Updated: 07/06/2021

Reliable fastening of the workpiece is a guarantee of the accuracy and quality of engraving or milling processing.

Each CNC machine is equipped with a universal work table designed for installing workpieces of various configurations. For this purpose, they are provided with longitudinal grooves into which clamping screws are inserted. With their help, the workpiece is pressed against the table surface and subsequently does not move due to the forces created by the rotating cutter.

Standard work tables of machines with a movable portal are not suitable for processing large-sized sheets of MDF, plywood, plastics, and composite materials. Part of the machined surface is covered by clamping bars, and there is a risk of damaging the workpiece when tightening the screw. Problems often arise with thin sheets: due to low rigidity, they are deformed when touched by a cutter. Many manufacturers of mechanical engineering equipment equip milling machines with vacuum tables. Most often, this device is offered as an additional option, and its cost is quite high.

Matrix (lattice) work tables of a CNC machine

Matrix tables are made of sheet composite material based on phenolic resins and synthetic fibers.

The surface of the working table is divided by blind channels in the form of a lattice, to which vacuum is supplied through special holes. In order to create a vacuum area for fixing a part on the work table of a CNC machine, it is necessary to insert a sealing cord into the channels around one or more vacuum supply holes. In this case, the cord should not protrude beyond the perimeter of the workpiece being secured, and its ends should be tightly closed to prevent air leaks. The remaining unused openings of the worktable vacuum supply system are closed with rubber plugs.

This method of attaching a workpiece to a CNC machine table is most effective when processing the upper plane of a part with cutters. However, if in the process of manufacturing MDF facades it is necessary to process the sides of the workpiece, or to perform a curved cut, when the lower edge of the cutter should extend beyond the workpiece, then in order not to damage the surface of the work table, a so-called “sacrificial” substrate is used.

Any available porous materials can be used as a “sacrificial” substrate. As a rule, this is sanded chipboard, rough MDF or HDF.

Due to the porosity of the substrate material, by the force of the vacuum system, air is quickly pumped out of its internal structure, and a vacuum area is created on the surface. Thus, if you place the laminated part blank on this substrate, it will be pressed tightly against it and securely fixed.

Using a “sacrificial” substrate on the desktop of a CNC machine, you can mill individual parts, as well as cut and process large-format sheets using Nesting technology.

However, it is worth noting that when cutting large-format sheets on a CNC milling machine in this way, you can encounter a strong loss of vacuum in the area of the cuts and, as a result, small parts and scraps are displaced or fly out from under the tool. To minimize the likelihood of such situations occurring, before using a “sacrificial” substrate, you should make sure that the vacuum pump has sufficient power and the supply elements of the vacuum system have sufficient throughput.

The design features of a matrix-type work table will help solve the problem in a situation where you need to process small workpieces on a CNC machine, or eliminate the possibility of parts moving when processed using Nesting technology. The fact is that manufacturers of woodworking CNC milling machines practically offer a worktable design consisting of several autonomous matrix worktables separated by T-slots.

The effect of dividing the working surface into separate zones is achieved when, in accordance with the programmed order of processing parts from large-format panels, by opening or closing the valves of the vacuum system, all the power from the operation of the vacuum pump is not distributed over several zones, but is transferred to the area where processing is currently being done.

T-shaped grooves on the working surface of the CNC machine allow you to fix the workpiece without using a vacuum system, using mechanical clamps (clamps). On the one hand, this method allows you to reliably fix small parts. On the other hand, turn off the vacuum pump and save energy when processing workpieces using the engraving method, when the entire process can take several hours.

It should also be noted that some CNC machine manufacturers offer a set of vacuum suction cups, similar to those used on console tables, as an additional option for the matrix work table.

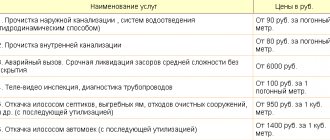

| Technology and crafts |

| Silkscreen printing |

Silkscreen printing

Vacuum table device

Now I will tell you a secret. Let it be small but important :). I will tell you about the design of a vacuum table. What is hidden under this formidable name? As the printing surface of the table, thick plexiglass (plexiglass), plastic, or stainless steel is often used (this is cool:). An important requirement for the surface is that it must be smooth and flat :) without bumps, swellings or cracks.

We drill small holes of 1.5 - 2 mm across the entire surface of the table. The distance between them is 1.5 - 2 cm.

Rice. 27. .

On the back of the table we attach a rubber gasket, or there is such insulation for windows in the form of a hose. We attach a sheet of plexiglass or plastic with a hole for a suction cup to the gasket. The gap between the table and the sheet of plastic should be from 0.5 to 1.5 cm.

Rice. 28. .

The essence is clear: air is pumped out of the gap, and air is sucked in through the holes in the table, the holes work like small vacuum cleaners :) Now any sheet of paper sticks to the table and does not move. This will allow you to achieve accurate registration when printing in multiple colors.

You can increase the suction force by filling some of the holes with sheets of paper, and vice versa, if the suction is too strong, weaken it by removing the sheets from the holes.

