In our article we will show in detail online the tables and dimensions of ball bearings in millimeters according to GOST. These parts are intermediate links between rotating axes and shafts. They also take on radial or longitudinal loads and transfer them to other parts of the mechanism. With their help, rotation, rocking or regular movement with a low coefficient of friction is ensured.

Kinds

They are classified according to the type of force transmission and the design of the supporting elements (balls, rollers, needles and other complex geometric shapes). All units for this purpose are built on the rolling principle.

Ball ones are divided into:

- • radial;

- • self-centering;

- • supporting;

- • radial contact.

Roller:

- • radial and thrust with cylindrical rolling elements;

- • with conical rotating parts.

Registry:

Let's look at the technical parameters in more detail.

Table of seating dimensions and series of single-row radial ball bearings

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003 | 103 | 17 | 35 | 10 | 0,04 | |

| 6004 | 104 | 20 | 42 | 12 | 0,07 | |

| 6005 | 105 | 25 | 47 | 12 | 0,08 | |

| 6006 | 106 | 30 | 55 | 13 | 0,12 | |

| 6007 | 107 | 35 | 62 | 14 | 0,15 | |

| 6008 | 108 | 40 | 68 | 15 | 0,19 | |

| 6009 | 109 | 45 | 75 | 16 | 0,24 | |

| 6010 | 110 | 50 | 80 | 16 | 0,26 | |

| 6011 | 111 | 55 | 90 | 18 | 0,38 | |

| 6012 | 112 | 60 | 95 | 18 | 0,41 | |

| 6013 | 113 | 65 | 100 | 18 | 0,44 | |

| 6014 | 114 | 70 | 110 | 20 | 0,6 | |

| 6015 | 115 | 75 | 115 | 20 | 0,64 | |

| 6016 | 116 | 80 | 125 | 22 | 0,85 | |

| 6017 | 117 | 85 | 130 | 22 | 0,89 | |

| 6018 | 118 | 90 | 140 | 24 | 1,17 | |

| 6019 | 119 | 95 | 145 | 24 | 1,22 | |

| 6020 | 120 | 100 | 150 | 24 | 1,27 | |

| 6021 | 121 | 105 | 160 | 26 | 1,59 | |

| 6022 | 122 | 110 | 170 | 26 | 1,95 |

This type is the most common and is used in mechanisms that have rotating parts: in electric motors, in gearboxes, in belt and chain drives of various sizes, from wristwatches to the power plants of an ocean liner.

The specific markings, table of sizes and numbers of bearings by diameter are the same for all types. They differ in technological features, level of protection and the presence of mounting grooves in the unit.

With one protective washer

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003 Z | 60103 | 17 | 35 | 10 | 0,04 | |

| 6004 Z | 60104 | 20 | 42 | 12 | 0,07 | |

| 6005 Z | 60105 | 25 | 47 | 12 | 0,08 | |

| 6006 Z | 60106 | 30 | 55 | 13 | 0,12 | |

| 6007 Z | 60107 | 35 | 62 | 14 | 0,16 | |

| 6008 Z | 60108 | 40 | 68 | 15 | 0,2 | |

| 6009 Z | 60109 | 45 | 75 | 16 | 0,25 | |

| 6010 Z | 60110 | 50 | 80 | 16 | 0,26 | |

| 6011 Z | 60111 | 55 | 90 | 18 | 0,39 | |

| 6012 Z | 60112 | 60 | 95 | 18 | 0,42 | |

| 6013 Z | 60113 | 65 | 100 | 18 | 0,44 | |

| 6014 Z | 60114 | 70 | 110 | 20 | 0,62 | |

| 6015 Z | 60115 | 75 | 115 | 20 | 0,64 |

The parameters and weight of these parts coincide with the data given above. The only difference for ISO is the additional letter z. For example, 6321 Z. According to GOST, the number 60 is placed in front of the number.

With two protective washers

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003 ZZ | 80103 | 17 | 35 | 10 | 0,04 | |

| 6004 ZZ | 80104 | 20 | 42 | 12 | 0,07 | |

| 6005 ZZ | 80105 | 25 | 47 | 12 | 0,08 | |

| 6006 ZZ | 80106 | 30 | 55 | 13 | 0,12 | |

| 6007 ZZ | 80107 | 35 | 62 | 14 | 0,16 | |

| 6008 ZZ | 80108 | 40 | 68 | 15 | 0,2 | |

| 6009 ZZ | 8109 | 45 | 75 | 16 | 0,25 | |

| 6010 ZZ | 80110 | 50 | 80 | 16 | 0,26 | |

| 6011 ZZ | 80111 | 55 | 90 | 18 | 0,39 | |

| 6012 ZZ | 80112 | 60 | 95 | 18 | 0,42 | |

| 6013 ZZ | 80113 | 65 | 100 | 18 | 0,44 | |

| 6014 ZZ | 80114 | 70 | 110 | 20 | 0,62 | |

| 6015 ZZ | 80115 | 75 | 115 | 20 | 0,64 | |

| 6016 ZZ | 80116 | 80 | 125 | 22 | 1,86 |

The data for this type of nodes is the same as in the first statement. They only differ in the addition of the symbol ZZ for ISO and for GOST - the additional 80.

With one-sided seal

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003RS | 160103 | 17 | 35 | 10 | 0,04 | |

| 6004RS | 160104 | 20 | 42 | 12 | 0,07 | |

| 6005RS | 160105 | 25 | 47 | 12 | 0,08 | |

| 6006RS | 160106 | 30 | 55 | 13 | 0,12 | |

| 6007RS | 160107 | 35 | 62 | 14 | 0,16 | |

| 6008RS | 160108 | 40 | 68 | 15 | 0,2 | |

| 6009RS | 160109 | 45 | 75 | 16 | 0,25 | |

| 6010RS | 160110 | 50 | 80 | 16 | 0,26 | |

| 6011RS | 160111 | 55 | 90 | 18 | 0,39 | |

| 6012RS | 160112 | 60 | 95 | 18 | 0,42 | |

| 6013RS | 160113 | 65 | 100 | 18 | 0,44 | |

| 6014RS | 160114 | 70 | 110 | 20 | 0,62 | |

| 6015RS | 160115 | 75 | 115 | 20 | 0,64 | |

| 6016RS | 160116 | 80 | 125 | 22 | 1,86 | |

| 6017RS | 160113 | 85 | 130 | 22 | 0,89 | |

| 6018RS | 160113 | 90 | 140 | 24 | 1,16 |

The parameters of these nodes coincide with the register above, with the exception of the letters in the ISO marking and the numbers in GOST. Instead of Z, RS is written, and 10 is inserted before the four-digit number.

Double sided

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | D1 mm | a mm | b mm | Weight, kg | Scheme |

| 6003 2RSТ | 750103 | 17 | 35 | 10 | 33,17 | 2,06 | 1,35 | 0,04 | |

| 6004 2RSТ | 750104 | 20 | 42 | 12 | 39,75 | 2,06 | 1,35 | 0,07 | |

| 6005 2RSТ | 750105 | 25 | 47 | 12 | 39,75 | 2,06 | 1,35 | 0,08 | |

| 6006 2RSТ | 750106 | 30 | 55 | 13 | 52,6 | 2,08 | 1,35 | 0,12 | |

| 6007 2RSТ | 750107 | 35 | 62 | 14 | 59,61 | 2,08 | 1,9 | 0,15 | |

| 6008 2RSТ | 750108 | 40 | 68 | 15 | 64,82 | 2,49 | 1,9 | 0,19 | |

| 6009 2RSТ | 750109 | 45 | 75 | 16 | 72,83 | 2,49 | 1,9 | 0,24 | |

| 6010 2RSТ | 750110 | 50 | 80 | 16 | 76,81 | 2,49 | 1,9 | 0,25 | |

| 6011 2RSТ | 750111 | 55 | 90 | 18 | 86,79 | 2,87 | 2,7 | 0,37 | |

| 6012 2RSТ | 750112 | 60 | 95 | 18 | 91,82 | 2,87 | 2,7 | 0,4 |

The data for such parts is analogous to the material given in the previous heading. Only the number 2 is inserted before RS, and 180 is written before the number.

