Bearings are the heart of roller skates. In this case, it does not matter at all what type of videos we are talking about.

It is the bearing that makes the wheels rotate, thanks to which the latter allow the rollers to develop the desired speed. The quality of bearings directly affects the results of roller skaters in competitions and marathons, and also affects the comfort in amateur skating.

This large and comprehensive guide will allow you not only to understand the differences, but also to easily determine the type of part that is suitable for your style and level of riding.

Standards (brands) of bearings

All bearings are divided into 2 standards (grades): 608 and 688. They are also called sizes.

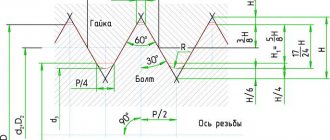

- Brand 608 is based on standardization of the production process: the number 60 indicates the product series, and the number 8 indicates the inner diameter of the bearing.

Classic roller skates and quad rollers are usually equipped with 608 standard bearings, which are easy to maintain and allow you to maintain high speed for a long time when skating.

- Brand 688 has the same outer and inner diameter of 8 mm as standard 608 bearings, but they are thinner, which reduces their weight by 2.5 times.

Standard 688 bearings also accelerate well and maintain speed, but are more sensitive to dirt, dust, and water, and therefore require more careful maintenance.

Symbol of balls according to GOST 3722

[td]Additional designation

Ball Diameter–Degree of Accuracyfor example: H25.6-20 ball with a diameter of 25.6 mm with 20 degrees of accuracy

In additional notation:

the letter “N” – balls used in rolling bearings. letter “B” – balls not sorted by diameter.

Ball diameter:

designation of nominal diameter in millimeters

Degree of accuracy:

The measure of precision of balls is influenced by the following values: – deviation of the average diameter of balls used in the form of individual parts – variation in the size of balls in diameter in a batch – variability of a single diameter – deviation from the spherical shape – surface roughness parameters.

Read also: How to connect an Internet cable

There are 10 degrees of precision

GOST

standard : 200, 100, 60, 40, 28, 20, 16, 10, 5, 3 (listed in order of increasing accuracy)

Accuracy classes

steel balls according to

DIN 5401

: G700, G600, G500, G300, G200, G100, G80, G40, G28, G20, G16, G10, G5, G3 (listed in order of increasing accuracy)

The higher the accuracy of the ball, the smaller the deviations from size and shape!

ABEC bearing markings

In the production of roller skates (as well as skateboards and scooters), bearings are usually marked with the designation “ABEC” with the addition of an odd number from 1 to 9.

The abbreviation ABEC itself stands for rather unusually as Annular Bearing Engineering Council or “Bearing Engineering Committee”, and the number characterizes the accuracy of the tolerance during production. Moreover, the lower the number, the lower the tolerance (not the speed!), and, accordingly, the cost of the part.

How do the markings (classes) differ?

Estimating the rotation speed of a bearing by class is the biggest misconception among buyers. Many people believe: the higher the number in the marking, the faster the rollers will go. But that's not true.

The marking determines how accurately the bearing is manufactured. And the larger the number, the more “jewelry” and more ideally the part is made.

The class will affect the rolling of the rollers (the duration of rolling without additional push) and durability, but not the speed. In addition, the marking determines what style of riding the part is suitable for.

What does speed depend on?

We have already found out that the number in the marking is not an indicator of speed. So ABEC 9 bearings may not be the fastest by default, but will provide longer lasting torque.

The following factors can affect the speed:

- Quality and consistency of the lubricant used

A more flexible and thick lubricant slows down the rotation speed, but at the same time increases the service life.

Conversely, liquid lubricant allows better acceleration at first, but quickly evaporates, leaks and requires very frequent maintenance for the bearings. In addition, the use of the latter is completely inappropriate for videos from the “fitness” series.

- Quality and frequency of service

Bearings of any marking (provided there are no defects) will perform their function properly for the first time after purchase. But depending on the mileage and riding conditions, the performance will gradually deteriorate.

The load and duration of riding will eventually require updating the lubricant, and the inevitable ingress of dust, sand and dirt will require timely cleaning and possibly even replacement of the part.

