How is ultrasonic testing carried out?

The method is more often used to control the strength of welds. An ultrasonic weld flaw detector operates on the following principle. Certain deformations, called acoustic or elastic waves, propagate into the thickness of the metal. They come in several types:

- infrasound;

- sound;

- ultrasonic;

- hypersonic.

During the propagation of ultrasound, the medium through which it diverges performs measured oscillations relative to the equilibrium point. Longitudinal and transverse vibrations can act in solid bodies. Both types of waves allow you to control the strength of welds as accurately as possible. The speed of delivery and propagation of ultrasound directly depends on the strength and internal environment of the material under study. The intensity of the sound waves can be controlled.

As the sound wave travels, its intensity subsides. The density of the material can be judged from the rate at which this occurs. The device shows the ultrasonic attenuation coefficient, forming it based on their scattering and absorption indicators. The accuracy of the readings is high, which allows you to get a clear picture of the quality of welds, metal, and other solid materials.

Methods of use

The visual method of inspection with a laser scanner is used in the following cases:

- identification of cracks, traces of corrosion and erosion , ulcers, pores, nicks on the surface of the material;

- detection of major damage, traces of deformation of invisible structural parts , contamination, depressurization;

- searching for foreign objects or damaged areas inside products;

- inspection of the nature of damage detected by another flaw detection method.

It is used to control the location and quality of welded joints in optical and ultrasonic examination.

Optical method

When visually inspecting a seam, the instrument is held along the joint. In this case, the device is positioned so that the scanner beam crosses the joint perpendicularly. A special program analyzes the displayed image about the state of the welded joint and emits a signal if the tested surface does not meet the established tolerance standards.

Ultrasonic method

During ultrasonic testing, the device is used to constantly monitor the location of ultrasonic sensors and fix them in the optimal position for testing.

How does an ultrasonic weld flaw detector work?

Science knows only a few ways to work with ultrasonic devices to control the density of welds and other metal compounds. Their differences are only in the method of assessing the information received. Any type of data assessment complies with the current GOST.

Ultrasonic testing equipment: operating principle

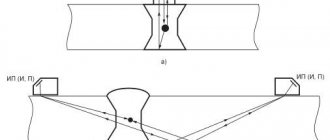

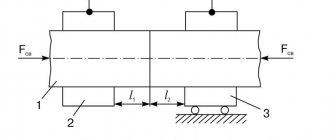

Devices used for ultrasonic testing of pipes and metal structures operate on a similar principle. The main working element is a piezoelectric sensor plate made of barium titanite or quartz. The piezoelectric sensor is located in the probe - it is placed along the connections and smoothly moved in a reciprocating motion. While the probe is moving, a high-frequency current flows to the plate, which is why it emits ultrasonic vibrations perpendicular to its length.

The reflected waves are received by the same plate with a receiving probe. It converts the oscillations into alternating current, which immediately rejects the wave on the oscilloscope monitor. As a result, an intermediate peak appears. During ultrasound diagnostics, the sensor sends short alternating pulses of elastic vibrations with different durations, which are separated by pauses. Due to this, the presence and depth of the defect is determined.

Ultrasound source

Despite the different methods of collecting analytical data, ultrasonic metal flaw detectors use a similar method of operation. The main part of the device is a plate made of quartz or titanium barium. The plate is located in a special probe (search head). The probe is slowly moved along the surface under study, recording the wave extinction coefficient. The wave is supplied due to the action of an electric current, as a result of which ultrasound beams are generated. Based on the data obtained, we can talk about the density of the connection, the presence of defects, cavities, cracks, and other unnecessary deformations.

Disadvantages of ultrasonic testing

All non-destructive testing methods have their disadvantages and limitations. Ultrasonic flaw detection is no exception. Among its disadvantages:

- It is impossible to establish the real size of the defect.

- If ultrasonic testing of metal with a coarse-grained structure is carried out, difficulties may arise. The reason is significant scattering and strong attenuation of waves.

- The need for special surface preparation before introducing ultrasonic pulses into the metal.

- The person taking measurements with the device must be highly qualified.

- If the surface of the test sample is rough, there are irregularities on it, or the product is too small in size, thickness or irregular in shape, then measurements with a flaw detector are quite difficult.

- To conduct the study, it is necessary to ensure direct contact between the product and the device.

