dimitrovgrad

- Dmitrov

- Dolgoprudny

- Domodedovo

- Donskoy

- Dubna

E

- Yegoryevsk

- Yeysk

- Ekaterinburg

- Elabuga

- Dace

- Essentuki

AND

- Zheleznogorsk

- Zheleznogorsk

- Railway

- Zhigulevsk

- Zhukovsky

Z

- Zarechny

- Zelenogorsk

- Zelenodolsk

- Zlatoust

AND

- Ivanovo

- Ivanteevka

- Izhevsk

- Izberbash

- Irkutsk

- Iskitim

- Ishim

- Ishimbay

Y

Yoshkar-Ola

TO

- Kaliningrad

- Kaluga

- Kamensk-Uralsky

- Kamensk-Shakhtinsky

- Kamyshin

- Kansk

- Kaspiysk

- Kemerovo

- Kineshma

- Kirishi

- Kirov

- Kirovo-Chepetsk

- Kiselevsk

- Kislovodsk

- Klimovsk

- Wedge

- Klintsy

- Kovrov

- Kogalym

- Kolomna

- Komsomolsk-on-Amur

- Kopeisk

- Korolev

- Kostroma

- Kotlas

- Krasnogorsk

- Krasnodar

- Krasnokamensk

- Krasnokamsk

- Krasnoturinsk

- Krasnoyarsk

- Kropotkin

- Krymsk

- Kstovo

- Kuznetsk

- Kumertau

- Kungur

- Mound

- Kursk

- Kyzyl

L

- Labinsk

- Leninogorsk

- Leninsk-Kuznetsky

- Lesosibirsk

- Lipetsk

- Liski

- Lobnya

- Lysva

- Lytkarino

- Lyubertsy

M

Oil filter VAZ 2107: what is it for and how to change it

- Magadan

- Magnitogorsk

- Maykop

- Makhachkala

- Mezhdurechensk

- Meleuz

- Miass

- Mineral water

- Minusinsk

- Mikhailovka

- Mikhailovsk

- Michurinsk

- Moscow

- Murmansk

- Moore

- Mytishchi

N

- Naberezhnye Chelny

- Nazarovo

- Nazran

- Nalchik

- Naro-Fominsk

- Nakhodka

- Nevinnomyssk

- Neryungri

- Neftekamsk

- Nefteyugansk

- Nizhnevartovsk

- Nizhnekamsk

- Nizhny Novgorod

- Nizhny Tagil

- Novoaltaysk

- Novokuznetsk

- Novokuibyshevsk

- Novomoskovsk

- Novorossiysk

- Novosibirsk

- Novotroitsk

- Novouralsk

- Novocheboksarsk

- Novocherkassk

- Novoshakhtinsk

- New Urengoy

- Noginsk

- Norilsk

- Noyabrsk

- Nyagan

ABOUT

- Obninsk

- Odintsovo

- Ozyorsk

- October

- Omsk

- Eagle

- Orenburg

- Orekhovo-Zuevo

- Orsk

P

- Pavlovo

- Pavlovsky Posad

- Penza

- Pervouralsk

- Permian

- Petrozavodsk

- Petropavlovsk-Kamchatsky

- Podolsk

- Polevskoy

- Prokopyevsk

- Chill

- Pskov

- Pushkino

- Pyatigorsk

R

- Ramenskoye

- Revda

- Reutov

- Rzhev

- Roslavl

- Rossosh

- Rostov-on-Don

- Rubtsovsk

- Rybinsk

- Ryazan

WITH

- Salavat

- Salsk

- Samara

- Saint Petersburg

- Saransk

- Sarapul

- Saratov

- Sarov

- Free

- Severodvinsk

- Seversk

- Sergiev Posad

- Serov

- Serpukhov

- Sertolovo

- Sibay

- Slavyansk-on-Kuban

- Smolensk

- Solikamsk

- Solnechnogorsk

- Pinery

- Sochi

- Stavropol

- Stary Oskol

- Sterlitamak

- Stupino

- Surgut

- Sizran

- Syktyvkar

T

- Taganrog

- Tambov

- Tver

- Timashevsk

- Tikhvin

- Tikhoretsk

- Tobolsk

- Tolyatti

- Tomsk

- Troitsk

- Tuapse

- Tuymazy

- Tula

- Tyumen

U

- Nodal

- Ulan-Ude

- Ulyanovsk

- Urus-Martan

- Usolye-Sibirskoye

- Ussuriysk

- Ust-Ilimsk

- Ufa

- Ukhta

F

Fryazino

X

- Khabarovsk

- Khanty-Mansiysk

- Khasavyurt

- Khimki

H

- Chaikovsky

- Chapaevsk

- Cheboksary

- Chelyabinsk

- Cheremkhovo

- Cherepovets

- Cherkessk

- Chernogorsk

- Chekhov

- Chistopol

- Chita

Sh

- Shadrinsk

- Shawls

- Mines

- Shuya

SCH

- Shchyokino

- Shchelkovo

E

- Elektrostal

- Elista

- Engels

YU

- Yuzhno-Sakhalinsk

- Yurga

I

- Yakutsk

- Yaroslavl

Delivery

Courier delivery:

Term:3-5

days in Moscow from

350 rub.

, outside the Moscow Ring Road: Delivery calculator ▼

Distance from MKAD:

Item weight: kg

Cost of delivery 180

rub

Transport company:

from Moscow Delivery information ► (Dispatch of TC is carried out on 100% prepayment)

Delivery distance:

Item weight: kg

Cost of delivery 180

rub