Designation of conical rollers GOST

| 1 character | 2 character | 3 character | 4 character | 5 character |

| Nominal diameter (smaller) | (multiplier sign) | Nominal diameter (larger) | (multiplier sign) | Nominal length |

| 3.65×4.2×7.1 4.79×5.53×10.04 4.92×5.61×7.94 5.12× 5.5×10.94 5.52×6, 08×8.1 5.82×6.5×10.5 5.95×6.5×12.54 6.3×7.06×12.4 6.34×7.1×9.66 6 ,34×7.1×10.8 6.36x7x11.04 6.76×7.5×12.04 6.78×7.03×9.51 6.8×7.2×15.41 7, 18×8.22×14.95 7.2×7.8×13.64 7.26×8.35×15.67 7.27×8.32×10.1 7.42×8.4× 14 7.49×8.22×10.45 7.5×8.6×14.96 7.54×8.05×14.62 7.61 ×8.4×11.27 7.7×8 ,4×14.84 7.7×8.4×14.9 7.75×8.4×14.9 8.12x10x13.5 8.31×9.65×19.2 8.36×9, 45×17.7 8.44x9x10.8 8.58×9.42×12.06 8.63×9.5×11 8.76×9.6×16.1 8.8×10.03×17 ,67 8.81x9x14.52 9.04x9.6x16.1 9.14x9.34x15.5 9.16x10.3x16.3 9.16x10.3x16, 4 9.29×9.58×11.1 9.34×10.5×26.45 9.371×10.9×22 9.47×10.63×16.66 9.57×10.51×13 .59 9.57×10.77×22.25 9.59×10.49 ×12.86 9.77×10.5×14.03 9.93×12.2×16.4 10.13x11x16, 54 10.17x11.05x33.53 10.43x11x20.91 10.45x11x20.91 10.6x11x15.32 10.61x12.33x31 10.74x11.5x29.02 10.76 ×11.6×19.26 10.83×12.397×22.5 10.96×12.09×18.4 10.99×12.23×20.3 11.19×12.2×14.51 11.2×12.7×21.8 11.31×12.2×20.24 11.32×12.37×15.1 11.4×12.8×22.8 11.49×12, 65×16.66 11.7×12.82×21.56 11.73×13.8× 12.12x13x25.04 12.3×13.76×25.5 12.35×13.7 ×25.9 12.63×13.6×15.9 12.7×14.14×23.6 12.79×14.4×26.4 12.85×14.87×33.11 13, 19x14x23.04 13.19x14x24.04 13.53x15x28.1 13.62x15.73x30.35 13.64x14.8x19.1 13.65x15.7x33.5 13.72x 14.8×17.7 13.78×14.6×23.54 13.78×15.44×23.88 13.8×15.01×17.39 13.85×15.38×25, 11 14.13×14.6×18.04 14.39×15.55× 26.56 14.9×15.55×26.56 15.28×16.9×26.6 15.94×17 .4×20.9 15.94×18.1×35.4 16.09×17.4 ×18.8 16.18×18.59×34.61 16.24x18x33.6 16.32x18x32.1 16 .34×18.15×29.7 16.34×18.5×29.7 16.44×17.5×30.3 16.5×17.62×31.29 16.8×17.6 ×30.3 16.8×18.2×22.3 16.83×18.15×30.26 16.85×17.6×28.4 16.94×18.54×22.98 16, 94×18.546×22.98 17.06x20x42.2 17.38×19.55× 35.5 17.4×19.55× 35.5 17.48×18.4×35 17.48×18.4 ×35.1 17.57×18.8×35.1 18.04× 20.8×45.36 18.09×19.5×23 18.16x20x35.1 18.16×20.18×33, 1 18.195×19.5×23.1 18.47×20.9×37.6 18.77x20x36.08 19.2×20.75×35.5 19.45×20.5×40.06 19.648× 21.47×26.23 19.648×21.57×26.23 19.9x22x40.1 20.08×22.53×40.1 20.23x23x45.43 20.76×23.71×48.3 22, 5×24.3×29.3 22.69x24x30 22.88 ×25.2×14.3 22.88×25.2×44.3 23.1×24.65×44.33 23.41×26 ,23×46.9 23.41×26.23× 46.91 46.9 23.48x25x43.5 23.53x25x42.1 23.61×27.6×33.02 23 ,86x26x49.1 23.93x27.04x51 24.33x25.6x29.1 24.91x29.6x33.9 25.42x28.5x44.25 25.53x28x47 , 2 25.83x28.6x52.93 26.64x29x45.2 26.67x28x50.59 26.74x28.6x53.3 26.74x28.6x53.32 26.75x28, 8×29.5 26.97×30.91×56.67 27.02x28x28.1 27.14 27.76x30x32 27.87×30.85×57.14 28.2x31x40, 2 28.77x31.1x53.4 28.932x30.71x29.82 29.05x31x44.73 29.12x30x25.1 29.36x31.2x30.23 30.06x31.4x 38.33 30.12x32x43.32 30.21x32x41.17 31.34x36.8x45 31.5x33x57.3 31.5x35x50.2 31.52x33.6x59.64 31.64x38x52.58 31 , 95×35.9×64.77 32.12x35x66.1 32.32x34x36.1 32.87×36.52×62.8 32.92x34x41.11 33.66×36.3×60.44 34.66x37x67, 1 34.66x37x67.16 34.76x37x64.1 35.78x38x51 36.03x39x68.21 37.8x40x63.17 38.28x40x49.1 38.28x40x49.17 38.95x40x30.17 39.8x44 x60.3 40.05×41, 9×42.4 40.05×41.9×42.58 40.47x45x74.3 40.71x43x52.53 40.77 ×43.75×57.08 42.41x45x74.19 42.8x48x85.36 42.82 ×44.6×51 42.82×44.6×51.04 43.44x46x42.15 45.38x48x60.2 45.38x48x60.26 45.69x48x66.1 48.29 ×55.2×50.2 49, 17x52x54.34 50.3x58.5x59.6 50.97x54x58.1 50.97x54x58.15 52.46x54.8x67 55.35x58.5x60.38 55.72x60x70.5 55 .8×64.3×66.05 63.7×67.2× 80.3 65.61×68.6×68.8 67.97x80x87 71.2x75x87.3 73.7x78x82.51 | ||||