With groove on outer ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | D1 mm | a mm | b mm | Weight, kg | Scheme |

| 6003N | 50103 | 17 | 35 | 10 | 33,17 | 2,06 | 1,35 | 0,04 | |

| 6004 N | 50104 | 20 | 42 | 12 | 39,75 | 2,06 | 1,35 | 0,07 | |

| 6005 N | 50105 | 25 | 47 | 12 | 39,75 | 2,06 | 1,35 | 0,08 | |

| 6006N | 50106 | 30 | 55 | 13 | 52,6 | 2,08 | 1,35 | 0,12 | |

| 6007 N | 50107 | 35 | 62 | 14 | 59,61 | 2,08 | 1,9 | 0,15 | |

| 6008N | 50108 | 40 | 68 | 15 | 64,82 | 2,49 | 1,9 | 0,19 | |

| 6009 N | 50109 | 45 | 75 | 16 | 72,83 | 2,49 | 1,9 | 0,24 | |

| 6010N | 50110 | 50 | 80 | 16 | 76,81 | 2,49 | 1,9 | 0,25 | |

| 6011 N | 50111 | 55 | 90 | 18 | 86,79 | 2,87 | 2,7 | 0,37 | |

| 6012N | 50112 | 60 | 95 | 18 | 91,82 | 2,87 | 2,7 | 0,4 |

The ISO marking says 6003 N, according to GOST 50103.

With groove and one protective washer

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | D1 mm | a mm | b mm | Weight, kg | Scheme |

| 6003 ZN | 150103 | 17 | 35 | 10 | 33,17 | 2,06 | 1,35 | 0,04 | |

| 6004 ZN | 150104 | 20 | 42 | 12 | 39,75 | 2,06 | 1,35 | 0,07 | |

| 6005 ZN | 150105 | 25 | 47 | 12 | 39,75 | 2,06 | 1,35 | 0,08 | |

| 6006 ZN | 150106 | 30 | 55 | 13 | 52,6 | 2,08 | 1,35 | 0,12 | |

| 6007 ZN | 150107 | 35 | 62 | 14 | 59,61 | 2,08 | 1,9 | 0,15 | |

| 6008 ZN | 150108 | 40 | 68 | 15 | 64,82 | 2,49 | 1,9 | 0,19 | |

| 6009 ZN | 150109 | 45 | 75 | 16 | 72,83 | 2,49 | 1,9 | 0,24 | |

| 6010 ZN | 150110 | 50 | 80 | 16 | 76,81 | 2,49 | 1,9 | 0,25 | |

| 6011 ZN | 150111 | 55 | 90 | 18 | 86,79 | 2,87 | 2,7 | 0,37 | |

| 6012 ZN | 150112 | 60 | 95 | 18 | 91,82 | 2,87 | 2,7 | 0,4 | |

| 6013 ZN | 150113 | 65 | 100 | 18 | 96,8 | 2,87 | 2,7 | 0,42 |

Here the designations are as follows: 6003 ZN or 150103.

With groove and two protective washers

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | D1 mm | a mm | b mm | Weight, kg | Scheme |

| 6003 ZZN | 450103 | 17 | 35 | 10 | 33,17 | 2,06 | 1,35 | 0,04 | |

| 6004 ZZN | 450104 | 20 | 42 | 12 | 39,75 | 2,06 | 1,35 | 0,07 | |

| 6005 ZZN | 450105 | 25 | 47 | 12 | 39,75 | 2,06 | 1,35 | 0,08 | |

| 6006 ZZN | 450106 | 30 | 55 | 13 | 52,6 | 2,08 | 1,35 | 0,12 |

ISO – 6003 ZZN, GOST – 450103.

With double seal groove

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003 2RS | 180103 | 17 | 35 | 10 | 0,04 | |

| 6004 2RS | 180104 | 20 | 42 | 12 | 0,07 | |

| 6005 2RS | 180105 | 25 | 47 | 12 | 0,08 | |

| 6006 2RS | 180106 | 30 | 55 | 13 | 0,12 | |

| 6007 2RS | 180107 | 35 | 62 | 14 | 0,16 | |

| 6008 2RS | 180108 | 40 | 68 | 15 | 0,2 | |

| 6009 2RS | 18109 | 45 | 75 | 16 | 0,25 | |

| 6010 2RS | 180110 | 50 | 80 | 16 | 0,26 | |

| 6011 2RS | 180111 | 55 | 90 | 18 | 0,39 | |

| 6012 2RS | 180112 | 60 | 95 | 18 | 0,42 | |

| 6013 2RS | 180113 | 65 | 100 | 18 | 0,44 | |

| 6014 2RS | 180114 | 70 | 110 | 20 | 0,62 |

The groove is designated by the letter N, and the seal is designated by RS or 2RS.

Not Found

| Prev. Track. home |

In table 126—142 show mainly bearings with inner diameter d

up to 100-120 mm, but the corresponding GOSTs provide for values

of d

less than and above 100-120 mm, as well as some intermediate sizes

d.

The tables are restrictive in relation to GOST and in terms of bearing series.

The values of the maximum rotation speed nlimit are indicated in the tables for cases where grease is used in bearings.

When using liquid lubricant, the value of the maximum speed npre is increased by approximately 20%.

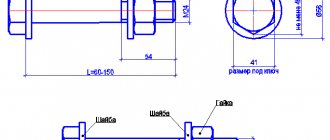

126. Single-row radial ball bearings (according to GOST 8338-75)

d—

nominal bore diameter of the inner ring;

D is

the nominal diameter of the outer cylindrical surface of the outer ring;

B is

the nominal width of the bearing; r is the nominal coordinate of the mounting chamfer.

Dimensions, mm

| Bearing designation | d | D | B | r | Balloons | Weight, kg | S, N | C0, N | n*pre·10-3, min-1 | |

