General characteristics of steel grade 30ХМА

The heat-resistant relaxation grade 30ХМА belongs to low-alloy medium-carbon steels. It has little flake sensitivity and is not prone to temper brittleness .

30ХМА is characterized by a pronounced uneven distribution of phosphorus and sulfur throughout the thickness of the rolled product. To lower the threshold of cold brittleness and increase the mechanical properties of this grade, alloying elements are introduced into 30KhMA , which form solid solutions and chemical compounds with carbon, iron and other elements and change its properties. In addition, to increase corrosion resistance , a small amount of copper is added to it.

Steel grade 30ХМА is chrome-molybdenum and has limited weldability by manual and automatic submerged arc welding and gas protection. Preheating and subsequent heat treatment are recommended.

| Substitute: | 35ХМ |

| GOST standards: | GOST 8479-70, GOST 1133-71, GOST 8319.0-75, GOST 2590-2006, GOST 2591-2006, GOST 2879-2006, GOST 103-2006, GOST 1051-73, GOST 4543-71, GOST 7417-75, GOST 8559-75, GOST 8560-78, GOST 10702-78, GOST 14955-77, GOST 8732-78 (ST SEV 1481-78), GOST 9567-75, GOST 12132-66, GOST 23270-89 (ISO 2938- 74), GOST 30563-98, GOST 30564-98, GOST 8731-87, GOST R 53383-2009 |

| Application: | general purpose forgings, shafts, rotors and disks of steam turbines, flanges, fasteners with operating temperatures up to 450 degrees, long products |

Read more about the use of 30XMA here >>

Steel 30ХМА

Total information

| Substitute |

| Steel 35XM, Steel 35XRA |

| Type of delivery |

| Long products, including shaped steel: GOST 4543-71, GOST 259071, GOST 2591-71, GOST 2879-69. Calibrated rod GOST 7417-75, GOST 8559-75, GOST 8560-78, GOST 1051-73. Polished rod and silver GOST 14955-77. Strip GOST 103-76. Forgings and forged blanks GOST 1133-71, GOST 8479-70. |

| Purpose |

| Gears, shafts, axles, studs, nuts, and various other parts operating at temperatures up to 450-500°C. |

Chemical composition (according to GOST 4543-2016)

| Chemical element | % |

| Carbon (C) | 0.26-0.33 |

| Silicon (Si) | 0.17-0.37 |

| Copper (Cu), no more | 0.30 |

| Molybdenum (Mo) | 0.15-0.25 |

| Manganese (Mn) | 0.40-0.70 |

| Nickel (Ni), no more | 0.30 |

| Phosphorus (P), no more | 0.025 |

| Chromium (Cr) | 0.80-1.10 |

| Sulfur (S), no more | 0.025 |

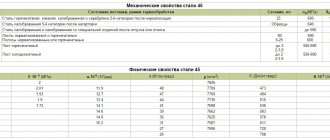

Mechanical properties

Mechanical properties

| Heat treatment, delivery condition | Section, mm | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | KCU, J/m2 | HB |

| Bar. Hardening 880 °C, low. Temperature 540 °C, water or oil. | |||||||

| 15 | 735 | 930 | 12 | 55 | 78 | ||

| Forgings. Hardening. Vacation. | |||||||

| KP 395 | <100 | 395 | 615 | 17 | 45 | 49 | 187-229 |

| KP 440 | 100-300 | 440 | 635 | 16 | 45 | 59 | 197-235 |

| KP 440 | 100-300 | 440 | 635 | 14 | 40 | 54 | 197-235 |

| KP 490 | <100 | 490 | 655 | 16 | 45 | 59 | 212-248 |

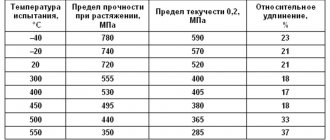

Mechanical properties at elevated temperatures

| test t, °C | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | KCU, J/m2 |

| Hardening 880 °C, oil. Vacation 650 °C | |||||

| 260 | 590 | 730 | 20 | 70 | 186 |

| 200 | 490 | 660 | 21 | 70 | |

| 300 | 520 | 710 | 21 | 69 | 206 |

| 400 | 480 | 630 | 22 | 75 | 199 |

| 500 | 430 | 500 | 22 | 80 | 142 |

| 600 | 340 | 330 | 29 | 89 | 142 |

| Sample 6 mm in diameter, 30 mm long, pressed. Deformation speed 16 mm/min. Strain rate 0.009 1/s | |||||

