Characteristics of steel grade St3sp

St3sp - Structural carbon steel of ordinary quality, welds well, welding is carried out without heating and without subsequent heat treatment, welding methods: manual arc welding, automatic submerged arc welding and gas protection, KTS, ESW. For thicknesses greater than 35 millimeters, heating and subsequent heat treatment are recommended; it is not prone to flake sensitivity and there is no tendency to temper brittleness. Machinability by cutting in the hot-rolled state at HB 124 σB = 400 MPa Kυ hard alloy. = 1.8 and Kυ b.st. = 1.6, has found its application in the design of load-bearing elements of welded and non-welded structures and parts operating at positive temperatures, used in the manufacture of At400C class fittings; St3sp steel has relatively high toughness and ductility, slightly higher than St3ps steel. Forging at temperatures from 1300 to 750 0C, cooling is carried out in air. St3ps steel is not prone to temper brittleness and is magnetic.

Physical and mechanical properties

St3 steel, the characteristics of which will be discussed in detail, is used as a basis in the manufacture of simply a huge number of different workpieces. This can be attributed to unique physical and mechanical properties. The mechanical properties of St3 steel, which are controlled during the production of blanks, are as follows:

- Temporary resistance.

- Yield limit.

- The degree of bending under high force.

- Relative extension.

- Impact strength at a certain temperature.

The most important technical characteristics of carbon steel 3 are as follows:

- The surface has a hardness of 131 MPa.

- The density of steel is non-uniform, the weight can also vary over a wide range.

- Weldability is not subject to any restrictions.

- The structure is not prone to temper brittleness.

The considered properties of steel 3 determine its widespread use in the construction industry. Various rolled products, which are used in mechanical processing, have also become widespread.

Interpretation of steel grade St3sp

Decoding of steel: The letter at the beginning indicates a group of steel which defines the criteria for the ultimate strength for the chemical composition; if there is no letter, then such steel belongs to group A, and is supplied to consumers based on mechanical properties (such steel may have a high sulfur or phosphorus content). Letters St. indicate that the steel is of ordinary quality, although most steels are high quality. The numbers from 0 to 6 are the conventional brand number depending on the chemical composition and mechanical properties. Typically, the higher the number, the more carbon and the greater the strength. In our case, 3 indicates the carbon content in the alloy is 0.14–0.22%. The letters after the brand number indicate the degree of deoxidation: cn - calm. In terms of price, calm steels have become more expensive than semi-calm and boiling steels. Mild steel is steel obtained as a result of deoxidation. It is obtained by deoxidation with aluminum, manganese and silicon. The level of oxygen in it is so reduced that during metal processing no reaction occurs between carbon and oxygen, and the presence of non-metallic slags and their inclusion is reduced to a minimum. Calm steel has a dense structure and good mechanical properties. It is less prone to negative reactions to welding heat and to aging. The features of a homogeneous microstructure give the alloy maximum corrosion resistance and ductility.

Application of steel St3

The technical parameters of St3 allow it to be used for the production of loaded elements of welded structures and parts of machines and mechanisms operating at positive temperatures.

Some types of rolled products, in particular those of the fifth category, are used in the production of metal structures that can operate at temperatures from -40 to 425 degrees Celsius under alternating loads.

After constructing complex structures, it makes sense to carry out heat treatment, in particular annealing. This operation is necessary to relieve stress arising after welding work.

Read also: How to make a transformer for spot welding

In addition, this material is used in the production of At400s construction reinforcement.

Sheets made from this steel are used for the production of parts produced using cold stamping technology. It is used to produce troughs for collecting coolants and waste oils installed on machines, containers of various sizes and purposes, covers for machine equipment, casings, etc.

Supply St3sp

Supplied in the form of long products, including shaped steel according to the regulations of GOST 2590-88 Hot-rolled round steel , GOST 2591-88 Hot-rolled square steel , GOST 8239-89 Hot-rolled steel I-beams , GOST 19771-93 Equal-flange bent steel angles, GOST 19772 -93 Bent steel angles, unequal flanges , GOST 8278-83 Bent steel channels, equal flanges , GOST 8281-80 , unequal , GOST 8283-93 steel trough equal flange profiles , GOST 380-94 Carbon steel of ordinary quality , GOST 85 09-93 Steel corners hot-rolled equal flange , GOST 8510-86 rolled steel angles unequal-flanged , GOST 8240-97 Hot-rolled steel channels , GOST 535-88 Rolled bars and shaped carbon steel of ordinary quality , GOST 2879-88 Rolled hot-rolled hexagonal steel, GOST 19903-2015 Hot rolled sheet products , GOST 19904-90 Cold-rolled sheets , GOST 16523-97 Rolled thin sheets of high-quality and ordinary quality carbon steel for general purpose, GOST 503-81 Cold-rolled low-carbon steel strip, GOST 103-76 Hot-rolled steel strip , GOST 82-70 Hot-rolled steel Wide-band universal, GOST 3282-74 Wire Steel low-carbon general purposes , GOST 17305-71 Carbon structural steel wires, GOST 10705-80 steel power steel pipes , GOST 10706-76 Pipes steel eight-dimensional , GOST 3262-75 Pipes steel water and gap-pipes .

