Characteristics of steel grade BSt4kp

BSt4kp - Structural carbon steel of ordinary quality, limited weldability, welding is carried out without heating and without subsequent heat treatment, welding methods: manual arc welding, automatic submerged arc welding and gas protection, KTS, ESW, manual argon arc welding, mechanized welding with a consumable electrode in a medium carbon dioxide. For thicknesses greater than 35 millimeters, heating and subsequent heat treatment are recommended; it is not prone to flake sensitivity and there is no tendency to temper brittleness. Cutting machinability in the hot-rolled state at HB 152 and σ = 400 MPa. Kυ tv.sp. = 1.7 and Kυ b.st. = 1.7, has found its application in the production of hollow steel, channels, angle steel, and is used for welded, riveted and bolted structures of increased strength in the form of long, shaped and sheet metal, as well as for lightly loaded parts. Forging at temperatures from 1250 to 850 0C, cooling is carried out in air.

Marking and decoding of alloy steels

Designation is alphanumeric. Alloying elements have symbols - they are designated by letters of the Russian alphabet.

Designations and interpretation of letters of alloying elements of steels

A – nitrogen (indicated in the middle of the mark) B – niobium C – tungsten D – manganese D – copper E – selenium K – cobalt M – molybdenum N – nickel P – phosphorus P – boron C – silicon T – titanium F – vanadium X – chromium C – zirconium Yu – aluminum Ch – rare earth

Alloy structural steels

At the beginning of the stamp there is a two-digit number indicating the carbon content in hundredths of a percent. Alloying elements are listed below. The number following the symbol of the element shows its content as a percentage; if there is no number, then the content of the element does not exceed 1.5%. Steel 30Х2М. This grade of steel contains about 0.30% carbon, 2% chromium, and less than 1% molybdenum.

Alloy tool steels

At the beginning of the brand there is a single-digit number indicating the carbon content in tenths of a percent. If the carbon content is more than 1%, the number is not indicated; then alloying elements are listed, indicating their content.

Interpretation of steel grade BSt4kp

Interpretation of steel: The letter B at the beginning denotes a group of steel that determines the tensile strength criteria for the chemical composition. Steel with a name starting with the letter B comes with a guaranteed chemical composition, strength is 20 MPa lower than steel of group A, and may also differ in mechanical properties from group A. Letters St. indicate that the steel is of ordinary quality, although most steels are high quality. The numbers from 0 to 6 are the conventional brand number depending on the chemical composition and mechanical properties. Typically, the higher the number, the more carbon and the greater the strength. In our case, 4 indicates the carbon content in the alloy is 0.18–0.27%. The letters after the brand number indicate the degree of deoxidation: kp - boiling. In terms of price, boiling steels are the cheapest, but their cold brittleness threshold is 30 - 40% higher than calm steels.

Cast irons with special properties

Depending on the purpose, wear-resistant, anti-friction, heat-resistant and corrosion-resistant cast irons are distinguished.

Wear-resistant (anti-friction) cast irons

Designated by a combination of the letters AChS, AChK, AChV. The letters C, K, B indicate the type of cast iron: gray, malleable, high-strength. The number indicates the cast iron number. Chromium, nickel, copper, and titanium are used to alloy antifriction cast irons.

Heat-resistant and heat-resistant cast irons

They are designated by a set of capital letters of the Russian alphabet and the letters following them. The letter "C" is cast iron.

The letter “Ш” at the end of the mark means the spherical shape of graphite. The remaining letters indicate alloying elements, and the numbers following them correspond to their percentage content in the cast iron.

Heat-resistant cast irons are used for the manufacture of parts for contact devices of chemical equipment operating in gas environments at temperatures of 900-110000C.

Supply of BSt4kp

Supplied in the form of long products, including shaped steel according to GOST 2590-88 Hot-rolled round steel, GOST 2591-88 Hot-rolled square steel, GOST 8239-89 Hot-rolled steel I-beams, GOST 19771-93 Equal-flange bent steel angles, GOST 19772 -93 Bent steel angles, unequal flange, GOST 8278-83 Bent steel channels, equal flange, GOST 8281-80 Bent steel channels, unequal flange, GOST 8283-93 Bent steel trough equal flange profiles, GOST 380-94 Carbon steel of ordinary quality, GOST 8509-93 Steel corners hot-rolled equal flange, GOST 8510-86 Hot-rolled steel angles unequal-flanged, GOST 8240-97 Hot-rolled steel channels, GOST 535-88 Rolled bars and shaped carbon steel of ordinary quality, GOST 2879-88 Rolled hot-rolled hexagonal steel

