In our article we will show in detail online the tables and dimensions of ball bearings in millimeters according to GOST. These parts are intermediate links between rotating axes and shafts. They also take on radial or longitudinal loads and transfer them to other parts of the mechanism. With their help, rotation, rocking or regular movement with a low coefficient of friction is ensured.

Kinds

They are classified according to the type of force transmission and the design of the supporting elements (balls, rollers, needles and other complex geometric shapes). All units for this purpose are built on the rolling principle.

Ball ones are divided into:

- • radial;

- • self-centering;

- • supporting;

- • radial contact.

Roller:

- • radial and thrust with cylindrical rolling elements;

- • with conical rotating parts.

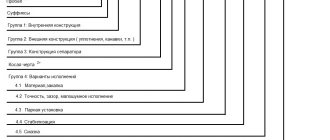

Classification of rolling bearings

The classification of rolling bearings is based on the following characteristics:

- by type of rolling elements: ball and roller. The latter, in turn, are divided into the following groups: with short and long cylindrical rollers; with twisted ones; with needles; with conical and spherical rollers;

- by type of perceived load: radial, radial-thrust, thrust-radial, thrust and linear;

- by the number of rows of rolling elements: single-row, double-row, multi-row;

- according to the ability to compensate for shaft misalignments: self-aligning and non-self-aligning.

In Fig. 2 shows the main types of rolling bearings:

- a) angular contact ball bearing;

- b) angular contact ball bearing with four-point contact;

- c) self-aligning double-row radial ball bearing;

- e) radial ball bearing for housing units;

- e) radial roller bearing

- g) angular contact (tapered) roller bearing;

- h) self-aligning radial roller bearing;

- i) thrust roller bearing;

- j) self-aligning double-row radial roller bearing with barrel-shaped rollers (spherical);

- l) thrust ball bearing;

- m) angular contact roller bearing;

- n) rollers and thrust needle bearing cage.

In table 1 shows a comparison of rolling bearings by performance characteristics.

Rice. 2. Appearance and design of the main types of rolling bearings

Table 1. Comparison of rolling bearings by performance characteristics : +++ – very good; ++ – good; + – satisfactory; o – bad; x – unsuitable

Registry:

Let's look at the technical parameters in more detail.

Table of seating dimensions and series of single-row radial ball bearings

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003 | 103 | 17 | 35 | 10 | 0,04 | |

| 6004 | 104 | 20 | 42 | 12 | 0,07 | |

| 6005 | 105 | 25 | 47 | 12 | 0,08 | |

| 6006 | 106 | 30 | 55 | 13 | 0,12 | |

| 6007 | 107 | 35 | 62 | 14 | 0,15 | |

| 6008 | 108 | 40 | 68 | 15 | 0,19 | |

| 6009 | 109 | 45 | 75 | 16 | 0,24 | |

| 6010 | 110 | 50 | 80 | 16 | 0,26 | |

| 6011 | 111 | 55 | 90 | 18 | 0,38 | |

| 6012 | 112 | 60 | 95 | 18 | 0,41 | |

| 6013 | 113 | 65 | 100 | 18 | 0,44 | |

| 6014 | 114 | 70 | 110 | 20 | 0,6 | |

| 6015 | 115 | 75 | 115 | 20 | 0,64 | |

| 6016 | 116 | 80 | 125 | 22 | 0,85 | |

| 6017 | 117 | 85 | 130 | 22 | 0,89 | |

| 6018 | 118 | 90 | 140 | 24 | 1,17 | |

| 6019 | 119 | 95 | 145 | 24 | 1,22 | |

| 6020 | 120 | 100 | 150 | 24 | 1,27 | |

| 6021 | 121 | 105 | 160 | 26 | 1,59 | |

| 6022 | 122 | 110 | 170 | 26 | 1,95 |

This type is the most common and is used in mechanisms that have rotating parts: in electric motors, in gearboxes, in belt and chain drives of various sizes, from wristwatches to the power plants of an ocean liner.

The specific markings, table of sizes and numbers of bearings by diameter are the same for all types. They differ in technological features, level of protection and the presence of mounting grooves in the unit.

With one protective washer

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003 Z | 60103 | 17 | 35 | 10 | 0,04 | |

| 6004 Z | 60104 | 20 | 42 | 12 | 0,07 | |

| 6005 Z | 60105 | 25 | 47 | 12 | 0,08 | |

| 6006 Z | 60106 | 30 | 55 | 13 | 0,12 | |

| 6007 Z | 60107 | 35 | 62 | 14 | 0,16 | |

| 6008 Z | 60108 | 40 | 68 | 15 | 0,2 | |

| 6009 Z | 60109 | 45 | 75 | 16 | 0,25 | |

| 6010 Z | 60110 | 50 | 80 | 16 | 0,26 | |

| 6011 Z | 60111 | 55 | 90 | 18 | 0,39 | |

| 6012 Z | 60112 | 60 | 95 | 18 | 0,42 | |

| 6013 Z | 60113 | 65 | 100 | 18 | 0,44 | |

| 6014 Z | 60114 | 70 | 110 | 20 | 0,62 | |

| 6015 Z | 60115 | 75 | 115 | 20 | 0,64 |

The parameters and weight of these parts coincide with the data given above. The only difference for ISO is the additional letter z. For example, 6321 Z. According to GOST, the number 60 is placed in front of the number.

With two protective washers

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003 ZZ | 80103 | 17 | 35 | 10 | 0,04 | |

| 6004 ZZ | 80104 | 20 | 42 | 12 | 0,07 | |

| 6005 ZZ | 80105 | 25 | 47 | 12 | 0,08 | |

| 6006 ZZ | 80106 | 30 | 55 | 13 | 0,12 | |

| 6007 ZZ | 80107 | 35 | 62 | 14 | 0,16 | |

| 6008 ZZ | 80108 | 40 | 68 | 15 | 0,2 | |

| 6009 ZZ | 8109 | 45 | 75 | 16 | 0,25 | |

| 6010 ZZ | 80110 | 50 | 80 | 16 | 0,26 | |

| 6011 ZZ | 80111 | 55 | 90 | 18 | 0,39 | |

| 6012 ZZ | 80112 | 60 | 95 | 18 | 0,42 | |

| 6013 ZZ | 80113 | 65 | 100 | 18 | 0,44 | |

| 6014 ZZ | 80114 | 70 | 110 | 20 | 0,62 | |

| 6015 ZZ | 80115 | 75 | 115 | 20 | 0,64 | |

| 6016 ZZ | 80116 | 80 | 125 | 22 | 1,86 |

The data for this type of nodes is the same as in the first statement. They only differ in the addition of the symbol ZZ for ISO and for GOST - the additional 80.

With one-sided seal

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003RS | 160103 | 17 | 35 | 10 | 0,04 | |

| 6004RS | 160104 | 20 | 42 | 12 | 0,07 | |

| 6005RS | 160105 | 25 | 47 | 12 | 0,08 | |

| 6006RS | 160106 | 30 | 55 | 13 | 0,12 | |

| 6007RS | 160107 | 35 | 62 | 14 | 0,16 | |

| 6008RS | 160108 | 40 | 68 | 15 | 0,2 | |

| 6009RS | 160109 | 45 | 75 | 16 | 0,25 | |

| 6010RS | 160110 | 50 | 80 | 16 | 0,26 | |

| 6011RS | 160111 | 55 | 90 | 18 | 0,39 | |

| 6012RS | 160112 | 60 | 95 | 18 | 0,42 | |

| 6013RS | 160113 | 65 | 100 | 18 | 0,44 | |

| 6014RS | 160114 | 70 | 110 | 20 | 0,62 | |

| 6015RS | 160115 | 75 | 115 | 20 | 0,64 | |

| 6016RS | 160116 | 80 | 125 | 22 | 1,86 | |

| 6017RS | 160113 | 85 | 130 | 22 | 0,89 | |

| 6018RS | 160113 | 90 | 140 | 24 | 1,16 |

The parameters of these nodes coincide with the register above, with the exception of the letters in the ISO marking and the numbers in GOST. Instead of Z, RS is written, and 10 is inserted before the four-digit number.