| Metal forming. Forgings | GOST 8479-70; |

| Classification, nomenclature and general norms | GOST 380-2005; |

| Long and shaped rolled products | GOST 2591-2006; GOST 535-2005; GOST 5422-73; GOST 5781-82; GOST 30136-95; GOST 8239-89; GOST 8240-97; GOST 8509-93; GOST 10884-94; GOST 2879-2006; GOST 9234-74; GOST 5267.0-90; GOST 25577-83; GOST 11474-76; GOST 4781-85; GOST 8510-86; GOST 19240-73; GOST 19425-74; GOST 30565-98; GOST 2590-2006; |

| Sheets and strips | GOST 14918-80; GOST 8568-77; GOST 16523-97; GOST 14637-89; GOST 19903-74; GOST 103-2006; |

| Ribbons | GOST 3560-73; GOST 6009-74; |

| Ribbons | GOST 19851-74; |

| Rails. Overlays. Linings. Crutches | GOST 5812-82; GOST 8142-89; GOST 16277-93; |

| Steel pipes and connecting parts for them | GOST 24950-81; GOST 10705-80; GOST 10706-76; GOST 12132-66; GOST 20295-85; GOST 8696-74; GOST 3262-75; GOST 10707-80; |

Harmful impurities for steel

During the steel rolling process, some harmful impurities are used or released, which include phosphorus and sulfur. When phosphorus reacts with ferrite, it significantly increases its brittleness when exposed to low temperatures or significantly reduces its strength when exposed to high temperatures. Excess sulfur in steel is called sulfur content. This defect leads to red brittleness of the material. The sulfur content in the raw materials should not exceed 0.05%, and phosphorus - 0.04%. It is also worth noting here that if the temperature is not high enough for ferrite to form, carbon will begin to precipitate. Its accumulations will accumulate between grains, as well as near defects in the crystal lattice. This has a very negative effect on St3sp strip steel.

Impact strength of steel St3sp

| Delivery condition, heat treatment | +20 | after mechanical aging | -20 |

| Sheet cross section 5-9 mm | 78 | 39 | 39 |

| Sheet cross section 10-25 mm | 68 | 29 | 29 |

| Sheet cross section 26-40 mm | 49 | ||

| Wide strip with a longitudinal section of 5-9 mm | 98 | 49 | 49 |

| Wide strip with a longitudinal section of 10-25 mm | 78 | 29 | 29 |

| Wide strip with a longitudinal section of 26-40 mm | 68 | ||

| Long and shaped rolled steel with a longitudinal section of 5-9 mm | 108 | 49 | 49 |

| Long and shaped rolled steel with a longitudinal section of 10-25 mm | 98 | 29 | 29 |

| Long and shaped rolled steel with a longitudinal section of 26-40 mm | 88 |

Mechanical properties of St3sp at normal temperature

| Type of delivery | Size | Eg. | sв | sT | d5 | y | KCU | Heat treatment |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Pipes, GOST 8696-74 | 372 | 245 | 23 | |||||

| Pipes, GOST 10705-80 | 372 | 225 | 22 | |||||

| Rolled goods, GOST 535-2005 | 370-490 | 205-255 | 23-26 | |||||

| Thick sheet, GOST 14637-89 | 370-480 | 205-245 | 23-26 | |||||

| Fittings, GOST 5781-82 | 373 | 235 | 25 | |||||

| Wire rod, GOST 30136-95 | 490-540 | 60 |

Mechanical properties of St3sp at elevated temperatures

| Test temperature, °C | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | KCU, J/m2 |

| Hot rolled billet dimensions 140x120 mm | |||||

| 20 | 220 | 445 | 33 | 59 | 154 |

| 300 | 205 | 199 | |||

| 500 | 180 | 285 | 34 | 80 | 119 |

| Hot-rolled sheets and shapes up to 30 mm thick | |||||

| 20 | 205-340 | 420-520 | 28-37 | 56-68 | |

| 200 | 215-285 | ||||

| 300 | 205-265 | ||||

| 400 | 155-255 | 275-490 | 34-43 | 60-73 | |

| 500 | 125-175 | 215-390 | 36-43 | 60-73 | |

| A sample with a diameter of 6 mm and a length of 30 mm is forged and normalized. Strain rate 16 mm/min, strain rate 0.009 1/s | |||||

