Wire bending, performed either manually or using various tools and special equipment, allows products made from this material to be given different configurations. During the bending process, the inner layer of the wire is subjected to compression, and the outer layer is subjected to tension. Wire bending machines, which today are presented in a wide variety of models, are very popular, since bent wire products are actively used to solve various industrial and household problems.

The simplest device for bending wire

To perform bending operations at home without any problems, it is best to choose wire made from soft materials. Simple bending of stiffer wires, if necessary, can be carried out using ordinary plumbing tools:

- pliers (with the help of such a tool, which every home craftsman has, you can form a simple bend in the wire, as well as securely fix its segment for further processing);

- pliers (using this tool, which is one of the types of pliers, you can perform bending of varying degrees of complexity);

- wire cutters or needle nose pliers (using such a tool, the wire can be cut into pieces of the required length).

Simple techniques for manual wire bending

If you need to make a product of complex configuration from wire using the bending method, it is better to first draw it on paper and periodically check the sketch. To form the simplest figures, such a sketch does not need to be used. For example, if you need to create a bent product of a rectangular shape, you can do this as follows:

- The wire at the place of its future bend is clamped in a bench vice.

- The upper (not clamped) part of the wire is bent using ordinary pliers or a hammer.

As a result of this simple procedure, a bend at a right angle is formed on the surface of the wire.

To produce a large number of similar wire parts, templates and homemade devices are used.

Manual bending rules

If you are going to manually bend the wire, you must adhere to a number of recommendations that will allow you to complete this procedure without harm to your own health.

- All bending procedures should be carried out only with gloves made of thick fabric.

- The wire that is being bent must be secured in a vice as securely as possible so that it does not jump out during operation.

- All tools and equipment that you are going to use for work must be in good working order and perform their assigned functions efficiently.

- Heavy tools and equipment that you use when bending should not be placed on the edge of the workbench, so as not to accidentally hit them and drop them on your feet.

- When carrying out all manipulations with the wire bending tool with one hand, the other should be kept as far as possible from the future bend. Pliers or any other tool can break off and injure a hand located close to the bending area.

Wire bending using improvised means is possible only in small quantities, since such a procedure is quite labor-intensive. In addition, this operation can only be used to create products of the simplest configuration.

A specialized wire bending machine allows you to produce various products in large volumes, including those with complex shapes.

Do-it-yourself wire bending devices

Metal wire, or rather, various products made from it, is widely used in any household.

Bending wire with your own hands using hand tools allows you to produce a fairly large number of household products, such as:

- clamps,

- brackets,

- hangers, etc.

But for this we have to use the softest and most flexible types of wire, so that we can easily bend the metal into the shape we need.

So, for working with wire up to 3 mm in diameter, round nose pliers, pliers and a bench vice are suitable, and you can cut the wire with wire cutters or side cutters. This set is quite enough to give the metal wire the desired shape and its subsequent processing.

Working with large diameter wire has certain difficulties. But if it is also rigid, then to bend it manually you will need to use special bending devices.

Of course, you can buy a ready-made bending device, but it’s quite possible to make the tool yourself. How to make a device for bending wire with your own hands from available parts can be seen in the photo.

Working with a wire bending machine

To produce a large number of bent products from wire, various techniques can be used, each of which uses special equipment. The most common and economical method is the coil bending method.

Bending using this technology occurs in several stages.

- The wire, which is wound on coils, is fed to a two-plane roller machine, which aligns it.

- After alignment, the wire is fed to a wire bending machine, on which the product of the required configuration is formed.

- The formed product is cut off, and the entire bending cycle is repeated again.

The use of this technology allows you to fully automate the bending process and thereby achieve high productivity.

Budget wire bending machine

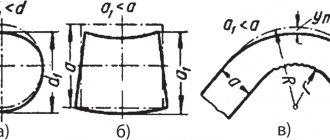

A wire bending machine can also look like a stationary template around which the wire is rolled using movable pressure rollers. Using such devices, bends of even the smallest radius can be formed on the surface of the wire, the value of which is comparable to the outer diameter of the workpiece. At the same time, the configuration of the product formed on such a machine can be quite complex.

The adjustable stops and variable arms of this template allow you to create many combinations of wire bends

A wire bending machine can also operate on the principle of pushing the workpiece through a system of rollers. When using such equipment, the end of the wire is connected to a special wire, which pulls the product through the working parts of the machine. A wire bending machine of this type, due to the features of its design, allows the production of products with even very complex shapes.

When leveling the wire, a wire bending machine is also used, which in this case is used for straightening. The working parts of such equipment can be straight frames or two-plane straight blocks. At the same time, rotating straightening frames are more efficient, which is why they are used in cases where leveling the surface of the wire needs to be done as smoothly and efficiently as possible.

Types of wire bending machines

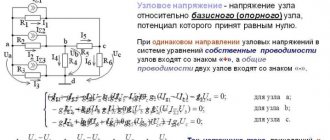

[Wire bending] is one of the ways to give it a new shape using manual or mechanical action using special equipment.

