Basic principles of metal bending

When a craftsman needs to get a product with corners of a certain shape, he can cut a metal sheet and then use a welding machine to connect the individual parts at the desired angle. However, heating the material to high temperatures changes its structure, which can negatively affect the properties of the metal.

In order not to violate the integrity of the workpiece or change the structure of the material, metal sheets can be bent. The principle of bending is that the outer layers of metal are stretched and the inner layers are compressed. The sheets are not preheated. The equipment operates on the principle of a system of levers, to which a master or drive transmits force. The maximum bending angle is determined depending on the thickness of the workpiece, the type of material, and its characteristics.

When bending sheets along a radius or at sharp angles, it is necessary to first check the accuracy of the alignment of the parts. If a misalignment occurs and the product is bent, microcracks may form, which will lead to destruction of the integrity of the workpiece during operation.

METAL BENDING TECHNOLOGY

The sheet metal bending process takes place in three stages:

- Elastic tension.

- Neutral state.

- Plastic tension.

Smooth, straight workpieces are most often subjected to cold processing, without heating.

Heating is used to develop parts with a thickness of 12 to 16 mm and high-carbon steels, monoplastic metals and titanium. It must be taken into account that for limitedly ductile metals and alloys, it is extremely important to take into account the location of the internal fibers. If the direction of the metal fiber coincides with the direction of movement of the axis of the workpiece to be bent, damage during the manufacturing process is unlikely. In connection with the above, to prevent product rejection, it is customary to take into account the following aspects:

- The direction of the fibers of the material to be processed;

- Permissible level of deformation, depending on the thickness of the workpiece;

- Metal fluidity indicators;

- Acceptable deviations from the shape of the specified final product.

With the correct calculation of all parameters, the presence of defects is reduced to a minimum.

Types of bending

There are two main ways to bend metal sheets:

- Longitudinal - the material does not heat up before bending. Because of this, it is impossible to bend workpieces of large thickness.

- Transverse - includes three technological operations - bending, upsetting, drawing. The part is preheated. The edges bend without heating.

Radial bending of metal is carried out using manual or industrial equipment. Depending on what shape of the finished product needs to be obtained, the design of the machines changes.

Press brake (Photo: Instagram / stankoprom)

TYPES OF SHEET METAL BENDING

It is customary to distinguish between two options for bending sheet metal:

Manual metal bending

This type of bending of metal using a hammer (mallet) and a fixing vice when it comes to sheet metal. This method is mainly relevant for home use, or limited production with small volumes of products produced.

Mechanical bending of metal

It is used in production conditions on high-tech equipment. To work with metal, machine tools, press brakes and rolling equipment are used.

Metal bending is usually classified into four types:

- Angular, or V-shaped;

- Angular, or U-shaped;

- Multi-angle;

- Radial.

Types and design of bending machines

Sheet metal products are processed using different types of bending equipment. Types of sheet benders:

- Manual mechanisms. They are machines that operate using a lever system. To bend the workpieces, the master needs to apply force through special handles that raise the pressure plate.

- Equipment with hydraulic, pneumatic drives, electric motors. These are industrial machines that reduce the effort on the part of the worker when bending.

- Vertical press brakes. The workpiece is located on the work table. The working part of the press begins to press on it from above. It is driven by a pneumatic or hydraulic system.

- Pipe benders with different control systems. They can be manual, equipped with drives that facilitate the work process.

- Angle pipe benders.

- Mandrel pipe benders.

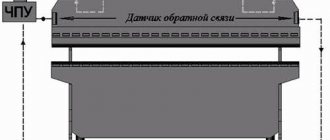

The difficulties of using machines directly depend on the control system. Manual models require precise checking of the placement of the workpiece, transferring forces to the levers to bend the workpiece. If a CNC system is installed on the equipment, the work process becomes more efficient, accurate, and faster. However, working on machines equipped with CNC is more difficult than on simple models. You need to know how to set settings, set algorithms, and remove errors.

How to order beautiful radius metal bending from us?

① Choose any basic profile on our website or draw your own sketch.

② Decide on color according to RAL or RR >>

③ Write a request to e-mail: [email protected] or call

④ Agree with the manager on the form of payment and production time

⑤ The order can be picked up at one of our offices or ordered delivered to your site

R.S. You can call our specialist for measurements and subsequent installation

You can order radius bending of sheet metal of any complexity.

Our specialists will perform all work with high quality and in full compliance with quality standards.

You can order metal bending service from us! Just dial our phone number or write

Creating a sheet metal bending machine

For defect-free bending, you can use homemade mechanisms. You can make them yourself without having additional skills. To do this, you need to create a drawing, prepare materials, tools:

- channels, metal corners;

- pressure plate;

- door hinges;

- wooden block;

- metal rods.