| 700 | 73 | 100 | 57 | 96 | |

| 800 | 51 | 63 | 95 | 95 | |

| 900 | 38 | 65 | 84 | 100 | |

| 1000 | 25 | 43 | 79 | 100 | |

| 1100 | 19 | 31 | 80 | 100 | |

| 1200 | 14 | 25 | 84 | 100 | |

Carbon steel grade st3sp - ordinary quality

Substitutes

Steel StZps, Steel S245

Foreign analogues

| Europe EN 10027-1 (EN 10027-2) | S235JR (1.0038) |

| Germany DIN | RSt37-2, USt37-2 |

| USA (AISI, ASTM) | A238/C |

| France (AFNOR) | E 24-2 |

| UK BS | 40B |

| Czech Republic (CSN) | 11375 |

| Poland PN/H | St3SV, St3SJ, St3S4U |

Decoding steel St3sp

- The letters “B” indicate that this steel, supplied according to mechanical properties and with separate requirements for chemical composition,

- The letters "St" stand for "Steel"

- number 3 indicates the conventional brand number depending on the chemical composition,

- the letters "sp" - calm (degree of steel deoxidation),

- If the letter “sp” is followed by a number, then it indicates the category. If there is no number, then steel category 1. Depending on the category, steel has different standardized indicators (see below).

Type of delivery

- Long products, including shaped steel: GOST 2590-88, GOST 2591-88, GOST 535-88, GOST 2879-88, GOST 19771-93, GOST 19772-93, GOST 8278-83, GOST 8281-80, GOST 8282 -83, GOST 8283-93, GOST 380-94, GOST 8509-93, GOST 8510-86, GOST 8239-89.

- Thick sheet GOST 19903-74.

- Thin sheet GOST 19903-74.

- Tape GOST 503-81, GOST 6009-74.

- Strip GOST 103-76, GOST 82-70, GOST 535-88.

- Forgings and forged blanks GOST 8479-70.

- Pipes GOST 8734-75, GOST 10706-76, GOST 10705-80.

Characteristics, application and purpose

St3sp steel belongs to structural carbon steels of ordinary quality for general purpose and is used for the manufacture of the following parts and structures:

- Load-bearing elements of welded and non-welded structures and parts operating at positive temperatures.

- Shaped and sheet products (5th category) - for load-bearing elements of welded structures operating under variable loads: with a thickness of rolled products up to 25 mm in the temperature range from -40 to +425 °C;

- for rolled products with thickness over 25 mm in the range from -20 to +425 °C, subject to delivery with guaranteed weldability.

According to the international standard ISO 630:1995, St3sp steel is designated E 235-C (Fe 360-C)

Steel 3 is a widely used steel in the petroleum, petrochemical and oil and gas industries. Welded and stamped products can be made from steel of this grade:

- frames,

- frames

- heavy oilfield equipment skids

- bases (blocks)

- parts of drilling and production derricks and masts

- brake bands

- pulleys

- Cam couplings for drilling rigs

- keys

- stubs

- mud pump covers

- racks

- brackets

- gear housings

- drilling rig frames, etc.

Temperature of critical points, °C

| Ac1 | Ac3 | Ar3 | Ar1 |

| 735 | 850 | 835 | 680 |

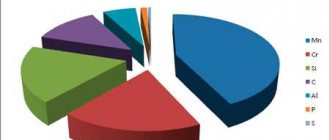

Chemical composition, % (GOST 380-94)

| C | Mn | Si | P | S | Cr | Ni | Cu | As |

| no more | ||||||||

| 0,14-0,22 | 0,40-0,65 | 0,12-0,30 | 0,04 | 0,05 | 0,30 | 0,30 | 0,30 | 0,08 |

Chemical composition, % (GOST 380-2005)

| steel grade | Mass fraction of chemical elements | ||

| carbon | manganese | silicon | |

| St3sp | 0,14-0,22 | 0,40-0,65 | 0,15-0,30 |

NOTE.

- The mass fraction of chromium, nickel and copper in St3sp steel should be no more than 0.30% each.

- The mass fraction of sulfur in St3sp steel should be no more than 0.050%, phosphorus - no more than 0.040%.

- The mass fraction of nitrogen in steel should be no more than:

- smelted in electric furnaces - 0.012%;

- open hearth and converter - 0.010%.

- The mass fraction of arsenic should be no more than 0.080%.

