Today, welding is one of the most popular technologies for connecting metal structures, since uniformity of the material in the bonding areas can only be achieved by welding. The resulting welds ensure reliable connection of individual elements of metal structures and do not allow moisture to pass through. The procedure for cleaning welds after welding plays an important role in this regard.

It should be understood that no matter how strong the welded joint turns out, this section will always be the weakest point of the metal structure. Therefore, it needs to be protected from premature destruction.

Cleaning of welded joints is a mandatory step after welding work, which is regulated by GOST 9.402-80. To carry out this type of work, different technologies can be used that have different effects on the metal surfaces being processed, for example, mechanical grinding, chemical etching, neutralization.

Methods

You can get rid of welds on metal in various ways:

- heat treatment;

- mechanical restoration;

- chemical treatment.

Heat treatment

It is used if it is necessary to clear residual stresses in the internal part . This type of processing is required after welding thin-walled metal structures. To carry out this procedure, you should slightly heat the part and then cool it according to a given temperature schedule.

This method is carried out in three stages. At the first stage, you need to heat the area around the weld, then you need to leave the element heated for a short time, at the end everything cools down. This method allows you to restore the properties of the material (ductility and strength), relieve internal stress and ensure the durability of the weld. But at the same time, it also has a number of disadvantages: irreversibility (if you were unable to carry out the treatment in accordance with the temperature schedule, then it will be almost impossible to correct the defect), such a procedure requires expensive professional equipment.

Heat treatment allows you to silently remove all slag from the seams.

To control the temperature regime, you can use various units: a pyrometer and a thermal imager (electronic devices, they measure the necessary indicators remotely), thermal paint and a thermal pencil (change their color when the temperature changes).

Mechanical restoration

This method allows you to remove slag, metal spatter and scale from welding seams by grinding. For the mechanical type, you will need either a strong wire brush or a special abrasive disc. In industrial enterprises, such elements are fixed in grinding machines (often in everyday conditions such a device is called a grinder). Before processing, it is worth choosing a suitable circle.

The best option for welds on stainless steel is aluminum zirconate, since it does not have a corrosive effect on such products. Special petal abrasive attachments are also often used. The latter should have petals created on a fabric basis. They are considered the most reliable compared to other varieties. Elements with petals on a fabric basis and coated with aluminum zirconate have a relatively high cost, but their cleaning is also distinguished by a special level of quality.

The simplest and cheapest option would be paper-based attachments. Most often they are made with aluminum oxide coating. But the price level will fully correspond to the level of quality of sanding the seams. Remember that such attachments should be selected taking into account the type of work. If you need to clean seams in hard-to-reach places in corners of complex metal structures, then it is better to take a small size of the abrasive element of the nozzle.

To file down the topmost coarse layer with scale and slag, it is permissible to use the largest size nozzle. In this case, it will not be able to damage the material itself.

Finishing is always carried out with the smallest grinding tool, so when carrying out such procedures several types of attachments of different sizes will be used.

Chemical treatment

The best result can be achieved by combining mechanical and chemical treatment of seams. The latter can be done by etching or passivation. This type is convenient for stripping at an angle. Etching most often acts as a preparatory step before machining. It must be performed using special chemicals. They will create a reliable coating that is resistant to corrosion.

In addition, this procedure makes it possible to remove places where oxidized chromium or nickel accumulates. If they are not removed promptly, they may become corroded. If the welds are small, then you can simply apply a chemical composition to their surface. Sometimes the part is completely dipped in the substance. After etching, passivation should be performed, which will give the metal additional strength. Passivation is the treatment of a part with a special solution, which allows the formation of a protective film on the surface of the product, which prevents the formation of a corrosive layer.

After chemical treatment, be sure to wash off all remaining solutions with water. In this case, wastewater must be disposed of as carefully as possible. After all, the liquid will contain a large amount of harmful heavy metals and acids. They can be slightly neutralized with alkalis.