| B20 - Classification, nomenclature and general standards | GOST 380-2005; |

| B22 – Long and shaped rolled products | GOST 5422-73; GOST 8240-97; GOST 535-2005; GOST 8510-86; GOST 2879-2006; GOST 2591-2006; GOST 2590-2006; GOST 19425-74; GOST 19240-73; GOST 8509-93; GOST 11474-76; GOST 9234-74; GOST 8239-89; |

| B23 - Sheets and strips | GOST 14918-80; GOST 103-2006; GOST 16523-97; |

| B24 - Tapes | GOST 6009-74; GOST 3560-73; |

| B42 - Rails. Overlays. Linings. Crutches | GOST 8142-89; GOST 8194-75; GOST 12135-75; GOST 5812-82; GOST 3280-84; GOST 16277-93; GOST 7056-77; GOST 22343-90; |

| B62 — Steel pipes and connecting parts for them | GOST 8642-68; GOST 10705-80; GOST 13663-86; GOST 3262-75; GOST 10707-80; GOST 8638-57; GOST 8645-68; GOST 8646-68; GOST 8644-68; GOST 8639-82; |

Supply of BSt2kp

Supplied in the form of long products, including shaped steel according to GOST 2590-88 Hot-rolled round steel, GOST 2591-88 Hot-rolled square steel, GOST 8239-89 Hot-rolled steel I-beams, GOST 19771-93 Equal-flange bent steel angles, GOST 19772 -93 Bent steel angles, unequal flange, GOST 8278-83 Bent steel channels, equal flange, GOST 8281-80 Bent steel channels, unequal flange, GOST 8283-93 Bent steel trough equal flange profiles, GOST 380-94 Carbon steel of ordinary quality, GOST 8509-93 Steel corners hot-rolled equal flange, GOST 8510-86 Hot-rolled steel angles unequal flange, GOST 8240-97 Hot-rolled steel channels, GOST 535-88 Rolled bars and shaped carbon steel of ordinary quality, GOST 2879-88 Rolled hot-rolled hexagonal steel, GOST 19903-2015 Rolled sheets hot rolled , GOST 19904-90 Cold-rolled sheets, GOST 16523-97 Rolled thin sheets of high-quality and ordinary quality carbon steel for general purpose, GOST 503-81 Cold-rolled low-carbon steel strip, GOST 103-76 Hot-rolled steel strip, GOST 82-70 Hot-rolled steel broadband universal, GOST 3282-74 General purpose low-carbon steel wire, GOST 17305-71 Carbon structural steel wire, GOST 10705-80 Electric-welded steel pipes, GOST 10706-76 Straight-seam electric-welded steel pipes, GOST 3262-75 Steel water-gas pipes.

Foreign analogues of steel grade BSt4kp

| USA | A573, A573Gr.70, A611Gr.D, K03000 |

| Germany | 1.0144, Fe430D1, St4403 |

| Japan | SM400A, SM400B, SM400C |

| France | E28-3, E28-4 |

| England | 4360-43C, 43C, 43D, Fe430D1FF, S275J2G3, S275N |

| European Union | S275J2G3, S275JO |

| Italy | Fe430B, Fe430CFN, Fe430DFF |

| Belgium | FE430D1FF |

| Spain | AE275D, Fe430D1FF |

| China | Q255 |

| Sweden | 1411, 1412, 1414 |

| Bulgaria | BSt4kp, WSt4kp |

| Poland | St4SX |

| Romania | OL42.1 |

| Czech | 11423 |

Buy BSt4kp steel in Moscow and the Moscow region

BSt4kp steel is widely used in various fields of industry, used in mechanical engineering, involved in the manufacturing industry, covers a wide range of construction, shipbuilding, and is partially used in aircraft production and many other areas of industry. There are a large number of steel grades, a huge part of the alloys are made to order, and those steel grades that are in great demand are partially stored for regular customers. The Metallpro company carries out wholesale and retail sales on the territory of the Russian Federation; BSt4kp steel is partly in our warehouse in the form of rolled metal products, and partly we ship directly from the metallurgical plant. With constant demand, we are ready to offer mutually beneficial cooperation, delivery directly from the factory by carriage standards, as well as by motor vehicles. You can buy BSt4kp steel in Moscow and the Moscow region at a competitive price from the Metallpro Trading Company under a mutually beneficial contract for a long partnership period.