Standardized indicators of St3sp steel by rolled category (GOST 535-2005)

| Category | Chemical composition | Temporary resistance σв | Yield strength σt | Relative elongation δ5 | Cold bending | Impact strength | ||||

| KCU | KCV | |||||||||

| At temperature, °C | After mechanical aging | At temperature, °C | ||||||||

| + 20 | -20 | + 20 | -20 | |||||||

| 1 | — | + | + | + | + | — | — | — | — | — |

| 2 | + | + | + | + | + | — | — | — | — | — |

| 3 | + | + | + | + | + | + | — | — | — | — |

| 4 | + | + | + | + | + | — | + | — | — | — |

| 5 | + | + | + | + | + | — | + | + | — | — |

| 6 | + | + | + | + | + | — | — | — | + | — |

| 7 | + | + | + | + | + | — | — | — | — | + |

NOTE

- The “+” sign means that the indicator is normalized, the “-” sign means that the indicator is not normalized.

- The chemical composition of steel according to heat analysis or in finished rolled products is in accordance with the order.

Parameters for the use of electric-welded straight-seam pipes made of St3sp steel (GOST 32569-2013)

| Steel grade, strength class, standard or specifications | StZsp5 GOST 380 | StZsp4-5 GOST 380 | StZsp4 GOST 380 | ||||

| Technical requirements for pipes (standard or specifications) | GOST 10705 group B | GOST 10706 group B | TU 14-3-377-87 | TU 14-3-1399-95 | GOST 10706 group B | ||

| Nominal diameter, mm | 10-500 | 450-1400 | 200-400 | 200, 350, 400, 500 | 400-1400 | ||

| Types of tests and requirements (standard or specifications) | GOST 10705 | GOST 10706 | TU 14-3-377-87 | TU 14-3-1399-95 | GOST 10706 | ||

| Transported medium (see designations in table 5.1) | Group B, C environments | Group B media Group B media, except LPG | Group B media, except steam and hot water | All media except group A(a) and LPG | Group B media, except LPG | ||

| Pipeline design parameters | Maximum pressure, MPa | ≤1,6 | ≤2,5 | ≤1,6 | |||

| Maximum temperature, °C | 300 | 200 | 300 | 200 | |||

| Pipe wall thickness, mm | — | ≤12 | — | ≤10 | — | ||

| Minimum temperature depending on the pipe wall thickness with stress in the wall from internal pressure [σ], °C | more than 0.35[σ] | minus 20 | |||||

| no more than 0.35[σ] | minus 40 | ||||||

NOTE. Groups of media, see table 5.1 GOST 32569-2013

Parameters for the use of electric-welded spiral-welded pipes made of St3sp steel (GOST 32569-2013)

| Steel grade, strength class, standard or specifications | StZspZ, StZsp2 GOST 380 | StZsp5 GOST 380 | ||

| Technical requirements for pipes (standard or specifications) | TU 14-3-943-80 | TU 14-3-954-80 | ||

| Nominal diameter, mm | 200-500 | 500-1400 | ||

| Types of tests and requirements (standard or specifications) | TU 14-3-943-80 | TU 14-3-954-80 taking into account the requirements of clause 2.2.10 GOST 32569-2013 | ||

| Transported medium (see designations in table 5.1) | All media except group A and LPG | All media except group A and LPG | ||

| Pipeline design parameters | Maximum pressure, MPa | ≤1,6 | ≤2,5 | |

| Maximum temperature, °C | 200 | 300 | ||

| Pipe wall thickness, mm | ≤6 | ≤12 | ||

| Minimum temperature depending on the pipe wall thickness with stress in the wall from internal pressure [σ], °C | more than 0.35[σ] | minus 30 | minus 20 | |

| no more than 0.35[σ] | — | minus 20 | ||

NOTE. Groups of media, see table 5.1 GOST 32569-2013

Application of St3sp steel for fasteners (GOST 32569-2013)

| steel grade | Technical requirements | Acceptable operating parameters | Purpose | |

| Wall temperature, °C | Medium pressure, MPa (kgf/cm2), no more | |||

| StZsp4 GOST 380 | STP 26.260.2043 | -20 to +300 | 2,5 (25) | Studs, bolts, nuts |

| 10 (100) | Washers | |||

Conditions for using St3sp steel for bodies, covers, flanges, membranes and valve assembly made from rolled products, forgings (stampings) (GOST 33260-2015)

| Material | ND for supply | Temperature of the working medium (wall), °C | Additional instructions for use |

| St3sp GOST 380 | Forgings GOST 8479 Long products GOST 535, categories 3-5 | -30 to 300 | For welded fittings for pressure PN≤2.5 MPa (25 kgf/cm2) |

| Sheet GOST 14637, categories 3-6 | -20 to 300 | For welded fittings for pressure PN 5 MPa (50 kgf/cm2). For categories 4, 5, sheet thickness for St3sp is no more than 25 mm; for category 3 sheet thickness no more than 40 mm |

Resistance of structural materials against crevice erosion (GOST 33260-2015)

| Durability group | Point | Erosion resistance against steel 12X18H10T | Material |

| Unstable | 6 | 0,005-0,05 | Steel VSt3sp3 and its welded joints. |

NOTE. The coefficient of erosion resistance of a material is the ratio of the rate of erosive wear of the material to the rate of erosive wear of steel 12Х18Н10Т (taken as 1).

