Steel 03KhGYu Steel 05G1B Steel 06G2AF Steel 06G2MFB Steel 06G2FR Steel 06KHGSYu Steel 07GBYU Steel 07GFB (07GFB-U) Steel 08G1NFB Steel 08G2MF (08G2MFA) Steel 08G2S Steel 08G2SFB S hoist 08G2T (08G2T-U) Steel 08G2FBT Steel 08GBYU Steel 08GBYUTR Steel 09G2 Steel 09G2D Steel 09G2S (09G2SA) Steel 09G2SD Steel 09G2FB (09G2BT) Steel 09GBYU Steel 09GNFB Steel 09GSNBTS Steel 09KHGN2AB Steel 10G2B Steel 10G2BD Steel 10G2BTYu Steel 10G2S1 Steel 10G2S1D Steel 10G2SB Steel 10G2SFB Steel 10G2T Steel 10G2FB Steel 10G2FBU Steel 10GNB Steel 10GS2 Steel 10GT Steel 10KhGSN1D (SHL- 45) Steel 10KhDP Steel 10KhN1M (VK-1A) Steel 10KhNDM Steel 10KhNDP Steel 10KhSND (SHL-4) Steel 12G (12GA) Steel 12G2AF Steel 12G2B Steel 12G2S Steel 12G2SB Steel 12G2SMF Steel 12G2SMFA Yu Steel 12GN2MFAYU Steel 12GNDYu Steel 12GS (Sv-12GS) Steel 12GSB Steel 12GF Steel 12KhGDAF Steel 12HSND Steel 13G1S (13G1S-U) Steel 13G1SB (13G1SB-U) Steel 13G2AF Steel 13GDF Steel 13GS (13GS-U) Steel 13GF (13GFA) Steel 14G2 Steel 1 4G2AF Steel 14G2AFD Steel 14GS Steel 14GF Steel 14KhGMDC Steel 14KhGS Steel 15G2AFD (15G2AFDps) Steel 15G2SF Steel 15G2SFD Steel 15G2FBU Steel 15GS Steel 15GF Steel 15GFD Steel 15KhDP Steel 15KhSND Steel 16G (16GA) Steel 16G2AF Steel 16G2AF D Steel 16G2SF (16G2SAF) Steel 16GD Steel 16GMYuch Steel 16GS Steel 16GFB Steel 16D Steel 17G1S ( 17G1S-U) Steel 17GS Steel 18G2AF (18G2AFps) Steel 18G2AFD (18G2AFDps) Steel 18G2S Steel 18YUT (Ch-33) Steel 19YuFT (Ch37) Steel 1Kh2M1 Steel 20G2S Steel 20GS Steel 20GS2 Steel 20 GSF (20GSFL) Steel 20Kh2G2SR Steel 20KhG2Ts Steel 20KhGS2 Steel 22G2 Steel 22GYU Steel 22S Steel 22KH2G2AYU Steel 22KH2G2R Steel 23KH2G2T Steel 25G2S Steel 25GS Steel 25S2R Steel 27GS Steel 28G2S1D Steel 28G2SFB (28G2SFBD) Steel 28S Steel 30ХS2 S tal 32G2Rps Steel 35GS Steel 45KhGMA Steel 80S Steel SVS-690 (Severstal-690) Steel X56

Description

Steel 10G2S1 is used : for the manufacture of various parts and elements of welded metal structures operating at temperatures from -70 ° C; devices, vessels and parts of steam boilers operating at temperatures from -70 °C to +475 °C under pressure; production of welded transitions, flanges, welded tees and other shaped parts of NPP pipelines with operating temperatures from -60 °C to +350 °C; parts of hydrogenerators.

Note

Low-alloy silicon-manganese steel. Degree of deoxidation - Sp. Steel 10G2S1 provides strength classes for long, strip and shaped rolled products KP 295 with a thickness from 32 to 100 mm, KP 325 with a thickness from 10 to 60 mm, KP 345 with a thickness of up to 10 mm. Steel 10G2S1 provides the strength class of sheets, wide-band universal rolled products and bent profiles KP 295 with a thickness of rolled products from 32 to 100 mm, KP 315 with a thickness of 20 to 60 mm, KP 325 with a thickness of 10 to 20 mm, KP 345 with thickness up to 10 mm., KP 355 with thickness up to 5 mm. without the use of additional strengthening treatment. When using quenching and tempering, rolled products with a cross section of up to 32 mm are supplied. strength class KP 390.

