Concept of crystal lattice + classification

Before delving into the complex topics of chemistry and physics in the school curriculum, I would like to give you comprehensive information regarding the terminology and classification of metallic elements through the lens of industry.

1) Industrial division of metals + their atomic-crystalline structure

The beginning of the metal era began in the 20th century. Copper, iron, silver and other elements have become an integral part of the life and industry of the population of most developed countries. The basic characteristics of metals, such as elasticity, ductility and strength, are determined by their atomic + crystalline structure.

2 units of measurement, what is the boiling point of iron

Knowledge of these properties will allow you to skillfully manipulate the properties and use them to obtain standard combinations of elements. In industrial terms, metals are divided into 5 large cooperations. I will tell you in more detail about each of them in a separate table.

| Group | Description | Spread (out of 5 ★) |

| Black | The category contains most of the planet's common metals, such as chromium and iron. This also includes alloys made from combinations of ferrous metals similar to ferroalloys. The global use of ferrous metals accounts for 88% of the total global demand. | ★★★★★ |

| Colored (light) | Magnesium, titanium and other elements with low density. They are more expensive to extract than black ones + they are found less frequently in nature due to deposits. They are used in precision construction, and for parts where their use is financially justified. | ★★★★ |

| Colored (heavy) | A distinctive feature is increased specific gravity + excellent conductivity of electrical current. They are used as reaction catalysts in the production of circuit boards and other electronics. | ★★★ |

| Noble | Corrosion protection and low specific gravity. In modern society, they are primarily used as a tool for countries to accumulate finances and for decoration. Prominent representatives are platinum and gold. | ★★ |

| Rare earth | Yttrium, lanthanum and other rare earth chemical elements from the metal group. They have a significant specific gravity and are very chemically active, which determines their use in instrument making and related fields. | ★★★ |

Alkali metals are also distinguished, but usually they are preferred to be classified in the same group as rare earth metals, because their basic characteristics are very similar to each other. Sodium, lithium and other elements of the group form alkalis during chemical reactions with water - hence the name of the group. Used in the production of all kinds of detergents.

Please note: the atomic crystalline structure of metals directly affects their physical and chemical properties. The electrical conductivity parameter plays a particularly important role in industry.

The crystalline structure is characteristic of metal elements that are in the solid phase of the state. Atoms independently arrange themselves in a clear (sometimes vague) geometric shape of a three-dimensional type. The resulting compounds and atomic locations are commonly called a crystal lattice. From a scientific point of view, the term is presented in almost the same way.

Crystal lattice (CL) is a mesh geometric image for studying the structure of crystals. Consists of nodes in which molecules/ions/atoms can be located, and compounds of these elements.

What parameters are used in the study:

- ECR;

- KR constant;

- packing density;

- the meaning of coordination.

A metal crystal lattice is a set of elementary cells that determines the symmetrical properties of the entire structure as a whole. The characteristics of the structural parts of the crystal lattice are described using 3 Brevet rules.

2) Classification of crystal lattices

The distribution by type of crystal lattices is made based on the natural origin of the particles + types of chemical bonds between the basic elements of the structure. Taking into account the above, we can distinguish 4 types of CR. I will provide more detailed information on 3 of them in a separate table, and we will discuss what a metal crystal lattice is in a separate paragraph of the article just below.

| Type KR | Peculiarities |

| Ionic | As the name suggests, the key elements of the structure are ions. The cells are connected to each other due to electrostatics, which gives the ICR electrical neutrality. The lack of saturation with directionality characterizes the lattice with large coordination numbers. According to physics - great hardness, refractoriness and non-volatility. Ionic compounds are also characterized by increased fragility. Even small shifts lead to the destruction of a huge area of the Kyrgyz Republic. |

| Nuclear | Cells of the CR are connected to each other due to covalent type bonds. Here there is a division into 3 categories depending on the structure - frame (diamond), layering (graphite) and chain (asbestos). The basic physical properties of atomic crystal lattices include a high degree of hardness, refractoriness, insolubility in water and lack of volatility. For the most part, ACR is characteristic of complex substances such as aluminum oxide or silicon oxide. |

| Molecular | Molecules are located at the nodes of the structure, and their connection is formed due to the same forces of the molecular type. They are often called hydrogen or van der Waals bonds. The simplest examples of substances with a molecular crystal lattice are ice and iodine. |

The crystalline structure is characteristic not only of pure substances, but also of various inorganic compounds. This is especially true for metal compounds such as alloys. Considering the proliferation of metals in industry and the domestic sphere, special attention needs to be paid to the analysis of the concept of a metal crystal lattice. What will I do next?