Mechanical properties of rolled products under tension, as well as cold bending test conditions (GOST 535-2005)

| steel grade | St3sp | |

| Tensile strength σв, N/mm2 (kgf/mm2), for rolled thickness, mm | up to 10 incl. | 380-490 (39-50) |

| St.10 | 370-480 (38-49) | |

| Yield strength σт, N/mm2 (kgf/mm2), for rolled thickness, mm (not less) | up to 10 incl. | 255(26) |

| St. 10 to 20 incl. | 245(25) | |

| St. 20 to 40 incl. | 235(24) | |

| over 40 to 100 incl. | 225(23) | |

| St. 100 | 205(21) | |

| Relative elongation δ5, %, for rolled thicknesses, mm (not less) | up to 20 incl. | 26 |

| over 20 to 40 incl. | 25 | |

| St.40 | 23 | |

| Bending until the sides are parallel (a - sample thickness, d - mandrel diameter), for rolling thicknesses, mm | up to 20 incl. | d = a |

| St.20 | d = 2a | |

NOTE

- By agreement between the manufacturer and the consumer, the following is allowed:

- reduction in yield strength by 10 N/mm2 (1 kgf/mm2) for shaped steel with a thickness of over 20 mm;

- reduction in relative elongation by 1% (abs.) for shaped rolled products of all thicknesses.

- It is allowed to exceed the upper limit of tensile strength by 49.0 N/mm2 (5 kgf/mm2), and by agreement with the consumer - without limiting the upper limit of tensile strength, provided that other standards are met. At the request of the consumer, exceeding the upper limit of temporary resistance is not allowed.

Impact strength of rolled products (GOST 535-2005)

| steel grade | St3sp | ||

| Rolled thickness, mm | St. 5.0 to 10.0 incl. | ||

| KCU, J/cm2 (kgf*m/cm2), not less | Sample type according to GOST 9454 | 2,3 | |

| At temperature, °C | +20 | 108(11) | |

| -20 | 49(5) | ||

| After mechanical aging | 49(5) | ||

| KCV, J/cm2 (kgf*m/cm2), not less | Sample type according to GOST 9454 | 12,13 | |

| At temperature, °C | +20 | 34(3,5) | |

| -20 | — | ||

NOTE

- The “-” sign means that the indicator is not standardized.

- Determination of the impact strength of round rolled products is carried out starting from a diameter of 12 mm, square - starting from the square side of 11 mm.

- It is allowed to reduce the value of impact strength on one sample by 30%, while the average value must not be lower than the standards specified in this table.

- Impact strength KCV is determined for rolled products with a thickness of up to 20 mm inclusive.

Mechanical properties of rolled products

| GOST | Delivery status | Section, mm | σ0.2, MPa | σв, MPa | δ5(δ4),% |

| no less | |||||

| GOST 380-94 | Hot rolled products | Up to 20 | 245 | 370-480 | 26 |

| St. 20 to 40 | 235 | 25 | |||

| St. 40 to 100 | 225 | 23 | |||

| St. 100 | 205 | 23 | |||

| GOST 16523-89 (transverse samples) | Hot rolled sheet | Up to 2.0 incl. | — | 370-480 | (20) |

| St. 2.0 to 3.9 incl. | (22) | ||||

| Cold rolled sheet | Up to 2.0 incl. | — | 370-480 | (22) | |

| St. 2.0 to 3.9 incl. | (24) | ||||

Mechanical properties of forgings

| GOST | Heat treatment | Section, mm | σ0.2, MPa | σв, MPa | δ5,% | ψ, % | KCU, J/cm2 | Hardness HB |

| no less | ||||||||

| GOST 8479-70 | Normalization | Up to 100 | 175 | 353 | 28 | 55 | 64 | 101-143 |

| 100-300 | 175 | 353 | 24 | 50 | 59 | |||

| Up to 100 | 195 | 392 | 26 | 55 | 59 | 111-156 | ||

| 100-300 | 195 | 392 | 23 | 50 | 54 | |||

Impact strength KCU (GOST 380-94)