Steel 10G2 structural alloy

Decoding

- According to GOST 4543-71, the number 10 in the designation of steel indicates the average mass fraction of carbon in steel in hundredths of a percent, i.e. carbon in steel 10G2 is about 0.10%

- The letter G indicates that the steel contains manganese (Mn), the number 2 behind the letter indicates that the steel contains approximately 2% manganese.

Substitute

Steel 09G2.

Steel analogues

| 10G2 (Bulgaria) | BDS 6354 |

| 12Mn6 (Germany) | DIN 17145 |

| 12Mn (China) | GB 1591-88 |

| 12Mn2A (China) | GB 5067-85 |

| 150M12 (UK) | BS 2772 Part 2 (89) |

| 1513 (US) | SAE J 403, AISI |

| CE 11 Mn (Euronorm) | EN 133-79 |

| S10Mn15 (Romania) | STAS 1126 |

| Z3 (Yugoslavia) | JUS C.H3. 052 |

| EI 738 (CIS) | THAT |

Type of delivery

- long products, including shaped steel: GOST 4543-71, GOST 2590-88, GOST 2591-88, GOST 2879-88.

- Calibrated rod GOST 4543-71, GOST 7417-75, GOST 8559-75, GOST 8560-78.

- Polished rod and silver steel GOST 4543-71, GOST 14955-77.

- Thick sheet GOST 19903-74, GOST 1577-93.

- Strip GOST 4543-71, GOST 103-76. GOST 82-70.

- Forgings and forged blanks GOST 4543-71, GOST 8479-70, GOST 1133-71.

- Pipes GOST 8731-74, GOST 8732-78, GOST 8733-74, GOST 8734-75, GOST 550-75, GOST 21729-76.

Characteristics and application [1]

Manganese case-hardened steel grade 10G2 with high ductility is used for the manufacture of various mechanical engineering parts from pipes, sheets, rolled products and forgings, as well as parts and elements of welded structures in the delivered state or after normalization.

Steel deforms well in cold and hot states and has excellent weldability; prone to temper brittleness.

Steel 10G2 is used for the manufacture of:

- Patrubkov,

- coils,

- tube bundles,

- fasteners,

- flanges,

- tube sheets,

- fittings,

- other parts operating at temperatures up to -70°C under pressure in the oil refining industry, as well as welded (less than 4 mm thick) and stamped parts.

Temperature of critical points, °C [1]

Chemical composition, % (GOST 4543-71)

| C | Mn | Si | P | S | Cu | Ni | Cr |

| no more |

| 0,07-0,15 | 0,17-0,37 | 1,2-1,6 | 0,035 | 0,035 | 0,30 | 0,30 | 0,30 |

Conditions for using 10G2 steel for bodies, covers, flanges, membranes and valve assembly made from rolled products, forgings (stampings) (GOST 33260-2015)

| Material | ND for supply | Temperature of the working medium (wall), °C | Additional instructions for use |

| Name | Brand |

| Alloy structural steel | 10G2 GOST 4543 | Forgings GOST 8479 | -70 to 475 | For welded fittings operated in a macroclimatic region with a cold climate, with mandatory impact bending testing at temperatures below minus 50°C to minus 70°C, with KCU ≥ 300 kJ/m2 (3.0 kgf*m/cm2) or KCV ≥ 250 kJ/m2 (2.5 kgf*m/cm2) |

| Long products GOST 4543 |

| Pipes GOST 550 gr.A and B, GOST 8733 gr.V, GOST 8731 gr.V | For GOST 550 pipes, additional testing at temperatures below minus 50°C to minus 70°C with a wall thickness of more than 12 mm, with KCU ≥ 300 kJ/m2 (3.0 kgf*m/cm2) or KCV ≥ 250 kJ/m2 (2.5 kgf*m/cm2) |

Conditions for using 10G2 steel for reinforcement fasteners (GOST 33260-2015)

| Material grade | Material standard or specification | Application options |

| Bolts, studs, screws | Nuts | Flat washers |

| Ambient temperature, °C | Nominal pressure Pn, MPa (kgf/cm2) | Ambient temperature, °C | Nominal pressure Pn, MPa (kgf/cm2) | Ambient temperature, °C | Nominal pressure Pn, MPa (kgf/cm2) |

| 10G2 | GOST 4543 | -70 to 425 | 20 (200) | -70 to 425 | 20 (200) | -70 to 425 | Not regulated |