To create a vacuum suction cup, companies selling equipment will persistently offer compressors. The price of such a thing reaches $900.

I, in turn, suggest using a regular vacuum cleaner. You can buy used, Soviet ones, very cheaply. The dust bag is removed from the vacuum cleaner to increase power. So the compressor is ready :) see fig. 29.

A little noisy, you can reduce the noise by placing the vacuum cleaner in a soundproof casing or simply covering it with pillows :).

Just don’t block the hole through which the air comes out, I don’t know what it’s called :) For convenience, you can put the switch on the leg of the printing table.

Rice. 29. ("").

Another option is to use a suction fan to create a suction fan, you will need 3-4 of them, secure them in a box and lead the hose to the vacuum table. It works much quieter :) see fig. thirty.

Rice. thirty. .

We made our first printing table from a kitchen table. The surface was made of plastic. For 3 days, my brother and I alternately drilled these holes... We drilled them in the apartment... After that, the neighbors didn’t say hello to us for half a year :).

By the way, the vacuum suction cup can be partially noticed with the help of an expensive branded spray adhesive, with the help of which the products are held on the printing table. Or, what is closer to us:) use thick glass as a printing surface, which we will rub with paraffin from an ordinary candle. And during the printing process we will occasionally repeat this procedure.

But I repeat, this only partially replaces the vacuum suction cup. And if we want to get serious about silk-screen printing, then we need a vacuum table...

A vacuum suction cup is used for working on flatbed printing machines; it is not needed for printing on cylindrical surfaces or fabrics.

| Content |

: ..

» » .. 1993-2007 .

Preparing for work

How to make a coordinate table with your own hands

Before assembly, we study the structure in parts. If there is nothing to choose from, then we buy the necessary materials for one-by-one assembly.

What materials should I use?

It is not forbidden to assemble a structure with your own hands from available materials. Everything comes into play:

- Plywood of any thickness.

- Boards or shields made from them. Any bars.

- Chipboard, fibreboard.

- Rolled steel and aluminum.

- Pipe rolling.

Required components

It is necessary to purchase additional components if a CNC milling table is planned. But a classic stationary machine is not difficult to make from:

- Any hand router.

- Drills.

Tools for work

For work we prepare:

- Wood glue.

- Nuts, screws and bolts of the required size.

- Cover material (MDF or plywood).

- Power tools (jigsaw, miter saw, etc.).

- Sandpaper.

- Marking tool.

Materials and tools for creating a vacuum table for CNC with your own hands

Before you start assembling a vacuum table with your own hands, you should evaluate what work will be performed on the CNC machine in the future. The materials that will be used also play a role. In the process of creating a project, it is necessary to find a balance between the area affected by the downforce and the force that will act on each of the sections (to avoid deformation of the material), determine the power of the required pump, etc.

In order to assemble the table yourself, you will need the following materials and tools:

- a sheet of wood or metal of the required size;

- metallic profile;

- Vacuum pump;

- heating element;

- control unit;

- drill;

- set of wrenches;

- soldering iron;

- screwdriver.

Types of clamping elements for console tables

How to make a table for a circular saw with your own hands?

Suckers. May differ in size (for wide and narrow parts) and height. A significant disadvantage of suction cups is the weak fixation of porous materials (sanded chipboard, plywood).

Vertical clamps. They can operate both from a vacuum system and from compressed air from the pneumatic system of the machine.

Stop plates. They are installed on stops when it is necessary to block small parts that do not allow for strong blocking using suction cups alone.

Horizontal clamps. Used for parts of large thickness (for example, made of solid wood).

CFT table. A smaller version of the matrix table. Separately, using hoses and fittings, it is connected to the vacuum system of the machine.

Counterpatterns. An analogue of a “sacrificial” substrate, which is fixed on the work table with suction cups, but has additional holes for inserting tubes for connection to a common vacuum system.

How to make a mounting plate

How to make a carpentry workbench with your own hands?

The mounting plate must be wider than the diameter of the cutter if you plan to work with several cutting attachments. It is more profitable or cheaper to form this element from 20 mm birch plywood.

But it is more practical to work on a homemade machine with cast polycarbonate as a mounting plate. The essence of the work is this:

- Remove the soleplate from the power tool, having first placed the mounting plate face up.

- Temporarily connect the plate and sole using double-sided tape.

- Select drills to match the diameter of the factory fasteners and drill the correct holes for fastening on the plate.

- Next, connect the homemade plate with the router and place it on the table for adjustment.

- An 8 mm drill is placed in the collet and the motor is lowered. You need to touch the plate with the drill and mark the center.

- Next, follow the mark to make a hole of the required diameter.

Vacuum tables VAC-MAT.

Tables for working with rigid polymer mats VAC-MAT.

