The most important blacksmith tool

Anvils are the most important tool that allows you to perform various forging works associated with cold and hot forging of metal. This element of the workshop is quite specific, but it is simply irreplaceable in the case of professional production of forged products.

Such a tool may vary depending on the type of problem being solved. It can have a variety of structural elements, sizes and shapes. There are mainly two types of forging anvils: one-horned and two-horned.

The first version of the device is in greatest demand. The horn is used in shaping the bends of metal products in figured forging.

What does the anvil consist of?

The sides allow you to make bends at right angles. The surface of the device itself is smooth and even, and also ground and hardened. This is the working part.

It contains two square and round holes, which are used when performing additional operations with products and when supporting the tool.

Based on weight, anvils are divided into small, medium and large. The best option is the heaviest models weighing 95 kg or more. Such devices allow you to work with large workpieces.

At home, such a tool is not one of the most necessary. However, its presence allows you to easily align various products, such as nails, wire or sheet metal.

Naturally, use for domestic purposes does not require the mandatory purchase of such a tool. However, if necessary, a homemade anvil can be made. It will easily allow you to perform all the simplest functions that are required of it.

Of course, it is extremely difficult to make a high-quality figured product using a homemade version. In this case, it is better to pay attention to professional models. But for all other needs, a hand tool will be the best choice.

Face

The front part of the anvil is the main working surface, which bears the entire load during the metalworking process. A prerequisite for manufacturing is the heat treatment of the face to a hardness with an HRC rating of 45–50.

The entire surface is carefully polished to an almost mirror-like shine. The edges on the sides of the anvil face are kept exactly at right angles. The ribs must be sharpened without chips or dents.

Many forging operations are performed on the face of the anvil, and bending of blanks and sheet metal is performed on the ribs.

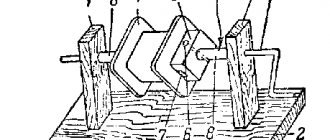

Types and structure of anvils: a) hornless, b) one-horned, c) two-horned. 1) face, 2.9) holes, 3) tail, 4) mounting brackets, 5) chair, 6) paws, 7) horn, not hardened platform.

1) face, 2.9) holes, 3) tail, 4) mounting brackets, 5) chair, 6) paws, 7) horn, not hardened platform.

Anvil elements

A blacksmith's anvil is a mandatory attribute of his workshop. With its help, a number of technological operations with metal are performed. This tool is used for forging, giving metal the required shape, hardening, etc.

This item is made of durable alloy steel, and its weight can exceed 300 kilograms, especially if we are talking about a stationary forging anvil.

It must be stable and durable, as it bears significant loads. Hitting the anvil with a hammer produces a smooth, clear sound. A dull ringing indicates the presence of cracks or voids in the instrument.

As noted earlier, there are one-horned and two-horned models. Why does the anvil have this shape? The point is this: the horn allows you to make bends with the necessary curvature, and the flat surface serves to do the main work.

Anvil mounting diagram.

The main elements of the device include:

- horn;

- shank;

- recess for forming holes;

- holes for installing tools and other forging equipment on the anvil;

- face;

- shoe;

- platform for cutting metal.

The protrusion on the side of the instrument is called a horn. Its shape varies depending on its purpose. In one-horned models it is cone-shaped. Used in forming metal bends and rolling out rounded parts.

The second horn is used in bending products at angles less than normal and is made in the shape of a truncated cone.

A face is a flat surface. It is on it that the main operations are performed.

The classic type of anvil always has holes. One of them is square - used as a tool holder, for example, a hammer. It is usually located at the end of the device. The second is round, fixes the wire when curling it, and is located near the horn.

The anvil should absorb the impulse from a blow to the front part. For these purposes, the device is installed on a durable wooden or sand cushion.

It is important that the face is positioned strictly horizontally. This will allow you to do the work with the highest quality.

Many people are interested in the question of how to set the anvil in height. The height of the anvil from the floor is correct if the hammer strikes the casing horizontally. In addition, it is important that the blacksmith does not have to make additional efforts to adjust the blow, bend down or lift the tool too high.

Anvil base

The base of the anvil can be a heavy wooden block (called a “chair”) dug into the ground. The depth to which the chair needs to be dug is at least 0.5 m. The anvil itself is attached to the base either with clamps or crutches. The chair in its upper part must be fastened with a steel hoop. The diameter of the log is recommended to be at least 600 millimeters. The ground around the chair must be thoroughly compacted. The top of the chair must be perfectly level, otherwise the anvil will bounce from the impacts.

If you don’t have a suitable block of wood, you can make it a composite one.

Stacked bases for anvils

It is also permissible to make the anvil base in the form of a cast iron or steel rack for mobility.

Single-horned anvil on a steel base

Anvil base

Sometimes they just use oak, maple or birch stump.