Double sided

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | D1 mm | a mm | b mm | Weight, kg | Scheme |

| 6003 2RSТ | 750103 | 17 | 35 | 10 | 33,17 | 2,06 | 1,35 | 0,04 | |

| 6004 2RSТ | 750104 | 20 | 42 | 12 | 39,75 | 2,06 | 1,35 | 0,07 | |

| 6005 2RSТ | 750105 | 25 | 47 | 12 | 39,75 | 2,06 | 1,35 | 0,08 | |

| 6006 2RSТ | 750106 | 30 | 55 | 13 | 52,6 | 2,08 | 1,35 | 0,12 | |

| 6007 2RSТ | 750107 | 35 | 62 | 14 | 59,61 | 2,08 | 1,9 | 0,15 | |

| 6008 2RSТ | 750108 | 40 | 68 | 15 | 64,82 | 2,49 | 1,9 | 0,19 | |

| 6009 2RSТ | 750109 | 45 | 75 | 16 | 72,83 | 2,49 | 1,9 | 0,24 | |

| 6010 2RSТ | 750110 | 50 | 80 | 16 | 76,81 | 2,49 | 1,9 | 0,25 | |

| 6011 2RSТ | 750111 | 55 | 90 | 18 | 86,79 | 2,87 | 2,7 | 0,37 | |

| 6012 2RSТ | 750112 | 60 | 95 | 18 | 91,82 | 2,87 | 2,7 | 0,4 |

The data for such parts is analogous to the material given in the previous heading. Only the number 2 is inserted before RS, and 180 is written before the number.

With groove on outer ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | D1 mm | a mm | b mm | Weight, kg | Scheme |

| 6003N | 50103 | 17 | 35 | 10 | 33,17 | 2,06 | 1,35 | 0,04 | |

| 6004 N | 50104 | 20 | 42 | 12 | 39,75 | 2,06 | 1,35 | 0,07 | |

| 6005 N | 50105 | 25 | 47 | 12 | 39,75 | 2,06 | 1,35 | 0,08 | |

| 6006N | 50106 | 30 | 55 | 13 | 52,6 | 2,08 | 1,35 | 0,12 | |

| 6007 N | 50107 | 35 | 62 | 14 | 59,61 | 2,08 | 1,9 | 0,15 | |

| 6008N | 50108 | 40 | 68 | 15 | 64,82 | 2,49 | 1,9 | 0,19 | |

| 6009 N | 50109 | 45 | 75 | 16 | 72,83 | 2,49 | 1,9 | 0,24 | |

| 6010N | 50110 | 50 | 80 | 16 | 76,81 | 2,49 | 1,9 | 0,25 | |

| 6011 N | 50111 | 55 | 90 | 18 | 86,79 | 2,87 | 2,7 | 0,37 | |

| 6012N | 50112 | 60 | 95 | 18 | 91,82 | 2,87 | 2,7 | 0,4 |

The ISO marking says 6003 N, according to GOST 50103.

With groove and one protective washer

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | D1 mm | a mm | b mm | Weight, kg | Scheme |

| 6003 ZN | 150103 | 17 | 35 | 10 | 33,17 | 2,06 | 1,35 | 0,04 | |

| 6004 ZN | 150104 | 20 | 42 | 12 | 39,75 | 2,06 | 1,35 | 0,07 | |

| 6005 ZN | 150105 | 25 | 47 | 12 | 39,75 | 2,06 | 1,35 | 0,08 | |

| 6006 ZN | 150106 | 30 | 55 | 13 | 52,6 | 2,08 | 1,35 | 0,12 | |

| 6007 ZN | 150107 | 35 | 62 | 14 | 59,61 | 2,08 | 1,9 | 0,15 | |

| 6008 ZN | 150108 | 40 | 68 | 15 | 64,82 | 2,49 | 1,9 | 0,19 | |

| 6009 ZN | 150109 | 45 | 75 | 16 | 72,83 | 2,49 | 1,9 | 0,24 | |

| 6010 ZN | 150110 | 50 | 80 | 16 | 76,81 | 2,49 | 1,9 | 0,25 | |

| 6011 ZN | 150111 | 55 | 90 | 18 | 86,79 | 2,87 | 2,7 | 0,37 | |

| 6012 ZN | 150112 | 60 | 95 | 18 | 91,82 | 2,87 | 2,7 | 0,4 | |

| 6013 ZN | 150113 | 65 | 100 | 18 | 96,8 | 2,87 | 2,7 | 0,42 |

Here the designations are as follows: 6003 ZN or 150103.

With groove and two protective washers

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | D1 mm | a mm | b mm | Weight, kg | Scheme |

| 6003 ZZN | 450103 | 17 | 35 | 10 | 33,17 | 2,06 | 1,35 | 0,04 | |

| 6004 ZZN | 450104 | 20 | 42 | 12 | 39,75 | 2,06 | 1,35 | 0,07 | |

| 6005 ZZN | 450105 | 25 | 47 | 12 | 39,75 | 2,06 | 1,35 | 0,08 | |

| 6006 ZZN | 450106 | 30 | 55 | 13 | 52,6 | 2,08 | 1,35 | 0,12 |

ISO – 6003 ZZN, GOST – 450103.

With double seal groove

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003 2RS | 180103 | 17 | 35 | 10 | 0,04 | |

| 6004 2RS | 180104 | 20 | 42 | 12 | 0,07 | |

| 6005 2RS | 180105 | 25 | 47 | 12 | 0,08 | |

| 6006 2RS | 180106 | 30 | 55 | 13 | 0,12 | |

| 6007 2RS | 180107 | 35 | 62 | 14 | 0,16 | |

| 6008 2RS | 180108 | 40 | 68 | 15 | 0,2 | |

| 6009 2RS | 18109 | 45 | 75 | 16 | 0,25 | |

| 6010 2RS | 180110 | 50 | 80 | 16 | 0,26 | |

| 6011 2RS | 180111 | 55 | 90 | 18 | 0,39 | |

| 6012 2RS | 180112 | 60 | 95 | 18 | 0,42 | |

| 6013 2RS | 180113 | 65 | 100 | 18 | 0,44 | |

| 6014 2RS | 180114 | 70 | 110 | 20 | 0,62 |

The groove is designated by the letter N, and the seal is designated by RS or 2RS.

Bearing accuracy classes

The accuracy class of a rolling bearing is an extremely important parameter, often no less important than its size, that is, a bearing of a lower class and a higher class are related to each other almost like two different bearings. Products of the highest degrees of accuracy are installed on machine tools and other mechanisms that require high rotational accuracy; agricultural equipment, widely used mechanisms, and general engineering products are installed in the lowest class. Bearings of the highest classes are also called precision. If we take the spindle of a metalworking machine as an example, then if a bearing of the sixth or zero class (low) is installed in it, it simply will not be able to process the products as expected.

The difference lies both in the manufacturing accuracy of the parts (tolerance), including their overall dimensions, and the entire bearing and the accuracy of its rotation, and if the accuracy of the parts is different, the bearing is assigned the class of the least accurate of them.

Of course, the accuracy class of a bearing greatly influences its price, for example, the same type 46115 in accuracy class 6 (for general use) will cost about 700 rubles, and in class T (high-precision for machine tools) - 2500, that is, more than 3 times more expensive.

Modern system of accuracy classes for rolling bearings

Bearing of the highest precision class

According to the modern bearing marking system adopted in our country, the following accuracy classes are distinguished in increasing order.

For ball and roller radial and angular contact ball bearings:

8, 7, normal, 6, 5, 4, T, 2

For tapered roller bearings:

8, 7, 0, normal, 6X, 6, 5, 4, 2

For thrust and radial thrust bearings:

8, 7, normal, 6, 5, 4, 2

The specified system is used in GOST 520-2002, which differs from previous versions, in particular, 520-89. The normal class is an analogue of the designation 0.