Diagnostic stages

Before starting the study, it is necessary to clean the metal from corrosion, paint, and other foreign matter. There is no need to clean the entire surface. It is enough to maintain a gap of up to 70 centimeters. In this form, the material is already ready for diagnostics, but it would be better to additionally ensure ultrasound permeability. For these purposes, grease, oil, glycerin, and other liquids containing fatty inclusions are used.

Before starting work, an ultrasonic weld flaw detector must be configured to achieve specific goals. There are several options here:

How to achieve the most accurate research results?

To obtain more accurate data, it is necessary to move the flaw detector probe in a zigzag manner along the surface of the material being examined. In this case, it is advisable to rotate the probe at least 10-15% around the axis of the metal. If the device emits any uncharacteristic vibrations, it is necessary to turn the probe as far as possible in the indicated place so that it becomes possible to accurately determine the dislocation of a poor-quality connecting seam. The search continues until the location of the matter where the ultrasound peak is highest is determined.

It should be taken into account that the ultrasound diagnostic device may produce errors due to wave reflection from the seams. For this purpose, additional research methods are used. If several diagnostic methods lead to the same answer, you can record the defect by recording the coordinates of the flaw. Equipment manufacturers, based on the requirements and rules of GOST, recommend diagnosing the same object at least twice with different devices.

The data obtained during operation of the ultrasonic flaw detector is recorded in a special journal or table. This allows you not only to quickly eliminate a flaw in the connection, but also to speed up re-diagnosis, because potential problem areas are already known.

Ultrasonic thickness gauges

The installation of ultrasonic testing makes it possible not only to determine defects in the sample, but also to measure the thickness of the material or its paint coating without violating the integrity of the latter.

Thickness is measured using a probe that is applied to the desired point. After this, the device turns on. High-frequency vibrations, having passed through the coating and hitting the surface, are reflected from it. Most often the surface is metal. The reflected vibrations entering the sensor are analyzed, and the path traveled by the pulses is calculated.

Thus, the thickness of the coating is determined. But this method is used not only to estimate the size of a layer of varnish or paint; it is used to determine the thickness of the metal workpiece. The method has many advantages. The main one is that measurements are made without damaging the surface. It does not need to be scratched, cut, etc.

Another advantage is the ability to determine the thickness of products in which only one side is accessible for research and it is impossible to place it between the measuring bolts. For example, it is very convenient to carry out ultrasonic testing of pipes, or rather, the thickness of their walls.

An important advantage of the devices is their compactness; they can be brought to any surface under study. Measurements are made as quickly as possible; almost anyone can do this; no special skills are required, although they are welcome. There is also no need to apply physical force. Such equipment has a very affordable price.

Defects that are accurately detected by ultrasound diagnostics

Inspection of welding seams, carried out using ultrasonic devices, gives a clear picture of the situation. Correctly performed work with the device almost 100% guarantees the accuracy of answering questions. But, nevertheless, the scope of use of the equipment has some limitations.

Problems that can actually be detected by an ultrasound sensor:

Diagnostics is most accurate if applied to the following types of metal:

Sutures that can be examined using ultrasound can be:

Field of application of ultrasonic flaw detector

Such devices are in greatest demand in the manufacturing sector. The diagnostic service can also be ordered privately to control welding seams during the construction of buildings, reconstruction of residential and industrial premises. Seam inspection is indispensable when you need to determine the degree of wear of water and gas pipes. Owners of the oil, chemical and engineering industries are actively purchasing equipment. Portable ultrasonic flaw detectors are used by geologists in the field, as well as laboratory assistants to examine small objects.

Ultrasonic flaw detector: price, delivery

The site presents the best models of devices. The range of prices and functionality will pleasantly surprise the company's clients. You can clarify the exact cost of a flaw detector by using the electronic communication form, indicating the exact model of the device. All models of diagnostic equipment are described in detail. Here visitors will learn information about the manufacturer, functionality, dimensions, and area of application of a particular flaw detector. Additional questions should be clarified with the consultant.

The price of any ultrasonic flaw detector also depends on the manufacturer. The entire range of the site is covered by a manufacturer's warranty. Targeted delivery to the regions is carried out. Free consultations are available to clients. Promotions and sales, information about which is regularly updated on the portal, will help you save.