| DW | z | |||||||||

| ultra-light series of diameters 9, normal series of widths 1 | ||||||||||

| 1000093 | 3 | 8 | 3 | 0,3 | 1,59 | 6 | 0,0007 | 560 | 186 | 43 |

| 1000094 | 4 | 11 | 4 | 0,3 | 2 | 7 | 0,0025 | 950 | 340 | 40 |

| 1000095 | 5 | 13 | 4 | 0,4 | 2 | 8 | 0,0025 | 1 080 | 390 | 38 |

| 1000096 | 6 | 15 | 5 | 0,4 | 2,38 | 8 | 0,0040 | 1470 | 555 | 38 |

| 1000097 | 7 | 17 | 5 | 0,5 | 3 | 7 | 0,0050 | 2020 | 777 | 36 |

| 1000098 | 8 | 19 | 6 | 0,5 | 3 | 8 | 0,0080 | 2240 | 880 | 34 |

| 1000099 | 9 | 20 | 6 | 0,5 | 3,5 | 7 | 0,0080 | 2680 | 1050 | 32 |

| 1000900 | 10 | 22 | 6 | 0,5 | 3,97 | 7 | 0,0090 | 3340 | 1 350 | 30 |

| 1000901 | 12 | 24 | 6 | 0,5 | 3,97 | 7 | 0,010 | 3390 | 1 350 | 28 |

| 1000902 | 15 | 28 | 7 | 0,5 | 3,18 | 12 | 0,017 | 3480 | 1480 | 22 |

| 1000903 | 17 | 30 | 7 | 0,5 | 3,5 | 11 | 0,018 | 3640 | 1 650 | 20 |

| 1000904 | 20 | 37 | 9 | 0,5 | 5 | 10 | 0,035 | 6550 | 3040 | 18 |

| 1000905 | 25 | 42 | 9 | 0,5 | 5 | 12 | 0,042 | 7320 | 3680 | 15 |

| 1000906 | 30 | 47 | 9 | 0,5 | 5 | 13 | 0,049 | 7590 | 3990 | 13 |

| 1000907 | 35 | 55 | 10 | 1,0 | 5,95 | 13 | 0,086 | 10400 | 5650 | 11 |

| 1000908 | 40 | 62 | 12 | 1,0 | 6,35 | 14 | 0,11 | 12200 | 6920 | 10 |

| 1000909 | 45 | 68 | 12 | 1,0 | 7,14 | 13 | 0,15 | 14300 | 8 130 | 9 |

| 1000911 | 55 | 80 | 13 | 1,5 | 6,35 | 18 | 0,19 | 16000 | 10000 | 7,5 |

| 1000912 | 60 | 85 | 13 | 1,5 | 7,14 | 19 | 0,26 | 16400 | 10600 | 6,3 |

| 1000915 | 75 | 105 | 16 | 1,5 | 8,73 | 18 | 0,38 | 24300 | 16800 | -5,6 |

Provided d

=1.2, 80÷340mm

Extra light diameter series 1, narrow width series 7

| 7000101 | 12 | 28 | 7 | 0,5 | 4,76 | 8 | 0,018 | 5070 | 2240 | 26 |

| 7000102 | 15 | 32 | 8 | 0,5 | 4,76 | 8 | 0,025 | 5590 | 2500 | 22 |

| 7000103 | 17 | 35 | 8 | 0,5 | 5,16 | 9 | 0,036 | 6050 | 2800 | 19 |

| 7000104 | 20 | 42 | 8 | 0,5 | — | — | 0,06 | 7020 | 3400 | — |

| 7000105 | 25 | 47 | 8 | 0,5 | 5,56 | 11 | 0,06 | 7610 | 4000 | 14 |

| 7000106 | 30 | 55 | 9 | 0,5 | 5,56 | 14 | 0,10 | 11 200 | 5850 | 12 |

| 7000107 | 35 | 62 | 9 | 0,5 | 5,56 | 15 | 0,11 | 12400 | 6950 | 10 |

| 7000108 | 40 | 68 | 9 | 0,5 | 6,35 | 16 | 0,13 | 13300 | 7800 | 9,5 |

| 7000109 | 45 | 75 | 10 | 1,0 | 6,35 | 17 | 0,17 | 15600 | 9300 | 9,0 |

| 7000110 | 50 | 80 | 10 | 1,0 | 6,35 | 18 | 0,18 | 16300 | 10000 | 8,5 |

| 7000111 | 55 | 90 | 11 | 1,0 | 7,14 | 17 | 0,28 | 17000 | 11 700 | 7,5 |

| 7000112 | 60 | 95 | 11 | 1,0 | 7,14 | 18 | 0,29 | 18600 | 12400 | 6,7 |

| 7000113 | 65 | 100 | 11 | 1,0 | 7,14 | 19 | 0,34 | 19000 | 13 100 | 6,3 |

| 7000114 | 70 | 110 | 13 | 1,0 | 7,94 | 18 | 0,45 | 22200 | 15300 | 6,0 |

Provided d

=75÷280mm

Extra light diameter series 1, narrow width series 0

| 16 | 6 | 17 | 6 | 0,5 | — | — | 0,008 | 2200 | 860 | — |

| 17 | 7 | 19 | 6 | 0,5 | 3,97 | 6 | 0,009 | 2200 | 1 160 | 34 |

| 18 | 8 | 22 | 7 | 0,5 | 3,97 | 7 | 0,012 | 3250 | 1 340 | 32 |

| 100 | 10 | 26 | 8 | 0,5 | 4,76 | 7 | 0,019 | 4620 | 1 960 | 30 |

| 101 | 12 | 28 | 8 | 0,5 | 4,76 | 8 | 0,022 | 5070 | 2240 | 26 |

| 104 | 20 | 42 | 12 | 1,0 | 6,35 | 9 | 0,07 | 9360 | 4500 | 17 |

| 105 | 25 | 47 | 12 | 1,0 | 6,35 | 10 | 0,08 | 11 200 | 5600 | 15 |

| 106 | 30 | 55 | 13 | 1,5 | 7,14 | 11 | 0,12 | 13300 | 6800 | 12 |

| 107 | 35 | 62 | 14 | 1,5 | 7,94 | 11 | 0,16 | 15900 | 8500 | 10 |

| 108 | 40 | 68 | 15 | 1,5 | 7,94 | 12 | 0,19 | 16800 | 9300 | 9,5 |

| 109 | 45 | 75 | 16 | 1,5 | 8,73 | 13 | 0,24 | 21 200 | 12200 | 9,0 |

| 110 | 50 | 80 | 16 | 1,5 | 8,73 | 12 | 0,25 | 21 600 | 13200 | 8,5 |

| 111 | 55 | 90 | 18 | 2,0 | 10,32 | 13 | 0,39 | 28 100 | 17000 | 7,5 |

| 112 | 60 | 95 | 18 | 2,0 | 11,11 | 12 | 0,39 | 29600 | 18300 | 6,7 |

| 113 | 65 | 100 | 18 | 2,0 | 10,32 | 15 | 0,45 | 30700 | 19600 | 6,3 |

| 114 | 70 | 110 | 20 | 2,0 | 12,3 | 13 | 0,60 | 37700 | 24500 | 6,0 |

| 115 | 75 | 115 | 20 | 2,0 | 12,3 | 14 | 0,66 | 39700 | 26000 | 5,6 |

| 116 | 80 | 125 | 22 | 2,0 | 13,5 | 14 | 0,85 | 47700 | 31 500 | 5,3 |

| 117 | 85 | 130 | 22 | 2,0 | 13,5 | 14 | 0,91 | 49400 | 33500 | 5,0 |

| 118 | 90 | 140 | 24 | 2,5 | 14,3 | 15 | 1,20 | 57200 | 39000 | 4,8 |

| 120 | 100 | 150 | 24 | 2,5 | 14,3 | 15 | 1,29 | 60500 | 41 500 | 4,3 |

Provided d

=105÷360mm

Light diameter series 2, narrow width series 0

| 23 | 3 | 10 | 4 | 0,3 | 1,59 | 7 | 0,0016 | 490 | 217 | 40 |

| 24 | 4 | 13 | 5 | 0,4 | 2,38 | 6 | 0,003 | 900 | 415 | 38 |

| 25 | 5 | 16 | 5 | 0,5 | 3,18 | 6 | 0,003 | 1 480 | 740 | 36 |

| 26 | 6 | 19 | 6 | 0,5 | 3,97 | 6 | 0,008 | 2 170 | 1 160 | 32 |