| Type of rental | Pattern cutting direction | Section, mm | KCU, J/cm2 | ||

| +20 °C | -20 °C | after mechanical aging | |||

| no less | |||||

| Sheet | Transverse | 5-9 | 78 | 39 | 39 |

| 10-25 | 68 | 29 | 29 | ||

| 26-40 | 49 | — | — | ||

| Wide band | Longitudinal | 5-9 | 98 | 49 | 49 |

| 10-25 | 78 | 29 | 29 | ||

| 26-40 | 68 | — | — | ||

| Varietal and shaped | Same | 5-9 | 108 | 49 | 49 |

| 10-25 | 98 | 29 | 29 | ||

| 26-40 | 88 | — | — | ||

Mechanical properties at elevated temperatures

| tsp, °C | σ0.2, MPa | σв, MPa | δ5,% | ψ, % | KCU, J/cm2 |

| Hot rolled billet dimensions 140×120 mm | |||||

| 20 | 220 | 445 | 33 | 59 | 154 |

| 300 | 205 | — | — | — | 199 |

| 500 | 180 | 285 | 34 | 80 | 119 |

| Hot-rolled sheets and shapes up to 30 mm thick | |||||

| 20 | 205-340 | 420-520 | 28-37 | 56-68 | — |

| 200 | 215-285 | — | — | — | — |

| 300 | 05-265 | — | — | — | — |

| 400 | 155-255 | 275-490 | 34-43 | 60-73 | — |

| 500 | 125-175 | 215-390 | 36-43 | 60-73 | — |

| A sample with a diameter of 6 mm and a length of 30 mm is forged and normalized. Deformation speed 16 mm/min, strain rate 0.009 1/s | |||||

| 700 | 73 | 100 | 57 | 96 | — |

| 800 | 51 | 63 | 95 | 95 | — |

| 900 | 38 | 65 | 84 | 100 | — |

| 1000 | 25 | 43 | 79 | 100 | — |

| 1100 | 19 | 31 | 80 | 100 | — |

| 1200 | 14 | 25 | 84 | 100 | — |

Endurance limit

| Sample | σ-1, MPa | n |

| Smooth | 191 | 107 |

| Notched | 93 | 107 |

NOTE. Sheet 40 mm thick in hot-rolled condition.

Technological properties

Forging temperature, °C: beginning 1300, end 750. Cooling in air.

Cutting machinability - Kv tv.spl = 1.8 and Kv b.st = 1.6 in the hot-rolled state at HB 124 and σw = 400 MPa.

Flock sensitivity - not sensitive.

Tendency to temper brittleness - not prone.

Welding

Weldability - weldable without restrictions; welding methods: RDS, ADS with flux and gas protection, ESW and KTS. For thicknesses above 36 mm, heating and subsequent heat treatment are recommended.

It is allowed to use steel st3sp for welded connections of pipeline fittings at a temperature of the working medium (wall) from -20 to 300 °C.

Welding materials for electric arc welding

| Base material grade | Electrode type according to GOST, TU (recommended brands of electrodes) | Application temperature, °C | Additional instructions |

| St3sp | E42, E46 GOST 9467 (ANO-4, ANO-5,OZS-6) | Not lower than -15 | — |

| E42A, E46A GOST 9467 (UONI-13/45, UONI-13/45A, 0ZS-2, SM-11) | Not lower than -30 | — | |

| E50A GOST 9467 (UONI-13/55) | below -30 to -40 | After welding, heat treatment - normalization plus tempering (630–660) °C, 2 hours |

Welding materials for gas shielded welding

| Base material grade | Welding wire grade according to GOST 2246, TU, recommended shielding gas or mixture of gases | Application temperature, °C |

| St3sp | Sv-08G2S Carbon dioxide GOST 8050, argon GOST 10157 | -20 to 300 |

Welding materials for submerged arc welding

| Base material grade | Welding wire grade according to GOST 2246, TU, Recommended flux grade according to GOST 9087 | Additional instructions | ||

| Electrodes, type according to GOST 10052 (recommended brands) | Welding wire, GOST 2246 or TU | |||

| Group A | Group B | |||

| 10Х18Н9Л, 12Х18Н9ТЛ GOST 977 08Х18Н10Т, 12Х18Н9Т, 12Х18Н10Т, 12Х18Н9 GOST 5632 08Х18Н10Т-VD TU 14-1-3581 10Х18Н9, 10Х18Н9-VD, 10Х1 8N9-Sh TU 108.11.937 15Х18Н12СЧТУ (EI 654) GOST 5632 10Х17Н13М3Т (EI 432) 10Х17Н13М2Т ( EI 448) GOST 5632 | St3sp GOST 380 | E-10Kh15N25M6AG2 (EA-395/9) E-10Kh25N13G2 (OZL-6, ZIO-8), E-11Kh15N25M6AG2 (NIAT-5, TsT-10) | Sv-07Х23Н13 | The welded joint is of unequal strength |

| E-10Х15Н25М6AG2 (EA-395/9) 582/23, 855/51 | Sv-10X16N25AM6 Sv-06X15N35G7M6B Sv-03X15N35G7M6B | The welded joint is of unequal strength. Welding materials are used for products under the jurisdiction of Rostechnadzor | ||