| 800 | 80 | 130 | 69 | 67 | |

| 1000 | 41 | 56 | 64 | 100 | |

| 1200 | 14 | 26 | 55 | 100 | |

Mechanical properties depending on tempering temperature

| holiday t, °С | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | KCU, J/m2 | HRСе |

| Hardening 880 °C, oil. | ||||||

| 200 | 1320 | 1520 | 12 | 50 | 69 | 49 |

| 300 | 1330 | 1450 | 11 | 51 | 49 | 45 |

| 400 | 1220 | 1370 | 12 | 55 | 69 | 42 |

| 500 | 1080 | 1130 | 16 | 60 | 127 | 36 |

Mechanical properties depending on the section

| Heat treatment, delivery condition | Section, mm | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | KCU, J/m2 | HRСе |

| Hardening 880 °C, oil. Vacation 500 °C. | |||||||

| Place of sample cutting - center | 40 | 650 | 820 | 17 | 71 | 147 | 27 |

| Place of sample cutting - center | 60 | 630 | 800 | 17 | 69 | 157 | 27 |

| Sample cutting location - 1/2R | 80 | 660 | 790 | 17 | 67 | 137 | 25 |

| Sample cutting location - 1/2R | 100 | 610 | 780 | 18 | 64 | 147 | 25 |

| Sample cutting location - 1/3R | 120 | 620 | 750 | 16 | 63 | 137 | |

| Quenching 880 °C, water. Vacation 500 °C. | |||||||

| Place of sample cutting - center | 40 | 790 | 930 | 13 | 61 | 118 | 30 |

| Place of sample cutting - center | 60 | 740 | 870 | 16 | 64 | 127 | 31 |

| Sample cutting location - 1/2R | 80 | 760 | 890 | 14 | 64 | 108 | 30 |

| Sample cutting location - 1/2R | 100 | 700 | 830 | 17 | 65 | 137 | 27 |

| Sample cutting location - 1/3R | 120 | 690 | 840 | 18 | 63 | 118 | 25 |

Critical point temperature

| Critical point | °C |

| Ac1 | 757 |

| Ac3 | 807 |

| Ar3 | 763 |

| Ar1 | 693 |

Impact strength

Impact strength, KCU, J/cm2

| Delivery condition, heat treatment | -20 | -40 | -60 |

| Hardening 880 C, oil. Holiday 350 C. | 42 | ||

| Hardening 880 C, oil. Holiday 550 C. | 147 | 108 |

Endurance limit

| σ-1, MPa | n | Heat treatment, steel condition |

| 407 | 1E+7 | Quenching 870 °C, water. Vacation 600 °C |

| 366 | HB 260. Hardening 880 °C, oil. Vacation 560 °C | |

| 304 | HB 212. Hardening 880 °C, oil. Vacation 650 °C |

Hardenability

Hardening 880 C. Hardness for hardenability strips HRCе.

| Distance from the end, mm / HRC e | |||||||||

| 1.5 | 3 | 4.5 | 6 | 9 | 12 | 15 | 18 | 21 | 24 |

| 49.5-54 | 48-53 | 46-52 | 43.5-51 | 37-48 | 33.5-44.5 | 30-39.5 | 28-37.5 | 26.5-35.5 | 24-34.5 |

Physical properties

| Test temperature, °C | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| Modulus of normal elasticity, E, GPa | 208 | 207 | 204 | 197 | 188 | 176 | 160 | |||

| Density, ρn, kg/cm3 | 7820 | 7800 | 7770 | 7740 | 7700 | 7660 | ||||

| Thermal conductivity coefficient W/(m °C) | 46 | 44 | 42 | 42 | 39 | 37 | 36 | 32 | ||

| Ud. electrical resistance (ρ, NΩ m) | 230 | |||||||||

| Test temperature, °C | 20- 100 | 20- 200 | 20- 300 | 20- 400 | 20- 500 | 20- 600 | 20- 700 | 20- 800 | 20- 900 | 20- 1000 |

