Key Features and Applications

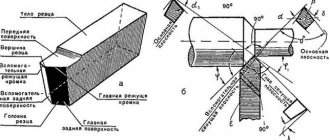

The design consists of a working part made of tool steel and a shank. The working surface of step and cone drills for metal is formed by a groove running along a sharp tip in the form of a stepped or smooth cone, respectively. The diameter of the section is marked along the length of the barrel - using the marks, the size of the hole to be made is determined. These cutters can be used to drill through metal no more than 6 millimeters thick, wood, drywall, plastic, fiberglass, etc.

When using a conical drill for metal, burrs do not appear, so the holes do not need to be further processed with a needle file or grinder. The sharp tip eliminates the need for a centering tool and makes it possible to drill into high-density metal. There are also models with an additional layer of abrasive coating, which increases the strength of the edges and extends the service life of the product.

Step drills are used in car repair, construction, laying utility networks, and installing plumbing equipment. Installed on machines, special two-handed drills of pneumatic and electric type, on conventional drills with reliable fixation of the part (otherwise the tool will jam).

Self-sharpening

Only the cutting edge (groove) is sharpened. It is prohibited to sharpen the transitions of step drills, as this leads to a change in the geometry of the working surface and the formation of burrs during operation. Improper sharpening leads to a decrease in the quality of the tool, often to complete unusability.

The long service life of conical drills requires periodic re-sharpening. At home, drills with a straight translational groove are the easiest to use. This is done manually using abrasive rods, diamond stones for knives or sandpaper.

Any home craftsman needs to know how to sharpen a step drill for metal with a spiral flute. The process requires the use of sharpening machines, on which the drill is directed so that the abrasive wheel passes exclusively in a spiral. For simultaneous smooth rotation, special devices are used; feeding the drill manually is highly not recommended.

Selecting a cone drill

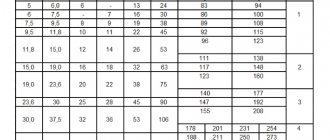

The ability to read markings is a key skill for all craftsmen, and conical drills are no exception. The marking indicates the diameters of the holes that the nozzle can make, the step pitch and the length of the product. It also provides information about the metal from which the device is made. For example, the marking Ø4−12/2 HRC 61±2 should be interpreted as follows:

- Ø4 - initial diameter;

- Ø12 - final diameter;

- 2 — pitch of step drill diameters (with the given parameters, it is possible to make holes Ø4, Ø6, Ø8, Ø10, Ø12);

- HRC - steel grade (in the example this is high-quality high-speed steel);

- 61±2 - Rockwell hardness.

Pay attention to the length of individual steps and/or the total length of the working surface. The type of shank plays an important role - the compatibility of the cutter with drilling equipment depends on it. Shanks can be cylindrical, conical or hexagonal.

Cone drills are made from more than forty different grades of steel. The average consumer does not need to understand all the differences between them; it is easier to remember the abbreviation HSS. Its presence means that the drill can be used in high-speed processing, and during intense heating it will not deform or lose its strength characteristics.

Manufacturers of step drills

Products made in China are of low quality (there are exceptions). To buy a good cone drill, you should pay attention to tools made in Europe and Russia.

1. “Zubr” - stepped drills from a domestic manufacturer are of reasonable cost. The quality is at a fairly high level.

Cone drills can be made from ordinary tool steel or coated with more wear-resistant alloys. In the latter case, the price will be significantly higher, but the quality of the cutting surface will remain sharp longer even when performing a large volume of work.

2. “Attack” - Russian-made conical drills, which in quality and cost are not inferior to the best products from foreign companies.

Reviews about the products of this company are only positive, so you don’t have to worry about the quality, and in order not to overpay, you should select a tool taking into account the maximum diameter that will be needed in the work.

3. “Bosch” - the products of this German company are excellent for professionals and for working with metal at home.

The diameters on the tool are marked using a laser system, so in case of long-term use, the inscriptions are not erased. To increase the drilling speed, the top of the Bosch step drill is sharpened crosswise, and the workpiece is ground in both the transverse and radial directions.

Such processing of the tool allows, when using it, to obtain a high-quality hole, the diameter of which will fully correspond to the stage of the product.

4. “Falon-Tech” - drills from a German company have an additional titanium coating, which allows you to increase the tool life by more than 2 times.

The product has a laser marked diameter and a standard shank that is ideal for use with a screwdriver or hand drill.

Despite the increased quality of the product, its cost remains low. If you need to purchase a cone drill for home use, then the choice of products from this company is the most optimal.

All of these cutting tools do an excellent job of drilling metal up to 4 mm thick. If you need to work with thicker metal, it is recommended to use core drills.

Conclusion

We figured out what a cone drill is needed for. A properly selected product will last for many years. When working with metal of small thickness, to obtain high-quality holes, the use of drills of this design is the optimal solution.

Characteristics of brands

You should purchase products from trusted stores, giving preference to well-known brands. The quality of steel in cheap no-name drills may not correspond to reality, and dubious stores often sell banal counterfeits at an inflated price. Recommended brands for purchase:

- German: Falon Tech, Karnasch, Ruko, Topcraft;

- Polish: Geko;

- Russian: Attack, Globus;

- Ukrainian: Lezo, Zubr.