Afterwards, all this is carefully filtered and only then poured into a safe place.

Heat treatment

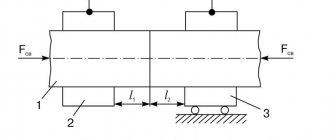

Heat treatment of welded joints must be carried out after welding thin-walled products that are especially susceptible to deformation under the influence of internal stresses. Such structures include pipelines, various containers, and pressure vessels.

Heat treatment of the weld

Heat treatment is also carried out for most critical structures, such as nuclear and chemical reactor vessels.

Heat treatment consists of heating the part and then cooling it according to a strictly specified temperature schedule.

Why is it needed?

During welding, a small area of the part near the seam is heated. Uneven heating leads to the emergence of internal stresses that can deform or even destroy the part. In addition, in the zone of uneven heating, the structure of the metal crystal lattice changes, which leads to a deterioration in its physical, mechanical and chemical properties.

Near the weld seam there is a hardening zone in which the strength is increased and the elasticity, on the contrary, is decreased. It is surrounded by a zone of softening, in which ductility is preserved, and the strength becomes lower than it was before welding.

Heat treatment of welded joints is designed to restore the internal structure of the metal and its properties, return the characteristics of strength, ductility and corrosion resistance to design values.

Features of the event

Processing is carried out at high temperatures, in the range of 600-1000 °C. This makes it possible to overcome the negative consequences of uneven heating and bring the structure of the weld and heat-affected zone closer to the structure of the part itself.

Processing takes place in three stages:

- The area near the seam heats up.

- The structure is kept in a heated state for some time.

- The product is cooled in accordance with the processing schedule.

Features of cleaning welding seams

Welding is one of the most common methods used to join metal parts. This is due to the fact that it allows high-quality and reliable fastening of parts of the product, forming a uniform seam that does not allow moisture to pass through.

We recommend: Using copper sulfate to protect wood

Nevertheless, it is the seam that is the weak point of any structure, especially if the edges for welding were not prepared correctly. Therefore, it is very important to follow all technological processes in order to obtain a reliable connection of parts.

- Features of cleaning products after welding

- Mechanical cleaning

- Chemical purification of the compound

- Bottom line

Features of cleaning products after welding

The final stage of welding work is to clean the joint from slag and scale.

This procedure is performed in several stages:

- seam treatment;

- antioxidant polishing;

- tinning the connection.

The first stage is performed to eliminate defects. These include holes, craters, fistulas, and cracks in sutures.

Main types of welded joints.

There are three main methods for processing a weld seam:

- thermal;

- mechanical;

- chemical.

The first method allows you to significantly reduce or completely eliminate residual stresses in the metal after welding. Heat treatment can be carried out in accordance with two technologies: local - only the joint area is heated, and general - the entire part is heated.

In addition to reducing stress, thermal annealing makes the structure of the seam and the area around it more resistant to external factors. In addition, the performance indicators of the product increase: corrosion resistance, heat resistance, etc. increase.

The essence of heat treatment is to heat a joint or part to a certain temperature. The product is then cooled at the required rate, depending on the type of part.

Heat treatment is carried out using specialized equipment.

There are four types of devices for performing this procedure:

- Induction units are used for pipelines. The operating principle of such devices is the use of air-cooled stranded copper wires that make up the inductor. The inductor is installed on the pipeline at a certain distance from it. The larger the gap, the worse the power of the device is used, so it should be installed flush to the weld.

- Flexible resistance heaters are one of the most common devices.

- Muffle furnaces. This type of device requires special attention to control the uniformity of heating of the product. Off-center installation of a part in a furnace can lead to disruption of heat treatment technology.

- Processing using gas-flame equipment. This method uses gas flame burners.

Tools that enable heat treatment are selected based on installation conditions, availability, and other factors. The main criteria that such units must satisfy are compliance with the set requirements, clear joining with seams, uniform heating of the joints, and low weight.