Differences between ABEC markings

As we mentioned above, you can select spare parts based on the markings depending on your riding style. In addition, it is worth explaining the purpose of other bearing models from the popular manufacturer Powerslide, which raise the most questions.

The most popular markings: ABEC 1, ABEC 3, ABEC 5, ABEC 7, ABEC 9:

- ABEC 1 and ABEC 3 have a lower accuracy class, but at the same time higher resistance to shock loads. Often installed in scooters, skateboards and roller skates of a very low price segment;

- ABEC 5 are most widely used in roller skates for children, fitness, FSK, slalom and aggressive skating by many manufacturers, due to the optimal price-quality ratio;

- ABEC 7, ABEC 9 – less resistant to impacts, but better able to cope with long-term loads. Hence they are used mainly in fitness videos and speedskating models.

In addition to the ABEC marking, there are other accuracy classes:

- RBEC - Roller Bearing Association

- ISO - International Organization for Standardization

- DIN - German industrial standards.

The correspondence between these classes and ABEC is presented in the table below:

Needle rollers GOST 6870

| nominal diameter D | X | L nominal length | end form | degree of accuracy |

In the form of the ends: letter A

rollers with a spherical end are designated.

The letter B

denotes rollers with a flat end.

There are three degrees of accuracy for needle rollers: 2, 3, 4

(in order of decreasing accuracy).

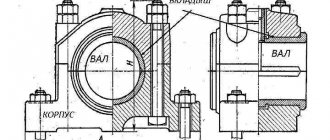

Single row roller bearings

FKL produces single-row radial rolling bearings in accordance with DIN 5412 part 1 and angular rings in accordance with ISO 246 and DIN 5412 part 1. These bearings are split. This makes installation and disassembly easier, and the contact of both rings can be tight. The contact line between track and rollers is modified to eliminate edge stressing. The ability to compensate for the angular error of these imported bearings for narrow rows 2, 3 and 4 is 4 arc minutes, and for wider rows 22 and 23 - 3 arc minutes.

Single row cylindrical rolling bearings are available in the following types: NU, N, NJ, NUP, NF, NU+HJ, NJ+HJ

Single row roller bearings. Data

Clips

The clips are mainly made of stamped steel sheet. Massive cages are made of brass (additional designation on bearings – M).

Temperature Application Range of Roller Bearing

Cylindrical bearings with a cage made of steel sheet or with a brass cage are used up to an operating temperature of 150 0 C, taking into account the material and heat treatment of the outer and inner rings.

