AUSTENITIC STAINLESS STEEL

Austenitic stainless steel contains a significant amount of chromium and a sufficient amount of nickel and manganese to form an “austenitic” microstructure, which give these grades of steel good formability, ductility and corrosion resistance (and also make the steel non-magnetic). The typical composition of austenitic steel contains 18% chromium and 8% nickel, which corresponds to the popular "zero" ("0") grade as defined by the American Iron and Steel Institute (AISI). This brand is known in Russia as AISI 304, DIN 1.4301 and corresponds to the Russian analogue 08Х18Н9. Austenitic steel grades are distinguished by high strength, have corrosion resistance in a wide range of aggressive environments and are characterized by good processability and weldability.

Cracking

Currently, ordinary steel is susceptible to a defect called stress corrosion cracking or SCC - Stress Corrosion Cracking. This type of corrosion usually occurs under certain conditions. The causative agent can be strong tensile stress, elevated temperature (50 degrees Celsius above zero). And if we talk about swimming pools, then due to constant exposure to water, this type of corrosion can occur even at 25 degrees.

Austenitic steel grades are quite susceptible to the influence of this defect. Ferritic alloy, as well as duplex stainless steel A890 3a according to ASTM and other grades, are more reliable in this regard. The high resistance coefficient allows this material to be used in the production of water heaters, brewing tanks, and desalination plants. That is, where there is increased temperature and contact with liquids.

It is completely prohibited to manufacture pool frames from ordinary austenitic steels due to this defect. Previously, it was necessary to use an alloy with a greatly increased nickel content, which led to an increase in the cost of the product. Today, duplex or super-duplex steel can be used.

AUSTENITIC-FERRITIC STAINLESS STEEL (DUPLEX)

Austenitic-ferritic steels are characterized by a high chromium content (18-22%) and a low (economical) nickel content (4-6%, in some cases up to 2%). Additional alloying elements - molybdenum, copper, titanium, niobium. The chemical composition of these steels is such that the ratio of austenite to ferrite after optimal heat treatment is approximately 1:1. This class of steels has a number of advantages compared to austenitic steels: higher (1.5-2 times) strength with satisfactory ductility and resistance to impact loads, greater resistance to intergranular corrosion and stress-corrosion cracking. They are mainly used in the manufacturing industry, construction and in products in contact with seawater.

General information

Duplex steel has gained recognition all over the world. What characteristics does it have? Firstly, the high strength of this material allows you to reduce the final weight of any product. Secondly, it is famous for its excellent corrosion resistance. This is especially noticeable when considering resistance to corrosion cracking.

It is worth saying that at the moment the raw material has not yet become familiar to manufacturers, and therefore every few years conferences are held at which technical articles are discussed on all the features of duplex steel. So far, despite the fairly high interest in this type of product, the share on the world market is only 1-3%.

MARTENSITIC STAINLESS STEEL

Martensitic, like ferritic grades, contain on average from 12% to 17% chromium, but have a higher carbon content. These steels are used primarily in a heat-treated state, often with a carefully ground and sometimes polished surface. They are used in the production of turbine blades, cutlery and razor blades.

Table of mutual conformity of austenitic stainless steels specified according to JIS, W.-nr., DIN, BS, EN, AFNOR, UNI, UNE, SS, AISI/SAE (ANSI/ASTM), GB standards. Table of mutual conformity of stainless ferritic and martensitic steels specified according to JIS, W.-nr., DIN, BS, EN, AFNOR, UNI, UNE, SS, AISI/SAE (ANSI/ASTM), GB standards. Table of mutual conformity of alloy steels specified according to the standards JIS, W.-nr., DIN, BS, EN, AFNOR, UNI, UNE, SS, AISI/SAE (ANSI/ASTM), GB. Table of mutual conformity of heat-resistant steels specified according to the standards JIS, W.-nr., DIN, BS, EN, AFNOR, UNI, UNE, SS, AISI/SAE (ANSI/ASTM), GB.

Reasons that influence the slow widespread adoption of duplex steels

High strength, a wide range of resistance to corrosion, an average degree of weldability - all this should increase the level of production of this material. But, you need to understand that such steels have certain disadvantages. They do not allow duplex steels to fully cover the market for these products.