Welding materials for welding steel st3sp with other steels

| Grades of welded steels | Welding materials | Application temperature, °C |

| St3sp | Sv-08, Sv-08A AN-348A, OSTS-45 ANTS-1 | Not lower than -20 |

Temperature of preliminary and accompanying heating and tempering when welding structures made of steel st3sp

| Grades of welded steels | Thickness of welded edges, mm | Temperature of preliminary and accompanying heating, °C | Interval between the end of welding and the start of tempering, hour | Temperature, °C | |

| welding | surfacing with austenitic class materials | ||||

| St3sp | Up to 36 | Not required | Not required | Not limited | Not required |

| Over 36 to 100 | 630-660 | ||||

| Over 100 | 100 | ||||

Recommended welding modes for correcting weld defects

| Welding materials | Main material | Diameter of electrode, wire, mm | Welding current strength, A | Arc voltage, V |

| USENI 13/45A* USENI 13/55 | St3sp | 3,0 4,0 5,0 | From 100 to 130 From 160 to 210 From 220 to 280 | From 22 to 26 |

| Sv-08G2S | 1,6 | From 100 to 120 | From 12 to 14 | |

| 2,0 | From 140 to 160 |

NOTE. * - along with the electrode brand UONI 13/..., it is possible to use the brand UONII 13/..., depending on the designation of the brand in the specifications of the electrode manufacturer.

Modes of electric arc welding of samples and products

| Electrode brand | Main material | Electrode diameter, mm | Welding current strength, A | Arc voltage, V |

| USENI 13/45A*, USENI 13/55 | St3sp | 3 4 5 | From 110 to 130 From 160 to 210 From 220 to 280 | From 22 to 26 |

NOTE. * - along with the electrode brand UONI 13/..., it is possible to use the brand UONII 13/..., depending on the designation of the brand in the specifications of the electrode manufacturer.

Modes of argon arc welding of samples for incoming inspection of welding materials

| Electrode brand | Main material | Electrode diameter, mm | Welding current strength, A | Arc voltage, V |

| Sv-08G2S | St3sp | 1,6 2,0 3,0 | From 100 to 120 From 150 to 170 From 200 to 240 | From 12 to 14 |

Linear expansion coefficient α*106, K-1

| steel grade | Temperature, K (°C) | |||||||||||

| 323 (50) | 373 (100) | 423 (150) | 473 (200) | 523 (250) | 573 (300) | 623 (350) | 673 (400) | 723 (450) | 773 (500) | 823 (550) | 873 (600) | |

| St3sp5 | 11,5 | 11,9 | 12,2 | 12,5 | 12,8 | 13,1 | 13,4 | 13,6 | 13,8 | 14,0 | 14,2 | 14,4 |

Young's modulus (normal elasticity) E, GPa

| steel grade | Temperature, K (°C) | ||||||||||

| 293 (20) | 323 (50) | 373 (100) | 423 (150) | 473 (200) | 523 (250) | 573 (300) | 623 (350) | 673 (400) | 723 (450) | 773 (500) | |

| St3sp5, | 200 (2,04) | 197 (2,01) | 195 (1,99) | 192 (1,96) | 190 (1,94) | 185 (1,88) | 180 (1,84) | 175 (1,79) | 170 (1,73) | 165 (1,68) | 160 (1,63) |

Thermal conductivity coefficient λ W/(m*K)

| Steel grade | λ W/(m*K), at test temperature, °C | |||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | |

| St3sp | — | 55 | 54 | 50 | 45 | 39 | 34 | 30 |

Find out more

Alloyed tool steel 9ХС…

Structural alloy steel 20KhN4FA…

Steel 14Х17Н2 (EI268)

Steel 7ХГ2ВМФ tool stamping…

Mechanical properties of rolled steel St3sp

| Heat treatment, delivery condition | Section, mm | σ0.2, MPa | σB, MPa | δ5, % | δ4, % |

| Hot rolled products | <20 | 245 | 370-480 | 26 | |

| Hot rolled products | 20-40 | 235 | 370-480 | 25 | |

| Hot rolled products | 40-100 | 225 | 370-480 | 23 | |

| Hot rolled products | >100 | 205 | 370-480 | 23 | |

| Hot rolled sheets | <2,0 | 370-480 | 20 | ||

| Hot rolled sheets | 2,0-3,9 | 370-480 | 22 | ||

| Cold rolled sheets | <2,0 | 370-480 | 22 | ||

| Cold rolled sheets | 2,0-3,9 | 370-480 | 24 |

Valid elements

The regulatory document (GOST) also regulates the chemical composition of carbon steels of ordinary quality. The content of an element such as silicon in steels with different degrees of deoxidation can vary within the following limits:

- boiling – up to 0.05%;

- semi-quiet (St1ps, St2ps, St3ps, etc.) – 0.05–0.15%;

- calm – 0.15–0.3%.