| 27 | 7 | 22 | 7 | 0,5 | 3,97 | 7 | 0,013 | 3250 | 1 350 | 30 |

| 29 | 9 | 26 | 8 | 1,0 | 4,76 | 7 | 0,019 | 4620 | 1 960 | 26 |

| 200 | 10 | 30 | 9 | 1,0 | 5,95 | 6 | 0,030 | 5900 | 2650 | 24 |

| 201 | 12 | 32 | 10 | 1,0 | 5,56 | 7 | 0,037 | 6890 | 3 100 | 22 |

| 202 | 15 | 35 | 11 | 1,0 | 5,95 | 8 | 0,045 | 7800 | 3550 | 19 |

| 203 | 17 | 40 | 12 | 1,0 | 7,14 | 7 | 0,060 | 9560 | 4500 | 17 |

| 204 | 20 | 47 | 14 | 1,5 | 7,94 | 8 | 0,10 | 12700 | 6200 | 15 |

| 205 | 25 | 52 | 15 | 1,5 | 7,94 | 9 | 0,12 | 14000 | 6950 | 12 |

| 206 | 30 | 62 | 16 | 1,5 | 9,53 | 9 | 0,20 | 19500 | 10000 | 10 |

| 207 | 35 | 72 | 17 | 2,0 | 11,11 | 9 | 0,29 | 25500 | 13700 | 9 |

| 208 | 40 | 80 | 18 | 2,0 | 12,7 | 9 | 0,36 | 32000 | 17800 | 8,5 |

| 209 | 45 | 85 | 19 | 2,0 | 12,7 | 9 | 0,41 | 33200 | 18600 | 7,5 |

| 210 | 50 | 90 | 20 | 2,0 | 12,7 | 10 | 0,47 | 35 100 | 19800 | 7,0 |

| 211 | 55 | 100 | 21 | 2,5 | 14,29 | 10 | 0,60 | 43600 | 25000 | 6,3 |

| 212 | 60 | 110 | 22 | 2,5 | 15,88 | 10 | 0,80 | 52000 | 31 000 | 6,0 |

| 213 | 65 | 120 | 23 | 2,5 | 16,67 | 10 | 0,98 | 56000 | 34000 | 5,3 |

| 214 | 70 | 125 | 24 | 2,5 | 17,46 | 10 | 1,08 | 61 800 | 37500 | 5,0 |

| 215 | 75 | 130 | 25 | 2,5 | 17,46 | 11 | 1,18 | 66300 | 41000 | 4,8 |

| 216 | 80 | 140 | 26 | 3,0 | 19,05 | 10 | 1,40 | 70200 | 45000 | 4,5 |

| 217 | 85 | 150 | 28 | 3,0 | 19,84 | 11 | 1,80 | 83200 | 53000 | 4,3 |

| 218 | 90 | 160 | 30 | 3,0 | 22,23 | 10 | 2,2 | 95600 | 62000 | 3,8 |

| 220 | 100 | 180 | 34 | 3,5 | 25,4 | 10 | 3,2 | 124 000 | 79000 | 3,4 |

Provided d

=105÷360mm

Medium diameter series 3, narrow width series 0

| 34 | 4 | 16 | 5 | 0,5 | 3,18 | 6 | 0,005 | 1450 | 740 | 35 |

| 35 | 5 | 19 | 6 | 0,5 | 3,97 | 6 | 0,008 | 2 190 | 1 160 | 32 |

| 300 | 10 | 35 | 11 | 1,0 | 7,14 | 6 | 0,05 | 8060 | 3750 | 20 |

| 301 | 12 | 37 | 12 | 1,5 | 7,94 | 6 | 0,06 | 9750 | 4650 | 19 |

| 302 | 15 | 42 | 13 | 1,5 | 7,94 | 7 | 0,08 | 11 400 | 5400 | 17 |

| 303 | 17 | 47 | 14 | 1,5 | 9,53 | 6 | 0,11 | 13500 | 6650 | 16 |

| 304 | 20 | 52 | 15 | 2,0 | 9,53 | 7 | 0,14 | 15900 | 7800 | 13 |

| 305 | 25 | 62 | 17 | 2,0 | 11,51 | 7 | 0,23 | 22500 | 11 400 | 11 |

| 306 | 30 | 72 | 19 | 2,0 | 12,3 | 8 | 0,34 | 28 100 | 14600 | 9 |

| 307 | 35 | 80 | 21 | 2,5 | 14,29 | 7 | 0,44 | 33200 | 18 000 | 8,5 |

| 308 | 40 | 90 | 23 | 2,5 | 15,08 | 8 | 0,63 | 41000 | 22400 | 7,5 |

| 309 | 45 | 100 | 25 | 2,5 | 17,46 | 8 | 0,83 | 52700 | 30000 | 6,7 |

| 310 | 50 | 110 | 27 | 3,0 | 19,05 | 8 | 1,08 | 61 800 | 36000 | 6,3 |

| 311 | 55 | 120 | 29 | 3,0 | 20,64 | 8 | 1,35 | 71 500 | 41 500 | 5,6 |

| 312 | 60 | 130 | 31 | 3,5 | 22,23 | 8 | 1,70 | 81900 | 48000 | 5,0 |

| 313 | 65 | 140 | 33 | 3,5 | 23,81 | 8 | 2,11 | 92300 | 56000 | 4,8 |

| 314 | 70 | 150 | 35 | 3,5 | 25,4 | 8 | 2,60 | 104 000 | 63000 | 4,5 |

| 315 | 75 | 160 | 37 | 3,5 | 26,99 | 8 | 3,10 | 112000 | 72 500 | 4,3 |

| 316 | 80 | 170 | 39 | 3,5 | 28,58 | 8 | 3,60 | 124 000 | 80000 | 3,8 |

| 317 | 85 | 180 | 41 | 4,0 | 30,16 | 8 | 4,30 | 133 000 | 90000 | 3,6 |

| 318 | 90 | 190 | 43 | 4,0 | 31,75 | 8 | 5,10 | 143 000 | 99000 | 3,4 |

| 320 | 100 | 215 | 47 | 4,0 | 36,51 | 8 | 7,00 | 174 000 | 132000 | 3,0 |

Provided d

=110÷150mm

Heavy diameter series 4, narrow width series 0

| 403 | 17 | 62 | 17 | 2,0 | 12,7 | 6 | 0,27 | 22900 | 11 800 | 12 |

| 405 | 25 | 80 | 21 | 2,5 | 16,67 | 6 | 0,5 | 36400 | 20400 | 9 |

| 406 | 30 | 90 | 23 | 2,5 | 19,05 | 6 | 0,72 | 47000 | 26700 | 8,5 |

| 407 | 35 | 100 | 25 | 2,5 | 20,64 | 6 | 0,93 | 55300 | 31 000 | 7,0 |

| 408 | 40 | 110 | 27 | 3,0 | 22,23 | 6 | 1,20 | 63700 | 36500 | 6,7 |

| 409 | 45 | 120 | 29 | 3,0 | 23,02 | 7 | 1,52 | 76 100 | 45500 | 6,0 |

| 410 | 50 | 130 | 31 | 3,5 | 25,4 | 7 | 1,91 | 87 100 | 52000 | 5,3 |

| 411 | 55 | 140 | 33 | 3,5 | 26,99 | 7 | 2,3 | 100000 | 63000 | 5,0 |

| 412 | 60 | 150 | 35 | 3,5 | 28,58 | 7 | 2,8 | 108000 | 70000 | 4,8 |

| 413 | 65 | 160 | 37 | 3,5 | 30,16 | 7 | 3,4 | 119000 | 78000 | 4,5 |

| 414 | 70 | 180 | 42 | 4,0 | 34,93 | 7 | 5,3 | 143000 | 105000 | 3,8 |

| 416 | 80 | 200 | 48 | 4,0 | 38,1 | 7 | 7,0 | 163 000 | 125000 | 3,4 |

| 417 | 85 | 210 | 52 | 5,0 | 39,69 | 7 | 8,0 | 174 000 | 135000 | 3,2 |

| 418 | 90 | 225 | 54 | 5,0 | — | — | 11,4 | 186 000 | 146000 | — |

* With plastic lubricant. Note. The weight of the bearings is calculated with a cage stamped from a steel sheet with a steel density of 7.85 kg/dm3. An example of the designation of an extra-light radial ball bearing of diameter series 1, width series 0 with d