Maximum permissible temperatures for the use of 10G2 steel in environments containing ammonia (GOST 33260-2015)

| steel grade | Temperature of application of steels, °C at partial pressure of ammonia, MPa (kgf/cm2) |

| St. 1(10) to 2(20) | St. 2(20) to 5(50) | St. 5(50) to 8(80) |

| 10G2 | 300 | 300 | 300 |

NOTE. Application conditions are established for a nitrogen layer corrosion rate of no more than 0.5 mm/year.

Maximum permissible temperature for the use of steels in hydrogen-containing environments (GOST 33260-2015)

| steel grade | Temperature, °C, at partial pressure of hydrogen, PH2, MPa (kgf/cm2) |

| 1,5(15) | 2,5(25) | 5(50) | 10(100) | 20(200) | 30(300) | 40(400) |

| 10G2 | 290 | 280 | 260 | 230 | 210 | 200 | 190 |

NOTE:

- The parameters for using 10G2 steel indicated in the table also apply to welded joints.

- The partial pressure of hydrogen is calculated by the formula: PH2 = (C*Pp)/100, where C is the percentage of H2 in the system; PH2—partial pressure of H2; Pp—working pressure in the system.B.

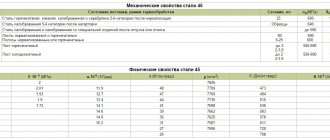

Mechanical properties of heat-treated case-hardened alloy steel 10G2 [2]

| steel grade | 3hardening | Vacation | Properties according to GOST 4543-71 |

| temperature, °C | cooling medium | temperature, °C | cooling medium |

| 1st 3quenching or normalization | 2nd 3hardening | σТ, kgf/mm2 | σв, kgf/mm2 | δ5, % | ψ, % |

| no less |

| 10G2 | 900 | 780-800 | Air | 180 | Air | 25 | 43 | 22 | 50 |

- σТ—yield strength (physical), kgf/mm2

- σв — tensile strength (temporary tensile strength), kgf/mm2

- σ-1—bending endurance limit with a symmetrical loading cycle, kgf/mm2

- aH—impact strength, kgf*m/cm2

Influence of test temperature on the mechanical properties of alloy case-hardened steel 10G2 [2]

| steel grade | Heat treatment mode | Test temperature, °C | σТ kgf/mm2 | σв kgf/mm2 | δ5, % | ψ, % | aH, kgf*m/cm2 |

| 10G2 | Normalization at 900 °C | 20 | 28 | 47 | 31 | — | — |

| 400 | 23 | 40 | 27 | — | — |

| 450 | 20 | 36 | 30 | — | — |

| 500 | 18 | 30 | — | — | — |

| 600 | 12 | 16 | 36 | — | — |

The influence of tempering temperature on the mechanical properties of alloy case-hardening steel 10G2 [2]

| steel grade | Thermal steel processing mode | Temperature, °C | σТ kgf/mm2 | σв kgf/mm2 | δ5, % | ψ, % | aH, kgf*m/cm2 | Hardness HB (HRC) |