The tools you need are a welding machine, a drill with metal drills, a grinder, and a grinder.

Stages of manufacturing the machine:

- Initially, you need to prepare the materials, cut the channels, corners, and rods to size using a grinder.

- Assemble a frame with stable legs. Connect the individual parts using a welding machine. Clean the seams with a sander and coat them with an anti-corrosion compound.

- Connect two corners with door hinges to create a movable structure.

- Weld metal rods onto one of the corners to act as handles.

- Attach the movable structure to the frame so that you can work with workpieces.

Some craftsmen make mechanisms without a base, which are mounted on a finished workbench.

Channel (Photo: Instagram / stockwood.ru_moscow)

The following colors are available:

| RAL 1014 | RAL 5005 | RAL 7024 |

| RAL 1015 | RAL 6002 | RAL 8017 |

| RAL 3005 | RAL 6005 | RAL 9003 |

| RAL 3009 | RAL 7004 | RAL 9004 |

| RAL 3011 | RAL 7005 | RAL 9006 |

| RR 32 | RR 11 | RR 29 |

Other colors and coatings are available upon request

If you choose a color from stock items, then the planks (additional elements and flashings) can be picked up the next day. We make fence caps and chimneys within 5 working days. If the color is custom-made, then the production time is individual, but in any case it increases by 1-3 weeks due to the delivery of materials.

Powder painting is possible in any RAL color, including with additional effects.

Sheet metal bending allows you to create complex seamless metal structures with high precision shapes and sizes. The absence of welds and other connections on the surface of the structure provides not only its aesthetics, but also additional protection against corrosion and negative environmental influences.

Using radius bending, you can make curved canopies, weather vanes, ebbs and ventilation grilles.

Metal bending processes:

- the metal becomes thinner and its cross section is deformed;

- the neutral layer shifts towards a smaller radius.

Hand bending

To know how to work with metal sheets and produce products of the required shape, you need to take into account the bending radii of sheet metal. The maximum and minimum radii can be viewed using special tables that can be found on the Internet. Stages of the technological process:

- The integrity of the sheet is checked.

- The ratio of the thickness of the workpiece, the forces transmitted through the equipment to it, and the strength of the metal is calculated.

- A drawing of the future product is made.

- The angle is set on the equipment.

After starting, bending is performed. It is important to double-check the accuracy of the part alignment so that misalignment does not occur.

Radius bending is a separate technological process by which metal sheets are processed. It allows you to deform metal without changing its structure. The master needs to calculate the angles, taking into account the type of metal, alloys, and sheet thickness. Incorrect calculations will lead to the formation of microcracks that will affect the integrity of the part.

Advantages of the method

This method is a good alternative to other processing methods, such as cutting, welding or riveting. This method, in comparison with others, has several advantages. This:

- Cost-effective, no waste during processing.

- Preservation of the mechanical strength of the workpiece, absence of welds.

- Anti-corrosion resistance of the finished product. In the place where the bend is made, the structure of the material does not change.

- Attractive appearance of the finished product.

There are several types of radial bending of sheet metal. The processing method is selected depending on the type of the original workpiece.

Bend a corner radius

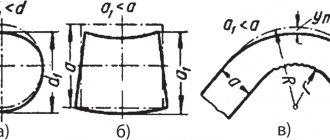

Bending a metal corner along a radius is a rather complex technological operation, since any bending is a simultaneous compression of the inner and stretching of the outer layer of metal, and, in the case of a profile in the form of a corner, such processes cannot proceed evenly, which will be accompanied by an attempt to longitudinally displace one from these layers.

Directly for a metal corner, two main methods of bending in the profile plane are used - this is when one of the shelves lies in a vertical plane, and the other in a horizontal one, and its bending will be:

- inside the radius of curvature of the deformation, in which case it will be greatly compressed,

- outside the radius of curvature of the deformation, accordingly, it will stretch.

Cold bending of a metal corner using the rolling method on special profile bending equipment allows you to bend both a steel corner and an aluminum profile, thereby obtaining products of almost any radius with an ideal shape.

You can see how to bend a corner along a radius with your own hands in this video.

It is worth keeping in mind that for both hot and cold bending methods there are maximum radius values that directly depend on the size of the corner flanges and its thickness. So, you can simply calculate the radius by which it is permissible to bend a corner, according to the following values:

- the permissible radius for an equal-flange corner must be a minimum of 45 times the width of the shelf;

- for an unequal-sided profile, the permissible radius cannot be less than 45 times the width of the shelf for a larger shelf and 50 for a smaller one.

But it is better and easier to be guided by the values given in the tables.

Tables of the minimum permissible bending radii of steel angles depending on the type, size and ratio of the shelves