= 50 mm,

D

= 80 mm,

H

= 16 mm:

Bearing according to GOST 8338-75

127. Single-row radial ball bearings with protective washers (according to GOST 7242-81)

Dimensions, mm

| Bearing size designations | d | D | IN | G | Weight, kg | S , N | C 0,H | nprev10-3, min-1. | |

| with one protective washer | with two protective washers | ||||||||

| Diameter series 1 | |||||||||

| 60018 | 80018* | 8 | 22 | 7 | 0,5 | 0,012 | 3250 | 1340 | 32 |

| 60104 | 80104 | 20 | 42 | 12 | 1,0 | 0,070 | 9360 | 4500 | 17 |

| 60106 | 80106 | 30 | 55 | 13 | 1.5 | 0.120 | 13 300 | 6800 | 12 |

| *For bearing 80018 n pre = 25,000. Available d = 7, 9, 10÷17, 25, 35 ÷ 120 mm. | |||||||||

| Diameter series 2 | |||||||||

| 60024 60025 60026 60027 60029 60200 60201 60202 60203 60204 60205 60206 60207 60208 60209 60210 60212 60214 60218 60220 | 80024 80025 80026 80027 80029 80200 80201 80202 80203 *1 80204 80205 80206 *2 80207 80208 *3 80209 80210 80212 80214 80218 802220 | 4 5 6 7 9 10 12 15 17 20 25 30 35 40 45 50 60 70 90 100 | 13 16 19 22 26 30 32 35 40 47 52 62 72 80 85 90 110 125 160 180 | 5 5 6 7 8 9 10 11 12 14 15 16 17 18 19 20 22 24 30 34 | 0,3 0,5 0,5 0,5 1,0 1,0 1,0 1,0 1,0 1,5 1,5 1,5 2,0 2,0 2,0 2,0 2,5 2,5 3,0 3,5 | 0,004 0,006 0,010 0,013 0,019 0,030 0,037 0,045 0,065 0,106 0,12 0,19 0,29 0,36 0,41 0,46 0,80 1,06 2,20 3,16 | 900 1480 2170 3250 4620 5900 6890 7800 9560 12700 14000 19500 25500 32000 33200 35100 52000 61800 95600 124000 | 415 740 1160 1350 1960 2650 3100 3550 4500 6200 6950 10000 13700 17800 18600 19800 31000 37500 62000 79000 | 38 36 32 30 26 24 22 19 17 15 12 10 9,0 8,5 7,5 7,0 6,0 5,0 — 3,4 |

| •1 For bearing 80203 n pred = 12,500 min-1. | |||||||||

| Diameter series 3 | |||||||||

| 60302 60303 60305 60306 60307 60308 60309 60310 60311 60314 | 80302 80303 80305 80306 80307 80308 80309 80310 80311 80314 | 15 17 25 30 35 40 45 50 55 70 | 42 47 62 72 80 90 100 110 120 150 | 13 14 17 19 21 23 25 27 29 35 | 1,5 1,5 2,0 2,0 2,5 2,5 2,5 3,0 3,0 3,5 | 0,08 0,11 0,23 0,34 0,44 0,64 0,80 1,08 1,37 2,50 | 11400 13500 22500 28100 33200 41000 52700 61800 71500 104000 | 5400 6650 11400 14600 18000 22400 30000 36000 41500 63000 | 17 16 11 9 8,5 7,5 6,7 6,3 5,6 4,5 |

| Note. The standard applies to radial ball bearings with protective washers of the following diameter series: 1; 2; 3 and 9. An example of the designation of a single-row radial ball bearing, with one protective washer, light series of diameters 2 s d = 6 mm, Bearing 60026 GOST 7242-81 | |||||||||

128. Single-row radial ball bearings with seal (according to GOST 8882-75)

Bearings of type 160000 can be manufactured with rings from bearings of type 180000.

Dimensions, mm

| Diameter series 2 and 5, width series 0 | |||||||||||||||

| Designation of bearings of diameter series 2 and 5 for types | d | D | B for diameter series | r | r1 | Weight kg | S, N episode 2 | So, N episode 2 | S, N series 5 | Co, N episode 5 | n pre10-3, min-1 | ||||

| 160000 | 180000 | 2 | 5 | ||||||||||||

| 160200 160201 160202 160203 160204 160205 160208 | 160500 160501 160502 160503 160504 160505 160508 | 180200 180201 180202 180203 180204 180205 180208 | 180500 180501 180502 180503 180504 180505 180508 | 10 12 15 17 20 25 40 | 30 32 35 40 47 52 80 | 9 10 11 12 14 15 18 | 14 14 14 16 18 18 23 | 1,0 1,0 1,0 1,0 1,5 1,5 2,0 | 0,5 0,5 0,5 1,0 1,5 1,5 2,0 | 0,05 0,06 0,06 0,08 0,14 0,15 0,45 | 5900 6890 7800 9560 12700 14000 32000 | 2650 3110 3550 4500 6200 6950 17800 | 5900 6890 7800 9560 12700 14000 32000 | 2650 3100 3550 4500 6200 6950 17800 | — 15 — 12 10 8,5 5,6 |

| An example of the designation of a single row radial ball with one bearing seal diameter series 2 s d = 25 mm, D = 52 mm and B = 15 mm: Bearing 160205 GOST 8882-75 | |||||||||||||||

129. Radial ball bearings with a locking groove on the outer ring and thrust rings according to GOST 2893-82

Bearing

The thrust ring is in a free state

*Dimensions D2 and g refer to the thrust ring mounted on the bearing.

Dimensions, mm

| Bearing designation | d | D | D1 | B | a | b | r | C, H | Co, H | n* pre x x 10-3, min-1 | Weight kg | |||

| max. | name | max. | name | max. | name | |||||||||

| Diameter series 3 | ||||||||||||||

| 50305 50306 50307 50308 50309 50310 50311 50312 | 25 30 35 40 45 50 55 60 | 62 72 80 90 100 110 120 130 | 59,61 68,81 76,81 86,79 96,80 106,81 115,21 125,22 | 59,11 68,30 76,30 86,28 96,29 106,30 114,71 124,71 | 17 19 21 23 25 27 29 31 | 3,28 3,28 3,28 3,28 3,28 3,28 4,06 4,06 | 3,07 3,07 3,07 3,07 3,07 3,07 3,86 3,86 | 2,2 2,2 2,2 3,0 3,0 3,0 3,4 3,4 | 1,9 1,9 1,9 2,7 2,7 2,7 3,1 3,1 | 2,0 2,0 2,5 2,5 2,5 3,0 3,0 3,5 | 22500 28100 33200 41000 52700 61800 71500 81900 | 11400 14600 18000 22400 30000 36000 41500 48000 | 11 9 8,5 7,5 6,7 6,3 5,6 5,0 | 0,23 0,35 0,43 0,63 0,79 1,06 1,33 1,6 |

| Diameter series 4 | ||||||||||||||

| 50406 50408 50410 50412 | 30 40 50 60 | 90 110 130 150 | 86,79 106,81 125,22 145,24 | 86,28 106,80 124,71 144,73 | 23 27 31 35 | 3,28 3,28 4,06 4,90 | 3,07 3,07 3,86 4,65 | 3,0 3,0 3,4 3,4 | 2,7 2,7 3,1 3,1 | 2,5 3,0 3,5 3,5 | 47000 63700 87100 108000 | 26700 36500 52000 70000 | 8,5 6,7 5,3 4,8 | 0,72 1,17 1,88 2,80 |