The design of the mats allows air to be pumped out from the volume of many chambers formed between the workpiece and the polymer mat. As a result, through processing of workpieces becomes possible (making holes, windows or going around the contour of a workpiece from one installation). All mats have a standard size of 300x200x2.5 mm, but differ in rigidity, which ultimately affects the manufacturing accuracy of the workpiece being processed. The mats are consumables and are replaced as soon as they are damaged by the cutting tool. As a rule, one mat is used for through processing of parts of one type. When switching to another type of parts, the mat is replaced. VAC-MAT tables can be made in various designs, including, as in the case of lattice tables, modular. There are also adapter boards that can be installed on grid tables to work with VAC-MAT mats.

Manufacturing stages

After preparing all the tools and components, as well as studying the drawings and the principle of the equipment, you can begin assembling the table with your own hands.

Workpiece alignment

To ensure that the workpieces being processed do not copy the unevenness of the slab, the table must initially be perfectly flat. Therefore, the prepared sheet of metal should be leveled. It is enough to make 1-2 passes with a spiral cutter until it touches completely. The diameter of the cutter is 20 mm.

We make the work surface and boxes

The first step is to create a working surface. In the prepared and leveled sheet, it is necessary to make neat holes in a checkerboard pattern using a drill. The back side of the sheet is intended for adjoining the pump.

To make the structure more reliable, it is necessary to install partitions on the working surface. Their main function is to protect the future table from deformation during operation.

DIY groove cutting

The grooves should be cut in accordance with the selected pattern. Be sure to order the sealing cord in advance and cut grooves depending on its diameter. To begin with, it is better to make the depth of the grooves 2.5 -2.7 mm. If necessary, you can increase it. In operating condition, the cord should not protrude above the surface, otherwise there may be a loss of vacuum.

Making the route

You will need a PVC pipe with a diameter of 25 or 32 mm. The purchased equipment has through holes through which the pipes are routed to the circuit. If the working surface is continuous, you will have to make a slab of two parts, seal the joint and feed the route from the end.

For each branch you will need a separate ball valve, with which during operation you can use only those zones that are necessary.

Drilling holes

The holes in the plate have different purposes. The number of different holes also varies:

- each zone has 1 hole for supplying vacuum at the intersection of the grooves;

- along the centers of the squares to secure to a standard table, and the quantity will directly depend on the rigidity of the slab;

- to fix the workpiece at the ends - holes in the center of the squares.

Pump selection

This is the main detail in the entire design and special attention must be paid to the selection of the pump. If the stove itself is made according to a certain pattern, then you can see which pump is in the original

If this is not possible, then you will have to select equipment experimentally.

The cheapest option for a DIY table would be vortex blowers. Their advantages: do not require shutdown when the maximum vacuum threshold is reached, small size, ease of installation.

Control block

This is the electronic part of the table, which is necessary to regulate the heating of the working area. As a result, the workpieces are more securely fixed. The control unit has several types of implementation, and which one is suitable largely depends on the CNC machine to which the table is being made.

Manufacturing procedure

To make a working vacuum table with your own hands, you only need to find a workpiece of the appropriate size. You already have the equipment for this - this is a portal milling machine. We suggest considering a homemade lattice-type vacuum table as the easiest to manufacture. In the future, you can buy an adapter board and work with VAC-MAT polymer mats.

Workpiece design and selection

To make a vacuum table for CNC with your own hands, you will have to develop the drawings yourself; the machine manufacturer is unlikely to share them. However, the main dimensions can still be taken from catalogs. As a sample, you can take any of the products from Witte Barskamp KG, which produces vacuum tables for CNC milling machines.

They make grid slabs with a grid pitch of 12.5 mm, a groove width of 4 mm, and thicknesses of 32.5, 38 and 48 mm. The width from the edge of the plate to the axis of the first groove is half a step (6.25 mm). Horizontal dimensions can be chosen arbitrarily, based on the dimensions of the parts being processed.

The manufacturer offers modular plates, but owners of milling machines prefer to make one-piece structures with several vacuum zones (closed circuits).

The most budget-friendly materials are 16-20 mm plywood or laminated chipboard sheets. If there are no financial restrictions, you can purchase a textolite or duralumin plate (D16T, D16AT) 8-12 mm.

Workpiece alignment

Initially, the workpiece for the CNC vacuum table must be made perfectly flat, so that subsequently the processed parts do not copy the unevenness when clamped. To do this, you need to make 1-2 passes on both surfaces with a finishing spiral cutter with a diameter of 20 mm until they touch completely.

Grooving

The grooves are milled in accordance with the selected pattern. The width of the groove must correspond to the diameter of the sealing cord, so it is better to order it in advance. As for the depth, you will have to experiment here: make the depth 2.5-2.7 mm, and then deepen it if necessary. Depending on the stiffness and porosity, the seals compress differently.

It is necessary to ensure that in working condition the cord does not protrude above the working surface, and there is no loss of vacuum.

Making the route

To make a vacuum route, a PVC pipe with a diameter of 25 or 32 mm is suitable, and if the standard table has through holes, the pipes are fed through them from below (to each circuit). If the work table is solid, then the vacuum plate will have to be made of two parts (in the form of a sandwich), the joint will have to be sealed and the route will have to be fed from the end.