Ionic type

Oppositely charged ions are located at nodes that create an electromagnetic field that characterizes the physical properties of a substance. These will include: electrical conductivity, refractoriness, density and hardness. Table salt and potassium nitrate are characterized by the presence of an ionic crystal lattice.

Don't miss: the mechanism of metal bond formation, specific examples.

What is a metal crystal lattice: generalized terminology and properties

If the previously described CRs had only one component at the nodes, then the metal crystal lattice consists of multiple repetition structures, at the connection points of which there are 2 types of cells.

The former are ions with a positive charge, and the latter are neutral atoms. Relatively free electrons move freely between the RC sites. You can see the diagram of the metal grill in the figure above.

1) Features of the structure and classification of the metal crystal lattice

Depending on the interatomic distance, crystalline compounds in alloys and pure metal structures can be divided into 2 subtypes - isotropic and anisotropic. In the first case, the distance between the ions and atoms at the nodes of the structure is equal. Fluctuations can range from 0.1% to 3%, no more. If the distance between the nodes of the crystal lattice along and upward differs, the resulting crystal is classified as anisotropic. A clear idea of the parameters of such missile launchers can only be obtained after studying the direction.

Important: in practice, it is almost impossible to find metals or their alloys that will have a clear, homogeneous structure. In 95%+ of cases, a metal element from many crystals has a different crystal lattice. For this reason, another category in the crystal structure, called quasi-isotropic, was created.

The second parameter in metal crystal lattices, which gave impetus to the introduction of another classification, is the interatomic distance of nearby elements. A separate unit of measurement is used here - the angstrom. The average value for various metals in their pure form is about 3-7 angstroms.

Classification of CR by type:

- Cube The lattice has the correct shape with volumetric centering. The number of connection nodes contained is 9. An example of a metal with a cubic crystal lattice is iron.

- Cube with centered faces. Here the number of connection nodes has already been increased to fourteen. Face-centered CR is found in gold, lead and other non-ferrous + precious metals.

- Hexagonal. The crystal lattice already contains as many as 17 nodes with extremely close placement to each other. This geometry is relevant for zinc, magnesium, and so on.

Iron is especially striking, because when heated above a temperature of 920 degrees Celsius, its crystal lattice is transformed from an ordinary cubic lattice to a cubic one with centered faces.

2) Properties of the metal crystal lattice

The properties of metals directly depend on the crystal structure, which means that most of the characteristics of the elements are equal to the Raman parameters.

As in other areas, the properties of a metal crystal lattice are classified into 2 categories - physical and chemical. I will include the following general physical properties of metals:

- ductility;

- plastic;

- ductility;

- characteristic metallic sheen;

- thermal conductivity;

- electrical conductivity.

I note that the physical properties for various pure elements in metals can have a big difference. For example, the series “Ag Cu Au Al Mg Zn Fe Pb Hg” has a lower value of heat and current conductivity. This also includes the division into non-ferrous and ferrous metals, as well as classification depending on density (light and heavy), hardness (soft and hard) and melting point (low-melting and refractory).

12 physical and chem. characteristics of the metal that melts in the hands

The general chemical properties of metals include:

- are reducing agents;

- interaction with oxygen and the resulting formation of oxides;

- interaction with halogens;

- active metals can react with hydrogen;

- obtaining sulfides through chemical reactions with sulfur;

- some elements among metals can cooperate with nitrogen, releasing nitrides;

- obtaining carbides in contact with carbon;

- phosphides are the result of bonds with phosphorus;

- obtaining intermetallic compounds due to the interaction between metal components.

I consider the intercourse of metals when exposed to temperatures to be a particularly interesting chemical interaction. During the heating process, the elements dissolve into each other, and, as a result, we obtain a metal alloy. I will also say a few words about them later.

3) Metal lattice in alloys

An alloy is a combination of several chemical elements at once. In most cases, these are metals, but compounds containing inclusions of non-metals cannot be discounted. The simplest example of an alloy of a metal and a non-metal is carbon.