Roller bearings without inner ring (RNU)

The bearing rollers without inner ring (RNU) run on a hardened and ground shaft whose dimensions F are machined to G6 (housing bore to K6). Shaft diameter J is machined to tolerance h9 (F and J – see bearing size table).

Other types of bearings from Wicked

Powerslide's companion brand, Wicked, also produces bearings for roller skates such as Rustproof, Twincam ILQ9, Swiss, etc.

- Twincam ILQ7, ILQ9 Pro/Classic (Inline Line Quality)

Unlike ABEC, which is a validated industry rating, ILQ is not a standard that defines bearing quality, but simply refers to the name used on Twincam bearings for marketing purposes.

Twincam have similar markings to ABEC and are of good quality. “Pro” bearings have a nylon cage and, as a rule, are used by speed skaters, while “Classic” bearings have a steel cage, which is more suitable for city skating and freestyle;

- Rustproof SUS - suitable for riding (mainly training, but not competition) in conditions of high humidity. Made of stainless steel and less susceptible to corrosion;

- Swiss is a Swiss-made model that does not have any ABEC marking, but is distinguished by the highest technical characteristics, quality and speed. That is why many athletes prefer it in high-speed roller skating.

Based on comments from the manufacturer itself, of all the “unlabeled” models listed, the fastest by far are the Swiss bearings, followed by the ILQ Pro, ILQ Classic, and finishing with the Rustproof SUS rating.

GOST designation of spherical rollers

| 1 character | 2 character | 3 character |

| Nominal diameter | (multiplier sign) | Nominal length |

| 4×45×55×7,55,9×8,56×106,48×11,56,5×10,58,5×8,58,6×1010×1311×911×13,30911×13,31212,5×12,4313,5×11,64214×12,0614×12,06114×16,54515×12,17415×12,615×14,9416×13,9816,5×16,73216,5×21,05817×15,08117×15,45717×19,65517,5×22,89218×15,18518×17,94718×23,05418,5×16,79319,5×16,16819,5×17,49920×16,70420×25,45620,5×19,19921×20,1822×28,58622×30,09923×18,5823×19,3423×20,14423×23,10923×28,0623×32,123,5×23,73124,4×19,73824,5×19,73824,5×22,1124,5×26,65325×21,426×23,34326×33,06626×33,12426×36,07226,5×27,02827×23,23927×25,24927×29,829×29,55829×31,31629×36,129,5×24,76529,5×24,76630×41,5830×42,74331×26,57231×26,67731×32,51932×29,0632×44,14833×36,10233×45,19434×29,19835×29,235×31,45635×33,7635×37,9135×40,1535,5×31,28936×31,2136×42,61737×33,39737×5838×31,54138×44,78538×62,03838,5×55,17239×35,60839×43,73539×43,74140×50,13140×51,12140×52,10340×54,24542×37,1842×37,18442×39,35243×52,8144×39,0444×45,30545×41,57846×43,7248×43,45848×53,15748×55,06648×63,150×46,11350×48,58350×48,68350×56,64852×47,0652×47,08452×50,59152×59,5556×52,60356×68,15256×70,07158×72,1958×75,25258×78,3460×56,22960×75,1764×5965×90,28468×63,46169×61,35869×90,4675×98,40176×67,38585×110,585×115,3790×135,32992×87,582100×130,17110×100,197150×200 | ||

Technologies and materials used

- Freespin technology uses a special lubricant to ensure smooth surfaces and fast rotation of Wicked ABEC 5, ABEC 7 and ABEC 9 bearings. This bearing consists of an inner and outer ring, balls and raceway

- Ceramic - ceramic bearings that offer benefits such as reduced friction, weight and increased wear resistance

Most ceramic bearings are hybrid bearings, combining ceramic balls with a steel outer and inner ring and raceway. Fully ceramic options are quite rare due to their high cost.

Professional ceramic bearings are made from silicon nitride (Si2N4), are usually black in color, are approximately 30% stronger than steel bearings, are more rounded and smooth with a universal shape that guarantees significant reduction in friction.

- Stainless steel is a material that combines chromium (not less than 10.5%), carbon (not more than 1.2%) with the addition of nickel or other elements. This material is permanently coated with a protective layer of chromium oxide, which forms on the surface naturally due to the reaction of chromium and water from the air. If the surface is scratched, the protective layer is regenerated again, which protects the stainless steel from corrosion.

