The die, or as it is also called the die, is used for cutting threads on various surfaces. As a rule, these surfaces are round. However, there are some types of lechers, which will be discussed a little below, which are intended not only for cylindrical round products.

Threading dies

It must be said that the tool is used for cutting only external threads on pipes or any other materials. For cutting internal threads, a tool called a tap is used.

Classification of leroks

Today, the industry produces a large variety of different dies for cutting screw connections. It is clear that they all differ in many ways. In addition to such an obvious difference as size, there are a number of other characteristics on the basis of which classification can be made:

- Form;

- Housing design;

- Thread cutting method.

There are, of course, other differences, but the above are the most obvious.

The following types can be distinguished by shape:

- Tubular;

- In the form of hexagons;

- In the form of a square;

- Round.

Dies for cutting metric and imperial threads

By design the following are distinguished:

- Solid;

- Split;

- Sliding.

According to the method of cutting threads, they are divided into the following types:

- For round threads. Manufactured according to GOST 13536-68;

- For cylindrical. Manufactured according to GOST 9740-71;

- For conical. Manufactured according to GOST 6211-81;

- For inch, the regulatory standard is GOST 61111-52, and for metric - GOST 9150-81.

Die holder

Round-shaped materials are most widespread. They allow you to make carvings in just one pass. For example, sliding dies for cutting threads of other shapes can guarantee quality only after three or four passes. However, they also have a drawback. For example, their use is recommended only when the requirements for threads on pipes or other objects are no higher than the second accuracy class.

Round dies (GOST 13536-68) allow you to produce threads of fine and coarse pitch, both in the metric and inch systems.

When working, it is important to take into account that the diameter of the chip holes and the dimensions of the thread itself are directly affected by the outer diameter of the die for cutting threads.

Main characteristics

Dies for cutting screw threads (both metric and conical) are characterized by high accuracy. The basis is alloyed (for example, steel grade 9ХС, ХВСГФ) or high-speed steel (for example, steel grade R18, R6M5K8). Recently, innovative developments have been used - hard alloys. The material is very hard and has low wear resistance. After a long period of use, the solid die does not reduce the quality of cutting.

The sliding die behaves differently in operation. Cutting devices have less accuracy because they are springy. The inaccuracy is no more than 0.1-0.3 mm. The disadvantage is easily compensated by the fact that it is possible to regulate the cut diameter. For more precise adjustment, lock screws are used. Sliding dies have low wear resistance.

All types of round dies or dies are a multifunctional tool. It is enough to have one set to get a wide variety of threads.

The strength of the threaded nut is due to its hardening. This allows you to operate the tool at operating temperatures up to 500-900 degrees.

The tool steel from which dies and dies are made is distinguished by high red resistance, that is, the ability to maintain design strength during prolonged heating, and also increases cutting properties.

Depending on the size of the thread to be cut, dies made of high-speed steel with increased hardenability are selected.

Some technical characteristics and certain types of dies

It must be said right away that all such tools are used only in conjunction with special holders.

Such clamping tools, as a rule, can function normally with several hole diameters at once. For example, one holder is used with all lerks with a diameter of up to 1 cm, the same one holder is used with all lerks with a diameter from 12 mm to 24 mm, and the same situation with tools with diameters from 27 mm to 42.

Thread cutting tool

As mentioned earlier, there are tools that are capable of cutting pipe threads in metric and inch systems. The above dimensions are based on the metric system. There will always be a marking in the form of the letter “M” on the case. The full designation will also contain the thread pitch, that is, 8.10 and so on.

It will look like this: M8, M33 and so on.

DIY thread cutting

Threading

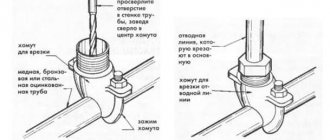

If you need to cut a thread, you will need dies, as well as a special fastening device for the pipe.