It is worth installing a ball valve on each branch of the vacuum wire in order to use only those areas where the workpiece falls. The line is connected into a single manifold and connected to a vacuum pump.

Drilling holes

It is necessary to make holes in the slab for the following purposes:

- To supply vacuum, 1 for each zone - at the intersection of the grooves.

- For fastening to a standard table - in the centers of the protruding squares. The number of holes must be selected based on the rigidity of the vacuum plate. If it is made of aluminum, you can do without drilling and only attach the edges. The holes must be countersunk so that the nut is completely recessed. The clamping screw should also not protrude above the surface.

- To fix the workpiece at the ends - at the centers of the squares. You need to press the nuts into these holes (from below). A thread is simply cut into a duralumin table. When processing a workpiece of a small area, the pressing force is often insufficient to securely hold it. To prevent shifting, it is fixed with strips with grooved holes.

You can view the designs of additional fasteners on the websites of manufacturers of equipment for machine tools.

Pump selection

In order for a home-made vacuum table to work no worse than the “factory” one, maximum attention must be paid to this issue. If the mesh in the slab is made exactly according to the sample, just look at which pump is recommended. Otherwise, you will have to experiment or order a calculation.

When choosing a pump version, you should pay attention to vortex blowers. This is the most budget-friendly equipment, in which, apart from bearings, there are no other wearing elements. It does not require mandatory shutdown when maximum vacuum is reached, and is compact and easy to install.

One important design step that was not mentioned in the article is drawing up cost estimates. However, it is after completing the work on the estimate that you can definitely decide whether to try to assemble a vacuum table for CNC with your own hands, or whether it will be easier and more profitable to order a finished product.

Vacuum operating principle

To understand the principle of operation of devices with vacuum fixation of workpieces, it is necessary to understand the very definition of vacuum, its strength and possibilities of use.

By definition, a vacuum is a space free of matter. In this case, vacuum refers to a technical term that characterizes the area of vacuum that is created between the vacuum table of a CNC machine and the workpiece installed on it. However, in reality, the workpiece is not affected by vacuum, but by atmospheric air pressure, which presses it to the table surface.

In normal conditions, atmospheric air presses on the part from all sides. If you pump out the air under one side of the part using a vacuum pump, the atmospheric pressure under it will decrease. According to the law “The force of action is equal to the force of reaction,” external atmospheric pressure will press the part against the plane of the vacuum table until the resistance force of the table is equal to the pressure force of the atmosphere.

On the surface of the earth, the force of atmospheric air pressure is approximately 1 kg/cm2. That is, a weight of approximately 100 kg presses on the plane of a part with sides of 10 by 10 cm. However, in reality, the clamping force of a part on the vacuum table of a CNC machine can differ significantly from the calculated force.

In the technical characteristics of vacuum pumps there is such an indicator as the maximum residual pressure - the maximum vacuum value that the design of this unit can achieve. In addition, due to air leaks in the vacuum supply lines and the fixing elements of the CNC work table, the vacuum force may be lost. Therefore, the actual effect of atmospheric pressure on the part is much less.

It should be noted that the vacuum force may vary depending on the power of the vacuum pump, but it will never be higher than the force of atmospheric pressure.

What does a vacuum table look like?

This device is a processing surface with a coating divided into sectors. Special suction cups and grooves are evenly distributed over the area of the device, which secure the workpiece in the required position. The larger the area of the vacuum table, the more functional and expensive it is.

The workpieces are fixed using a special vacuum pump. It is he who is responsible for reliable fastening of the workpiece to the table surface. Thanks to this invention, curved processing of sheet parts with large dimensions became possible.

It is noteworthy that vacuum vacuum cleaners are preferably used for processing wooden workpieces. If there is a need to perform similar work with metal, then magnetic tables are used for these purposes.

It is worth noting that depending on the size and functionality, the price of vacuum tables can vary significantly. At the same time, even the cheapest factory vacuum table will cost the buyer at least 150-170 dollars.

You can also purchase a used device, but the quality of such a table will always be in question. It is because of the factors listed above that many craftsmen create vacuum tables at home.

The main differences between professional equipment and homemade equipment

A homemade table has several specific advantages:

- it is cheaper than the factory version;

- can be made to individual sizes and for certain functional features;

- easy to maintain, since it is easier to get all the necessary spare parts for repairs.

At the same time, the factory model has original parts and can last longer than a homemade one. At the same time, creating a vacuum table with your own hands requires effort and time.

The vacuum table for the milling machine makes work more convenient and fixes the workpiece. Some equipment models allow you to rotate the workpiece at the desired angle. If the CNC machine does not include a table, then you can make it yourself using the available diagrams and drawings.

Is it possible to do it yourself?

Buying a finished stove is quite expensive, so you can make it yourself. This is not a complicated process, but it is necessary to have all the necessary tools and parts in the kit.