Thrust rings in free state

Dimensions, mm

| D | D1 | D2 | l | f | g | g1 (deviation according to H14) | |||

| max. | name | max. | name | max. | name | ||||

| Medium diameter series 3, heavy series diameter 4 | |||||||||

| 62 72 80 90 100 110 120 130 150 | 67,7 78,6 86,6 96,5 106,5 116,5 129,7 139,7 159,7 | 59,0 68,2 76,2 86,2 96,2 106,2 114,6 124,6 144,5 | 58,4 67,6 75,6 85,6 95,4 105,4 113,8 123,8 143,3 | 4,04 4,85 4,85 4,85 4,85 4,85 7,21 7,21 7,21 | 3,89 4,70 4,70 4,70 4,70 4,70 7,06 7,06 7,06 | 1,7 1,7 1,7 2,46 2,46 2,46 2,82 2,82 2,82 | 1,60 1,60 1,60 2,36 2,36 2,36 2,72 2,72 2,72 | 4 5 5 5 5 5 7 7 7 | 2,6 3,6 3,6 3,6 3,6 3,6 5,3 5,3 5,3 |

| Designation of a radial single-row ball bearing with a locking groove on the outer ring of series 3 with d = 40 mm, D = 90 mm and B = 23 mm: Bearing 50308 GOST 2893-82 | |||||||||

130. Radial spherical double-row ball bearings (according to GOST 28428-90)

| type 1000 with cylindrical bore | type 111000 with tapered bore |

Dimensions, mm

| Bearing type designation | d | D | B | r | Balloons | C, H | Co, H | n pre x x 10-3, min-1 | Weight *, kg | ||

| 1000 | 111000 | Dw _ | z | ||||||||

| Diameter series 2, width series 0 | |||||||||||

| 1005 1006 1007 1008 | — | 5 6 7 8 | 19 19 22 22 | 6 6 7 7 | 0,5 | 3,18 3,18 3,18 3,18 | 8 8 10 10 | 2150 2150 2650 2650 | 540 540 655 655 | 32 32 30 30 | 0,009 0,009 0,014 0,014 |

| 1009 1200 1201 1202 1203 | — | 9 10 12 15 17 | 26 30 32 35 40 | 8 9 10 11 12 | 1,0 | 3,97 4,76 4,76 5,56 5,56 | 9 9 10 10 12 | 3900 5530 5590 7410 7930 | 930 1370 1500 2040 2420 | 26 24 22 19 18 | 0,022 0,033 0,040 0,050 0,073 |

| 1204 1205 1206 | 111204 111205 111206 | 20 25 30 | 47 52 62 | 14 15 16 | 1,5 | 6,35 6,14 7,94 | 12 12 14 | 9950 12100 15600 | 3180 4000 5800 | 15 13 10 | 0,12 0,14 0,22 |

| 1207 1208 1209 1210 | 111207 111208 111209 111210 | 36 40 45 50 | 72 80 85 90 | 17 18 19 20 | 2,0 | 7,94 8,73 9,53 9,53 | 16 17 16 18 | 15900 19000 21600 22900 | 6600 8550 9600 10800 | 9 8,5 7,5 7,0 | 0,32 0,42 0,47 0,53 |

| 1211 1212 1213 1214 1215 | 111211 111212 111213 111214 111215 | 55 60 65 70 75 | 100 110 120 125 130 | 21 22 23 24 25 | 2,5 | 10,32 11,11 11,11 11,9 12,7 | 19 19 21 20 20 | 26500 30200 31200 34500 39000 | 13300 15500 17200 18700 21500 | 6,3 5,6 5,3 5,0 4,8 | 0,71 0,90 1,15 1,26 1,36 |

| 1216 1217 1218 | 111216 111217 111218 | 80 85 90 | 140 150 160 | 26 28 30 | 3,0 | 12,7 14,29 15,86 | 22 21 19 | 39700 48800 57200 | 23500 28500 32000 | 1,5 4,0 3,8 | 1,67 2,10 2,52 |

| 1220 1222 | 111220 111222 | 100 110 | 180 200 | 34 38 | 3,5 | 17,46 19,84 | 20 20 | 68900 88400 | 40500 52000 | 3,4 3,0 | 3,70 5,15 |

| Diameter series 5 | |||||||||||

| 1506 1507 1508 1509 1510 1511 1512 1513 | 111506 111507 111508 111509 111510 111511 111512 111513 | 30 35 40 45 50 55 60 65 | 62 72 80 85 90 100 110 120 | 20 23 23 23 23 25 28 31 | 1,5 2,0 2,0 2,0 2,0 2,5 2,5 2,5 | 7,94 9,53 9,53 9,53 9,53 — — — | 14 14 16 18 19 — — — | 15300 21600 22500 23400 23400 26500 33800 43600 | 5700 8200 9450 10700 11500 13400 16600 21600 | 9,5 8,5 7,5 7,0 6,3 — — — | 0,26 0,40 0,50 0,54 0,59 0,81 1,09 1,46 |

| Diameter series 3 | |||||||||||

| 1300 | — | 10 | 35 | 11 | 1,0 | 5,56 | 9 | 7250 | 2000 | 18 | 0,06 |

| 1301 1302 1303 | 12 15 17 | 37 42 47 | 12 13 14 | 1,5 | 6,35 6,35 7,14 | 9 10 11 | 9360 9560 12500 | 2600 2800 3660 | 18 17 14 | 0,07 0,09 0,13 | |

| 1304 1305 1306 | 111304 111305 111306 | 20 25 30 | 52 62 72 | 15 17 19 | 2,0 | 7,14 8,73 9,53 | 12 12 13 | 12500 17800 21200 | 3660 6000 7700 | 12 9,5 9,0 | 0,16 0,26 0,39 |

| 1307 1308 1309 | 111307 111308 111309 | 35 40 45 | 80 90 100 | 21 23 25 | 2,5 | 10,32 11,11 12,7 | 14 15 15 | 25100 29600 37700 | 9800 12200 15900 | 7,5 6,7 6,3 | 0,51 0,71 0,96 |

| 1310 1311 | 111310 111311 | 50 55 | 110 120 | 27 29 | 3,0 | 14,29 15,08 | 13 15 | 43600 50700 | 17500 22500 | 5,6 5,0 | 1,21 1,58 |

| 1312 1313 1314 1315 1316 | 111312 111313 111314 111315 111316 | 60 65 70 75 80 | 130 140 150 160 170 | 31 33 35 37 39 | 3,5 | 15,88 16,67 18,26 19,05 20,64 | 16 16 16 16 15 | 57200 61800 74100 79300 88400 | 26500 29500 35500 38500 42000 | 4,5 4,3 4,0 3,8 3,6 | 1,96 2,5 3,0 3,6 4,2 |

| 1317 1318 1320 | 111317 111318 111319 | 85 90 100 | 180 190 215 | 41 43 47 | 4,0 | 21,43 23,81 26,99 | 16 15 15 | 97500 117000 133600 | 48500 56000 64000 | 3,4 3,2 2,8 | 5,0 5,8 8,3 |

| Diameter series 6 | |||||||||||

| 1605 1606 | 111605 111606 | 25 30 | 62 72 | 24 27 | 2,0 | 10,32 11,91 | 11 11 | 24200 31200 | 7500 10000 | 9,5 8,5 | 0,34 0,50 |

| 1607 1608 1609 | 111607 111608 111609 | 35 40 45 | 80 90 100 | 31 33 36 | 2,5 | 13,49 14,29 15,08 | 11 12 12 | 39700 44900 54000 | 12900 15700 19400 | 7,0 6,3 5,6 | 0,68 0,93 1,23 |

| 1610 1611 | 111610 111611 | 50 55 | 110 120 | 40 43 | 3,0 | 17,46 19,05 | 12 12 | 63700 76100 | 23600 28000 | 5,3 4,5 | 1,61 2,10 |