These bearings are used primarily for skating in wet weather (for example, for off-road rollers or in speed races and marathons).

- Chrome steel is an alloy of iron, carbon and some other elements, which is obtained by immersing ordinary steel in an electrolyte solution containing chromium and allowing the formation of a protective layer.

The most popular material for the inner and outer races, as well as the balls and raceways in the bearing, is 52100 series chrome-plated steel. Thanks to special heat treatment and a smooth surface, each component provides high resistance to bearing fatigue, as well as fast and quiet rolling.

- Carbon steel is a high-tech material used in aviation, Formula 1 cars and a huge range of sports equipment, but often misleads consumers when it comes to bearings.

Carbon steel bearings cannot withstand high loads at high speeds and are not resistant to corrosion. High friction between the balls and raceway significantly reduces speed and performance. Such products have a low cost and, as a rule, are used in budget skate models for beginners.

- Carbon hybrid steel is used in the manufacture of Wicked Carbon Pro bearings - a combination of chrome and carbon steel.

The outer and inner rings, along with the raceway, are made of stronger chrome steel, and the balls are made of carbon. These bearings provide more comfortable and smooth rolling than models made entirely of carbon steel.

Ball size table - nominal diameter D. Applicability in rolling bearings

Weight per 1000 pcs. kg:

| D, mm | weight 1000pcs, kg |

[/td]

0,250.00008 kg.0,30.00011 kg.0,360.00016 kg.0,3970.00025 kg.0,40.00026 kg.0,50.00051 kg.0,5080.00054 kg.0,60.00089 kg.0,6350.00105 kg.0,680.00129 kg.0,70.00141 kg.0,7940.00206 kg.0,80.0021 kg.0,840.00243 kg.0,850.00252 kg.10.00411 kg.1,1910.00694 kg.1,20.0071 kg.1,30.00903 kg.1,50.0139 kg.1,5880.0164 kg.1,9840.0321 kg.20.0329 kg.2,3810.0554 kg.2,50.0642 kg.2,7780.0881 kg.30.111 kg.3,1750.132 kg.3,50.176 kg.3,5720.187 kg.3,9690.257 kg.40.263 kg.4,3660.342 kg.| D, mm | weight 1000pcs, kg |