Quite often, to avoid heating losses, various heat insulators are used.

Defects in welds.

There are several metal processing technologies. Preheating is used both before and during welding when working with low-carbon steels.

High tempering involves heating the material to 650-750 °C. The exact temperature value is determined by the grade of steel. This treatment lasts up to five hours and reduces stress by 80%!, and also increases the elasticity and resistance of the metal to mechanical loads.

Normalization is applied to carbon and low-alloy steel grades. The process is carried out at 950 °C. Upon completion of processing, the part is held and cooled under normal conditions. As a result, grain size and stress are reduced and joint strength is increased.

Mechanical cleaning

An important stage of welding is not only the implementation of preparatory work, but also the correct cleaning of the welds. This process is mandatory and is enshrined in the relevant GOST.

Symbols for welds.

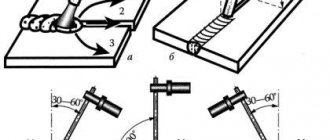

So how do you clean a welded joint? The easiest way to clean a weld is to simply brush with a wire brush. However, using a portable sander or a simple grinder with a sanding wheel for stripping will be more effective.

This simple processing method will allow you to get rid of the most common defects, which include scale, oxides, traces of tarnish, and burrs. As a result, the joint of the workpiece will be of higher quality.

We recommend: How to choose a compressor for a sandblaster

In terms of price-quality ratio, this technology is one of the most profitable methods for preparing edges before and after welding. In this regard, it is not surprising that most masters use this method.

When choosing a grinding wheel to clean a seam after welding, it is important to take into account some nuances, otherwise you should not expect a good processing result. Preference should be given to attachments with fabric-based petals.

It is characterized by higher wear resistance compared to paper versions, which is necessary in such an aggressive type of work as grinding welding joints.

It should be borne in mind that fabric-based attachments with this coating are expensive. However, in this case it is better not to save money, because with the right tool the job will be easier and the end result will be of better quality.

Chemical purification of the compound

As already described above, mechanical processing allows you to achieve acceptable results, however, the best quality of cleaning the weld after welding is achieved when this method is combined with chemical cleaning. This includes etching and passivation.

Chemical for cleaning seams.

Etching is carried out using specialized compounds. They allow you to obtain a uniform anti-corrosion coating on the surface of the product. In addition, areas with tarnish are removed - places where chromium and nickel oxides accumulate, which are characterized by low corrosion resistance.

Small areas of the seams to be treated are etched by simply applying the compound to the required area. In some cases, the product is completely dipped into a container with a special solution. The interaction time of the part with the mixture is different in each specific case and is selected individually.

Passivation is the process of treating a metal product with a special solution. As a result of this process, a protective film is formed on the treated surface of the part. A distinctive feature of the resulting coating is its resistance to corrosion.

The essence of this technology for cleaning edges for welding is the use of mild oxidants. As a result of interaction with stainless steel, free metal is removed from its surface and the formation of a protective coating on the surface of the product is activated.

Passivation can be carried out using sprays for treating stainless steel or a special paste.

The fact is that such water contains an increased amount of acids and heavy metals, so such wastewater is characterized by an increased danger to the environment. First, acids should be neutralized using alkaline solutions, and then the water should be filtered. The resulting waste must be disposed of.

To understand how to properly clean welding seams, you need to familiarize yourself with GOST, which describes in detail the technology for processing joints. There are two main methods for cleaning a weld seam: mechanical treatment and chemical treatment.

In the first case, the metal, for example stainless steel, is subjected to grinding and polishing. In the second case, etching and passivation technology is used. Special solutions are used to pickle stainless steel after welding. Most often, these methods are combined to achieve the best results.

Mechanical cleaning of the weld

The simplest option for mechanical cleaning is manual cleaning with a wire brush. However, such processing is much simpler and more effective when performed with a portable grinding machine or an ordinary grinder equipped with a flap sanding attachment or an abrasive wheel. Using this method you can get rid of many weld defects:

- scale;

- oxides and burrs;

- traces of discoloration.