A number or letter indicating the accuracy class is placed to the left of the bearing number, immediately before the dash (exactly the last character, since there can be several characters, and the first, leftmost one, can indicate a radial clearance group or something else). Let's look at an example:

70-42415KM

The number 7 here indicates a group of radial clearance greater than normal, 0 is the accuracy class (if there are no other signs in the additional designation, 0 is not written), 42415 is the number itself.

In addition to the above accuracy classes for tapered roller bearings, the mounting height indicator is set to normal and increased degrees of accuracy. Normal accuracy has no special designation. Increased accuracy is indicated by the letter “U”, which is placed in the number to the right of the accuracy class designation, but to the left of the dash sign (for example, 6U-7307A).

Interchangeability of accuracy classes

Very often, especially for some old equipment, bearings are needed that are no longer produced in one or another accuracy class. You need to select a product suitable for the same unit. Accuracy classes can be divided into two groups - the first includes T, 2 and 4, the second - 5, 6, 0. Moreover, recently for the first group there has been a tendency to combine the classes included in it into one (and for the second too , since 5th grade is practically no longer available). Thus, the industry leader in our country, EPK, sells many types of bearings of classes T and 4 at the same price, from which we can reasonably conclude that they are not much different.

System adopted abroad

In imported bearings, the number of accuracy classes is smaller (which is apparently what our industry is moving towards) - there are only three of them: standard class (P6), which is usually not indicated in the number, P4 and P2. Some manufacturers also use P5. However, despite standardization, the specific manufacturer is extremely important - bearings of different brands made according to seemingly the same accuracy class can be very different. The most high-precision bearings (P2) from leading manufacturers are of strategic value and are not supplied to other countries (for example, it is almost impossible to buy in Russia). It is worth noting that the products of leading foreign manufacturers such as SKF (Sweden), FAG and INA (Germany), Koyo, NSK, NTN (Japan), Timken (USA) and some others exceed the Russian 6th in terms of accuracy of fitting dimensions and rotation class and is close to the Russian 5th class or even exceeds it, approaching the 4th.

It is worth noting that in fact there are several different standards (click on the thumbnail below): in addition to ISO, these are AFNOR (France), ABEC/RBEC (USA), DIN (Germany), JIS (Japan). We will not focus on them, since in the domestic market it is easiest to navigate by ISO, and in general, for the vast majority of consumers, the accuracy classes of imported rolling bearings are not of interest - almost all products are sold according to an accuracy class similar to our 6, and even higher - the products of our factories are too expensive and much more economical. It is much more important, as mentioned above, to navigate by brand (see the section “imported bearings”).

What to pay attention to

In addition to the actual accuracy class of the rolling bearing, it is extremely important that it be identical, that is, not a fake, and that it be manufactured by an enterprise with history and a well-known trademark, and not with the brand and passport of a fly-by-night company that will no longer exist in a couple of years (manufactured Such bearings are usually found in semi-handicraft factories in China and no one even thinks about all sorts of accuracy classes there - as long as there are minimal production costs). Recently, a huge number of such products have appeared on the Russian market - and very often it is bearings of high accuracy classes that are counterfeited, since, firstly, they can be sold at a much higher price, and secondly, in order to buy them, the consumer needs to make an effort to search - not every company can afford to keep in warehouses, as you already understood, very expensive products in sufficient quantities. Under these conditions, it is very convenient for dishonest businessmen to act.

A typical counterfeit of the products of the Saratov Bearing Plant - there are not even any additional markings in the number. Separator with potholes and nicks.

There is another very important nuance - a significant part of bearings of the highest accuracy classes are used at extremely high speeds and quickly exhaust their service life without losing their appearance. That is, a product that is actually unusable for use looks like new. Such bearings are often sold to commercial companies at bargain prices, and then go on sale again!

Angular contact ball bearings

This type provides a reaction in two planes along the axis and perpendicular to it. When using a two-row model, the shaft is fixed in space.

Dimensions in the table of angular contact ball bearings, single-row, one-piece

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 7203B | 66203 | 17 | 40 | 12 | 0,07 | |

| 7204B | 66204 | 20 | 47 | 14 | 0,11 | |

| 7205 B | 166205 | 25 | 52 | 15 | 0,14 | |

| 7206B | 66206 | 30 | 62 | 16 | 0,2 | |

| 7207 B | 66207 | 35 | 62 | 17 | 0,29 | |

| 7208 B | 66208 | 40 | 72 | 18 | 0,37 | |

| 7209 B | 66209 | 45 | 85 | 19 | 0,43 | |

| 7210 B | 66210 | 50 | 90 | 20 | 0,48 | |

| 7211B | 66211 | 55 | 100 | 21 | 0,63 | |

| 7212B | 66212 | 60 | 110 | 22 | 0,81 | |

| 7213B | 66213 | 65 | 120 | 23 | 1 | |

| 7214B | 66214 | 70 | 125 | 24 | 1,1 |

Standard sizes and weights of double-row angular contact ball bearings in the table

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 3203B | 3056203 | 17 | 40 | 17,5 | 0,1 | |

| 3204B | 3056204 | 20 | 47 | 20,6 | 0,17 | |

| 3205B | 3056205 | 25 | 52 | 20,6 | 0,19 | |

| 3206B | 3056206 | 30 | 62 | 23,8 | 0,3 |

Additional symbols of Russian rolling bearings

I. Designation of bearing accuracy class

According to GOST 520-89, the following bearing accuracy classes are established:

- 0, 6, 5, 4, 2, T - for ball and roller, radial and ball angular contact bearings;

— 0, 6, 5, 4, 2 — for thrust and thrust-radial bearings;

— 0, 6Х, 6, 5, 4, 2 — for tapered roller bearings.

In the symbol for bearings of accuracy class 6X

They only put down the X sign.

Additional bearing accuracy classes have been established - 8 and 7

below accuracy class 0 for use upon request of consumers in non-critical units.

The list of accuracy classes is given in order of increasing accuracy.

Accuracy class 0 in the absence of special requirements (for radial clearance, etc.) is not indicated in the bearing designation. Accuracy classes are placed with a hyphen immediately before the digital part of the bearing symbol.

For example:

6-205, where the 6th accuracy class of the radial single row bearing is 205.

II. Designation of radial clearance of bearings

Radial clearances in bearings are indicated by group numbers according to GOST 24810-81: “Rolling bearings. Gaps. Dimensions".

The radial clearance group designation is indicated to the left of the bearing accuracy class designation.

For example:

70-205, where 7 is the radial clearance group, 0 is the accuracy class of the radial single-row bearing 205. The normal radial clearance group is not indicated in the bearing designation. Special requirements for the radial clearance, different from GOST 24810-81, are indicated by the letter N.

For example:

NO-42317 M, where N is an additional radial clearance group, and 0 is the accuracy class of the bearing 42317 M.

III. Bearing friction torque designation

The magnitude of the friction moment (in gcm) of radial and angular contact bearings is determined by the technical specifications TU37.006.085-79 “Friction torque standards”.

The standard bearing friction moment is conventionally indicated by the number of the corresponding row, placed before the designation of the radial clearance. At the same time, in the symbol designation of angular contact bearings, as well as radial single-row bearings with radial clearance according to the normal group of GOST 24810-81, the letter M is placed in place of the radial clearance designation.

Examples of bearing designations:

125-25 — single-row radial ball bearing, accuracy class 5 according to GOST 520-89 with radial clearance according to the second group of GOST 24810-81 with a friction moment along the first row;

4M6-1000900 - single row radial ball bearing 1000900, accuracy class 6 according to GOST 520-89 with radial clearance according to the normal group of GOST 24810-81 with a friction moment along the fourth row.

IV. Designation of bearing categories

Depending on the availability of additional technical requirements, GOST 520-89 establishes three categories of bearings - A, B, C:

— Category A includes bearings of accuracy classes 5, 4, 2, T;

— category B includes bearings of accuracy classes O, 6X, 6, 5 (subject to additional requirements);

— Category C includes bearings of accuracy classes 8, 7, O, 6.

At the customer's request, it is allowed to manufacture bearings of certain accuracy classes in accordance with the requirements of GOST 520-89 without being assigned to categories A, B, C, while additional requirements provided for bearings of categories A, B, C are not established.