| 10G2 | Quenching from 820°C in water | 300 | — | 113 | 4 | 50 | — | 300 |

| 400 | 96 | 100 | 5 | 52 | — | 266 |

| 500 | 83 | 87 | 9 | 55 | — | 230 |

| 600 | 66 | 71 | 12 | 63 | — | 206 |

| 700 | 44 | 60 | 20 | 61 | — | 164 |

| Quenching from 850°C in water | 300 | — | 95 | 7 | 52 | — | 295 |

| 400 | 88 | 92 | 6 | 55 | — | 282 |

| 500 | 84 | 82 | 11 | 60 | — | 215 |

| 600 | 61 | 68 | 11 | 60 | — | 215 |

| 700 | 42 | 60 | 22 | 69 | — | 170 |

| Quenching from 880°C in water | 300 | 113 | 115 | 4 | 53 | — | 314 |

| 400 | 97 | 101 | 6 | 56 | — | 252 |

| 500 | 81 | 87 | 13 | 58 | — | 246 |

| 600 | 67 | 73 | — | 63 | — | 193 |

| 700 | 44 | 59 | 22 | 69 | — | 170 |

| Quenching from 820°C in water | 300 | 77 | 88 | 4 | 59 | — | 217 |

| 400 | 57 | 74 | 5 | 61 | — | 200 |

| 500 | 69 | 76 | 10 | 59 | — | 186 |

| 600 | 58 | 66 | 12 | 63 | — | 170 |

| 700 | 41 | 56 | 20 | 68 | — | 160 |

| Quenching from 850°C in water | 300 | 85 | 91 | 5 | 51 | — | 292 |

| 400 | 81 | 83 | 7 | 61 | — | 252 |

| 500 | 67 | 77 | 14 | 59 | — | 230 |

| 600 | 62 | 69 | 19 | 62 | — | 183 |

| 700 | 43 | 55 | 22 | 72 | — | 162 |

| Quenching from 880°C in water | 300 | 93 | 100 | 6 | 54 | — | 229 |

| 400 | 92 | 95 | 8 | 56 | — | 229 |

| 500 | 76 | 82 | 11 | 62 | — | 200 |

| 600 | 61 | 71 | 20 | 68 | — | 180 |

| 700 | 43 | 58 | 22 | 65 | — | 167 |

The influence of heat treatment on the endurance limit of alloy case-hardening steel 10G2 [2]

| steel grade | Heat treatment mode | σ-1kgf/mm2 | σvkgs/mm2 |

| 10G2 | Normalization at 880°C | 29 | 60 |

Mechanical properties

| GOST | Delivery status | Section, mm | KP | σ0.2, MPa | σв, MPa | δ5, % | ψ, % | KCU, J/cm2 | Hardness NV, no more |

| no less |

| GOST 4543-71 | Bar. Normalization at 920 °C | 25 | — | 245 | 420 | 22 | 50 | — | — |

| GOST 3479-70 | Forging. Normalization | Up to 100 | 215 | 215 | 430 | 24 | 53 | 54 | 123-167 |

| 100-300 | 430 | 20 | 48 | 49 |

| 300-500 | 430 | 18 | 40 | 44 |

| GOST 8731-74 | Seamless hot-deformed, heat-treated pipe | — | — | 265 | 470 | 21 | — | — | 197 |

| GOST 8733-74 | Seamless cold- and heat-deformed heat-treated pipe | — | — | 245 | 420 | 22 | — | — | 197 |

Mechanical properties at elevated temperatures [2]

| tsp, °С | σ0.2, MPa | σв, MPa | δ, % |

| 20 | 265 | 460 | 31 |

| 400 | 225 | 390 | 27 |

| 500 | 175 | 295 | — |

| 600 | 115 | 160 | 36 |

NOTE. Normalization at 900 °C, cool. on air.

Impact strength KCU [3]

| Heat treatment | KCU, J/cm2, at temperature, °C |

| +20 | -40 | -70 |

| Sheet 10 mm thick: | |

| in delivery condition | 86-98 | 70-88 | 41-50 |

| annealing at 900 °C | 280 | 153 | 117 |

| normalization at 900 °C | 364 | 276 | 185 |

| hardening from 900 °C; tempering at 500°C | 321 | 304 | 211 |

NOTE. σ4251/10000 = 137 MPa; σ4851/10000 = 69 MPa; σ5501/10000 = 26 MPa.

Mechanical properties depending on tempering temperature

| ttp, °С | σ0.2, MPa | σв, MPa | δ5, % | ψ, % | KCU, J/cm2 | Hardness HB |

| 200 | 780 | 930 | 13 | 40 | 59 | 350 |

| 300 | 680 | 850 | 14 | 50 | 20 | 330 |

| 400 | 590 | 760 | 18 | 59 | 98 | 240 |

| 500 | 580 | 680 | 21 | 65 | 127 | 200 |

| 600 | 570 | 660 | 23 | 65 | 186 | 170 |

NOTE. Quenching in water.

Endurance Limit [1]

| σв, MPa, steel after normalization at 880 °C | σ-1, MPa, |

| 530 | 221 |

| 590 | 289 |

Technological properties [4]

- Forging temperature, °C: beginning 1250, end 800-780. Workpieces with a cross-section of up to 100 mm are cooled in air.

- Weldability - weldable without restrictions. Welding methods: RDS, ADS under submerged arc and gas shield, ESW.

- Tendency to temper brittleness - not prone.