The selection of the hole is based on what thread is needed and what the diameter should be. Basically, for cutting new threads, inch dies for cutting cylindrical shapes are used. To avoid confusion, there are markings on the body of the dies. For example, the designation L indicates a left-handed thread. You definitely need to pay attention to what grade of steel it is. Before starting work, the thread must be prepared. Using a file, a small chamfer is removed, and the area is treated with any lubricant. The holder is secured to the holder using clamping screws. Die holder is a device for fixing dies while cutting external threads. This is a universal tool that works with different sizes of lechers.

Read also: Sand for sandblasting machines

After fastening, it is brought to the pipe and made at least two turns towards the thread. In this case, you need to slightly press the lever to cut it into the metal. It is done according to this principle: 2-3 turns are made forward, then half a turn back. And so the work continues until the required thread length is reached. When performing work, you need to monitor the position of the eyepiece relative to the pipe. If you do not take care of this, you can cut the wrong thread.

Checking the correctness of the work done is done by screwing a nut onto a pipe that matches the thread and diameter.

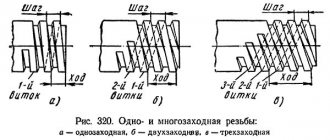

Lerks are divided into non-rifled and cut. Using a cutting blade will result in more accurate cutting. With it, it is possible to correct the thread diameter with a locking screw. If there is a need to replace a piece of water pipe that has a thread, then you will need to use a split-type tap. The thread can be round, as well as rectangular, trapezoidal and triangular.

Taps are special devices for cutting internal threads in an existing hole. You can cut internal threads using a tap in several approaches. For the first approach, you must have a rough tap. It is impossible to confuse this tap; it comes with a riss on the tail section. Then follows another approach, already using a medium tap with 2 risks. And when completing the work, use a finishing tap with three marks.

There are many varieties of lerok. The die is used together with a clamping device - a die holder. This tool is suitable for several hole diameters.

Types of thread cutting devices

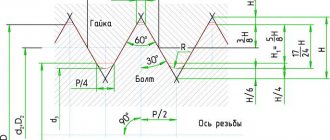

Metric indicator. Marking "M". It is the main type that is used for the production of parts such as bolts, studs, etc. They cut metric threads that have a triangular profile, the diameter of which can be from one to seventy-six millimeters.

The M10 marking indicates a 10 mm metric thread.

The thread can be cut to any diameter, since the dimensions can be from one to sixty millimeters. Each die has its own main thread pitch. The thread pitch is the segment connecting the threads. In addition to the main die, there are additional ones. There may be several of them. The main or step is more than the additional ones.

Using a thread gauge, you can accurately measure the taper pitch.

Left die. It is mainly used in rotary connections, in which right-hand threads cannot be used, because in this case, unwinding will simply occur. Marked - “LH”. This thread is needed in most designs in order to avoid arbitrary loosening of the fastener during rotation. There are metric, pipe and inch. Pipe die. In order not to be confused with metric ones, it is marked with the letter “G”. Unit of measurement inch. Thread size – 1/8-22”. Produced in accordance with GOST. They come with one set and two.

One inch is equal to twenty-five point four millimeters.

Pipe conical. Used for cutting round conical threads. They are mainly used in production in fuel pipelines and machine tools. Marked "K". They have a special structure that ensures single-sided threading. They have a intake cone with angles from thirty to fifty-five degrees and a small width of the feathers in order to reduce the effort during cutting and friction.

Conical blade. Marking "K". A distinctive feature of this type is the elongated front part of the lecher. In this part, the incomplete thread in the calibration zone becomes full. Which helps to cut threads along the entire product. But since there is no calibrating part in the design of this type, the greatest load occurs at the end of cutting, so the use of special cartridges will be required.

Inch die. The purpose of this tool is to cut threads in inch systems, which are accepted in America, Canada and other foreign countries. It is used mainly in the repair of imported equipment, in parts manufactured according to Western designs, etc. These tools work with steel, cast iron and metal products.

Die quality

For the production of blades, high-speed steel of such types as R6M5, 9ХС, ХСС is used. Less commonly you can find the P18 type, still made in the Soviet Union. The quality of Soviet products is very good. A modern manufacturer that produces good products is the Tulamash plant.