The designation of categories A and B is given by:

- before the gap sign, in the absence of requirements for the friction moment and a gap group different from normal, for example A25-204;

- before the accuracy class, in the absence of requirements for the friction moment and normal clearance group, for example A5-205, while for bearings of accuracy class 0 the sign O is indicated in the designation, for example B0-205.

In the symbol for bearings of categories A and B with additional technical requirements, a sign (1, - 2, 3, etc.) indicating additional technical requirements is indicated before the category sign. The sign of additional technical requirements is not marked on the bearing rings, but is indicated in the design documentation, on the box or parcel, in the shipping documentation of the bearings, as well as when ordering them.

In the symbol for category C bearings, the category is not indicated or marked.

V. Designations characterizing the material of bearing parts, design differences and special technical requirements.

Bearings that differ from the main type in materials of parts, design, coatings, clearances, cleanliness of processing, permissible deviations in the dimensions of parts and other characteristics, have the following additional designations, affixed to the right of the main designation.

| Additional designation marks | |||

| № | On first execution | During subsequent executions | Features |

| 1. | A | — | Bearings, high load capacity |

| 2. | B | B1, B2, BZ, etc. | Massive separator made of tin-free bronze |

| 3. | G | G1, G2, GZ, etc. | Massive separator made of ferrous metals |

| 4. | D | D1, D2, DZ, etc. | Aluminum alloy separator |

| 5. | E | E1, E2, EZ, etc. | Separator made of plastic materials |

| 6. | TO | K1, K2, KZ, etc. | Design changes to bearing parts |

| 7. | L | L1, L2, LZ, etc. | Brass separator |

| 8. | R | P1, P2, RZ, etc. | Bearing parts made of heat-resistant steels |

| 9. | U | U1, U2, UZ, etc. | Additional technical requirements for cleanliness of parts, radial clearance, axial play, coatings, etc. |

| 10. | X | X1, X2, XZ, etc. | Bearing parts made of case-hardened steels |

| 11. | E | E1, E2, EZ, etc. | Bearing parts made of ShKh steel with special additives |

| 12. | YU | Yu1, Yu2, SW, etc. | Stainless steel bearing parts |

| 13. | I | Ya1, Ya2, YaZ, etc. | Bearings made from rarely used materials (hard alloys, glass, ceramics, etc.) |

| 14. | W | W1, W2, WЗ, etc. | Evacuated steel bearing parts |

| 15. | N | H1, H2, NC, etc. | Rings and rolling elements or only one ring made of modified heat-resistant steel (except for double-row radial-spherical roller bearings) |

| 16. | M | — | Modified Contact |

VI. Designations of special requirements for bearings regarding noise (vibration)

Bearing noise standards are provided for by the relevant standards, as well as special specifications. In this case, bearings receive an additional designation: the letter Ш and a digital index (Шl, Ш2, ШЗ, etc.).

As the digital index increases, the requirements for bearing noise during operation become more stringent.

The designations of these special requirements are placed to the right of the main bearing symbol after indications of design differences (K), cage material (D, L, E, B) or rings (Y, X, P), etc.

For example:

5-8322 LSh1, where 5 is the accuracy class of the single thrust ball bearing 8322, L is the brass separator, Sh1 is the noise level.

VII.

Designation of special release of bearing parts. When manufacturing bearings with parts made of ShKh15 and ShKh15-SG steels with increased tempering, the letter T with or without a digital index is placed in the bearing designation.

| Additional designations | T | T1 | T2 | T3 | T4 | T5 |

| Ring tempering temperature, °C | 200 | 225 | 250 | 300 | 350 | 410 |

These additional designations are placed to the right of the main bearing designation.

For example:

75-205 ET2 - designation of a radial single-row ball bearing 205, 5th accuracy class with radial clearance according to the 7th group, a plastic separator and a ring release temperature of 240-260 ° C.

VIII. Designation of types of lubricant added to closed bearings during their manufacture

Closed bearings filled with grease have the following additional designations:

| Additional designations | Lubricant brand |

| C1 | OKB-122-7 |

| C2 | CIATIM-221 |

| C3 | VNIINP-210 |

| C4 | CIATIM-221S |

| C5 | CIATIM-202 |

| C6 | PFMS-4S |

| C7 | VNIINP-271 |

| C8 | VNIINP-235 |

| C9 | LZ-31 |

| C10 | E158 |

| C11 | VNIINP-262, SIOL |

| C12 | VNIINP-260 |

| C13 | VNIINP-281 |

| C14 | FIOL-2U |

| C15 | VNIINP-207 |

| C16 | VNIINP-246 |

| C17 | LITOL-24 |

| C18 | VNIINP-233 |

| C19 | VNIINP-286 |

| S20 | VNIINP-274 |

| S21 | ERA |

| S22 | SVEM,(VNIINP-288) |

| S23 | CV joint-4 |

Thrust ball

This series of parts is designated by two types.

Single

| ISO marking | Analogue GOST | d mm | d1 mm | D mm | D1 mm | T mm | Weight, kg | Scheme |

| 51104 | 8104 | 20 | 35 | 35 | 20,2 | 10 | 0,04 | |

| 51105 | 8105 | 25 | 42 | 42 | 25,2 | 11 | 0,06 | |

| 51106 | 8106 | 30 | 47 | 47 | 30,2 | 11 | 0,07 | |

| 51107 | 8107 | 35 | 52 | 52 | 35,3 | 12 | 0,08 | |

| 51108 | 8108 | 40 | 60 | 60 | 40,2 | 13 | 0,12 | |

| 51109 | 8109 | 45 | 65 | 65 | 45,2 | 14 | 0,15 | |

| 51110 | 8110 | 50 | 70 | 70 | 50,2 | 14 | 0,16 | |

| 51111 | 8111 | 55 | 78 | 78 | 55,2 | 16 | 0,24 | |

| 51112 | 8112 | 60 | 85 | 85 | 60,2 | 17 | 0,29 | |

| 51113 | 8113 | 65 | 90 | 90 | 65,2 | 18 | 0,34 | |

| 51114 | 8114 | 70 | 95 | 95 | 70,2 | 18 | 0,36 | |

| 51115 | 8115 | 75 | 100 | 100 | 75,2 | 19 | 0,42 |

There are no English letters in the ISO marking, and numbers begin with 511. According to the state standard, four-digit numbers with a prefix of 81.

With backing ring

| ISO marking | Analogue GOST | d mm | D mm | d1 mm | D2 mm | D3 mm | C1 mm | R mm | S mm | T mm | Weight, kg | Scheme |

| 53203+U203 | 18203 | 17 | 35 | 35 | 38 | 26 | 4,00 | 32 | 16 | 15 | 0,071 | |

| 53204+U204 | 18204 | 20 | 40 | 40 | 42 | 30 | 5,00 | 36 | 18 | 17 | 0,102 | |

| 53205+U205 | 18205 | 25 | 47 | 47 | 50 | 36 | 5,50 | 40 | 19 | 19 | 0,155 | |

| 53206+U206 | 18206 | 30 | 52 | 52 | 55 | 42 | 5,50 | 45 | 22 | 20 | 0,182 | |

| 53207+U207 | 18207 | 35 | 62 | 62 | 65 | 48 | 7,00 | 50 | 24 | 22 | 0,279 | |

| 53208+U208 | 18208 | 40 | 68 | 68 | 72 | 55 | 7,00 | 56 | 28,5 | 23 | 0,35 | |

| 53209+U209 | 18209 | 45 | 73 | 73 | 78 | 60 | 7,50 | 56 | 26 | 24 | 0,388 | |

| 53210+U210 | 18210 | 50 | 78 | 78 | 82 | 62 | 7,50 | 64 | 32,5 | 26 | 0,464 | |

| 53211+U211 | 18211 | 55 | 90 | 90 | 95 | 72 | 9,00 | 72 | 35 | 30 | 0,752 | |

| 53212+U212 | 18212 | 60 | 95 | 95 | 100 | 78 | 9,00 | 72 | 32,5 | 31 | 0,817 | |

| 53213+U213 | 18213 | 65 | 100 | 100 | 105 | 82 | 9,00 | 80 | 40 | 32 | 0,912 | |

| 53214+U214 | 18214 | 70 | 105 | 105 | 110 | 88 | 9,00 | 80 | 38 | 32 | 0,967 | |

| 53215+U215 | 18215 | 75 | 110 | 110 | 115 | 92 | 9,50 | 90 | 49 | 32 | 1,018 |

Double row thrust ball bearings

| ISO marking | Analogue GOST | d mm | d1 mm | D mm | D1 mm | T mm | S mm | Weight, kg | Scheme |