This technology is loved by many welding professionals also because it is perhaps the most profitable in terms of price-quality ratio.

However, it is very important to choose the right grinding wheel, otherwise you cannot count on excellent results.

The best material for treating welds on stainless steels is aluminum zirconate because it is non-corrosive to the metal and is significantly stronger than aluminum oxide, also used to make flap abrasives.

It is also important that the petals have a fabric backing, because it is more reliable and durable than a paper backing, which is necessary for such an aggressive type of work as grinding welds. It should be noted that nozzles with a fabric base, and even coated with aluminum zirconate, are much more expensive than conventional paper nozzles coated with aluminum oxide, but the price is worth it - the work will be easier and more efficient. In addition, the use of such attachments minimizes the possibility of the formation of a corrosion center at the grinding site, which is very important for the high-quality performance of important work.

Depending on the scale and subtlety of the work being performed, you should use attachments with different abrasive grain sizes - the product line of the main manufacturers offers a variety of grain sizes, so you need to have several sizes in your arsenal. Moreover, to perform high-quality work, sequential processing with different attachments will be required to reduce the grain size.

So, for example, to roughly remove the main layer of scale or metal deposits, you need to use nozzles with the largest grains, then finer processing is performed with a nozzle with finer grains, finishing processing is done with the finest abrasive grains.

In this case, the size must be changed sequentially; no more than one size can be skipped. And if you need to achieve mirror-like evenness and shine of the weld, then it is forbidden to skip even 1 size. Otherwise, untreated risks may appear, and all work will have to start from the very beginning.

Grinding welds in hard-to-reach places - cavities, holes, on thin edges - is difficult and at the same time responsible; special tools are used here - burrs, which are mounted in a straight grinder. Burrs come in many different shapes and sizes, so choosing the right tool for the job is easy.

Cleaning the Seams After Welding with a Grinder

We clean up the weld seam after welding

Nowadays, welding is one of the popular technologies for joining metal structures, because the homogeneity of the material in the fastening areas can only be achieved by welding. The resulting welds ensure reliable connection of individual parts of metal structures and do not allow water to pass through. The procedure for cleaning weld seams after welding plays an important role for this purpose.

Cleaning of welded joints is an essential step after welding work, which is regulated by GOST 9.402-80. To carry out this type of work, various technologies will be used that have different effects on the iron surfaces being processed, for example, mechanical grinding, chemical etching, neutralization.

Technologies for cleaning weld seams

There are three main methods for cleaning joints after welding:

- Heat treatment . The method allows you to remove residual stresses from the material that are formed during welding. Heat treatment is of two types: local (heating/cooling of only the weld itself is carried out) and general (heat treatment of one hundred percent of the entire iron structure).

- Processing by mechanical method . Residual slag is removed from the surface of the material, and the cleaned seam is checked for strength. For example, the welding joint is cleaned of slag formation and tapped with a hammer.

- Chemical cleaning . A special anti-corrosion material is applied to the area where the elements of their metal structure are connected. For example, welding seams are treated with a primer paint and varnish composition.

We recommend: Choosing a sandblasting gun

It’s important to keep it in mind! Residues of slag in the joint will contribute to the development of metal corrosion.

We draw the seam to the standard. Welding area

Support the project: account P87010548 (by any method convenient for you) WebMoney Z118921972326.

How to properly process welding seams

How to properly process welding seams

#painting #autopainting #how topaint #garage #onb #brest #autorepair.

Cleaning up welds after welding must be approached personally and the equipment and consumables must be selected correctly.

For example, the tool will find application:

- regular brush for metal;

- special grinding machine;

- angle grinder with abrasive wheels.