| Linear expansion coefficient (α, 10-6 1/°С) | 11.6 | 12.5 | 13.2 | 13.8 | 14.3 | |||||

| Specific heat capacity (s, J/(kg °C)) | 462 |

Foreign analogues of Steel 30ХМА

Legend

| Mechanical properties | |

| σB | temporary tensile strength (tensile strength), MPa |

| σ0.2 | conditional yield strength, MPa |

| σcom | compressive strength, MPa |

| σco0.2 | compressive yield strength, MPa |

| σ0.05 | elastic limit, MPa |

| σben | bending strength, MPa |

| σ-1 | endurance limit during bending test with a symmetrical loading cycle, MPa |

| δ5, δ4, δ10 | relative elongation after rupture, % |

| ψ | relative narrowing, % |

| ν | relative shift, % |

| ε | relative settlement at the appearance of the first crack, % |

| τK | ultimate torsional strength, maximum shear stress, MPa |

| τ-1 | endurance limit during torsion testing with a symmetrical loading cycle, MPa |

| KCU and KCV | impact strength, determined on a sample with concentrators of the U and V types, J/cm2 |

| HRСе and HRB | Rockwell hardness (scale C and B respectively) |

| HB | Brinell hardness |

| H.V. | Vickers hardness |

| HSD | Shore hardness |

| Physical properties | |

| E | normal modulus of elasticity, GPa |

| G | modulus of elasticity in torsional shear, GPa |

| ρn | density, kg/m3 |

| λ | thermal conductivity coefficient, W/(m∙°C) |

| ρ | electrical resistivity, Ohm∙m |

| α | linear thermal expansion coefficient, 10-61/°С |

| With | specific heat capacity, J/(kg∙°С) |

Share:

769

see stock and prices >>

Chemical composition in % of material 30ХМА

| C | Si | Mn | Ni | S | P | Cr | Mo | Cu |

| 0.26 — 0.33 | 0.17 — 0.37 | 0.4 — 0.7 | up to 0.3 | up to 0.025 | up to 0.025 | 0.8 — 1.1 | 0.15 — 0.25 | up to 0.3 |

The temperature of the critical points of the material is 30ХМА.

| Ac1 = 757, Ac3(Acm) = 807 |

Mechanical properties at T=20oC of material 30ХМА.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Bar | F 15 | 930 | 735 | 12 | 50 | 880 | Quenching 880oC, oil, Tempering 540oC, water, |

| The hardness of the material is 30ХМА after annealing, | HB 10 -1 = 229 MPa |

Physical properties of the material 30ХМА.

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 2.08 | 7820 | 230 | |||

| 100 | 2.07 | 11.6 | 46 | 7800 | 462 | |

| 200 | 2.04 | 12.5 | 44 | 7770 | ||

| 300 | 1.97 | 13.2 | 42 | 7740 | ||

| 400 | 1.88 | 13.8 | 42 | 7700 | ||

| 500 | 1.76 | 14.3 | 39 | 7660 | ||

| 600 | 1.6 | 37 | ||||

| 700 | 36 | |||||

| 800 | 32 | |||||

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

Technological properties of material 30ХМА.

| Weldability: | limited weldability. |

| Flock Sensitivity: | sensitive. |

| Tendency to temper brittleness: | not inclined. |

Remaining metal steel 30ХМА for March-April 2021.