| 29428 | 9039428 | 140 | 257 | 280 | 198 | 85 | 86 | 24,1 | |

| 29436 | 9039436 | 180 | 342 | 360 | 250 | 109 | 110 | 52,6 | |

| 29452 | 9039452 | 260 | 460 | 480 | 346 | 132 | 154 | 107,8 | |

| 29488 | 9039488 | 440 | 745 | 780 | 576 | 206 | 260 | 413 |

Bearing characteristics

These are parameters and their values that allow you to judge the suitability of a bearing for solving certain problems and compare different bearings with each other. The list of bearing characteristics is regulated by industry standards, and the methods for determining them are generally accepted and described in detail. Technical parameters of bearings are indicated by bearing manufacturers in catalogs; they can also be found in our online store on product pages.Bearing type

Depending on the type of friction, bearings are divided into rolling bearings and plain bearings. The former are classified according to the directions of the perceived loads, the type of rolling elements and the number of their rows, as well as specific design features. The latter are classified according to the directions of the perceived loads, the properties of the lubricating layer and the materials used.

Dimensions and weight

The main dimensional characteristics of bearings are indicated in the dxDxh format, where d is

the hole diameter

, D is

the outer diameter

, h is

the width

. All numbers are in mm. Sometimes additional sizes are provided.

The mass is indicated in kilograms or, for miniature bearings, in grams.

Load capacity

It can be static or dynamic in nature.

The direction can be radial or axial, in accordance with the direction of the load. The static load rating

is the load at which a fixed bearing begins to deform.

Dynamic load capacity

is the load at which the bearing fulfills its basic life without wear.

Resource

The basic life of the rolling bearing is 106 (million) revolutions. The rated life is calculated using a formula depending on the ratio of the effective load and dynamic load capacity. The actual service life depends on many factors: temperature, lubrication, contamination, shock loads, etc.

Friction

The frictional moment characterizes the resistance to rotation of the bearing and the energy loss in it.

Rotation speed

The rated speed

is the one at which the bearing does not overheat.

The maximum rotation speed

is the one at which it does not collapse.

Accuracy and internal clearance

There are many dimensional tolerances for each bearing size, as well as tolerances for rotational accuracy.

An indicator that combines these tolerances is accuracy class

. Internal clearance is play in the bearing.

Material

The main materials of bearing rings and rolling elements: bearing steel, stainless steel, ceramics, polymers.

Seals and separators

Availability, material, design are indicated.

Designation

In encoded form it contains data on the type, dimensions and other basic technical characteristics of the bearing.

Radial bearings

Usually we mean radial ball bearings, but this type also includes cylindrical roller bearings and self-aligning ball bearings. In them, the rolling elements are located in the radial direction relative to the races; accordingly, they are designed for a load directed at a right angle to the shaft.

Angular contact bearings

This type usually includes angular contact ball bearings and tapered roller bearings. In single-row design they are designed for radial loads and axial loads in one direction, and in double-row design they are designed for radial loads and axial loads in both directions. They work best under combined loads, that is, a combination of radial and axial loads.

Thrust bearings

Depending on the type of rolling elements, there are ball and roller thrust bearings, as well as needle bearings as a type of roller. Used for axial loads: single thrust bearing for unidirectional loads, double thrust bearing for bidirectional loads.

Needle bearings

Radial, thrust and linear needle bearings of various designs. Since the needle rollers are very thin, extremely compact dimensions can be achieved, which is why needle bearings are often available as just a cage with needles or with another outer ring. One or both raceways are located directly on the shaft and in the housing.

Table with examples of sizes, load capacities and rotation speeds of rolling bearings

| d, mm | D, mm | B, mm | C, kN | C0, kN | Rated rotation speed, rpm | Limit speed, rpm | ||

| 1 | bearing 6205 | 25 | 52 | 15 | 14,8 | 7,8 | 18 000 | 28 000 |

| 2 | bearing 6204 | 20 | 47 | 14 | 13,5 | 6,55 | 20 000 | 32 000 |

| 3 | bearing 6203 | 17 | 40 | 12 | 9,95 | 4,75 | 24 000 | 38 000 |

| 4 | bearing 6314 | 70 | 150 | 35 | 111 | 68 | 6300 | 9500 |

| 5 | bearing 6004 | 20 | 42 | 12 | 9,95 | 5 | 24 000 | 38 000 |

| 6 | bearing 6005 | 25 | 47 | 12 | 11,9 | 6,55 | 20 000 | 32 000 |

| 7 | bearing 6006 | 30 | 55 | 13 | 13,8 | 8,3 | 17 000 | 28 000 |

| 8 | bearing 22318 E | 90 | 190 | 64 | 610 | 695 | 2600 | 3600 |

| 9 | bearing 22319 CC/W33 | 95 | 200 | 67 | 670 | 765 | 2600 | 3400 |

| 10 | bearing 7315 BEGAM | 75 | 160 | 37 | 132 | 104 | 5300 | 5300 |

| 11 | bearing 7208 BECBP | 40 | 80 | 18 | 36,5 | 26 | 11000 | 11000 |

| 12 | bearing 6200 | 10 | 30 | 9 | 5,4 | 2,36 | 56000 | 34000 |

| 13 | bearing HK 1512 | 15 | 21 | 12 | 7,65 | 9,5 | 15000 | 16000 |

| 14 | bearing HK 1514 RS | 15 | 21 | 14 | 7,48 | 10 | 15000 | 9500 |

| 15 | bearing 6322 | 110 | 240 | 50 | 203 | 180 | 3800 | 6000 |

| 16 | bearing 6303 | 17 | 47 | 14 | 14,3 | 6,55 | 22000 | 34000 |

| 17 | bearing 6308 | 40 | 90 | 23 | 42,3 | 24 | 11000 | 17000 |

| 17 | bearing 6206 | 30 | 62 | 16 | 20,3 | 11,2 | 15000 | 24000 |

| 18 | bearing 6320 | 100 | 215 | 47 | 174 | 140 | 4300 | 6700 |

| 19 | bearing 1208 ETN9 | 40 | 80 | 18 | 19,9 | 6,95 | 11000 | 18000 |

| 20 | bearing 1209 EKTN9 | 45 | 85 | 19 | 22,9 | 7,8 | 11000 | 17000 |

General catalog of SKF rolling bearings (pdf, V=54 Mb)

Cylindrical roller bearings

These parts compare favorably with ball parts due to the increased load on the axle. The contact area of the roller is much wider than that of a spherical bearing. Some modifications allow longitudinal displacement along the axis.

We will show tables that can be used to determine the size by bearing number:

Without flanges on the outer ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| N 1007 | 2107 | 35 | 62 | 14 | 0,18 | |

| N 1008 | 2108 | 40 | 68 | 15 | 0,22 | |

| N 1009 | 2109 | 45 | 75 | 16 | 0,29 | |

| N 1110 | 2110 | 50 | 80 | 16 | 0,31 |

With single breasted inner ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| NJ 1034 | 42134 | 170 | 260 | 42 | 8,2 | |

| NJ 1036 | 42136 | 180 | 280 | 46 | 10,1 |

With one built-in and one free flange on the inner ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| NUP 305 | 92305 | 25 | 62 | 17 | 0,24 | |

| NUP 306 | 92306 | 30 | 72 | 19 | 0,36 | |

| NUP 307 | 92307 | 35 | 80 | 21 | 0,48 |

Designation of imported bearings - is there a foreign GOST for marking components?