Left die

Sometimes a situation arises when a left-hand thread on a pipe is necessary. This is why there is such a tool as the left threading die. I must say that its use is extremely rare. In most cases, such threads are needed when the element is constantly in rotation.

It's easy to explain. We are accustomed to the fact that all rotation is directed clockwise. And if the screw is right-handed, the element will constantly unwind.

In appearance, all such left-handed instruments are no different from standard ones. The only difference is in the markings; the left ones always have “LH”.

How to make a carving

The threaded connection includes 2 components:

- Internal thread

- External thread

A separate tool is used to produce each type of threaded surface. Internal threads are created using taps . The tap is used in conjunction with the driver. The external thread is created with a die , which in turn is installed in the die holder.

How to cut a thread with a tap.

Pipe dies

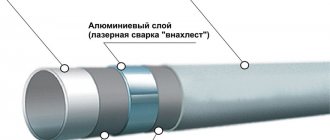

The thread on a water pipe differs slightly from the usual one, primarily in size. This is due to the fact that the binding starts from an inch. There's just one catch. If the pipe is 10 inches, this does not mean that its diameter is 2.54 * 10 = 25.4 mm. Its diameter will be about 33 millimeters. This is due to the fact that conversion to the metric system is accompanied by the addition of two wall thicknesses.

Pipe dies

To avoid such confusion with dies, they began to be produced separately for water pipes. It is quite easy to distinguish them from standard ones - on the body there is a marking in the form of the Latin letter “G”.

Thus, it turns out that there are lerks on G1/2, G ¾, and so on.

In general, pipe tools allow you to make cuts on a pipe with dimensions from G1/8 to G2.

Conical (inch) tools

These are the same devices as in the previous case. Only on the pipe they make not a cylindrical thread, but a conical one. The body is marked in the form of the letter “K”.

All such products, like the taps themselves, are made from three types of steel:

- R6M5;

- 9ХС;

- CSU.

These types of steel are the most commonly used today. But a species like P18 is quite rare, but it was very common during the Soviet era.

It should be noted right away that all old products that have the USSR quality mark on their body are of better quality than modern ones.

Conical dies

Quality of the tools used

On sale you can find dies made from a wide variety of alloys. The following metals can be used in manufacturing:

- High-speed steel 9ХС and ХСС, Р6М5. Today it is found on sale more often than other steels. This is due to its exceptional performance and relatively low cost. Less commonly used is P18 steel, which was common at the time of the existence of the USSR.

- The quality of a tool largely depends on the precision of its production. If the shape accuracy is poor, or there are defects on the surface, then this indicates poor quality of the tool.

The cost of the tool may depend on a fairly large number of factors. As a rule, instruments from foreign manufacturers are much more expensive than domestic ones.

Terms of use

To make a screw on pipes, you will need a set of dies (GOST 9740-71), a driver, that is, a die holder, and a pipe clamp.

From the set of tools, select the blade that is suitable in diameter and pitch.

If it is not possible to visually determine what is needed, there is usually a corresponding marking on the case, usually on the side.

It is also important not to forget that the screw can be either right-handed or left-handed.

The process itself begins with preparing the pipe. To do this, the pipe is chamfered, which is easiest to do with a file. After this, any lubricating component is applied to the treated area. It can be vegetable oil, motor oil, or even ordinary lard.

Next, the die for cutting the thread, which must first be secured in the die holder, is brought to the pipe. It makes no less than two full turns, the direction of which coincides with the direction of the thread.

In the process of this work, with your second hand you need to press down on the blade from above so that it can cut into the metal. Once this happens, you can continue to screw to the required depth.

However, screwing should not be unidirectional. It is best to make a couple of turns forward and at least half a turn back.

Checking the operation is carried out by simply screwing the nut of the required size and with the required pitch.

Metric thread dies

It must be said that the highest quality and most accurate cutting is obtained with a split die. It has a locking ring that allows you to adjust the thread diameter.