An increased degree of strength is considered one of the disadvantages when it comes to the manufacturability of pressure processing of raw materials. This indicates a lower ability to undergo deformation processes than austenitic steels. For this reason, the material is unsuitable for the manufacture of products that require a high degree of ductility. When the ability for this type of deformation is at an acceptable level, sufficient force is required to give a suitable shape to the raw material, for example, when bending pipes. There is one exception to the rule regarding unsatisfactory cutting machinability: the LDX 2101 brand, manufactured by Outokumpu.

The process of melting duplex steels is quite complex and labor-intensive. If the production technology is violated, a larger number of undesirable phases may appear.

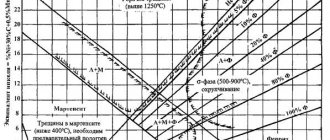

The formation of the sigma phase is observed when there is a deficiency in the cooling rate during production and welding. If a large amount of alloying elements predominates in the steel, then the likelihood of the formation of this phase increases. In this case, super duplex steels are the most vulnerable.

Typically, 475-degree brittleness occurs during the formation of a phase called α′ (alpha prime). This temperature regime is dangerous. It is worth noting that fragility can also appear at temperatures of 300 degrees Celsius. This provokes the emergence of certain restrictions on the maximum temperature for using this raw material. Often this limitation further narrows the range of possible areas of use.

It is important to note that even with the minimum permissible temperature conditions for the use of such material, there are certain restrictions. When tested for impact resistance, duplex steels have a brittle-ductile transition. The permissible temperature regime for testing products used for the manufacture of structures for offshore oil and gas production is 46 degrees Celsius.

Chemical composition and interaction of elements

Duplex steels, unlike a large group of martensitic stainless alloys, have a reduced carbon content. In most alloys this level does not exceed 0.03%. This significantly improves the corrosion resistance of duplex grades. The low carbon range reduces the precipitation of chromium carbides, which deplete chromium areas adjacent to the grain boundaries, reducing intergranular corrosion resistance.

Nickel in duplex steels increases resistance to organic and inorganic acids and has a positive effect on the passivity of steel.

Manganese increases the abrasion resistance of products, reduces ductility and increases resistance to adhesive wear, but its too high concentration can help reduce the critical temperature of pitting corrosion.

Tungsten further increases resistance to pitting and stress corrosion and stabilizes ferrite.

Copper in high concentrations impairs ductility and weldability, so its concentration is limited

Review of basic duplex properties

They are as follows:

1. The strength of the material is several times greater than that of other types. 2. Features an impressive range of corrosion resistance values. This makes it possible to choose the appropriate brand depending on the purpose. 3. High degree of impact resistance is up to - 80 degrees Celsius. This significantly limits the scope of use in cryogenic environments. 4. High degree of resistance to corrosion cracking. 5. Excellent weldability of large sections. 6. The emergence of some difficulties during machining and stamping. 7. The maximum temperature of use of the material in question is limited to 300 degrees Celsius.

The price of this material is affordable, so it can be bought in our country at a good price. It has many advantages. For example, the cost of two-phase raw materials is significantly lower than the price of other stainless metals. The strength characteristics are significantly higher than those of the AISI 300 class product. This makes it possible to use much less raw materials for the same type of equipment.

Duplex steel is actively used in the automotive industry. Many enterprises use this material. This allows you to create a transport model that meets the basic protection requirements, without increasing the weight of the product. With the use of modern technologies and materials, as a rule, the weight of the car increases by about a third. That is why it is worth using two-phase steels to significantly reduce the weight of vehicles. At the same time, the security problem is solved. Duplex allows us to produce cars that meet all basic safety standards. At the same time, there is no increase in the price of the final product due to the use of this type of raw material.

Features of the use of the material

Austenitic-ferritic steels have found application in Russia and abroad. They are most often used as a structural material in industry and due to their high strength and protection even when operating at elevated temperatures. This type of steel is used in the creation of heat exchange equipment. The distribution is due to protection against corrosion cracking as a result of exposure to elevated temperatures. At the same time, the material turned out to be an order of magnitude better than alloys based on various metals. It is not prone to crevice corrosion and does not form pitting.

Types of stainless steel grades

Stainless steel was patented in 1913 in England. From that time on, a new stage in the development of the steel industry and metallurgy began. This is due to the unique properties of the alloy:

- High strength.

- Simple processing.

- Good weldability.

- Long term of active use while maintaining the original appearance.

- High resistance to rust formation.

There are several types of stainless steel, which differ in composition and properties.