If with domestic products everything is clear and each manufacturing company is obliged to adhere to the established numbering requirements for years, then abroad each manufacturer himself comes up with a system convenient for him. Usually it is less detailed and detailed than in Russia, and also has the following drawback - without detailed instructions, and for a Russian person translated into his native language, nothing is clear. You can trust the seller, but he himself often does not know the smallest details that make up the code.

How to determine the bearing series - instructions

There are four main categories. Extra light (number 1), light (2 or 5), medium (3 or 6) and heavy – 4.

To determine which of them the model belongs to, you should find the core of the marking; it is located between two dashes. If there is no suffix or postfix, then the number may stand alone. There are two situations. If there is a slash, then the indicator we need is the first one to the left of it. If there is no slash, then it is third.

How to find out the hole diameter - instructions

These are the very first (right) numbers of the kernel.

If the entry contains the ending - 0X, then this X is a number from 1 to 9 in millimeters. If the entry is 05X, then X is a rounded number, but not more than 10 mm.

The signs 00, 01, 02 and 02 indicate a range from 10 to 20; the code can be converted into exact values using the table above. If they are followed by 9 (i.e. 900 or 901), then again rounding has occurred.

If there is any two-digit value, it should be multiplied by 5. The rule with “nine” in third place remains appropriate here.

And if there is a slash in the marking, then either this is an exception, or the large diameter is more than 50 centimeters.

How to determine its external dimensions by the bearing number - instructions

This is the last kernel value. It stands on the edge, to the left. These are the dimensions, that is, the multiplied width and height. If the inner ring remains the same, then the outer one increases according to the following markings: 0, 8, 9, 1, 7, 2, 3, 4, 5. The ratio of the values can be determined using the table.

How to find out the number

The easiest way is to use electronic catalogs containing all dozens of values. Numbering is easier to master if you first measure the main parameters - outer and inner radius, width, height.

Tapered roller bearings

They have the same advantages as cylindrical ones: high load, the ability to disassemble. In addition, they allow you to adjust the gap between the rolling surfaces after working. These include the following types.

Single row

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width T in mm | Weight in kg | Scheme |

| 30204 | 7204 | 20 | 47 | 15,25 | 0,12 | |

| 30205 | 7205 | 25 | 52 | 16,25 | 0,15 | |

| 30206 | 7206 | 30 | 62 | 17,25 | 0,24 |

With a large cone angle

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width T in mm | Weight in kg | Scheme |

| — | 27305 | 25 | 62 | 18,25 | 0,26 | |

| — | 27306 | 30 | 72 | 20,75 | 0,39 | |

| — | 27307 | 35 | 80 | 12,75 | 0,52 |

Double row

| ISO marking | Analogue GOST | Inner diameter mm | Outer diameter mm | Width T in mm | Width B in mm | Weight in kg | Scheme |

| — | 9716 | 340 | 520 | 180 | 135 | 118 | |

| — | 9717 | 360 | 540 | 185 | 140 | 132 | |

| — | 9718 | 380 | 560 | 189 | 141 | 169 |

Four-row

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width T in mm | Width B in mm | Weight in kg | Scheme |

| — | 2077140 | 200 | 310 | 275 | 10 | 75,8 | |

| — | 2077144 | 220 | 340 | 305 | 10 | 10,4 | |

| — | 2077148 | 240 | 360 | 310 | 10 | 108,7 |

Spherical roller bearings

They combine the ability to withstand high loads and have a deviation in the axes of landing and rotation. They are also called self-centering.

Double-row with sides on the inner ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 22208 | 3508 | 40 | 80 | 23 | 0,58 | |

| 22209 | 3509 | 45 | 85 | 23 | 0,6 | |

| 22210 | 3510 | 50 | 90 | 23 | 0,65 |

With beadless inner ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 22208 | 53508 | 40 | 80 | 23 | 0,58 | |

| 22209 | 53509 | 45 | 85 | 23 | 0,6 | |

| 22210 | 53510 | 50 | 90 | 23 | 0,65 |

Spherical double-row with sides on the inner ring with a landing cone 1:12

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 22208 CCK | 153508 | 40 | 80 | 23 | 0,58 | |

| 22209 CCK | 153509 | 45 | 85 | 23 | 0,6 | |

| 22210 CCK | 153510 | 50 | 90 | 23 | 0,65 | |

| 22211 CCK | 153511 | 55 | 100 | 25 | 0,88 | |

| 22212 CCK | 153512 | 60 | 110 | 28 | 1,2 |

Spherical double-row with sides on the inner ring with a cone 1:30

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 24024 K30 | 4113124 | 120 | 180 | 60 | 5,4 | |

| 24026 K30 | 4113126 | 130 | 200 | 69 | 7,95 | |

| 24028 K30 | 4113128 | 140 | 210 | 69 | 8,45 | |

| 24030 K30 | 4113130 | 150 | 225 | 75 | 10,5 |

Spherical double-row with a beadless ring with a hole with a taper of 1:30

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 24024 CCK30 | 4153124 | 120 | 180 | 60 | 5,4 | |

| 24026 CCK30 | 4153126 | 130 | 200 | 69 | 7,95 | |

| 24028 CCK30 | 4153128 | 140 | 210 | 69 | 8,45 | |

| 24030 CCK30 | 4153130 | 150 | 225 | 75 | 10,5 |

Flatbed with inner ring with seat cone 1:12

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 22208 CCK | 153508 | 40 | 80 | 23 | 0,58 | |

| 22209 CCK | 153509 | 45 | 85 | 23 | 0,6 | |

| 22210 CCK | 153510 | 50 | 90 | 23 | 0,65 | |

| 22211 CCK | 153511 | 55 | 100 | 25 | 0,88 |

Thrust spherical single row

| ISO marking | Analogue GOST | d mm | d 1 mm | D mm | D 1 mm | T mm | S mm | Weight in kg | Scheme |

| 29428 | 9039428 | 140 | 257 | 280 | 198 | 85 | 86 | 24,1 | |

| 29436 | 9039436 | 180 | 342 | 360 | 255 | 109 | 110 | 52,6 | |

| 29452 | 9039452 | 260 | 460 | 480 | 346 | 132 | 154 | 107,8 |

Ball bearings

What is this?

A ball bearing is a type of rolling bearing that uses steel balls as rolling elements. This is the most numerous type of bearings, due to its relatively low cost and ability to absorb radial and small axial loads at high rotation speeds. They are used as supports for rotating bodies (shafts, wheels, etc.).

What are ball bearings made of?

Ball bearings have high loads and a small contact area between the ball and the raceways of the rings. Therefore, high demands are placed on materials in terms of wear resistance and endurance. Bearing parts are made from bearing steel, induction hardened (only the top layer of the raceways), or volumetric hardened. For special operating conditions - from high-temperature, low-temperature bearing steels and ceramics.

Rolling bearings for normal operating conditions

: neutral environment, -30 degrees to + 120 degrees. Bearing parts (rings and balls) are made of high-carbon chromium steels of type ШХ of various modifications (EC standard SAE 52100-CR6) and are subjected to heat treatment. Separators are made of low-carbon steel, brass and polymers.

Stainless steel

: for work in aggressive environments (alkali, acid). Made of corrosion-resistant steel types 95X18, X65Cr14, X105CrMo17 in accordance with ISO 683-17:1999 and EN 10088-1:1995 standards.

High temperature bearings

: for work in high temperature environments (above 120 degrees: steel industry, roasting carts). Heat-resistant high-alloy steels of type 80MoCrV42-16, corresponding to ISO 683-17:2014, as well as high-chromium steels and with molybdenum additives Kh12M, Kh12F1, 40Kh10S2M, 30Kh13N7S2 steels. BECO produces a wide range of modern high-temperature bearings in the BHTS series. These bearings maintain hardness and performance even in extreme temperatures ranging from -30 to +280 degrees.