| Name | brand | size | remainder | price |

| Circle | 30ХМА | 105mm | 1,634 | 155000 |

| Pipe | 30ХМА | 108×10mm | 0,237 | 125000 |

| Pipe | 30ХМА | 108×9mm | 1,135 | 125000 |

| Round forging | 30ХМА | 110×125mm | 1 | 106000 |

| Pipe | 30ХМА | 127×10mm | 2,73 | 125000 |

| Circle | 30ХМА | 130mm | 3,185 | 118000 |

| Pipe | 30ХМА | 133×12mm | 0,575 | 92000 |

| Circle | 30ХМА | 14.7mm | 0,345 | 119688,3 |

| Circle | 30ХМА | 140mm | 1,01 | 100000 |

| Circle | 30ХМА | 14mm | 0,79 | 92000 |

| Circle | 30ХМА | 160mm | 5,423 | 121000 |

| Circle | 30ХМА | 16mm | 0,33 | 100000 |

| Circle | 30ХМА | 170mm | 2,76 | 100000 |

| Circle | 30ХМА | 18.5mm | 0,929 | 119688,3 |

| Pipe | 30ХМА | 180×36mm | 5,333 | 165000 |

| Circle | 30ХМА | 180mm | 0,228 | 100000 |

| Circle | 30ХМА | 18mm | 1,211 | 155000 |

| Circle | 30ХМА | 190mm | 3,791 | 121000 |

| Round forging | 30ХМА | 195×70mm | 1 | 111000 |

| Circle | 30ХМА | 20.5mm | 0,52 | 119688,3 |

| Circle | 30ХМА | 200mm | 1,245 | 121000 |

| Circle | 30ХМА | 20mm | 0,281 | 118000 |

| Circle | 30ХМА | 210mm | 1,22 | 100000 |

| Pipe | 30ХМА | 219×36mm | 5 | 157700 |

| Circle | 30ХМА | 22.5mm | 0,585 | 111599,8 |

| Circle | 30ХМА | 22mm | 0,239 | 100000 |

| Circle | 30ХМА | 240mm | 9,119 | 133000 |

| Circle | 30ХМА | 24mm | 1,38 | 100000 |

| Circle | 30ХМА | 25mm | 2,583 | 155000 |

| Round forging | 30ХМА | 260×70mm | 1 | 111000 |

| Circle | 30ХМА | 260mm | 1,23 | 123000 |

| Round forging | 30ХМА | 260mm | 0,64 | 104260 |

| Circle | 30ХМА | 270mm | 0,275 | 121000 |

| Pipe | 30ХМА | 273×17mm | 1,739 | 111000 |

| Circle | 30ХМА | 2870mm | 5,6 | 123000 |

| Circle | 30ХМА | 28mm | 0,285 | 92000 |

| Circle | 30ХМА | 290mm | 14,759 | 167500 |

| Round forging | 30ХМА | 300×330mm | 0,405 | 106000 |

| Square | 30ХМА | 300mm | 5,014 | 160000 |

| Round forging | 30ХМА | 300mm | 0,64 | 104260 |

| Sheet | 30ХМА | 30mm | 1,304 | 107000 |

| Round forging | 30ХМА | 310×460mm | 0,625 | 106000 |

| Circle | 30ХМА | 310mm | 7,595 | 167500 |

| Circle | 30ХМА | 320mm | 2,403 | 175000 |

| Circle | 30ХМА | 32mm | 0,2 | 92000 |

| Circle | 30ХМА | 330mm | 0,426 | 175000 |

| Circle | 30ХМА | 340mm | 0,25 | 123000 |

| Circle | 30ХМА | 350mm | 5,691 | 175000 |

| Round forging | 30ХМА | 360mm | 9,58 | 143000 |

| Circle | 30ХМА | 36mm | 0,46 | 92000 |

| Circle | 30ХМА | 370mm | 1,71 | 175000 |

| Round forging | 30ХМА | 370mm | 4,79 | 143000 |

| Round forging | 30ХМА | 380mm | 6 | 143000 |

| Circle | 30ХМА | 390mm | 2,993 | 175000 |

| Round forging | 30ХМА | 390mm | 5,97 | 143000 |

| Round forging | 30ХМА | 395×5730mm | 5,8 | 113000 |

| Round forging | 30ХМА | 400×5890mm | 5,8 | 113000 |

| Circle | 30ХМА | 400mm | 3,959 | 175000 |

| Round forging | 30ХМА | 400mm | 5,84 | 133000 |

| Pipe | 30ХМА | 406×13mm | 1,11 | 93300 |

| Circle | 30ХМА | 415mm | 6,11 | 175000 |

| Round forging | 30ХМА | 415mm | 5,172 | 223500 |

| Hexagon | 30ХМА | 41mm | 2,392 | 106000 |