- Flock sensitivity - not sensitive.

Density ρп kg/cm3 at test temperature, °С

Linear expansion coefficient α*106, K-1

| steel grade | α*106, K-1 at test temperature, °C |

| 20-100 | 20-400 |

| 10G2 | 11,3 | 14,7 |

Thermal conductivity coefficient λ W/(m*K)

| Steel grade | λ W/(m*K), at test temperature, °C |

| 200 | 300 | 400 |

| 10G2 | 38 | 37 | 36 |

Young's modulus (normal elasticity) E, GPa

| Steel grade | At test temperature, °C |

| 20 |

| 10G2 | 204 |

Bibliography

- Materials in mechanical engineering. T.2. Structural steel: Handbook. Ed. I.V. Kudryavtsev, E.P. Mogilevsky - 1967

- Tylkin M.A. Thermist Repair Service Handbook - 1981.

- Gudkov S.I. Mechanical properties of steel at low temperatures: Directory.-M.: Metallurgy - 1967.

- Brand of steels and alloys / Ed. V.G. Sorokina - M.: Mechanical Engineering - 1989

Find out more

Steel 8X3 tool die…

High-quality carbon structural steel…

Steel 15

R6M5K5 high-speed tool steel…

Standards

| Name | Code | Standards |

| Classification, nomenclature and general norms | IN 20 | GOST 19281-89 |

| Steel pipes and connecting parts for them | B62 | GOST 20295-85, GOST 24950-81, STO 79814898 105-2008 |

| Sheets and strips | B23 | GOST 82-70, GOST 5520-79, GOST 17066-94, GOST 19903-74, GOST 19904-90, GOST 19282-73, GOST 19903-90, TU 14-1-4632-93 |

| Long and shaped rolled products | B22 | GOST 8239-89, GOST 8240-97, GOST 8278-83, GOST 8281-80, GOST 8282-83, GOST 8283-93, GOST 8509-93, GOST 8510-86, GOST 9234-74, GOST 11474-76, GOST 2590-2006, GOST 2591-2006, OST 5.9087-84 |

| Welding and cutting of metals. Soldering, riveting | B05 | OST 36-58-81 |

| Long and shaped rolled products | B32 | TU 14-1-1271-75, TU 14-136-367-2008 |

| Sheets and strips | B33 | TU 14-105-471-86, TU 14-1-5241-93, TU 14-1-4431-88 |

Chemical composition

| Standard | C | S | P | Mn | Cr | Si | Ni | Fe | Cu | N | As | Al | V | Ti | Nb |

| GOST 5520-79 | ≤0.12 | ≤0.04 | ≤0.035 | 1.3-1.65 | ≤0.3 | 0.8-1.1 | ≤0.3 | Remainder | ≤0.3 | ≤0.008 | ≤0.08 | ≤0.03 | — | ≤0.03 | — |

| GOST 19281-89 | ≤0.12 | ≤0.04 | ≤0.035 | 1.3-1.65 | ≤0.3 | 0.8-1.1 | ≤0.3 | Remainder | ≤0.3 | ≤0.008 | ≤0.08 | ≤0.05 | — | ≤0.03 | — |

| GOST 17066-94 | ≤0.12 | ≤0.04 | ≤0.035 | 1.3-1.6 | ≤0.3 | 0.8-0.9 | ≤0.3 | Remainder | ≤0.3 | ≤0.008 | ≤0.08 | ≤0.03 | ≤0.1 | ≤0.03 | ≤0.02 |

Fe is the basis. According to GOST 17066-94, the mass fraction of arsenic is allowed up to 0.015%, while the mass fraction of phosphorus should be no more than 0.030%. According to GOST 19282-73, it is allowed to modify steel with calcium and rare earth elements based on the introduction of no more than 0.02% calcium and 0.05% rare earth elements into the metal. According to GOST 19281-89 and GOST 19282-73, the addition of aluminum and titanium is allowed in order to obtain a mass fraction in rolled aluminum of no more than 0.050%, titanium - no more than 0.030%. According to GOST 5520-79, when smelting steel from Kerch ores, the mass fraction of arsenic is allowed up to 0.15%, while the mass fraction of phosphorus should be no more than 0.030%. At the request of the consumer, the mass fraction of sulfur should not exceed 0.025, 0.030 or 0.035%, and phosphorus 0.030 or 0.035%. When melting steel in electric furnaces, the mass fraction of nitrogen should be ≤ 0.012%.

