General information about threading

When choosing a tool for cutting threads, you should take into account the characteristics of the threaded surfaces. These include the following points:

- The cutting of turns is carried out mechanically using special equipment. When metal is removed, grooves and coils are formed that fit perfectly with the surface of the second element.

- All thread cutting tools and technologies used can be divided into two categories: manual and automated. For a long period, screw-cutting lathes were used.

- When using hand tools for thread cutting, lubricant must be used. It significantly extends the service life of devices and simplifies the threading process itself.

Thread cutting with different types of dies

It is worth considering that manual versions have an internal surface, which determines the size of the turns and their location. In the case of processing on a screw-cutting lathe, the parameters of the future threaded surface are determined by the feed and speed of movement of the caliper.

Using the die

Cutting dies are also called dies.

This cutting device is essentially a nut that is equipped with holes. They create edges for cuts. Depending on the shape of the slicing tray, there are:

- round;

- sliding;

- split;

- whole.

Using a device such as a ladder, you can quickly prepare any type of tubular product for connection.

The die must be aligned with the end part of the tubular product strictly perpendicularly. If misalignment is allowed, there is a possibility of a thread breaking, or the diameter of the thread may change. In both cases, the final result will be unsatisfactory.

It is recommended to perform all work with the lecher smoothly, avoiding jerking. When operating with this device, you should lubricate the cutters and the surface part of the thread from time to time.

Upon completion of the final turn, the die must be returned up and the threads are passed again.

Shaped cutters for thread cutting

When using turning and screw-cutting equipment for thread cutting, you should select the most suitable cutter. Manufacturers produce special versions of cutters for thread cutting, which are characterized by their specific features:

- During production, a cutting part of a certain shape is created. Due to this, a groove of the required shape is formed.

- The cutting part is made of tool steel, which is hardened. Due to this, the possibility of rapid wear of the cutting edge is eliminated during operation.

- The use of the method under consideration makes it possible to process the surfaces of large workpieces.

Shaped cutters

In production shops, a screw-cutting lathe is often used, since there are practically no dies and taps for working with large-diameter workpieces. In addition, when threading, a serious load arises.

Hand tools

Manual pipe threading tools are the main type for cutting threads in everyday life; their use has the following features:

- Availability. Manual devices have the lowest price among devices of this type and are therefore available to any owner.

- Functionality. When applying cutting, a main device (die holder, knob) is used, into which a cutting tool with the required parameters is inserted.

Rice. 5 Bison die and taps in thread-cutting tool sets

- Compactness. Manual devices take up little space and do not require large spaces for operations.

Threaded dies for increased productivity

Some thread cutting tools are characterized by high efficiency when used. An example is thread dies, which can be used to produce threads of almost any size. Their advantages include the following:

- Simple design.

- Versatility in use.

- High efficiency.

- Manufacturability.

Thread dies

The combs are represented by multi-filament shaped cutters, which are of prismatic, round and rod type. Most often they are used for cutting threads with fine pitches and low profile heights.

What are the threads on pipes?

Despite the simplicity of equipping a pipe with threads, it is definitely impossible to do without some recommendations. It is important to be able to distinguish between different types of threads, which can be left-handed, right-handed, inch and metric. Left-handed threads require a counterclockwise movement when screwing a nut onto a bolt. Accordingly, with a right-hand thread everything is exactly the opposite.

Metric thread characteristics:

- Millimeters are used to indicate the structural dimensions of individual elements.

- The profile looks like an equilateral triangle.

- The thread pitch is quite small.

Inch thread has the following features:

- The unit of measurement for designating dimensions is the inch.

- The profile looks like a triangle with equal hips and an apex angle of 55 degrees.

- Has a large step size. The profile of the inch thread is quite large, which gives the thread significant durable characteristics.

Each thread has its own specific purpose. However, right-hand threads are still used much more often than left-hand threads.

Taps, dies and heads for thread cutting

The most widely used hand tools are for thread cutting. They can be used in industry and everyday life.

The most widely used versions are:

- Similar tools are used to make bolts and studs. Such a product is a round washer, inside of which several ribs protrude. External threads can be formed and calibrated in just one pass. There are various versions of tools on sale; hardened tool steel is used in manufacturing.

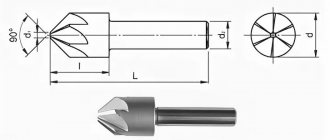

- Taps are used to produce internal threads. It is also manufactured using hardened tool steel, which is characterized by high wear resistance. The tap has the shape of a rod, the working part of which has several depressions and protruding edges. Due to this, the thread cutting process is significantly simplified.