Low temperature bearings:

for work in conditions of low temperatures (up to – 60 degrees: refrigeration chambers, equipment in high mountains, northern latitudes). BECO offers a ready-made solution: bearings of the BLS ZZ60 series are made of AISI 52100 alloy steel, equipped with low-temperature grease and protective covers.

What is the purpose of single-row and double-row ball bearings?

Single row.

These are the simplest and most popular rolling bearings for use in lightly loaded structures with radial and partially one-sided axial loads. In structures with double-sided loading, paired installation is practiced in each support.

Double row.

They are used in structures with average radial and variable (bilateral) axial loads.

What is the purpose of self-aligning ball bearings?

Typically, self-aligning bearings (invented by SKF about 100 years ago) are double-row spherical ball bearings with a spherical outer ring raceway. This allows you to compensate for shaft deflections under load or misalignment of supports during assembly within a range of up to 3 degrees. But they are not designed to work in structures with axial loads.

What are sealed bearings for?

Open ball bearings are used to handle normal loads and without special environmental requirements. The rolling bodies are open and not protected by anything.

For operation in dusty, humid, corrosive or extreme temperature environments, sealed bearings are used. Their rolling bodies are partially or completely isolated (tightness is ensured) from the external environment. For this purpose, protective seals in the form of metal washers or rubber or polymer seals are used. Another purpose of seals is to retain lubricant. Closed-type bearings are filled with lubricant at the factory for their entire service life and do not require replacement or replenishment of lubricant, unless the bearing design provides for it by the presence of a lubrication hole.

What is the purpose of finished bearing units?

This is a ready-made support (housing) made of cast iron, steel, stainless steel, aluminum or thermoplastic with an already installed single-row ball bearing, lubrication system and protective seal. They are self-aligning (the outer ring of the bearing and the housing have a spherical surface) and are capable of compensating for axial deviations of spaced supports. They are used when ease of assembly, installation, and quick replacement of units with bearing supports are required (agricultural machines, weaving machines, conveyor, construction, food equipment, etc.). In heavily loaded housing bearing assemblies, split cast iron housings and double-row ball or roller self-aligning bearings are used.

Where is the best place to buy ball bearings?

The Technobering company is the largest store of ball bearings, the official website of the distributor of leading manufacturers ISB, INA-FAG, NSK, SKF, Beco. All products are certified and comply with Russian GOST and ISO standards.

If you need bearings “for yesterday” according to the “set it and forget it” principle, purchase from a company with a long-standing reputation, a wide range of certified products and an easily accessible operational warehouse.

Experienced, intelligent Technobering specialists will advise, quickly select and recommend the most optimal bearing option from several possible ones.

Bearings website Technobering is a reliable supplier of quality solutions for bearing units!

Plain bearings

This unit does not have rolling elements. Its characteristics are as follows: the inner and outer cages are made along the same radius. Therefore, the axis, relative to the mandrel, has several degrees of freedom. Most often they are used in articulated joints.

Plain bearings with a hole and grooves for lubrication in the inner ring with a single-break ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 EC | ESHSP 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 EC | ESHSP 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 EC | ESHSP 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 EC | ESHSP 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

With double-break outer ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 20 EXC | ShSL 20 | 20 | 35 | 16 | 12 | 9 | 24 | 29 | 0,07 | |

| GEH 20 EXC | 2ShSL 20 | 20 | 47 | 26 | 15 | 22 | 23 | 35 | 0,19 | |

| GE 25 EXC | ShSL 25 | 25 | 42 | 20 | 16 | 7 | 29 | 35 | 0,12 | |

| GEH 25 EXC | 2ShSL 25 | 25 | 52 | 28 | 15 | 22 | 28 | 40 | 0,26 |

With holes and grooves in the inner ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 C | ESH 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 C | ShS 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 C | ESH 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 C | ESH 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

With grooves on inner and outer rings

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 S | ESH 10K | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 S | ShS 12K | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 S | ESH 15K | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 S | ESH 17K | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

Without holes and grooves with single break ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 E | ESR 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 E | ShP 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 E | ESR 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 E | ESR 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

With holes and grooves on outer and inner rings with single break ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10ES | ESHSP 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 ES | ShSP 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15ES | ESHP 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 ES | ESHSP 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

With double-break outer ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 EXS | ESHSL 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 EXS | ShSL 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 EXS | ESHSL 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 EXS | ESHL 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

Below we provide tables of closed sizes of rolling and sliding ball bearings.

Selection of bearing series

0

Selection of bearing series

Rolling bearings of almost all types are produced in several varieties (series), differing in size, load capacity and maximum rotation speed.

In Fig. 761, a, b shows, depending on the diameter d of the shaft, the dynamic load capacity and the maximum permissible rotation speeds for bearings of various sizes and series.

The dynamic load capacity increases, and the rotation speed decreases with the transition from light series to heavier ones and with increasing bearing diameter.

For example, for roller bearings the dynamic load capacity of medium series is approximately 1.7 times greater than that of light series; heavy series - the same number of times more than medium ones, and approximately 3 times more than light series.

The durability of bearings, due to its power-law dependence on the dynamic load capacity, increases more significantly with the transition to heavier series.

According to formula (345) durability

i.e., with n = const and P = const, durability is proportional to Cα. Consequently, all other things being equal, the durability of roller bearings of medium series is 1.73.33 ≈ 6 times longer than light ones; heavy series - the same number of times more than medium ones, and about 36 times more than light series.

In Fig. 761, c shows the relative durability L'h, calculated using formula (347) assuming the same loads and rotational speeds. The durability of a light series radial ball bearing with d = 100 mm is taken as one (Table 43).

As you can see, the durability of heavy series bearings is approximately one order of magnitude greater than the durability of light series bearings, and the durability of roller bearings is one to two orders of magnitude greater than the durability of ball bearings.

Based on Fig. 761, you can evaluate the comparative durability of bearings comparable in functionality and speed. In table Figure 43 shows the relative durability figures for radial ball and roller bearings with a diameter of 100 mm, assuming that the loads and rotation speed are the same (the durability of a light series ball bearing is taken as one).

As you can see, the durability of roller bearings exceeds the durability of ball bearings for the light series by 4 times, the medium series by 6 times and the heavy series by 10 times. The durability of a heavy series roller bearing is 150 times longer than that of a light series ball bearing.

When choosing a series, in addition to the load-bearing capacity, you should take into account the dimensions, weight and speed of the bearing. In Fig. 762 shows the main indicators of bearings of various types and series with the same shaft diameter (d = 80 mm). As shown in the figure, light series bearings have a significant advantage in terms of size, weight and speed. Their load-bearing capacity, of course, is less than that of bearings of medium and especially heavy series.

Most often, bearings of light and medium series are used, preferring, if necessary, to increase the dynamic load capacity by increasing the shaft diameter, which is as effective a means of increasing the load-bearing capacity and durability as making the series heavier. This method corresponds to the modern trend of using hollow shafts of increased diameter in power units as a means of increasing strength and rigidity and reducing the weight of the structure.

Heavy series bearings are used in low-speed units subjected to particularly high loads (rolling mill shafts). It is also advisable to use them in end installations of massive shafts, where the diameter of the journals, without compromising strength, can be made significantly smaller than the diameter of the working part of the shaft and thus reduce the dimensions of the bearing assembly.

Calculation of bearings using the given formulas and catalog data gives only average and, moreover, somewhat reduced durability values. According to statistical data, 50% of bearings have a service life of 3-4 times, and 10% have a service life of 10-20 times greater than the calculated one, and for high-precision bearings it is significantly longer than for normal-precision bearings. The durability and load-bearing capacity of bearings very much depend on the design of the unit, the correct installation of the bearings, the rigidity of the shaft and housing, the amount of interference on the seating surfaces and, especially, on lubrication conditions. Bearings in properly designed units, with appropriate preload, often operate for a period many times longer than designed. On the other hand, a high dynamic load rating does not guarantee reliability. Such bearings can quickly fail due to installation errors (bearing overtightening, axle misalignment, insufficient or excessive lubrication).