Photo of an anvil on a stump from the blacksmith festival

You can also use a wooden or metal barrel filled with sand, clay or earth, and place a wooden pillow on top.

Scheme of installing an anvil in a barrel

It is practical to cover the upper part of the chair with roofing iron, so that the chair does not burn from hot stumps and other things.

The height of the base is determined individually. It is recommended to make it at such a height that the blacksmith could touch the face of the anvil with the fingers of his lowered hand. Then he will not spend extra effort when forging, leaning forward and lifting the hammer too high. In other words, he will not get unnecessarily tired while working.

If a one-horned anvil is used (most often this is the case), then the horn should be to the left of the smith.

Due to the enormous load on the anvil during the forging process, it must be very firmly attached to the chair. The base should be strictly vertical, and the face of the anvil, accordingly, strictly horizontal. During forging, neither the anvil nor the chair should vibrate.

The anvil is placed at a distance of 1.5-2 meters from the forge and at approximately the same height; this makes it easier to transfer the hot workpiece from the forge to the working surface of the anvil.

Enough free space should be left around for hammer hammers and other auxiliary workers.

Even from this metal you can make a base for an anvil, watch a short video here. And on this page there is a photo of the assembly of that base step by step.

Metal

Almost anyone can make cold forging equipment and operate it.

See also:

To carry out work, the best inverter-type welding machines must have an output current of at least 160 A. The ssva-160-2 inverter is exactly such a machine. Using a forge, you can obtain a wide variety of workpieces for welding work. There are many examples of products made by welding and forging, photos of which can be viewed on Internet sites.

Sections: Anvil

Tags: metal forging at home

Previous article: Next article: Italian metal forging is a beautiful art

Types and types of anvils

Types of anvils, their shape and weight can vary significantly.

They are divided into several categories according to the above criteria, namely:

- hornless – massive instruments with a large weight, the value of which is in the range of 96 – 210 kg;

- one-horned - have only one cone-shaped horn, their weight varies from 70 to 210 kg;

- two-horned anvil - a device weighing from 100 to 270 kg;

- single-horned cantilever;

- shperaks are mini anvils weighing up to thirty kilograms.

The choice of anvil for hand forging is made based on the work that is planned to be performed. Heavier models are perfect for working with large and massive workpieces. Simple, lighter options with one horn are a good choice when working with small-sized structures.

Lightweight models are suitable for small jobs at home. If you need to make any homemade product, there is no better option.

An important criterion is the type of work performed. Here you should decide which option is better: a two-horned or one-horned model. In addition, anvils may have additional elements, for example, a vice, which allows you to perform work alone.

It is worth paying attention to the presence of holes used to place hammers and sledgehammers.

Shperaks, small in size and weight, are widely used in jewelry. In this area, products do not require serious impact processing, so they need an appropriate tool.

Drawing of an anvil for making it yourself.

Quite often, devices for performing jewelry work are made to order. They have various functional elements necessary to solve certain problems.

Sometimes one anvil may not be enough. In large workshops, it is advisable to have two options for devices: one stationary and the other portable.

Don't forget about proper installation. The quality of work directly depends on this. Despite everything, this device is quite heavy; its installation should be given due attention.

Falling and tipping over are common problems caused by improper installation. In addition, the stand must fulfill its direct functions: in addition to securely fixing the device, it must be able to absorb hammer blows.

A wooden block is the most commonly used type of stand. Its diameter usually ranges from 500 to 600 mm. Hard woods are used. These include oak, birch, ash, etc.

The installation height is determined by the height of the master. To prevent the wooden stand from creating additional unnecessary vibrations, it is buried in a hole more than half a meter deep. The bottom of the pit is compacted with a sand lining.

It is important that the chair is installed horizontally. This parameter can be easily checked using a level.

If buying an anvil is not affordable, then you can replace it with a homemade device. It can be made, for example, from a rail, channel or I-beam.

Such devices, made with your own hands, will last for decades. However, you should not think that they can fully replace a real, professional instrument. Hand anvils will not produce the same quality work as production models.

In this case, it is important to understand: the factory version, produced using casting technology, will be significantly better than homemade ones. Its design contains all the necessary components with a hardened surface.

In addition, in this model the horn has the correct shape, necessary, for example, in skillful figured forging. The factory model will last quite a long time.

Making an anvil with your own hands

The design of the anvil is quite simple. Its manufacture by hand does not require drawings, special skills or special tools and equipment. By and large, the device is a monolithic device with a special shape and planes that meet certain requirements.

At the moment, forging equipment is presented quite widely in specialized stores. There you can choose any tool, including an anvil, from a huge assortment of varieties. So does it make sense to make this device yourself?