Example:

- In the shipbuilding industry, mobile-type grinding machines are well used, because it is much easier to drive up to a fairly large iron structure than to constantly move the tool from one site to another.

Machining development

The manual method of mechanically cleaning a weld seam is the most common. For this purpose, you only need to have an ordinary iron brush. However, it is easier and more efficient to clean surfaces using a special grinding machine equipped with an abrasive wheel (special grinding attachment).

Mechanical cleaning of the weld after welding allows you to eliminate subsequent defects from the metal: burrs, oxides, scale, traces of tarnish. This technique is especially popular among welders due to its low cost.

However, in order for the job to be done perfectly, it is important to choose the right grinding attachment.

Aluminum zirconate is the ideal material for cleaning welded joints of steel products, because it is superior in strength to aluminum oxide and does not expose the metal to corrosive effects.

Development of chemical processing

The most efficient and effective method for cleaning welded

connections - this is the introduction of mechanical and chemical processing (passivation, etching).

Etching stripping

Cleaning of welds by etching is carried out before performing mechanical grinding of the surface. For this purpose, you use a special composition, so that a homogeneous layer is formed on the treated metal surface.

The etching technology can of course be used both for cleaning the specific joint of a welded joint, and also for processing the entire area of the iron workpiece.

This method eliminates tarnish on the metal that formed during welding work .

Types of heat treatment

Types of heat treatment of welds differ in their purpose. Experts distinguish the following processes:

- Rest. The structure is brought to 300 °C and kept for one and a half to two hours. Reduces mechanical stress and reduces the hydrogen content in the weld material.

- Vacation. Consists of heating up to 700 °C and holding for three hours. Almost completely relieves stress and makes it possible to increase plasticity.

- Normalization. The entire structure, including the seam, is heated to 800 °C and held for 30-40 minutes. Allows you to achieve uniformity and fine-grained metal structure. Used on products of small thickness.

- Austenization. The product is heated to 1100 °C and held for 120 minutes. Cooling is carried out at room temperature. Increases the ductility of high-alloy alloys by transforming their crystal structure.

- Annealing. Heating to 960 °C, holding for three hours and cooling at room temperature. Used for high alloy alloys to improve corrosion resistance.

Induction tempering of the weld

Preparing pipes for weld normalization

As a rule, the welded joint is cleaned before heat treatment.

Temperature control

When carrying out heat treatment, the heating temperature of the structure is of key importance. To control the temperature use:

- Thermal pencil and thermal paint. They are a chemical compound that changes color as temperature changes. Applied to the surface of the product.

- Thermal imagers and pyrometers. Electronic devices that measure temperature remotely.

Thermal pencils and thermal paint are traditional means that are quite labor-intensive to use and require constant visual monitoring by the operator and his prompt intervention if the parameters go beyond acceptable values.

Thermal imagers and pyrometers are more accurate and can be integrated into an automatic system for maintaining a constant temperature.

Processing methods

There are three methods by which welded joints are protected:

- Heat treatment. Thanks to this method, it is possible to remove residual stresses in the material resulting from welding work. Heat treatment is carried out using one of two technologies: local, when only the connection itself is heated or cooled, or general - the entire part is subject to temperature treatment.

- Mechanical restoration. In this case, the task is to remove slag residues and check the reliability of the connection. A typical example of machining is tapping a seam with a hammer or sanding it. If the slag is not removed, corrosion may develop.

- Chemical treatment. Applying protective coatings to joints is one of the ways to combat corrosion processes. The most affordable option for chemical protection is treating the seam with a primer paint and varnish material.

Below we will look at weld protection technologies in more detail.

Peculiarities

Cleaning the weld seams after welding is a necessary procedure. During such work, metal elements are strongly heated to the melting point, which leads to internal stress and a change in shape. In addition, small particles and slag will form on the seams. Currently, there are a large number of various methods and methods that allow you to remove welds from metal products. This can be done using special tools (sandpaper, milling cutter) or manually using wire brushes.