Please note: if an element incorporated into an alloy brings practical benefits to it (for example, improves corrosion resistance), such an additive is called an alloying additive; otherwise, we get a harmful impurity.

In metallurgy, there is such a thing as a mechanical mixture - this is a type of alloy in which the crystal lattices of the components are not capable of mutually dissolving. The resulting compound is little used in metallurgy, but it still exists as a phenomenon.

6 steps on how to distinguish copper from brass at home

The qualitative relationship of the components is typical for:

- solid solutions. When the atoms of the helper element are embedded inside the crystal lattice of the base component of the compound;

- chemical alloys. The highest quality method of joining metals. The result is a new crystal lattice, formed from the molecules of both components in more or less equal measure.

Depending on the fractional inclusion of alloying additives, the physics and chemistry of the behavior of alloys can differ significantly from each other. Particularly sensitive in this regard are arrangements made of metals and non-metals.

The final stage of the process of chemical combination of metal elements is called primary crystallization. After heating the element to the desired temperature (melting point), the mixing stage begins and subsequent cooling. At the last stage, the formation of central crystallization elements occurs, around which a full-fledged crystal lattice of the alloy is assembled from repeating center cells.

Central elements can be:

- cells along the rim of foundry equipment, where cooling occurs most quickly;

- non-metallic elements trapped in the alloy;

- alloying elements with a high reserve of refractoriness.

Crystal growth in 90% of cases occurs along a temperature gradient. Having encountered an obstacle, the structure takes on a tree-like appearance. At the junction of two such elements, grains are formed, from which a body of polycrystalline type is formed. Individual crystals that encounter obstacles in the later stages of their growth can grow up to 8,000 - 11,000 microns. Their spatial position does not have a clear direction, but is presented randomly. The entire set of small + large grains makes up a new formation called an alloy.

7 areas of application of the most fusible metal

Analysis of terminology and properties of a metal crystal lattice:

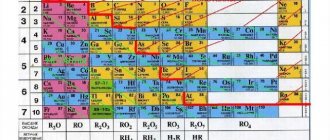

Position of non-metals and metals: periodic table

It is not always possible to find out which group a chemical element belongs to by external signs and physical properties. The properties of metals and nonmetals can be determined by their position on the periodic table.

To do this, you need to visually draw a diagonal from boron to astatine, from 5 to 85 numbers. In the upper right corner there will be predominantly non-metals. There are a minority of them in the table, only 22 elements. Metals are found on the right side of the periodic table at the top—mostly in groups I, II, and III.

Metal lattice in the context of welding

In fact, the welding process is the manual production of an alloy, the purpose of which is to connect independent elements into a single whole. The task is not an easy one, especially if you have to work with different types of metals that have too large a gap in melting point.

Problems arise during the cooling phase of the weld. I think every welder is familiar with the phenomenon of cracking. The basis of this phenomenon lies precisely in the properties of the metal lattice of the metal. The classification of defects is described in more detail in the table below.

| Defect | Description |

| Spot | Changes in the structure of the crystal lattice, which are comparable in size to an atom. Typical point defects are non-atomic sites, elements outside the RC sites and substituted non-metal elements that take the place of the main atom. |

| Linear | The main problem lies in one dimension, when the other two remain practically unchanged. Such defects are usually called dislocation defects. |

| Superficial | Here the problem is already 90% in two dimensions. The third dimension is not affected at all, or the problem is minor (less than 5 atomic sizes). |

| Volumetric | Obvious problems for the welder are pores, cracks and other damage to the surface of the welded area. |

It is physically impossible for even the most experienced craftsman to completely get rid of defects. The only thing a welder can do is to adhere to the technology + pay attention to the properties of the metals being welded.

That's all for today. I hope the information on the metal crystal lattice was useful to you. Good luck and good health!

Energy level

The differences between nonmetals and metals are primarily due to the structure of their atoms. Let's start with the number of electrons in the outer energy level. For metal atoms it varies from one to three. As a rule, they have a large radius, so metal atoms easily give up their outer electrons, since they have strong reducing properties.

Nonmetals have a larger number of electrons in the outer level. This explains their oxidative activity. Nonmetals add missing electrons, completely filling the energy level. The strongest oxidizing properties are exhibited by non-metals of the second and third periods of groups VI-VII.

A filled energy level contains 8 electrons. The halogens with valence I have the greatest oxidizing ability. Fluorine is the leader among them, since this element has no free orbitals.