Required materials and tools

To create a full-fledged vacuum table you will need:

- wooden or metal sheet of suitable size;

- metal profile;

- Vacuum pump;

- a heating element;

- Control block.

The tools you need are: drill, screwdriver, soldering iron and a set of wrenches.

Schemes and drawing for design

Efficiency of the vacuum system of a CNC machine

In comparison with other methods of fixing blank parts on the work tables of CNC machines in the production of MDF facades, the vacuum system has the following advantages:

- Easy and quick installation. Equipment of the matrix table and positioning of the suction cups is an order of magnitude faster than when using any other type of clamp;

- Ease and speed of changing workpieces. For example, when using a pedal to turn on/off the vacuum supply, the time for changing a part can reach 10-15 seconds;

- The ability to process large-format workpieces and parts with unusual geometry (if there is at least one flat surface on them);

- Unobstructed tool access to grip-free sides of workpieces;

- Gentle blocking of fragile and soft materials.

The vacuum system for fixing parts for processing on a CNC machine has its disadvantages. The main disadvantage is the weak clamping force of small parts and porous materials. There is a need to switch to the use of other workpiece fixation devices, including mechanical ones or those powered by high-pressure compressed air.

Another significant disadvantage is the need to constantly maintain cleanliness on the vacuum elements of the work table. On the one hand, this is necessary to prevent sawdust and shavings from getting into the vacuum system of the CNC machine, and on the other, to ensure the tightest fit of the workpieces to the surface of the vacuum clamps.

What is a homemade product: basic design elements

The basis of a homemade device is a vacuum table (working surface), to which the workpieces being processed are attached due to the discharge of compressed air. A mandatory element is a rubber seal.

The source of compressed air is a compressor, and the device that pumps out compressed air is a vacuum degasser.

1

Milling table design

It is customary to take strong sheet material as the basis for the design. It could be:

- MDF board;

- thick plywood;

- board made of boards of any thickness.

For each type of table, a material that is convenient for processing is selected. But it is logical to assume that the working part itself (the cover) or the plane receives the most load. Therefore it must be made of metal. Stainless steel is the ideal option.

To install a manual router, use a classic workbench or assemble a separate structure. The latter must be as stable as possible, since vibration during operation is guaranteed.

The tool itself is installed at the bottom of the table or workbench, so they provide such a position so that it is easy to remove and put back the hand router. After all, stationary milling machines are increasingly used for woodworking not on an industrial scale. In theory, nothing complicated: they assemble the stand, mount a power tool (drill, not a new router). If you try, then such an installation will not be inferior to the commercial version, because the master prepares the device for himself.

Grid vacuum table

Manufacturer:

V&F (ViF) Lattice vacuum table is designed for fixing workpieces of simple geometric shapes

| Modularity: | Yes |

| Application of coolant: | Yes |

| Foil processing: | No |

| Possibility of through processing: | No |

| Production of non-standard sizes: | Yes |

| Dimensions, mm: | 200x300…600x900 |

| Weight, kg: | from ~7 to ~40 |

How to make a vacuum table for CNC with your own hands

Reliable fastening of the workpiece is a guarantee of the accuracy and quality of engraving or milling processing.

Each CNC machine is equipped with a universal work table designed for installing workpieces of various configurations. For this purpose, they are provided with longitudinal grooves into which clamping screws are inserted. With their help, the workpiece is pressed against the table surface and subsequently does not move due to the forces created by the rotating cutter.

Grid vacuum table

One of the most familiar vacuum clamping fixtures since the days of vacuum clamping ever discovered is the grid vacuum table. This type of clamping device is used to secure workpieces of simple geometric shapes. The working surface of the table is made in the form of a lattice with grooves. The grooves are used to lay the vacuum sealing cord around the perimeter of the workpiece, forming a closed loop. The workpiece is laid out on the laid out contour and is based on the stops at the ends of the vacuum table. When vacuum is applied, the workpiece is pressed tightly against the table surface.

You can find out how the vacuum table works in the ARTICLES section.

Download catalog:

Vacuum tables and vacuum fastening systems ViF_VF.pdf

| Dimensions | |||||

| vendor code | Name | a, mm | in, mm | s, mm | Weight, kg |

| VSA-101-2030 | Grid vacuum table | 200 | 300 | 32,5 | 7 |

| VSA-101-2040 | Grid vacuum table | 200 | 400 | 32,5 | 9,5 |

| VSA-101-3030 | Grid vacuum table | 300 | 300 | 32,5 | 10 |

| VSA-101-3040 | Grid vacuum table | 300 | 400 | 32,5 | 12 |

| VSA-101-3050 | Grid vacuum table | 300 | 500 | 32,5 | 15 |

| VSA-101-4040 | Grid vacuum table | 400 | 400 | 32,5 | 18 |

| VSA-101-4060 | Grid vacuum table | 400 | 600 | 32,5 | 25 |

| VSA-101-6090 | Grid vacuum table | 600 | 900 | 32,5 | 36 |

| VSA-111-2030 | Modular grid vacuum table | 200 | 300 | 32,5 | 7 |

| VSA-111-2040 | Modular grid vacuum table | 200 | 400 | 32,5 | 9,5 |

| VSA-111-3030 | Modular grid vacuum table | 300 | 300 | 32,5 | 10 |

| VSA-111-3040 | Modular grid vacuum table | 300 | 400 | 32,5 | 12 |

| VSA-111-3050 | Modular grid vacuum table | 300 | 500 | 32,5 | 15 |

| VSA-111-4040 | Modular grid vacuum table | 400 | 400 | 32,5 | 18 |

| VSA-111-4060 | Modular grid vacuum table | 400 | 600 | 32,5 | 25 |

Operating principle and design of vacuum tables

The fundamental principle of operation of a vacuum table is the creation of an airless space by pumping air out of the chamber formed by the working chambers and the part. In fact, the material being processed is not affected by the vacuum itself generated by the device, but by atmospheric pressure, which ensures that the workpiece is pressed against the working surface.

The force of impact varies depending on the type and power of the pump installed in the mechanism, but it cannot exceed atmospheric pressure.

There are several types of vacuum work surface designs:

- Lattice. The chambers here are formed by longitudinal and transverse grooves applied to the working surface and forming a closed contour. If it is necessary to fix parts that are smaller than the table area, a specialized seal is used, which must be placed in grooves around the perimeter of the clamping area.

- Grooved (slotted). Such tables provide only longitudinal grooves. Tables of this type can be used for fixing small-sized parts with low tangential forces during processing, for example: drilling holes, engraving, etc. When working, it is necessary to have locking contours.

- Porous. A design feature is the presence of microporous inserts, which contribute to the distribution of pressing forces over the entire area of the workpiece. The devices allow you to fix even the thinnest materials (foil, etc.)

- VAC-MAT. The working field is divided into many autonomously operating vacuum chambers, which allows for through drilling, milling, etc. Such inserts wear out quickly and are consumables.

- FLIP-POD. The design of the table assumes the presence of many suction cups with high vacuum. It is designed for fixing workpieces with high mass and uneven surface.

Lattice vacuum tables in modular design

The modular principle allows you to connect several vacuum tables. Vacuum supply to each table is maintained thanks to connecting fittings.

| Options (grill) | Application |

| Ability to work using coolant | + |

| Possibility of straight through processing | — |

| Modularity | + |

| Foil processing | — |

| Manufacturing of non-standard sizes | + |

Calculation of shear force and separation of the workpiece from the vacuum table

Price on request

x

download page in PDF format Print page

About the companyDealersPartnersArticlesContactsDemonstration

Shtray, 2000-2020

Home | Milling machines | Machining centers | Marking | Milling and engraving machines CNC lathes | Vacuum equipment | Measuring tool | Site Map

117437, Moscow, st. Ostrovityanova, 13 Directions

Vacuum tables for MULTICUT machines

The MULTICUT company is one of the leading Russian manufacturers of CNC milling and engraving machines and tenoning and slotting coordinate units with program control. The company offers a wide range of machines whose tasks include cutting sheet materials and producing furniture facades.

One of the main advantages of the equipment is the integrated vacuum clamp in the basic configuration of the table. It consists of a pipeline system, shut-off valves and channels on the working surface. The following series of machines are equipped with a vacuum clamp:

The vacuum pump model is selected by MULTICUT technical specialists in accordance with the required pressing force.

Source

Main parts of the milling table

We mean the set of elements from which it is not difficult to assemble the installation on your own:

- Aluminum guides.

- Steel plate for working area. It's also a mounting plate. A router is attached to it.

- Sheet of plywood.

- For the base there is an MDF panel.

On this kind of tables, it is advisable to install the buttons necessary for turning on and quickly stopping (emergency lights). Upper clamping devices are included in the assembly plan in case of working with large parts.

Table type

There are only three of them. Milling tables are:

- Aggregate. It is possible to expand the saw plane.

- Portable. Small size, easy to carry weight.

- Stationary. The structure is weighty and very difficult to move on your own.

Cover material

- The base, cover or working surface must be covered with plastic (if we are talking about an MDF panel). But such a table can become saturated with moisture, which will affect the quality of the milling cut, plus the grooves in the swollen panel lose their normal mobility.

- Phenolic plastic. Optimal for a machine, but more expensive than an MDF panel.

- Steel. Aluminum, stainless steel or rolled sheet. Sometimes they also install cast iron. But the issue of corrosion is solved with paint.

Groove for stop

This is just a recess for a movable longitudinal stop or a built-in carriage. The groove is an ideal element of the table design; additional devices are used due to it. An analogue of a groove is a movable slide. They are perpendicular to the longitudinal stop, plus they are also movable.

Fixing the router

The hand tool is mounted on a rigid plate made of steel, stainless steel, aluminum, textolite, etc. The plate itself is mounted with a recess so that it can be recessed into a level with the lid.

Longitudinal stop

Fixed on the table. Its purpose is to correctly feed the workpiece. Longitudinal stops are stationary. This is convenient for processing the same type of material.