| 4,5 | 0.374 kg. |

| 4,763 | 0.444 kg. |

| 5 | 0.514 kg. |

| 5,159 | 0.564 kg. |

| 5,5 | 0.684 kg. |

| 5,556 | 0.705 kg. |

| 5,8 | 0.802 kg. |

| 5,953 | 0.867 kg. |

| 6 | 0.887 kg. |

| 6,35 | 1.05 kg. |

| 6,5 | 1.13 kg. |

| 6,747 | 1.26 kg. |

| 7 | 1.41 kg. |

| 7,144 | 1.5 kg. |

| 7,5 | 1.73 kg. |

| 7,541 | 1.76 kg. |

| 7,938 | 2.06 kg. |

| 8 | 2.1 kg. |

| 8,334 | 2.38 kg. |

| 8,5 | 2.52 kg. |

| 8,731 | 2.73 kg. |

| 9 | 3 kg. |

| 9,128 | 3.12 kg. |

| 9,525 | 3.55 kg. |

| 9,922 | 4.01 kg. |

| 10 | 4.11 kg. |

| 10,319 | 4.51 kg. |

| 10,716 | 5.06 kg. |

| 11 | 5.47 kg. |

| 11,112 | 5.64 kg. |

| 11,5 | 6.25 kg. |

| 11,509 | 6.26 kg. |

| 11,906 | 6.93 kg. |

| D, mm | weight 1000pcs, kg |

| 12 | 7.1 kg. |

| 12,3 | 7.65 kg. |

| 12,303 | 7.65 kg. |

| 12,7 | 8.42 kg. |

| 13 | 9.03 kg. |

| 13,494 | 10.1 kg. |

| 14 | 11.3 kg. |

| 14,288 | 12 kg. |

| 15 | 13.9 kg. |

| 15,081 | 14.1 kg. |

| 15,875 | 16.4 kg. |

| 16 | 16.8 kg. |

| 16,669 | 19 kg. |

| 17 | 20.2 kg. |

| 17,462 | 21.9 kg. |

| 18 | 24 kg. |

| 18,256 | 25 kg. |

| 19 | 28.2 kg. |

| 19,05 | 28.4 kg. |

| 19,844 | 32.1 kg. |

| 20 | 32.9 kg. |

| 20,638 | 36.1 kg. |

| 21 | 38 kg. |

| 21,431 | 40.4 kg. |

| 22 | 43.8 kg. |

| 22,224 | 45.1 kg. |

| 22,225 | 45.1 kg. |

| 23 | 50 kg. |

| 23,019 | 50.1 kg. |

| 23,812 | 55.5 kg. |

| 24 | 56.8 kg. |

| 24,606 | 61.2 kg. |

| 25 | 64.2 kg. |

| D, mm | weight 1000pcs, kg |

| 25,4 | 67.3 kg. |

| 26 | 72.2 kg. |

| 26,194 | 73.8 kg. |

| 26,988 | 80.8 kg. |

| 27,781 | 88.1 kg. |

| 28 | 90.2 kg. |

| 28,575 | 95.8 kg. |

| 30 | 111 kg. |

| 30,162 | 113 kg. |

| 31,75 | 132 kg. |

| 32 | 135 kg. |

| 32,544 | 142 kg. |

| 33,338 | 152 kg. |

| 34 | 162 kg. |

| 34,925 | 175 kg. |

| 35 | 176 kg. |

| 35,719 | 187 kg. |

| 36 | 192 kg. |

| 36,512 | 200 kg. |

| 38 | 225 kg. |

| 38,1 | 227 kg. |

| 39,688 | 257 kg. |

| 40 | 263 kg. |

| 41,275 | 289 kg. |

| 42,862 | 324 kg. |

| 44,45 | 361 kg. |

| 45 | 374 kg. |

| 46,038 | 401 kg. |

| 47,625 | 444 kg. |

| 49,212 | 490 kg. |

| 50 | 514 kg. |

| 50,8 | 539 kg. |

| 52,388 | 591 kg. |

Read also: How to ring a diode correctly

| D, mm | weight 1000pcs, kg |

| 53,975 | 646 kg. |

| 55 | 684 kg. |

| 57,15 | 767 kg. |

| 60 | 887 kg. |

| 60,325 | 902 kg. |

| 61,912 | 975 kg. |

| 63,5 | 1052 kg. |

| 65 | 1128 kg. |

| 66,675 | 1218 kg. |

| 69,85 | 1400 kg. |

| 73,025 | 1600 kg. |

| 75 | 1733 kg. |

| 76,2 | 1818 kg. |

| 79,375 | 2054 kg. |

| 80 | 2103 kg. |

| 82,55 | 2311 kg. |

| 85,725 | 2588 kg. |

| 88,9 | 2886 kg. |

| 90 | 2995 kg. |

| 92,075 | 3207 kg. |

| 95,25 | 3550 kg. |

| 98,425 | 3917 kg. |

| 100 | 4108 kg. |

| 101,6 | 4308 kg. |

| 104,775 | 4725 kg. |

| 107,95 | 5168 kg. |

| 108 | 5175 kg. |

| 110 | 5468 kg. |

| 111,125 | 5637 kg. |

| 114,3 | 6134 kg. |

| 120 | 7100 kg. |

| 127 | 8415 kg. |

| 150 | 13865 kg. |

Seals in bearings

The seal is necessary for:

- uniform distribution of balls and lubricant around the raceway

- preventing them from rubbing against each other

- achieving high speed.

To improve accuracy and prevent additional galling, it is important that the seal does not allow excessive radial movement. To do this, the seal is guided either by balls or by one of the rings.

Types of seals in bearings:

- steel (from the different types of steel we discussed above) - widely used in manufacturing, usually shaped like a crown and guided by an inner ring.

They have disadvantages such as heavy weight, risk of deformation of the protective coating upon impact, and corrosion of carbon steel.

- plastic - composite products, most often made from reinforced nylon by injection molding. Polyacetal (POM) can also be used.

Polymer materials such as polyethylene (PE) are used with stainless steel bearings, while polyether ether ketone (PEEK) is most often used with ceramic bearings.

A plastic crown covers the ball guide. Unlike steel, plastic seals have higher slip rates and cause sharp temperature fluctuations in operating torque. This allows you to increase the maximum speed by 60% with low noise levels.

The disadvantages listed for steel clamps, on the contrary, are advantages for plastic ones.