The bending itself occurs due to the compression of the inner layer, due to which the outer layer can be stretched and bent. Such technological work is in great demand, as is equipment for manual bending.

You can create products from bent wire with your own hands.

In this case, it is advisable to choose softer plastic materials for the process so that the wire can bend easily and doing the work with your own hands does not create difficulties.

If the wire is rigid and has a large diameter, then to process it manually you need to use certain tools:

- using pliers you can create a small bend of a few mm; they are also convenient for fixing material for subsequent processing;

- You can cut the wire into separate parts with wire cutters or needle-nose pliers;

- pliers (a type of pliers) are considered one of the most convenient and versatile tools for bending wire with your own hands.

Before you start manually bending the material for the rings, it is better to create a certain template on paper and periodically check it as you work. Simple shapes can be made without templates.

For example, to create a regular rectangular clamp, it is enough to first clamp part of the wire with a bench vice, and bend the remaining piece at a right angle using pliers or a hammer.

Rules for manual bending

When performing manual wire bending work with your own hands, you should adhere to certain safety rules that can protect your hands from possible injuries:

- Before starting work, it is advisable to put on gloves made of thick, dense fabric;

- Materials should be well secured so that they do not jump out of the vice during bending;

- All machines and tools for manual work must be in good working order;

- Do not place heavy objects on the edge of the table (for example, if you hit the pliers, you can drop them on your leg and get a noticeable bruise, or even injury to your fingers);

- When working with the wire with one hand, try to keep the other away from the bend (the pliers can break off and injure your hand).

Safety rules will protect your hands, but the DIY bending process itself is still quite complex and time-consuming. You can bend products by hand only if you have certain experience and knowledge.

Special equipment helps bend wire in large volumes. Let's study it in more detail.

Processing methods

If we talk about bending wire on a large scale (in production or a specialized plant), then various methods are used to plastically deform it.

One of the most common and economical is the bay processing method.

In this case, wire rings are wound onto coils, and then they are fed to two-plane roller machines that straighten the wire.

:

Afterwards, the material is processed on bending equipment (the required shape is created), at the end the wire is cut, and the entire work cycle is repeated again.

IMPORTANT TO KNOW: How to make a snail for cold forging with your own hands?

Moreover, all work is fully automated, which allows you to save time and money and use the device to create a simple curved structure with a development length of about 1000 mm.

For rolling wire with your own hands, there are special devices that consist of fixed templates of certain radii of curvature (the radius can be one or several).

The material is rolled around the created template using pressure rollers.

Basically, this technology is used to create bent products that have a small bending radius (about the same as the diameter of the wire).

The method of pushing the wire is reminiscent of the way 3-roll equipment works on a profile bending and spring-coiling machine.

The material is pushed into the device using a special wire, then it is pressed against various rollers, which makes it possible to change the bending parameters and make transitions to different radii.

This device allows you to bend various structures that have a complex configuration and large bending radii on the development - from 1000 mm or more.

:

You can straighten the wire using straightening equipment or a special device. This equipment includes units consisting of rotating leveling frames or two-plane leveling blocks.

In this case, rotating frames are preferable, as they allow the material to be aligned more smoothly.

Professional equipment

If only the simplest devices (vises, pliers) are used to bend wire on their own, then for mass industrial processing of the material professional machines are used (for example, for the production of key rings or springs for handles).

IMPORTANT TO KNOW: Shot blasting of metal

A wire bending machine with one bending console is one of the simplest and makes it possible to create bent products of simple shapes. The length of the sweep in this case should not exceed 1000 mm.

Double-cantilever machines can work with a reaming length of more than 1000 mm.

The material is cut into the required pieces, then it is deformed from both ends simultaneously.

Such equipment allows you to create products with a large number of bends. Machines with only one console can no longer perform this work.

Also, on double-console machines you can make figures with closed bends.

Wire bending on so-called 3D machines is becoming more and more popular these days.

:

Three-dimensional spatial bending can be done using a rotary bending console, which is controlled by an automated system.

Unfortunately, such material processing is quite expensive, so parts are mainly created using simple flat bending, and then, if necessary, individual parts are automatically welded.

But due to welding seams, products become more fragile and short-lived, so their cost is relatively budget-friendly.

Types of professional equipment

The simplest type of professional equipment used to bend wires are machines with one console. Meanwhile, such devices can only produce products of simple geometric shapes, the development length of which does not exceed 1000 mm.

More complex products with a development length of over 1000 mm make it possible to create double-cantilever equipment, in which the workpiece is deformed simultaneously from both ends. This machine can produce products with many complex curves.

The most complex wire products allow the creation of 3D machines on which bending can be performed simultaneously in three dimensions. The machines of this category are endowed with such unique functions by a rotary bending console, all movements of which are controlled by an electronic automated system. Despite all the advantages of processing using such equipment, it is quite expensive, so these machines are used in exceptional cases.