- Special heads can also be used to carry out the work in question. They can have different sizes and are used in conjunction with a special holder.

Taps

Threading dies

Threading head

The cost of hand tools is low, but they are characterized by high efficiency in use.

Tools for manual processing - tap

Pipe tapping is used to create threads inside products.

This range of equipment consists of screw-shaped tools. Using a tap, chip grooves are cut on the pipe. This tool is equipped with a shank that is attached to a machine or a crank. Taps come in various sizes, types and numbers. When cutting, use a set consisting of a pair of taps. They differ from each other in terms of the depth of the cut. So, for example, the first number is taken for roughing, and the second number for finishing.

How to properly cut turns on a water pipe

Recommendations for cutting turns on a water pipe are largely related to what technology is used. Hand tools for cutting external threads should be used taking into account the following information:

- It is necessary to use lubricants that are added to the cutting zone to reduce the wear of the cutting edge.

- At the time of work, you need to ensure that the tool is positioned strictly perpendicular to the workpiece. If it is displaced, the turns may be positioned incorrectly relative to each other.

- When thread cutting, attention is paid to ensuring that chips are removed from the cutting zone in a timely manner.

Tapping a water pipe

The work in question can also be carried out in domestic conditions.

Performances

In accordance with GOST 6111, pipe threads are used in detachable connections of pipelines designed for pumping liquid and gaseous working media. Moreover, relative to water and gas pipes (GOST 3262), it can also be conical, which is explained by the practical convenience of screwing on/screwing on connecting parts. The angle at the top of the conical thread profile is 60°, and the taper angle depends on the diameter and pitch of the thread, but cannot be less than 26°, otherwise the connection may self-unscrew.

A characteristic feature of all pipe threads - metric and inch - is the rounding of the top of the thread profile, which with standard thread cutting methods is 10% of its radius. This is due to the convenience of cutting pipe threads and the reduction of internal stresses on a relatively small body of metal for pipes of any type and range.

GOST 6357 also provides for metric pipe threads, both cylindrical and conical, although in practice they are used less frequently. The inclination angle of the cylindrical thread profile is 55°, which increases the number of turns in the same cutting area. This increases the complexity of connecting parts of the pipeline, although it increases the tightness.

Other types of threads (thrust, trapezoidal) are not cut on pipes, since this is associated with the appearance of additional stress concentrators, which significantly weaken the cross-section of the material.

Die work

Dies are used to process the outer cylindrical surface. Among the features of its application, the following points can be noted:

- The workpiece is secured in a vice. It must remain stationary during operation.

- Before using the tool, the cutting edge and the surface being processed are lubricated with oil.

- As a rule, a small chamfer is created on the end surface. It simplifies the process of screwing the die onto the surface to be treated.

- During work, you need to pay attention to ensure that the die does not move. Because of this, the thread may be cut unevenly and the die stroke becomes more difficult.

- For 2-3 turns along the thread, one turn is made in the opposite direction. This ensures the removal of chips from the processing zone and improves the quality of the resulting surface.

Die work

After completion of the work, the quality of the working surface is checked. To do this, just screw on the nut, which should have free play.

Clupp work

To carry out the work in question, a clamp can be used. It resembles a die, but is large in size. It is often used for cutting threads on pipes and is supplied in special sets with handles. Among the application features we note:

- The clamp is characterized by high efficiency, so the process of cutting turns is simplified.

- The instructions for using the die and die are almost identical, the only difference is how much force needs to be applied to obtain the required result.

Working with a manual clamp

Electric plug

A thread cutting kit is often represented by a combination of nozzles of various diameters. In the manufacture of the working part, wear-resistant material is also used, which does not dull during prolonged use.

Types of equipment for thread-cutting tools

You can resolve this issue by reading a brief description of each type of tool.

The die is a nut with holes along its axes for the cutting edge and a hole for chip removal. It is usually used in everyday life and small-scale repair and construction work for cutting external threads on pipes.

The tap is used for the production of internal threads, used both in manual equipment and installed on machines.

The cutter and comb are usually made of high-alloy steel and are used in threading dies and machines for cutting internal and external threads.

The thread-cutting die with combs is gradually replacing the tool with a die (die) due to higher productivity and versatility. The clamps are manual and electric. They are suitable for cutting threads of different geometries - metric, inch, conical, with a certain, including variable, pitch.

The manual thread-cutting die is lightweight, compact, and easy to carry. It does not depend on power supply and is affordable.

Electric clamps are much more functional than manual ones. They cut threads faster and do not require much physical effort from the master. The volume of work performed per unit of time increases significantly. Note that in terms of thread cutting accuracy, high-quality manual dies are not inferior to electric ones.