Alloys of ordinary quality grade St0 should not contain silicon, like manganese. Such an important element as carbon can be contained in carbon steels of different grades in the following quantities:

- St0 – up to 0.23%;

- St1 – 0.06–0.12%;

- St2 – 0.09–0.15%;

- St3 – 0.14–0.22%;

- St4 – 0.18–0.27%;

- St5 – 0.28–0.37%;

- St6 – 0.38–0.49%.

The manganese content in carbon steels of ordinary quality is regulated by the standard within the following limits:

- St1 and St2 – 0.25–0.5%;

- calm and semi-quiet alloys of grade St3 – 0.4–0.65%;

- boiling steel grade St3 – 0.3–0.6%; St4 – 0.4–0.7%;

- StGsp and St3Gps – 0.8–1.1%;

- semi-quiet, as well as calm alloys St5 and St6 - 0.5–0.8%;

- St5Gps – 0.8–1.2%.

GOST also regulates the content of such an element as nitrogen in carbon steels of ordinary quality. Its quantity may vary within the following limits:

- in steels produced by smelting in converter and open-hearth furnaces - up to 0.01%;

- in alloys that are smelted in electric furnaces - up to 0.012%.

Carbon steel grade St5sp is used for the manufacture of parts operating at temperatures up to 420 degrees: rivets, nuts, bolts, rods. asterisks, etc.

The remaining elements, including harmful impurities, may be contained in carbon steel alloys of ordinary quality in the following quantities:

- phosphorus (except St0) – up to 0.04%;

- sulfur – no more than 0.05%, and in steel grade St0 – 0.06–0.07%;

- chromium, nickel, copper - up to 0.3% (in steel grade St0, the quantitative content of these elements is not standardized).

Mechanical properties of St3sp forgings

| Section, mm | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | KCU, J/m2 | HB |

| Normalization | ||||||

| <100 | 175 | 353 | 28 | 55 | 64 | 101-143 |

| 100-300 | 175 | 353 | 24 | 50 | 59 | 101-143 |

| <100 | 195 | 392 | 26 | 55 | 59 | 111-156 |

| 100-300 | 195 | 392 | 23 | 50 | 54 | 111-156 |

Foreign analogues of steel grade St3sp

| USA | A284Gr.D, A57036, A573Gr.58, A611Gr.C, GradeC, K01804, K02001, K02301, K02502, K02601, K02701, K02702, M1017 |

| Germany | 1.0038, 1.0116, DC03, Fe360B, Fe360D1, RSt37-2, RSt37-3, S235J0, S235J2G3, S235JR, S235JRG2, St37-2, St37-3, St37-3G |

| Japan | SS330, SS34, SS400 |

| France | E24-2, E24-2NE, E24-3, E24-4, S235J0, S235J2G3, S235J2G4, S235JRG2 |

| England | 1449-2723CR, 1449-3723CR, 3723HR, 40B, 40C, 40D, 4360-40B, 4360-40D, 4449-250, 722M24, Fe360BFU, Fe360D1FF, HFS3, HFS4, HFW3, HFW4, S235J2G 3, S235JR, S235JRG2 |

| European Union | Fe37-3FN, Fe37-3FU, Fe37B1FN, Fe37B1FU, Fe37B3FN, Fe37B3FU, S235, S235J0, S235J2G3, S235JR, S235JRG2 |

| Italy | Fe360B, Fe360BFN, Fe360C, Fe360CFN, Fe360D, Fe360DFF, Fe37-2, S235J0, S235J2G3, S235J2G4, S235JRG2 |

| Belgium | FE360BFN, FE360BFU, FED1FF |

| Spain | AE235BFN, AE235BFU, AE235D, Fe360BFN, Fe360BFU, Fe360D1FF, S235J2G3, S235JRG2 |

| China | Q235, Q235A, Q235A-B, Q235A-Z, Q235B, Q235B-Z, Q235C |

| Sweden | 1312, 1313 |

| Bulgaria | BSt3ps, BSt3sp, Ew-08AA, S235J2G3, S235JRG2, WSt3ps, WSt3sp |

| Hungary | Fe235BFN, Fe235D, S235J2G3, S235JRG2 |

| Poland | St3S, St3SX, St3V, St3W |

| Romania | OL37.1, OL37.2, OL37.4 |

| Czech | 11375, 11378 |

| Finland | FORM300H, RACOLD03F, RACOLD215S |

| Austria | RSt360B |

- Structural steel

- Tool steel