There is one more nuance with pipes. For example, they can have several types of screw connections:

- Persistent, that is, when the elements being connected are subjected to constant, large one-sided pressure;

- Rectangular, that is, when the elements being connected are in motion;

- Trapezoidal;

- Triangular.

Any of these types is made in the sequence described above.

Conclusion: As you can see, the screw is used everywhere, as it is a fairly reliable, reusable fastening method.

For this reason, there are quite a lot of tools that are capable of cutting threads, both external and internal. Each of them has its own differences and application specifications. In addition, each of them has its own GOST, which regulates their production.

Material of manufacture

The following grades of steel are used as raw materials for the production of dies:

- alloyed specialized tool 9XC;

- alloyed instrumental XBCGF;

- high-speed tool P18;

- tungsten-molybdenum high-speed tool P6M5 and P6M5K5;

- self-hardening high-speed tool molybdenum-cobalt-containing R6M5F2K8

Lerks can also be made from hard alloys approved by GOST 3882-74. Their list is contained in the table.

| Group | Metal grade | Physical and mechanical characteristics | ||

| Hardness HRA, not less | Density, g/cm3 | Ultimate strength when exposed to bending kgf/mm2, not less | ||

| Titanium-tantalum-tungsten | T8K7 | 90,5 | 12,8-13,1 | 155 |

| TT20K9 | 91,0 | 12,0-12,5 | 150 | |

| TT10K8B | 80,9 | 13,5-13,8 | 165 | |

| TT8K6 | 90,5 | 12,8-13,3 | 135 | |

| TT7K12 | 87,0 | 13,0-13,3 | 170 | |

| Titanium-tungsten | T5K10 | 88,5 | 12,5-13,1 | 145 |

| T14K8 | 89,5 | 11,2-11,6 | 130 | |

| T15K6 | 90,0 | 11,1-11,6 | 120 | |

| T30K4 | 92,0 | 9,2-9,8 | 100 | |

| Tungsten | BK20-KC | 82,0 | 13,4-13,7 | 215 |

| BK15 | 86,0 | 13,9-14,4 | 190 | |

| BK11-BK | 87,0 | 14,1-14,4 | ||

| BK20 | 84,0 | 13,4-13,7 | 210 | |

| BK10-KC | 85,0 | 14,2-14,6 | 190 | |

| BK11-B | 86,0 | 14,1-14,4 | 200 | |

| BK4-B | 88,0 | 14,9-15,2 | 150 | |

| BK10-XOM | 89,0 | 14,3-14,7 | ||

| BK10 | 87,0 | 14,2-14,6 | 180 | |

| BK8-BK | 87,5 | 14,5-14,8 | ||

| BK8-B | 86,5 | 14,4-14,8 | 185 | |

| BK8 | 88,0 | 14,5-14,8 | 170 | |

| BK6-B | 87,5 | 14,6-15,0 | 170 | |

| BK6-OM | 90,5 | 14,7-15,0 | 130 | |

| BK6-M | 90,0 | 14,8-15,1 | 145 | |

| BK3-M | 91,0 | 15,0-15,3 | 120 | |

| BK6 | 88,5 | 14,6-15,0 | 155 | |

| BK3 | 89,5 | 15,0-15,3 | 120 | |

Dies whose cutting edges are made of these carbide alloys are capable of threading high-alloy steel rods. They are well suited for use in industrial environments.

Pipe threading

| Author | Share | Rate |

| Victor Samolin |

Interesting on the topic:

Purpose and correct choice of clamp

Designations and classification of pipe threads

Range of aluminum pipes and features of their application

Comments on this article

Andrey There is one more nuance in pipe threads that you forgot to mention.

This is a seam on an electric-welded pipe that “throws” the die into the trash, or rather paints the cutting part. 03.11.2015 at 18:36Ruslan One inch, by the way, is not 2.54 mm, but 25.4 mm. 10″ pipe has a diameter of 254 mm + two wall thicknesses 01/19/2016 at 18:44