Sliding stops are ideal for milling various elements according to dimensions. The quality of operation of the entire machine depends on the longitudinal stop, its stability and smoothness.

Vacuum groove tables

This type of vacuum tables is designed for securing workpieces with a small contact area (small products, workpieces with a large number of holes and windows). The use of flat mats with a high coefficient of friction makes it possible to create additional force from the shear of the workpiece relative to the fastening plane.

A flat mat is placed on the plate, in which holes are knocked out, located under the supporting surface of the workpiece, as shown in the figures. When secured, the workpiece is pressed tightly against the mat. On these tables, just like on the VAC-MAT tables, through-processing of workpieces is possible. After perforation, the mat will serve as a template for fastening and processing similar parts.

Features of choosing a router design

The capabilities of modern CNC equipment are enormous. But no machine is universal. Each model has its own characteristics and preferred area of application. Before choosing a specific design, you should clearly determine what the machine will be used for. An attempt to combine everything in one will lead to large material and physical costs, without guaranteeing results.

Today, there are two directions in the design of desktop routers. The first, the simplest, is focused on processing wood, plastic and other soft workpieces. Such machines do not place high demands on structural materials and are simple and low in cost. They are available for self-production, without the use of additional equipment. Metal products on such devices are usually not milled. In rare cases, only soft non-ferrous metals are sharpened at low feed rates.

The second direction of milling cutters is focused on working with metal workpieces. These machines have a significant mass and consist of parts that can only be completed using a serious machine park.

The second most important parameter of the machine is the dimensions of the processed parts. Beginners immediately want a large field where they can do whatever they want

But the larger the machine, the more technical problems will have to be solved during its design. And its cost will not be the most optimal. If there are no specific tasks for a large machine, then it is recommended in the first project to limit the processing field to the size of a standard A4 paper sheet. The maximum you can choose is A3.

Manufacturing stages

After purchasing all the necessary materials and tools, you can proceed to assembling the table yourself.

Manufacturing of working surface and box

At the beginning of making a vacuum table for CNC, you need to create a working surface with your own hands. To do this, take a pre-prepared sheet of material. Holes are carefully drilled in it, in a checkerboard pattern, using a drill or screwdriver. Later, from the back, the surface will be adjacent to the vacuum pump, which serves to securely fasten the products. To increase the reliability of the structure, partitions are installed. They prevent the table from deforming during use.

Box

The most significant thing here is the height, since the table is designed for a numerically controlled machine. A stable structure is assembled from metal and wooden parts to secure the working surface. The surface above the working area will act as a holder for the heating element. It is desirable that the box be collapsible: this will facilitate further work, setting up equipment or transporting the table in the future.

The desktop should be as stable and reliable as possible. Therefore, it is advisable to avoid short-lived or moving connections in the design. To make it easier to move the tool, you can use adjustable height feet. This will allow you to work on uneven surfaces, providing stability.

A heating element

Vacuum forming of plastic also requires a special table. During operation, the product is exposed to a vacuum field and a heating element, which heats the plastic to the required temperature. To do this, a heating panel is installed above the table. Nichrome thread has proven itself best as a heating element. However, due to the high cost of the material, as well as the difficulty of finding it on the open market, halogen lamps are usually used for self-production.

A sheet of metal is taken as a workpiece. Holes for lamps are also drilled in it, after which the heating elements are secured and the electrical part is installed. All lamps must be connected in parallel. With a more complex design, the electrical part is output to a controller or separate switches to heat certain parts of the work area. The connection is made using soldering and copper wires. To reduce wiring, have a more pleasing appearance, ease of operation and greater wiring reliability, it is recommended to use a printed circuit board or several small circuit boards. The design of the light panel should also be dismountable for maintenance.

Vacuum pump

The most important piece of equipment. Serves to create a vacuum and securely fix the part. It is best to use a specialized vacuum generator with a pressure gauge. If a dedicated vacuum pump is not available, several vacuum fans will do. It is possible to replace them with industrial vacuum cleaners, but in practice their efficiency is lower.

When connecting, it is important to reduce the air flow as much as possible, that is, insulate from the entrance to the working surface. A pressure gauge is needed to measure results: too much vacuum can damage the part, work surface or equipment

With a more complex table design, the heating part regulators and pressure gauge are installed in the control unit.

Control block

The electronic part of the vacuum table is needed to effectively regulate the heating of the working area and create a more stable fixation of parts. There are many options for implementing a control unit; the biggest role here is played by a milling machine and numerical control installed in the working equipment. The most optimal one is selected based on the tasks, budget, and availability of specific elements. For optimal operation, a microcontroller with display and one relay per control unit are required.

Temperature and pressure sensors are used for comfortable operation. The minimum configuration requires one sensor and 2 relays: one to turn the pump on/off, the other to control the heating panel. To delimit the work area, use the clamp and heat only for part of the table, it is necessary to use a larger number of relays and, accordingly, a more efficient controller. Installing a reliable control unit will make work more comfortable and will allow you not to be distracted by pressure gauge readings.