Physical properties of steel 10

| Temperature | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| 0C | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 2.1 | 7856 | 140 |

| 100 | 2.03 | 12.4 | 57 | 7832 | 494 | 190 |

| 200 | 1.99 | 13.2 | 53 | 7800 | 532 | 263 |

| 300 | 1.9 | 13.9 | 49.6 | 7765 | 565 | 352 |

| 400 | 1.82 | 14.5 | 45 | 7730 | 611 | 458 |

| 500 | 1.72 | 14.85 | 39.9 | 7692 | 682 | 584 |

| 600 | 1.6 | 15.1 | 35.7 | 7653 | 770 | 734 |

| 700 | 15.2 | 32 | 7613 | 857 | 905 |

| 800 | 12.5 | 29 | 7582 | 875 | 1081 |

| 900 | 14.8 | 27 | 7594 | 795 | 1130 |

| 1000 | 12.6 | 666 |

| 1100 | 14.4 | 668 |

At a temperature of +20 0C, the density of steel is 7856 kg/m3

Mechanical characteristics

| Section, mm | sТ|s0.2, MPa | σB, MPa | d5, % | d4 | y, % | kJ/m2, kJ/m2 |

| Hot rolled sheet as delivered |

| 2-3.9 | — | ≥490 | — | ≥17 | — | — |

| 4-7 | ≥380 | ≥520 | ≥22 | — | — | — |

| 8-32 | ≥350 | ≥500 | ≥22 | — | — | ≥587 |

| Sections and shaped rolled products made of high-strength steel as delivered in accordance with GOST 19281-89 (strength class indicated) |

| 32-100 | ≥295 | ≥430 | ≥21 | — | — | — |

| 10-60 | ≥325 | ≥450 | ≥21 | — | — | — |

| ≤10 | ≥345 | ≥480 | ≥21 | — | — | — |

| The sheet is in delivery condition according to TU 14-1-5241-93. Quenching + Tempering (transverse samples) |

| 10-50 | ≥325 | ≥450 | ≥21 | — | — | — |

| Rolled thick sheet and broadband universal, in delivery condition GOST 19282-73 and Sheet 2-18, 19-22 categories, heat-treated, in delivery condition GOST 5520-79 |

| ≤5 | ≥355 | ≥490 | ≥21 | — | — | — |

| Sheets 16 mm thick. Normalization (cross-sectional samples) |

| — | ≥380 | ≥520 | ≥26 | — | ≥70 | — |

| The sheet is in delivery condition according to TU 14-1-5241-93. Quenching + Tempering (transverse samples) |

| 8-10 | ≥345 | ≥490 | ≥21 | — | — | — |

| Rolled thick sheet and broadband universal, in delivery condition GOST 19282-73 and Sheet 2-18, 19-22 categories, heat-treated, in delivery condition GOST 5520-79 |

| 10-20 | ≥335 | ≥480 | ≥21 | — | — | — |

| Sheets 16 mm thick. Normalization (cross-sectional samples) |

| — | ≥350 | ≥475 | ≥25 | — | ≥65 | — |

| Rolled thick sheet and broadband universal, in delivery condition GOST 19282-73 and Sheet 2-18, 19-22 categories, heat-treated, in delivery condition GOST 5520-79 |

| 20-32 | ≥325 | ≥470 | ≥21 | — | — | — |

| Sheets 16 mm thick. Normalization (cross-sectional samples) |

| — | ≥335 | ≥470 | ≥19 | — | ≥57 | — |

| Rolled thick sheet and broadband universal, in delivery condition GOST 19282-73 and Sheet 2-18, 19-22 categories, heat-treated, in delivery condition GOST 5520-79 |

| 32-60 | ≥325 | ≥450 | ≥21 | — | — | — |

| Sheets 16 mm thick. Normalization (cross-sectional samples) |

| — | ≥260 | ≥510 | ≥19 | — | ≥60 | — |

| Rolled thick sheet and broadband universal, in delivery condition GOST 19282-73 and Sheet 2-18, 19-22 categories, heat-treated, in delivery condition GOST 5520-79 |