| 1612 1613 1614 1616 | 111612 111613 111614 111616 | 60 65 70 80 | 130 140 150 170 | 46 48 150 170 | 3,5 | 20,64 21,43 23,02 26,99 | 12 13 13 13 | 87100 95600 111000 135000 | 33000 38500 44500 58000 | 4,0 3,6 3,2 2,6 | 2,60 3,20 3,92 6,10 |

| Example of designation of a double row spherical deep groove ball bearing, type 1000, diameter series 3 s d = 35 mm, D= 80 mm, B = 21 mm: Bearing 1307 GOST 28428-90 | |||||||||||

| * Weight is given for bearings type 1000. | |||||||||||

| Bearing type designations | Balloons | Design parameters | |||||||

| e | Y | Y 0 | X | ||||||

| 1000 | 111000 | Dw | z | F0/Fr £e | F0/Fr >e | F0/Fr £e | F0/Fr >e | ||

| Lightweight Diameter Series 2 | |||||||||

| 1005 1006 1007 1008 | — | 3,18 3,18 3,18 3,18 | 8 8 10 10 | 0,34 0,34 0,33 0,33 | 1,87 1,87 1,89 1,89 | 2,90 2,90 2,92 2,92 | 1,96 1,96 1,98 1,98 | 1,0 | 0,65 |

| 1009 1200 1201 1202 1203 | — | 3,97 4,76 4,76 5,56 5,56 | 9 9 10 10 12 | 0,33 0,32 0,33 0,33 0,31 | 1,87 1,96 1,88 1,90 2,05 | 2,89 3,03 2,92 2,94 3,18 | 1,95 2,05 1,97 1,99 2,15 | ||

| 1204 1205 1206 | 111204 111205 111206 | 6,35 6,14 7,94 | 12 12 14 | 0,27 0,27 0,24 | 2,31 2,32 2,58 | 3,57 3,60 3,99 | 2,42 2,44 2,70 | ||

| 1207 1208 1209 1210 | 111207 111208 111209 111210 | 7,94 8,73 9,53 9,53 | 16 17 16 18 | 0,23 0,22 0,21 0,21 | 2,74 2,87 2,97 3,13 | 4,24 4,44 4,60 4,85 | 2,87 3,01 3,11 3,28 | ||

| 1211 1212 1213 1214 1215 | 111211 111212 111213 111214 111215 | 10,32 11,11 11,11 11,9 12,7 | 19 19 21 20 20 | 0,20 0,19 0,17 0,18 0,18 | 3,20 3,40 3,70 3,50 3,60 | 5,00 5,27 5,73 5,43 5,57 | 3,39 3,57 3,88 3,68 3,77 | ||

| 1216 1217 1218 | 111216 111217 111218 | 12,7 4,29 5,86 | 22 21 19 | 0,16 0,17 0,17 | 3,90 3,69 3,76 | 6,10 5,71 5,82 | 4,13 3,87 3,94 | ||

| 1220 1222 | 111220 111222 | 17,46 19,84 | 20 20 | 0,17 0,17 | 3,63 3,64 | 5,63 5,64 | 3,81 3,82 | ||

| Diameter series 5 | |||||||||

| 1506 1507 1508 1509 1510 1511 1512 1513 | 111506 111507 111508 111509 111510 111511 111512 111513 | 7,94 9,53 9,53 9,53 9,53 — — — | 14 14 16 18 19 — — — | 0,39 0,37 0,33 0,31 0,29 — — — | 1.59 1,69 1,90 2,06 2,20 — — — | 2,47 2,62 2,94 3,19 3,41 — — — | 1,68 1,77 1,99 2,16 2,31 — — — | 1,0 | 0,65 |

| Diameter series 3 | |||||||||

| 1300 | — | 5,56 | 9 | 0,33 | 1,91 | 2,96 | 2 | 1,0 | 0,65 |

| 1301 1302 1303 | 6,35 6,35 7,14 | 9 10 11 | 0,35 0,33 0,33 | 1,81 1,89 1,92 | 2,80 2,92 2,97 | 1,90 1,98 2,01 | |||

| 1304 1305 1306 | 111304 111305 111306 | 7,14 8,73 9,53 | 12 12 13 | 0,29 0,28 0,26 | 2,17 2,26 2,46 | 3,35 3,49 3,80 | 2,27 2,36 2,58 | ||

| 1307 1308 1309 | 111307 111308 111309 | 10,32 11,11 12,7 | 14 15 15 | 0,25 0,23 0,25 | 2,57 2,61 2,54 | 3,98 4,05 3,93 | 2,69 2,74 2,66 | ||

| 1310 1311 | 111310 111311 | 14,29 15,08 | 13 15 | 0,24 0,23 | 2,68 2,70 | 4,14 4,17 | 2,80 2,82 | ||

| 1312 1313 1314 1315 1316 | 111312 111313 111314 111315 111316 | 15,88 16,67 18,26 19,05 20,64 | 16 16 16 16 15 | 0,23 0,23 0,22 0,22 0,22 | 2,80 2,79 2,81 2,84 2,92 | 4,33 4,31 4,35 4,39 4,52 | 2,93 2,92 2,95 2,97 3,06 | ||

| 1317 1318 1320 | 111317 111318 111320 | 21,43 23,81 26,99 | 16 15 15 | 0,22 0,22 0,24 | 2,90 2,82 2,67 | 4,49 4,36 4,14 | 3,04 2,95 2,80 | ||

| Diameter series b | |||||||||

| 1605 1606 | 111605 111606 | 10,32 11,91 | 11 11 | 0,47 0,44 | 1,34 1,43 | 2,07 2,22 | 1,40 1,50 | 1,0 | 0,65 |

| 1607 1608 1609 | 111607 111608 111609 | 13,49 14,29 15,08 | 11 12 12 | 0,46 0,43 0,42 | 1,36 1,46 1,51 | 2,11 2,25 2,33 | 1,43 1,52 1,58 | ||

| 1610 1611 | 111610 111611 | 17,46 19,05 | 12 12 | 0,43 0,41 | 1,48 1,52 | 2,29 2,35 | 1,55 1,60 | ||

| 1612 1613 1614 1616 | 111612 111613 111614 111616 | 20,64 21,43 23,02 26,99 | 12 13 13 13 | 0,41 0,38 0,38 0,37 | 1,56 1,65 1,68 1,68 | 2,41 2,55 2,59 2,61 | 1,63 1,73 1,76 1,76 | ||

404 Not Found

The requested URL /bottom.php was not found on this server.

Additionally, a 404 Not Found error was encountered while trying to use an ErrorDocument to handle the request.

Angular contact ball bearings

This type provides a reaction in two planes along the axis and perpendicular to it. When using a two-row model, the shaft is fixed in space.