Needle Bearing Size Chart

| International designation | Russian designation (GOST) | Dimensions (mm) | Load capacity (kN) | Weight (kg) | ||||

| d | Fw | D | B | Dynamic | Static | |||

| NK 32/20 | 524706 | 32 | 32 | 42 | 20 | 23,3 | 40,5 | 0,068 |

| RNA 49/28 | 42549/28 | 32 | 32 | 45 | 17 | 25,1 | 36,5 | 0,073 |

| RNA 69/28 | 62549/28 | 32 | 32 | 45 | 30 | 39,6 | 65,5 | 0,14 |

Plain bearings

| International designation | Russian designation (GOST) | Dimensions (mm) | Load capacity (kN) | Weight (kg) | ||||

| d | Fw | D | B | Dynamic | Static | |||

| RNA 4010V | 4024110 | 62 | 62 | 80 | 30 | 59,6 | 153 | 0,44 |

| RNA 4911 | 4254911 | 63 | 63 | 80 | 25 | 57,2 | 106 | 0,26 |

| RNA 6911 | 6254911 | 63 | 63 | 80 | 45 | 89,7 | 190 | 0,47 |

Thrust-radial roller

| International designation | GOST | Dimensions (mm) | Weight (g) | ||||

| d | D | de | De | Bx | |||

| AXK 2035 | 999904 | 20 | 35 | 22 | 34 | 2 | 5 |

| AXK 2542 | 999905 | 25 | 42 | 29 | 41 | 2 | 7 |

| AXK 3047 | 219806 | 30 | 47 | 34 | 46 | 2 | 8 |

Table fields

They display the names of the main parameters and their geometric dimensions.

ISO marking

It is standard for most countries of the world, which indicates the number and design features.

GOST

It is a Russian analogue and performs the same functions.

Node internal diameter

It is measured in millimeters (mm) and is designated by the English letter d.

Outside diameter

Denoted as D.

Width

Measured in mm and identified by a capital B.

Weight

The measure is in kilograms (kg).

Scheme

Explains the basic structure.

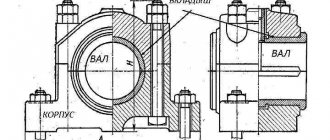

Rolling bearings. General characteristics. Basic designs

Rolling bearings are the main type of support for rotating (swinging) parts. The bearing consists of outer 1 and inner 2 elbows between which the rolling elements . To protect the rolling elements from contact with each other, they are separated from each other by a separator which significantly reduces friction losses (Fig. 25.2).

Rolling bearings are standardized and manufactured in highly specialized mass production by bearing factories. Therefore, it is extremely rare for an engineer to design rolling bearings. Much more often it is necessary to select a bearing for a support unit, design a support housing, ensuring manufacturability, controllability and maintainability of the unit, as well as assess the residual life of the bearing when modernizing or speeding up the operating mode of the equipment.

Classification . Rolling bearings are classified according to the characteristics listed below.

I. According to the shape of the rolling elements, they are divided into:

ball;

roller with short cylindrical, conical, barrel-shaped, needle and twisted rollers.

Rice

. 25.2. Ball bearings

Rice

. 25.3. Roller bearings

II. Based on the direction of the forces perceived relative to the shaft axis, they are divided into types:

radial (Fig. 25.2 a, 25.3 a), receiving predominantly radial loads acting perpendicular to the axis of rotation of the bearing;

radial thrust (Fig. 25.2 b, 25.3 b), perceiving simultaneously acting radial and axial loads;

persistent-radial , perceiving axial loads with the simultaneous action of a slight radial load;

persistent , perceiving only axial forces.

Ш. According to the ability of self-alignment, they are divided into non-self-aligning and self-aligning , allowing rotation of the axis of the inner ring relative to the axis of the outer ring.

IV. Based on the number of rows of rolling elements located in width, they are divided into non-uniform (Fig. 25.2; 25.3), two-row , four-row and multi-row .

The main consumer (external) characteristics of bearings are load capacity, speed, weight, dimensions, energy loss.

Bearings of the same bore diameter are divided according to outer diameter and width into series: ultra-light, extra-light, light, light wide, medium, medium wide and heavy.

For particularly high rotation speeds and light loads, it is advisable to use bearings of the ultra-light and extra-light series. To carry increased and heavy loads at high rotation speeds, light series bearings are used, and if their load capacity is insufficient, two bearings are placed in one support.

special bearings are manufactured for special reasons .

Advantages and disadvantages of bearings . Rolling bearings have a number of advantages compared to plain bearings: smaller (2-3 times) axial dimensions; less friction and resistance to starting under load and rotation at low and medium speeds, constant rotation resistance; ease of maintenance and lubricant supply; low cost and interchangeability. The disadvantages of rolling bearings compared to plain bearings are the following: large radial dimensions; low radial rigidity and, as a consequence, a tendency for the shaft to vibrate due to rhythmic rolling through the loaded support area; more complex installation; greater rotational resistance (due to friction between rolling elements, rings, cage and hydraulic losses) at high speeds and, as a result, low durability (due to overheating).

The industry produces rolling bearings of five accuracy classes: 0.6; 5; 4 and 2. Designations are given in order of increasing accuracy, determined by the tolerances for the manufacture of elements, as well as the standards for smooth rotation (stroke).

The main bearing dimensions are established by GOST 3478-79 (ST SEV 402-76). They include: internal d and external diameters D, width B (height H

) and the radius

r

of the ring chamfers.

Materials of bearing parts. Rings and rolling elements of bearings are made mainly from ball-bearing high-carbon chromium steels ШХ15 and ШХ15СГ, ШХ20СГ, as well as case-hardened alloy steels 18ХГТ, 20Х2Н4А, etc. At operating temperatures up to 100 °C, rolling bodies and rings usually have a hardness of 60-64 HRC, balls – 62-65 HRC.

Rings and rolling elements of bearings operating at elevated temperatures (up to 500 °C) in aggressive environments are made of heat-resistant and corrosion-resistant steels.

Bearing cages are subject to intense wear due to sliding friction with rolling elements and rings, so cages are made of antifriction materials. Mass bearing cages are made by stamping from soft carbon steel, which has good anti-friction properties. High-speed bearing cages are made of massive PCB, fluoroplastic, duralumin, brass and bronze (materials are listed in order of increasing speed of the bearing).

The main types of bearings and their characteristics are given in reference books.

25.3. Dynamic load capacity of rolling bearings. Selection of bearings and determination of their service life

Dynamic load capacity of bearings . It is more convenient to perform the calculation using the actual load R.

(25.6)

where L –

nominal bearing life, million revolutions;

C –

dynamic load capacity, N;

R –

equivalent load, N; q is an indicator of the degree of bearing fatigue curve;

–

calculated bearing life, million revolutions;

n –

ring rotation frequency, min-1;

Lh –

design life of the bearing, h.

The dynamic load rating C of radial and angular contact bearings refers (by agreement) to the constant radial load (in Newtons) that a bearing with a fixed outer ring can support during a nominal life of 1 million revolutions. The dynamic load capacity of thrust and radial thrust bearings is the constant central axial load (in Newtons) that the bearing can support during the nominal life of 1 million revolutions of one of the rings.

Accept q =

3 (

m

= 9) for ball bearings and q

=

3.33 (

m

= 6.66) for roller bearings.

The equivalent load for selecting bearings is determined taking into account the characteristics of their operation under operating conditions:

(25.7)

where V –

rotation coefficient (

V =

1 when the inner ring rotates,

V

= 1.2 when the outer ring rotates);

Kb –

safety factor, taking into account the influence of the nature of external loads on the durability of bearings;

KT –

temperature coefficient;

Fr –

radial force;

Fa – axial force; x –

radial load coefficient;

y –

axial load coefficient.

Product sizing

In everyday life or production, these parameters are measured with certain tools: calipers, micrometers, bore gauges.

External Diameter Measurement

Manufacturing parameters are maintained quite accurately. Therefore, you should not trust the readings of a caliper. If it shows a non-standard value, then the real data will be the closest indicators indicated in the register.

How to measure the inner diameter of a product

Construction stores sell a special device called a bore gauge. But it is better to take the closest number from the classic report card as the true value.