| Round forging | 30ХМА | 420mm | 2,56 | 143000 |

| Circle | 30ХМА | 430mm | 16,47 | 175000 |

| Round forging | 30ХМА | 430mm | 7,65 | 143000 |

| Circle | 30ХМА | 4440mm | 1 | 123000 |

| Round forging | 30ХМА | 445mm | 2,55 | 143000 |

| Circle | 30ХМА | 450mm | 4,89 | 175000 |

| Circle | 30ХМА | 45mm | 0,305 | 92000 |

| Round forging | 30ХМА | 460mm | 7,64 | 143000 |

| Round forging | 30ХМА | 465mm | 5,75 | 143000 |

| Circle | 30ХМА | 470mm | 12,38 | 175000 |

| Round forging | 30ХМА | 480mm | 6,43 | 133000 |

| Circle | 30ХМА | 490mm | 0,2 | 123000 |

| Round forging | 30ХМА | 495mm | 3,76 | 143000 |

| Circle | 30ХМА | 500mm | 5,5 | 123000 |

| Round forging | 30ХМА | 500mm | 6,62 | 133000 |

| Square | 30ХМА | 50mm | 0,45 | 92000 |

| Circle | 30ХМА | 510mm | 0,64 | 98000 |

| Round forging | 30ХМА | 510mm | 10,25 | 143000 |

| Round forging | 30ХМА | 525mm | 5,93 | 143000 |

| Round forging | 30ХМА | 530mm | 4,96 | 143000 |

| Round forging | 30ХМА | 540mm | 8,25 | 133000 |

| Circle | 30ХМА | 550mm | 5,56 | 123000 |

| Round forging | 30ХМА | 550mm | 6,81 | 143000 |

| Round forging | 30ХМА | 553mm | 2,3 | 145000 |

| Circle | 30ХМА | 560mm | 3,797 | 175000 |

| Round forging | 30ХМА | 560mm | 7,08 | 143000 |

| Round forging | 30ХМА | 580mm | 4,9 | 143000 |

| Round forging | 30ХМА | 590×3690mm | 8,24 | 113000 |

| Round forging | 30ХМА | 590mm | 5,64 | 143000 |

| Circle | 30ХМА | 60mm | 1,294 | 92000 |

| Circle | 30ХМА | 620mm | 6,71 | 123000 |

| Round forging | 30ХМА | 620mm | 8,12 | 143000 |

| Circle | 30ХМА | 63mm | 1,526 | 118000 |

| Round forging | 30ХМА | 640mm | 8,4 | 133000 |

| Round forging | 30ХМА | 650mm | 1,07 | 145000 |

| Round forging | 30ХМА | 660mm | 8,51 | 113000 |

| Circle | 30ХМА | 665mm | 6,74 | 123000 |

| Round forging | 30ХМА | 665mm | 1,21 | 145000 |

| Circle | 30ХМА | 680mm | 1,06 | 123000 |

| Round forging | 30ХМА | 680mm | 8,58 | 143000 |

| Circle | 30ХМА | 700mm | 0,365 | 123000 |

| Round forging | 30ХМА | 700mm | 16,78 | 143000 |

| Round forging | 30ХМА | 705×2920mm | 8,7 | 113000 |

| Circle | 30ХМА | 70mm | 1,444 | 92000 |

| Round forging | 30ХМА | 720×2690mm | 8,51 | 113000 |

| Round forging | 30ХМА | 720×2900mm | 8,7 | 113000 |

| Round forging | 30ХМА | 720×3040mm | 8,7 | 113000 |

| Round forging | 30ХМА | 720mm | 7,12 | 143000 |

| Round forging | 30ХМА | 725mm | 8,51 | 113000 |

| Round forging | 30ХМА | 735×2820mm | 8,51 | 113000 |

| Pipe | 30ХМА | 73×9mm | 2,76 | 123000 |

| Round forging | 30ХМА | 740mm | 0,7 | 160000 |

| Round forging | 30ХМА | 750mm | 8,63 | 143000 |

| Circle | 30ХМА | 75mm | 0,632 | 92000 |

| Round forging | 30ХМА | 790mm | 15 | 143000 |

| Round forging | 30ХМА | 800×1340mm | 6,92 | 113000 |

| Round forging | 30ХМА | 800mm | 8,67 | 143000 |

| Circle | 30ХМА | 80mm | 0,56 | 92000 |

| Circle | 30ХМА | 85mm | 1,678 | 155000 |

| Circle | 30ХМА | 930mm | 5,42 | 123000 |

| Round forging | 30ХМА | 930mm | 5,22 | 143000 |

| Circle | 30ХМА | 95mm | 0,301 | 92000 |