When answering this question, you need to decide for what tasks the tool will be used. In professional production, you should definitely choose a factory model. Its advantages include compliance with all necessary standards, as well as manufacturing features using casting technology.

Such an instrument is highly hard, has regularly shaped horns and perfectly straight side edges.

However, the price for a good model is quite high, especially in the case of large-sized options. However, there is no alternative to such devices; making them by hand is definitely not possible, because the weight of a forge anvil can reach 300 kilograms.

But for homework, a small-sized, lightweight anvil is perfect. You can just do it yourself. The described option is unlikely to have a negative impact on the quality of work.

One of the arguments in favor of hand-making the device is the fact that high demands are placed on anvils. For example, the edges of the device must be strictly straight and undeformed.

During constant use of the tool, quite often the edges become uneven. Of course, everything depends on the type of material used by the master in his work. Nevertheless, this defect must be eliminated. There are two ways to correct such a defect: buy a new device or repair the old one.

Naturally, repairs will cost less than purchase. It should be noted that restoring a hand-made anvil is a simpler task. So this is a great opportunity to save money once again.

Now we can safely move on to the question of how to make an anvil for forging metal? There is no point in providing any standard dimensions or drawings. There are a large number of different options for this equipment. Everyone can choose what suits them best.

The main goal is to understand and master manufacturing technology. The master will decide all other points himself, especially since on the Internet you can easily find various photographs of anvils and use them as a template when creating the most optimal version of such a forging device.

First of all, the issue related to installation should be resolved. In the case of a stationary option, as noted earlier, a massive stump should be used. But in the case of a portable model, a metal frame welded from corners is used.

Do not forget that it needs to be resistant to serious shock loads. This problem is solved by installing additional ribs in the frame, providing increased rigidity.

Although, of course, there are other methods to strengthen the structure. It all depends on the ingenuity of the master and his preferences.

If the base for the anvil is a stump, then it should be tightened with metal rings. Simply burying part of the tree's base in the ground is not a good idea. Even if properly treated with antiseptics, it will begin to deteriorate over time.

It is advisable to use a metal barrel placed in a hole as a base. Sand should first be poured into the barrel. The amount of sand depends on the preference of the blacksmith. As for the wood, it is selected from strong species. Which has already been mentioned earlier.

Installation of the device on the base is implemented in several ways. The most reliable option is fastening using metal brackets. They must be secured between the side surfaces of the hemp and the tool.

A similar installation method can be implemented using fittings. It must be bent into an “G” shape and welded to the base. Then, when the device is installed on the stump, the reinforcement is driven into its sides. As a result, any possibility of the device falling on your feet is eliminated.

This type of fastening will be very effective. The forging device will be securely connected to the base and will not lose grip even after a long period of use.

The second option is simpler. It consists in drilling holes in the sole. Bolts are subsequently inserted into them and screwed directly into the stump. The disadvantage of this method is the loosening of the tool after impacts. To avoid having to tighten the bolts from time to time, it is better to use staples.

According to industrial technology, forging anvils are made of 35L alloy steel. At home, an anvil is usually made from a rail or channel. One of the sides of the selected material will be used as a base.

You can make a face by welding a metal plate of the appropriate brand. You can do without it. In this case, you will have to spend a lot of time and effort on grinding one of the sides of the rail.

A handmade rail anvil will last a very long time. It is perfect for almost any household needs or small workshop.

It is worth noting one nuance: making such a forging tool from a channel is not the best option. On the one hand, it is simpler and more convenient to process. However, its strength characteristics are not high. As a result, the service life of the device will be short.

You can make a horn from an elongated part of the rail, treating it accordingly. However, you will have to spend not only a lot of effort, but also consumables, for example, angle grinder discs. This problem is much easier to solve by welding this part to a ready-made tool. Don't forget about the insert that is welded.

Thus, it can be noted that the best manufacturing material is rail. The characteristics of this material meet all the requirements, and it is quite cheap, perhaps the craftsman even already has it in his household.

The manual version will not be a replacement for a full-fledged factory device, but in case of small volumes of work it will be an excellent choice. It is important that during manufacturing no special skills, specialized tools or any drawings are needed.

Materials you will need:

- a piece of rail up to three hundred millimeters long;

- profile pipe;

- stump.

The necessary tools are a grinder and welding, depending on the type of structure.

Finally, after all the manufacturing work has been completed, the instrument can be given a nice final look through painting.

As you can see, every person can cope with the manufacture of such a simple but very important tool. This does not require the use of specialized equipment and does not require special skills. In addition, the materials used to create such a device are not so difficult to obtain.

The only problem may be the processing of the rail, in particular its grinding. The material from which it is made is highly durable, so you will have to spend a lot of disks on processing.

However, the result is worth it, because the end result is a reliable and durable anvil made by yourself. She, without any doubt, can become the pride of the workshop.