Pickup: Entrance and entry into the territory - Free.

Address:

Moscow, Kyiv highway, 22nd km, house. 4, building 4, floor 3, building D, entrance 20, warehouse 359a Directions ►

Payment

Choose the most suitable payment method for yourself Read more ▼

| Payment to the courier (cash/card) | Electronic money transfer | Cashless payment (for legal entities) |

Types and cost of lubricators

There are two types of lubricators for cars with LPG:

- with distributed supply;

- with general supply.

Lubricator for distributed oil supply

They also come with mechanical or electronic control of the fluid flow.

Table of manufacturers of lubricators and liquids for them, with prices:

| Lubricator manufacturer | Type of liquid supply | Control | price, rub. | Liquid manufacturer | Cost per 1 liter, rub. |

| Flashlube | general | electronic | 9800 | Flashlove | 1500 |

| Flashlube | general | mechanical | 3800 | GasLube (Digitronic) | 780 |

| JLM | distributed | mechanical | 6170 | Valvex | 1050 |

| Supap Oil | general | mechanical | 3590 | Liqui Moly | 1020 |

| Supap Oil | 980 |

What is it and what is a dropper for?

A tank is mounted in the engine compartment, from which the liquid flows through a pipeline (via vacuum at the inlet) into the intake manifold of the internal combustion engine. Next, mixing with air, passing through the open intake valve of the cylinder head (at the intake stroke), the mixture follows into the combustion chamber, from where, after the piston stroke, lubricant particles fall on the surface of the valve head and its seat. This is how lubrication/cooling of loaded parts occurs.

Manufacturers claim an increase in the service life of valves and their seats, which is achieved by a number of advantages of this device:

- reduction of thermal overloads of the seat-valve interface;

- preventing valve burnout;

- protection against seat subsidence;

- cooling, lubrication, cleaning of working mating surfaces.

In addition, the developers claim that the additive reduces harmful exhaust emissions, cleans fuel injectors and even reduces fuel consumption.

Is it really? There is no reliable information from open sources about any laboratory tests that have a clearly positive result. However, this system is widely used in Europe, America and not only on cars with gas equipment. But, as we know, the operating conditions, as well as the quality of the fuel, be it propane, methane, gasoline or diesel, are not comparable to ours.

Having studied the opinions of car owners who use a dropper, one can understand that there are those who see obvious benefits, there are those for whom there is no difference, but they were convinced of the positive effect of the lubricator when installing LPG. There is also an opinion that a dropper for HBO is a complete scam of money by manufacturers and installers, and the remedy for valve burnout is the correct setting of the gas installation and the installation of a UOZ variator.

One way or another, we cannot claim a negative effect when using the cooling system and valve lubrication. There are only a few questions to which there are no clear answers yet:

- how is a uniform distribution of oil portions achieved across the engine cylinders;

- why do we need additional lubrication of the working surfaces of the valves, if the standard internal combustion engine lubrication system already takes into account the supply of so-called “oil mist” into the intake tract;

- We consider the developers’ statements that the temperature load is reduced by 5-10 degrees when using a lubricant with HBO to be insignificant.