| 5-10 | ≥345 | ≥490 | ≥21 | — | — | — |

| Rolled sheets 32 mm thick (transverse samples) |

| — | ≥335 | ≥485 | ≥35 | — | ≥75 | — |

| Rolled thick sheet and broadband universal rolled metal in delivery condition GOST 19282-73. Quenching + Tempering |

| 10-40 | ≥390 | ≥530 | ≥19 | — | — | — |

| Rolled thick sheet and broadband universal, in delivery condition GOST 19282-73 and Sheet 2-18, 19-22 categories, heat-treated, in delivery condition GOST 5520-79 |

| 60-100 | ≥295 | ≥430 | ≥21 | — | — | — |

| Rolled sheets 32 mm thick (transverse samples) |

| — | ≥305 | — | ≥33 | — | ≥74 | — |

| Thin sheets of high strength steel in delivery condition GOST 17066-94 |

| 0.5-3.9 | ≥345 | ≥490 | — | ≥19 | — | — |

| Rolled sheets 32 mm thick (transverse samples) |

| — | ≥300 | ≥460 | — | — | ≥70 | — |

| Thin sheets of high strength steel in delivery condition GOST 17066-94 |

| 0.5-3.9 | ≥345 | ≥460 | — | ≥19 | — | — |

| Rolled sheets 32 mm thick (transverse samples) |

| — | ≥250 | — | — | — | ≥69 | — |

| — | ≥185 | ≥405 | ≥30 | — | — | — |

Mechanical properties steel 10

| GOST | Type of delivery, heat treatment mode | σв(MPa) | δ5 (%) | ψ % | NV, no more |

| 1050-88 | Hot-rolled steel, forged calibrated steel and silver steel of the 2nd category after normalization | 335 | 31 | 55 |

| 10702-78 | Steel calibrated and calibrated with special finishing: |

| after annealing or tempering | 335-450 | 55 | 143 |

| after spherodizing holiday | 315-410 | 55 | 143 |

| cold-worked without heat treatment | 390 | 8 | 50 | 187 |

| 1577-93 | Normalized or hot rolled strips | 335 | 8 | 55 |

| 16523-70 | Hot rolled sheet (transverse samples) | 295-410 | 24 | | |

| Cold rolled sheet (transverse samples) | 295-410 | 25 |

| 4041-71 | Heat-treated sheet of category 1-2 | 295-420 | 32 | 117 |

| 8731-87 | Hot-deformed, heat-treated pipes | 355 | 24 | 137 |

| 8733-87 | Cold- and heat-deformed heat-treated pipes | 345 | 24 | 137 |

| Cementation 920-950 °C. Quenching 790-810 °C, water. Vacation 180-200 °C, air. | 390 | 25 | 55 | hearts 137 surface 57-63 |

Description of mechanical symbols

| Name | Description |

| Section | Section |

| sT|s0.2 | Yield strength or proportional limit with tolerance for permanent deformation - 0.2% |

| σB | Short-term strength limit |

| d5 | Elongation after break |

| d4 | Elongation after break |

| y | Relative narrowing |

| kJ/m2 | Impact strength |

Mechanical properties of steel 10 at elevated temperatures

| Test temperature, °C | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % | KCU (kJ/m2) |

| normalization 900-920 °C |

| 20 | 260 | 420 | 32 | 69 | 221 |

| 200 | 220 | 485 | 20 | 55 | 176 |

| 300 | 175 | 515 | 23 | 55 | 142 |

| 400 | 170 | 355 | 24 | 70 | 98 |

| 500 | 160 | 255 | 19 | 63 | 78 |

The study of relaxation resistance by the free bending method showed that samples subjected to MMTO have lower relaxation resistance at 150°C than in the initial state (after annealing). Additional annealing of samples after MMTO at 300-500°C allows for a sharp increase in the relaxation resistance of steels 10 and 35. The stress drop in samples over 3000 hours after additional annealing at 400°C for steel 10 and at 500°C for steel 35 decreases by 10- 30 times in comparison with samples after MMTO without additional annealing. In this case, the maximum relaxation resistance was obtained at slightly higher temperatures of additional annealing after MMHT than the maximum values of the elastic limit.

The experimental data obtained suggest that the low relaxation resistance of the samples after MMTT is associated with insufficient stability of the fine structure of the metal. Additional pre-recrystallization annealing after MMTO makes it possible to more fully stabilize the structure and, thus, sharply increase the metal’s resistance to microplastic deformations under short-term and long-term loading.