- ZZ (2Z)

Bearings with such a seal are covered on both sides with a non-removable seal, which does not come into contact with the metal and is fixed to the outer ring by pressing. The seal cannot be removed after factory assembly. This means that you will not be able to disassemble the bearings, but only perform basic maintenance such as cleaning the outer ring and wiping off moisture after riding in wet weather.

The abbreviation Z in the suffix indicates the presence of one protective washer, and ZZ (or Z2) means two.

Used in videos in the low price segment.

- ZZS / ZS is a removable seal that does not come into contact with metal and is attached using a snap-on wire ring (C-ring). This technology prevents contact with the inner ring.

Advantages of the C-ring fastening: does not create excessive friction and heat, does not allow lubricant leakage (in the ZZS version), and does not require frequent maintenance.

Disadvantages: poor protection against dust and water (especially in the ZZ version).

- 2RU / RU is a seal made from nitrile rubber (NBR) connected to a steel sleeve. It is installed on the outer ring through a special recess (groove). It can be removed, but be very careful not to bend or cut the edges.

The seal has a very thin lip that does not contact the inner ring, providing greater protection than the ZZ and ZZS. It is important to use the correct cleaning materials because... Various types of lubricants and chemical elements often react with rubber.

- 2RS / RS - removable molded protective seal, also made of rubber (NBR), attached to the outer ring through a groove.

In such bearings, the rubber seal is in contact with the inner ring, which, unlike a metal screen, increases protection against dirt and water getting inside the part. On the other hand, this increases friction and reduces the ability to reach high speeds.

- Labyrinth seal (screen) - also made of rubber (NBR) and completely fills the space between the inner and outer ring of the bearing.

The seal is connected to the inner ring using grooves, which increases the tightness and prevents the penetration and accumulation of dirt and moisture inside, and also reduces the frequency of maintenance of the part without affecting the torque.

This type of seal is most often used in stainless steel bearings that are suitable for wet weather riding.

Closed and semi-closed bearings

Based on the name, you can guess that closed bearings are equipped with a seal on both sides, and semi-closed ones - on only one.

It is important that in a semi-closed bearing the open side faces the inside of the wheel to protect it from dirt and moisture.

Advantages of semi-closed bearings: lighter in weight and maintenance. Disadvantages: not protected from dirt and water, rapid evaporation of lubricant, more frequent maintenance.

Bearing lubricants

The lubricant forms a thin film between the contact points of the bearing elements (balls and raceway) to prevent friction, heat and corrosion.

The lubricant affects the maximum speed, heating temperature, torque level, noise and durability of the part.

Types of bearing lubricants:

- Mineral or synthetic grease - most often used in bearings intended to ride at high speeds.

There are many types of synthetic oils available in the market. And every professional speed skater has his own secret trick up his sleeve that makes his bearings go faster. And some rollers do not use any lubricants at all.

Mineral and synthetic lubricants differ in viscosity. And the lower it is, the more liquid the material will be: it will be easier to apply it to the bearing, the friction force decreases, the speed increases, but rapid evaporation will require more frequent maintenance.

- Silicone grease has a wide temperature range, changes viscosity to a lesser extent when heated, and repels water well.

Not used for high speed riding, but best suited for wet weather riding.

- Grease is a mixture of oils and a thickener that allows the material to remain inside the bearing longer without requiring frequent maintenance.

Excessive amounts of such grease in a bearing will reduce its performance and lead to increased resistance. The free space in the bearing is necessary to release heat between the balls and the raceway.

- Teflon is an additive used in the lubricant that inhibits corrosion and improves the performance of standard grease.

Bearing Maintenance

The first sign that your bearings need to be inspected is a sound or slow rotation. Regular maintenance of parts will at least save you money.

To do this you need:

- Disassemble the wheel and remove the bearing

- Remove the seal (if possible) using a needle

- Place all parts in a small container with a non-aggressive cleaning agent.

- Gently clean each component with a brush

- Dry clean parts on a towel

- Lubricate the bearing with synthetic or any other lubricant

- Assemble the bearing and insert it into the wheel.

There is no general advice on how often bearings should be serviced, just as there is no ideal range for washing a car.

Each roller is individual. The main thing is not to forget to wipe and dry the wheels after each ride in wet weather, and if you have the slightest discomfort or suspicion that something is wrong with the bearings, pay close attention to this yourself or with the help of a specialist.