Thanks to careful quality control in European factories, Polish and German tools are more efficient and durable, although they are more expensive. Drills from the countries of the former USSR are a compromise between price and quality, but when choosing them you need to make sure that the quality of the metal complies with GOST. It is recommended to refrain from purchasing suspiciously cheap Chinese products.

see also

Comments 131

You can correct it on a diamond wheel if your hands don’t shake :-). Carefully follow the groove along the drill, but I don’t think it will work by hand, because... The hardness of the drill is equal to the hardness of the nail file, and I have never seen diamond files.

A diamond file will sharpen any drill... Take a triangular one and just slightly adjust the edge...

As an option! Thank you

Just use a stone under the cutting edge, carefully adjust it and that’s it!

order on Ali for 120 rubles, I ordered these www.aliexpress.com/snapsh…ml?order >

It has many purposes, starting from drilling. Another plus is that one cone replaces a large number of drills.

So does it just replace a lot of drills or is it famous for something else?

drills the tin evenly,

There is a lot described below

It's called a reamer... you drill a hole and then expand it...

Scanning is something completely different! This is exactly the drill! It drills itself, the initial hole is 6mm or more

On the front surface.

With a diamond file, I corrected it a hundred times.

All that remains is to remember “Crazy Hands” and crafts made from a plastic bottle...

I sharpened on a diamond wheel. But not everything is simple there. The opposite side, especially after sharpening, does not allow the cutter to reach the circle. Therefore, I rounded this cutter into an oval on the sharpener, so that the cutting edge was higher than the opposite one, and then restored the sharpness on the wheel. It cuts nothing like that.

Well, it’s not the price of space, buy a new one... to sharpen it at home will be either pathetic or completely crap...

+1 especially since you can buy a small cone that is just up to 8-12mm

Well, it’s not the price of space, buy a new one... to sharpen it at home will be either pathetic or completely crap...

I don’t know about you, we have it for $27, I saw it and didn’t want to buy it, I looked on Aliexpress ru.aliexpress.com/item/He…01644_5,searchweb201560_8, it’s much cheaper there, but you don’t know what they’ll send.

I found here for $40)))

Probably depends on the impudence of the hucksters))

I found here for $40)))

and we’ve seen up to $100)))

That's about the same thing I took

I don’t know about you, we have it for $27, I saw it and didn’t want to buy it, I looked on Aliexpress ru.aliexpress.com/item/He…01644_5,searchweb201560_8, it’s much cheaper there, but you don’t know what they’ll send.

I bought a normal one, everything comes. I bought it for the first time in my general store for 600 rubles. It worked hard and died. I had to drill 20 mm holes in 2.5 mm thick galvanized steel, 400 pieces. I ordered a set of 3 different ones from the Chinese for 340 rubles. It’s called feel the difference))

I don’t know about you, we have it for $27, I saw it and didn’t want to buy it, I looked on Aliexpress ru.aliexpress.com/item/He…01644_5,searchweb201560_8, it’s much cheaper there, but you don’t know what they’ll send.

I often use it for work, so I bought it on Ali seven times, maybe more. All from different sellers, sets of three and individually, of different diameters, with a round shank and a hex adapter. Everything is five times cheaper or more than in stores, the quality is always better than store-bought ones, no matter what brand, the coating is titanium nitride (yellow), high-speed steel (which one is unknown) holds up well, here are a couple of sets offhand: ( ru.aliexpress. com/item/1s…01644_5,searchweb201560_8) (ru.aliexpress.com/item/3P…01644_5,searchweb201560_8)

I don’t know about you, we have it for $27, I saw it and didn’t want to buy it, I looked on Aliexpress ru.aliexpress.com/item/He…01644_5,searchweb201560_8, it’s much cheaper there, but you don’t know what they’ll send.

Recently I bought one for myself with Ali. The price is about six imported, the quality is excellent, but the wait is about a month.

I don’t know about you, we have it for $27, I saw it and didn’t want to buy it, I looked on Aliexpress ru.aliexpress.com/item/He…01644_5,searchweb201560_8, it’s much cheaper there, but you don’t know what they’ll send.

Haven’t I tried to read customer reviews about the product, or have I just discovered a great secret for someone?)))))

And what's in the reviews? They are usually positive, what do they write more specifically?

You take your shoes off, turn on your brain, look at the seller’s rating, and analyze what they write about a specific product. No normal person will write a good review if the product is crap. But if a potential buyer fails to spend an extra few minutes reading, then such deer will then write that everyone around is assholes, and that they, the noble D'Artagnans, have been sold a piece of crap by the bad Chinese... What, again a discovery for someone? )))

If you spend a few minutes and read the comments below, you can understand that I didn’t get it from eBay! And for everyone the word “good” means completely different things! For some, the Tavria is a good car, for others, only a Mercedes is a good car, and for others, a Volkswagen is a good car, because it breaks down not much more often than a Mercedes, to each his own!

I see no point in continuing this pointless dialogue. You need a branded tool, you choke a toad and buy it, or you take a pack of Chinese ones for the same money and use it calmly... Well, jerking off with a sharpening is masturbation IMHO))))

Well, it’s not the price of space, buy a new one... to sharpen it at home will be either pathetic or completely crap...

exactly this - you can say space, I bought it for about 100, many years ago, this is not bullshit or anything, but a professional instrument!

Better throw it away right away! than with an angle grinder! such things are crazy with an angle grinder! at least a Chinese sharpening machine where you can fix and accurately set sharpening angles. . By the way, if you get one like this, you won’t lose anything, you’ll just gain. many tools will be ok

using a grinder) or whatever) you attach it in a vice and off you go) or better yet with diamond burs