Required materials and tools

To make a vacuum table for a milling machine, you need to find all the components. To create functional equipment you will need:

- wooden or metal sheet of appropriate size,

- metal profile,

- Vacuum pump,

- a heating element,

- Control block.

Tools you will need: drill, screwdriver, wrenches, soldering iron. The remaining tools are used optionally, if available.

CNC machine stop systems

An integral part of any work table of a CNC machine or CNC machining center is a system of stops.

Typically, stops are placed on the front and side of the workbench, forming perpendicular stop lines, the intersection of which indicates the zero point of the origin of the machine's X and Y axes. Pneumatic cylindrical stops are installed as standard on CNC machines. Upon command from the control panel or when the pedal is pressed, the stops are raised to position the workpiece. Once the workpiece is locked by the clamping elements, an additional command is given to lower the stops, or they are retracted automatically after starting the machining program. In a more advanced version, the stop lines can be located on all four sides and the center line of the desktop. In this case, the working area of the CNC machine can be divided into 3-6 locking zones, in which several parts can be fixed at the same time and processed according to one program.

The difference between factory equipment and individual equipment

Creating working equipment allows you to adapt the tool to individual needs. Self-designed vacuum tables can be adjusted to the required dimensions and include all functions from milling to forming work. The main advantages of such a table are:

- cost savings;

- individual sizes and functional features;

- ease of maintenance due to the availability of spare parts.

The main disadvantages are the large expenditure of time and effort, less high reliability compared to factory analogues and the lack of warranty service.

https://youtube.com/watch?v=NtEWNCyI64Q

What is the difference between a homemade and factory vacuum table?

Working equipment created independently allows you to adapt the device to the needs of a specific production process. Do-it-yourself vacuum tables allow you to take into account all the nuances of processing parts related to their size, as well as include all functions - from milling to molding work. A vacuum table for a CNC machine, assembled independently, saves the user money and simplifies further maintenance of the device.

Vacuum tables can significantly improve the efficiency of the production process and improve the quality of manufactured products. This is achieved by creating the powerful clamping force needed to achieve consistent quality. If the CNC machine does not come with a ready-made table, you can make it yourself. This is a simple process, and diagrams and drawings of devices can be found freely available on the Internet.

- November 15, 2020

- 996

Table manufacturing stages

Before starting to purchase the material, determine the location in the workshop for future installation. When the future design will be used occasionally, then portable tables are chosen. But if there is a lot of space in the carpentry workshop, then a wide milling table, convenient for processing boards or panels of 2 meters, is productive.

Manufacturing of bed and table top

By frame we mean a frame with a support, but which also houses the tabletop itself. It is customary to assemble a bed from whatever is spared. No particular preference. You need to achieve rigidity and stability.

Before assembling the frame, it is advisable to take care of the operator’s comfort. Typically, the lower part of the frame deepens 10-20 cm from the lid itself. It’s more comfortable and therefore safer.

If you study the drawings and design features, it is not difficult to fit a convenient carpentry workbench under an old router. We remember that vibration occurs from the operation of the machine, so we are considering this option if the workbench is firmly standing.

It is customary for homemade products to use a reliable, stable, motionless frame, and it is advisable to weld it from a profile, since the entire load is transferred to the base. Fits:

- Steel pipe.

- Corner (trimmings).

- Channel.

Only then wooden beams and chipboard.

It is inexpensive to assemble a milling table for periodic use from a 25x25 or 40x20 profile pipe. Using an angle grinder, cut the profile into 4 legs, a rectangle (frame) and lower connecting parts. All this is strictly in size.

Then the profile is welded into a frame, complementing the structure with a pipe. The latter is necessary for the parallel stop. 4-6 legs must be framed with a profile or corner. But this is after installing the table top itself. Plus, the metal frame makes it possible to pre-weld a limiter for electrical equipment.

Application area

Milling machines are used for complex machining of parts in three coordinates. Among the simplest types of milling: the process of engraving and cutting parts from sheet materials. Feedstock: plywood, textolite, plastic. The result is flat parts, which are later assembled into some kind of structure. These can be boxes, caskets, electrical equipment housings, frames of volumetric products. Two-dimensional processing is also used to create artistic products.

A more complex type of processing is volumetric or three-dimensional. It allows you to cut products with complex surfaces from massive blanks. For example, machine-made wood carvings are often superior to hand-made ones. Installing an additional rotary axis on the machine further expands its capabilities. Four-axis turning allows you to produce cylindrical parts or three-dimensional products with highly complex relief. Examples include sculptures or curved furniture fronts. It is possible to create machines with an even greater number of degrees of freedom, but today this remains the domain of professionals.

In addition to classic milling, a CNC router can be used to perform other types of work. Instead of a milling head, plotter knives, lasers or 3D printer extruders can be easily mounted. In some cases, plasmatrons are installed for cutting metal. All these tools do not change the equipment design and control methods.