Impact strength of steel VSt3kp

| Type of delivery, heat treatment | 20 | 0 | -10 | -20 | -30 |

| Sheets 10-12 mm thick | 89-100 | 60-85 | 12-69 | 13-53 | 6-10 |

| Sheets 16-20 mm thick | 40-140 | 15-71 | 9-16 | 8-12 | |

| Sheets 30-32 mm thick | 30-115 | 6-13 | 6-13 | 7-9 | |

| Sheets up to 12 mm thick (shaped rolled products) | 64-149 | 83-112 | 83-114 | 14-63 |

Price for steel BSt4kp

The favorable price for the BSt4kp steel grade is explained by the presence of a competitive environment, low markups and loading from leading metallurgical plants directly, sometimes bypassing storage at transshipment points. Metalpro company bears full responsibility for the chemical composition of the supplied products and guarantees the quality of delivery. The cost of BSt4kp steel in warehouses in Moscow and the Moscow region is determined by the costs of warehousing and logistics. Metallpro Company can also supply BSt4kp steel directly from the metallurgical plant, which gives our partners an advantage to consistently save money and develop their business in a broad format.

The price for steel grade BSt4kp is determined personally with each company, monthly needs are individually negotiated and the form of payment is discussed. Warehouse services for custom-made items and logistics to the production site also form the cost of BSt4kp steel. The Metalpro company maintains an open dialogue personally with each of its clients; each transaction is accompanied by a personal manager from the production stage to the delivery of rolled metal to the customer. Full control at any stage from payment to delivery to the customer’s site gives the latter a complete picture.

GOST 380-94. Carbon steel of ordinary quality. Grades and general technical requirements

Carbon steel of ordinary quality

GOST 380-94

Brands and general technical requirements

Depending on the purpose, steel is divided into three groups:

- A - supplied according to mechanical properties;

- B - supplied according to chemical composition;

- B - supplied according to mechanical properties and chemical composition. Depending on the standardized indicators, steel of each group is divided into categories:

- groups A - 1, 2, 3;

- groups B - 1, 2;

- Groups B - 1, 2, 3, 4, 5, 6. Note. These categories do not apply to steel with a thickness of less than 4 mm. Steel is produced in the following grades:

- groups A - St0, St1, St2, St3, St4, St5, St6;

- Group B - BSt0, BSt1, Bst2, BST3, Bst4, BSt5, BST6;

- Groups B - VSt1, Vst2, VSt3. VSt4, VSt5, Steel of all groups with grade numbers 1, 2, 3, and 4 according to the degree of deoxidation is produced boiling, semi-calm and calm. Semi-quiet steel with grade numbers 1–5 is produced with normal and increased manganese content. Steel grades St0 and BSt0 are not distinguished by the degree of deoxidation. Steel grades VSt1, VSt2, VSt3 of all categories and all degrees of deoxidation, including with a high content of manganese, and at the request of the customer, steel grades BSt1, BSt2, BSt3 of the second category of all degrees of deoxidation, including with a high content of manganese, are supplied with a guarantee of weldability. The supply of group B steel with a guarantee of weldability is specified in the order and in the certificate. Steel with a carbon content in the finished product of more than 0.22% is used for welded structures under welding conditions that ensure the reliability of the welded joint.

Group A steel

| Temporary resistance | Relative extension | Cold bending | Yield strength | ||

| 1 | St0 - St6 | + | + | — | — |

| 2 | + | + | + | — |

Notes: 1. For steel grade St6, cold bending is not standardized. 2. The sign “+” means that the indicator is normalized. 3. For category 3 steel supplied for the manufacture of pipes, cold bending is not standardized

Group B steel

| Steel category | Steel grades of all degrees of deoxidation and with a high manganese content | Content of carbon, manganese, silicon, phosphorus, sulfur, arsenic, nitrogen | Content of chromium, nickel, copper |

| 1 | BSt0 - BST6 | + | — |

| 2 | BSt1 - BST6 | + | + |

Group B steel

For steel categories: 1 - VSt1 - VSt5 - the chemical composition, tensile strength, relative elongation and cold bending are standardized; — yield strength, impact strength and mechanical aging are not standardized. 2 - VSt2 - VSt5 - chemical composition, tensile strength, yield strength, relative elongation, cold bending are standardized. — impact strength and mechanical aging are not standardized. 3 - VSt3 - Vst4 - the chemical composition, tensile strength, yield strength, relative elongation, cold bending, impact strength at a temperature of + 20 degrees are normalized. — impact strength at a temperature of minus 20 degrees and mechanical aging are not standardized. 4 - VSt3 - the chemical composition, tensile strength, yield strength, relative elongation, cold bending and impact strength at a temperature of minus 20 degrees are standardized. - impact strength at a temperature of + 20 degrees and mechanical aging are not standardized. 5 - VSt3 - the chemical composition, tensile strength, yield strength, relative elongation, cold bending, impact strength at a temperature of minus 20 degrees and mechanical aging are standardized. — impact strength is not standardized at a temperature of + 20 degrees.