The chromium content in the alloy composition should not be less than 10.5%. It affects the corrosion resistance and type of metal. Only the right combination of components makes it possible to obtain high-quality steel with the required technical characteristics.

Steel production (Photo: Instagram / iskoro)

Austenitic stainless steel grades

One of the predominant additional components is nickel. Its content exceeds 7% of the total mass. Features of Austenitic Stainless Steel:

- high plasticity index;

- good weldability;

- wide operating temperature range;

- non-magnetic properties.

The most common grades of this type of stainless steel are 301, 304, 310. The higher the designation, the more alloying components the composition contains. Description:

- Products that will be subject to mechanical stress are made from it. The alloy has high wear resistance and ductility.

- It is used in all areas of industry. Has optimal technical characteristics.

- Heat-resistant steel, which is suitable for assembling heating equipment and furnaces. The material does not collapse when heated above 1000 °C.

Stainless steel oven (Photo: Instagram / gbmasterskie)

Ferritic stainless steel grades

According to the characteristics, this type of stainless steel can be compared with low-carbon steel. The main difference is high resistance to rust formation. Chromium content can reach 17%. The main representatives of this group are 403–420. Examples:

- Used for assembling welded metal structures.

- The composition contains an increased amount of sulfur. The alloy is easy to process on different machines.

- Used for making cutlery.

Varieties labeled 430, 440 are more expensive.

Grades of duplex austenitic-ferritic steel

It simultaneously has two crystal lattice structures - ferritic and austenitic. The second option is possible due to the small amount of nickel in the composition. The peculiarity is the combination of high strength and flexibility. Disadvantage: poor weldability. You can find super duplex steel on sale, which contains up to 5% nickel and 24% chromium.

Stainless steel bicycle (Photo: Instagram / metallobaza_2)

Martensitic stainless steel grades

A simple stainless steel look. Chromium content can reach 13%. Peculiarities:

- average resistance to rust;

- combination of strength and rigidity;

- minimum content of harmful impurities.

Heat-resistant austenitic stainless steel grades

The resistance of steel to high temperatures depends on two parameters - heat resistance and heat resistance. Heat-resistant material - does not change shape when heated strongly. When heat-resistant metal is heated strongly, scale and rust do not form on metal surfaces.

Kinds:

- chromium-silicon;

- chromium-nickel;

- chromium.

The chromium content reaches 18%, nickel - 10%.

Stainless steel pans (Photo: Instagram / posu.da312)

Decoding stainless steel grades

Choosing a stainless steel without theoretical and practical experience is very difficult. To avoid mistakes, you need to know how the symbols are deciphered:

- 10Х17Н13М3Т, 10Х17Н13М2Т. Features: high resistance to rust formation, good weldability. Composition - chromium (up to 18%), carbon (up to 0.1%), nickel (up to 14%), molybdenum (up to 3%), titanium (up to 0.7%), manganese (up to 2%), sulfur ( up to 0.02%), silicon (up to 0.8%), phosphorus (up to 0.035%).

- 10Х23Н18. A special feature is a large amount of nickel in the composition (up to 20%). The remaining components are chromium (up to 25%), silicon (up to 1%), manganese (up to 2%). Tempering may increase brittleness.

- 08Х18Н9, 08Х18Н10. They are used in various fields of industry. Composition: chromium (up to 19%), nickel (up to 10%), titanium (up to 0.5%), carbon (up to 0.8%).

- 08Х18Н10Т. Features: good weldability, maintaining corrosion resistance under high heat. Initially, the alloy has a low strength index. To increase it, it is necessary to carry out additional heat treatment.

- 12Х18Н10Т. Features: impact strength, resistance to high temperatures.

- 06ХН28МДТ. This brand is considered unique due to its high resistance to various aggressive factors. Therefore, finished metal structures can be installed in different climatic conditions. Composition: chromium (up to 25%), nickel (up to 29%), copper (up to 3.5%).

To learn how to decipher stainless steel markings yourself, you need to know several features:

- The first number, which comes before the beginning of the letters, indicates the percentage of carbon.

- Other elements are indicated by capital letters. The numbers that follow them indicate their percentage.

Stainless steel marking is carried out through one of two classifiers - AISI or GOST5632-2014. Before you go to the store to buy parts from this material, it is recommended to study the classifiers in detail in order to understand what the marking can tell you.