6 - VSt3 standardizes the chemical composition, tensile strength, yield strength, relative elongation, cold bending and mechanical aging. — impact strength is not standardized at +/- 20 degrees. Note. 1.Steel of categories 3, 4, 5 and 6 is supplied semi-calm and calm.

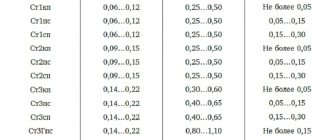

Table of chemical composition of steel according to GOST 380-94

| Steel grades | Element content in %. | |||||||

| carbon | manganese | silicon | phosphorus | sulfur | chrome no more | nickel | copper | |

| BSt0 | 0.23 max | — | — | 0,07 | 0,06 | — | — | — |

| BST1kp | 0,06-0,12 | 0,25-0,50 | 0.05max | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt1sp | 0,06-0,12 | 0,25-0,50 | 0,12 — 0,3 | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BStG1ps | 0,06-0,12 | 0,7-1,1 | 0.15max | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt2kp | 0,09-0,15 | 0,25-0,5 | 0.07max | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt2ps | 0,09-0,15 | 0,25-0,5 | 0,05 — 0,17 | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt2sp | 0,09-0,15 | 0,25-0,5 | 0,12 — 0,3 | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt2Gps | 0,09-0,15 | 0,7- 1,1 | 0.15max | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt3kp | 0,14-0,22 | 0,3 — 0,6 | 0.07max | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt3ps | 0,14-0,22 | 0,4 — 0,65 | 0,05 — 0,17 | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt3sp | 0,14-0,22 | 0,4 — 0,65 | 0,12 — 0,3 | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt3Gps | 0,14-0,22 | 0,8 — 1,1 | 0.15max | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt4kp | 0,18-0,27 | 0,4 — 0,7 | 0.07max | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt4ps | 0,18-0,27 | 0,4 — 0,7 | 0,05 — 0,17 | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt4sp | 0,18-0,27 | 0,4 — 0,7 | 0,12 — 0,3 | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt4Gps | 0,18-0,27 | 0,8 — 1,2 | 0.15max | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt5ps | 0,28-0,37 | 0,5 — 0,8 | 0,05 — 0,17 | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt5sp | 0,28-0,37 | 0,5 — 0,8 | 0,15 — 0,35 | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt5Gps | 0,28-0,37 | 0,22 — 1,2 | 0.15max | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt6ps | 0,38-0,49 | 0,5 — 0,8 | 0,05 — 0,17 | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

| BSt6sp | 0,38-0,49 | 0,5 — 0,8 | 0,15 — 0,35 | 0,04 | 0,05 | 0,3 | 0,3 | 0,3 |

Note. 1. In steel, the content of arsenic and phosphorus should not exceed 0.08% and 0.008%, respectively. 2. When deoxidizing semi-quiet steel with aluminum, titanium or other deoxidizing agents that do not contain silicon, as well as several deoxidizing agents (ferrosilicon and aluminum, ferrosilicon, titanium, etc.), the silicon content in the steel is allowed less than 0.05%. Deoxidation with titanium, aluminum and other deoxidizing agents that do not contain silicon is indicated in the certificate. 3. The nitrogen content in finished rolled products should not exceed 0.008%. 4. For boiling chemically sealed steel in finished rolled products, a silicon content of up to 0.15% is allowed, except if the steel is intended for cold heading or stamping, which is specified.

Marking of rolled products made from steel according to GOST 380-94

| steel grade | Marking colors |

| St0 | Red and green |

| St1 | White and black |

| St1Gps | White and red |

| St2 | Yellow |

| St2Gps | Yellow and red |

| St3 | Red and green |

| St3Gps | Red and blue |

| St4 | Black |

| St4Gps | Black and red |

| St5 | Green |

| St5Gps | Green and white |

| St6 | Blue |

Steel is marked with indelible paint, and regardless of the steel group and degree of deoxidation, the colors indicated in the table (see above) are used.