Dimensions in the table of angular contact ball bearings, single-row, one-piece

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 7203B | 66203 | 17 | 40 | 12 | 0,07 | |

| 7204B | 66204 | 20 | 47 | 14 | 0,11 | |

| 7205 B | 166205 | 25 | 52 | 15 | 0,14 | |

| 7206B | 66206 | 30 | 62 | 16 | 0,2 | |

| 7207 B | 66207 | 35 | 62 | 17 | 0,29 | |

| 7208 B | 66208 | 40 | 72 | 18 | 0,37 | |

| 7209 B | 66209 | 45 | 85 | 19 | 0,43 | |

| 7210 B | 66210 | 50 | 90 | 20 | 0,48 | |

| 7211B | 66211 | 55 | 100 | 21 | 0,63 | |

| 7212B | 66212 | 60 | 110 | 22 | 0,81 | |

| 7213B | 66213 | 65 | 120 | 23 | 1 | |

| 7214B | 66214 | 70 | 125 | 24 | 1,1 |

Standard sizes and weights of double-row angular contact ball bearings in the table

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 3203B | 3056203 | 17 | 40 | 17,5 | 0,1 | |

| 3204B | 3056204 | 20 | 47 | 20,6 | 0,17 | |

| 3205B | 3056205 | 25 | 52 | 20,6 | 0,19 | |

| 3206B | 3056206 | 30 | 62 | 23,8 | 0,3 |

Ball diameter in bearing

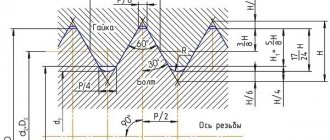

?The designation of all listed characteristics is made up of signs (numbers). The meanings of the numbers are determined by the places they occupy in the symbol (when reading from right to left): the main and second ones are the symbol for the diameter of the bearing hole (for bearings with a hole diameter of 10 mm or more); the third is a series of diameters; fourth - type of bearings; fifth and sixth – design; the seventh is a series of widths (elevations).

The diameter of the ball (for depiction in the drawings) is calculated by the formula: Dsh = 0.32 (D - d) where d is the diameter of the hole in the inner ring of the bearing, D is the diameter of the outer cylindrical surface of the outer ring of the bearing. The values of these two sizes can be found in GOST standards for the corresponding bearings or in encyclopedias on bearings . Key: Training manual “Design of units and parts of machines”, authors P.F. Dunaev, O.P. Lelikov. Page 161 (for the 2004 edition). The encyclopedic plates in the same book give the values of ball diameters for different bearings of the light and regular series for the diameter of the hole of the inner ring of the bearing in the range from 20 to 80 mm. for balls for various bearings (in technical circumstances the main values are contained).

The classification of rolling bearings is carried out on the basis of the following symptoms: According to the appearance of the rolling elements Ball, Roller (needle, if the rollers are thin and high); Based on the perceived load Radial (load along the shaft axis is not allowed). Radial - persistent, persistent - radial. They absorb loads both along and across the shaft axis. Often the load is along the axis of only one flow. Persistent (load across the shaft axis is not allowed). Linear. They provide mobility along the axis; rotation around the axis is not standardized or impossible. There are rail, telescopic or shaft linear bearings. Ball screw drives. The screw and nut are connected through the rolling elements. By the number of lines of rolling elements Single-row, Double-row, Multi-row; According to the ability to compensate for the misalignment of the shaft and bushing, self-aligning. Non-self-aligning.

Production of balls for bearings When you hold small metal balls made from ball bearings , you can’t help but see how smooth and perfectly round they are. To achieve such shapes and turn light metal wire into shiny metal balls, it is necessary to follow a rather complicated technological process that ensures the production of balls with an accuracy of hundredths of a micron. The ball is one of the most technologically complex parts. The main periods in the manufacture of balls for bearings 1. Cutting blanks for bearing balls From a coil of steel wire, blanks are cut with the approximate shape of the future ball. The workpieces, placed between two disk dies with grooves, are rolled until they are given a spherical shape (maximum pressure 20 tons). This type produces balls with a tolerance of 100 microns from the last size.

Stamped blanks of balls are early subjected to rough abrasive processing in special drums filled with abrasive chips, where the removal of ?‚?¤ Saturn ?? rings and center protrusions. Then the blanks shaped in this way go into ball-processing machines, which consist of a lower stationary and an upper rotating faceplate, equipped with cast iron disks of a special profile, between which the blanks are repeatedly rolled under pressure of up to 20 tons, acquiring a spherical shape with an allowance for subsequent grinding and finishing. Then the balls are subjected to heat treatment: heating, hardening and annealing in special muffle furnaces, giving the balls the required hardness (HRC 60 - 62).

The balls are made according to GOST 3722 from chromium-carbon steel, type ШХ15. At the customer's request, balls can be made from other grades of steel and fabrics. Balls are made heat-treated with a diameter of up to 45 mm of hardness 62... 66 HRC and with a diameter of over 45 mm of hardness 60... 66 HRC, but they can also be created with a different hardness. Balls of the same degree of accuracy are sorted into groups with very strict diameter tolerances. Any group is packaged in some kind of box. The size of the sorted group of balls is indicated in the markings on the box in direct terms of the usual deviation of the nominal diameter of the balls , for example: ball 5.953 - 20 GOST 3722 - 81 deltaDwm L = 1.0 microns.

Related posts:

- Bearing designation

- Wheel bearing size

- Symbol…

- GOST rolling bearings

- Bearing markings

https://pharmex-market.ru nebulizer prices.

Thrust ball

This series of parts is designated by two types.

Single

| ISO marking | Analogue GOST | d mm | d1 mm | D mm | D1 mm | T mm | Weight, kg | Scheme |

| 51104 | 8104 | 20 | 35 | 35 | 20,2 | 10 | 0,04 | |

| 51105 | 8105 | 25 | 42 | 42 | 25,2 | 11 | 0,06 | |

| 51106 | 8106 | 30 | 47 | 47 | 30,2 | 11 | 0,07 | |

| 51107 | 8107 | 35 | 52 | 52 | 35,3 | 12 | 0,08 | |

| 51108 | 8108 | 40 | 60 | 60 | 40,2 | 13 | 0,12 | |

| 51109 | 8109 | 45 | 65 | 65 | 45,2 | 14 | 0,15 | |

| 51110 | 8110 | 50 | 70 | 70 | 50,2 | 14 | 0,16 | |

| 51111 | 8111 | 55 | 78 | 78 | 55,2 | 16 | 0,24 | |

| 51112 | 8112 | 60 | 85 | 85 | 60,2 | 17 | 0,29 | |

| 51113 | 8113 | 65 | 90 | 90 | 65,2 | 18 | 0,34 | |

| 51114 | 8114 | 70 | 95 | 95 | 70,2 | 18 | 0,36 | |

| 51115 | 8115 | 75 | 100 | 100 | 75,2 | 19 | 0,42 |

There are no English letters in the ISO marking, and numbers begin with 511. According to the state standard, four-digit numbers with a prefix of 81.

With backing ring

| ISO marking | Analogue GOST | d mm | D mm | d1 mm | D2 mm | D3 mm | C1 mm | R mm | S mm | T mm | Weight, kg | Scheme |

| 53203+U203 | 18203 | 17 | 35 | 35 | 38 | 26 | 4,00 | 32 | 16 | 15 | 0,071 | |

| 53204+U204 | 18204 | 20 | 40 | 40 | 42 | 30 | 5,00 | 36 | 18 | 17 | 0,102 | |

| 53205+U205 | 18205 | 25 | 47 | 47 | 50 | 36 | 5,50 | 40 | 19 | 19 | 0,155 | |

| 53206+U206 | 18206 | 30 | 52 | 52 | 55 | 42 | 5,50 | 45 | 22 | 20 | 0,182 | |

| 53207+U207 | 18207 | 35 | 62 | 62 | 65 | 48 | 7,00 | 50 | 24 | 22 | 0,279 | |

| 53208+U208 | 18208 | 40 | 68 | 68 | 72 | 55 | 7,00 | 56 | 28,5 | 23 | 0,35 | |

| 53209+U209 | 18209 | 45 | 73 | 73 | 78 | 60 | 7,50 | 56 | 26 | 24 | 0,388 | |

| 53210+U210 | 18210 | 50 | 78 | 78 | 82 | 62 | 7,50 | 64 | 32,5 | 26 | 0,464 | |

| 53211+U211 | 18211 | 55 | 90 | 90 | 95 | 72 | 9,00 | 72 | 35 | 30 | 0,752 | |

| 53212+U212 | 18212 | 60 | 95 | 95 | 100 | 78 | 9,00 | 72 | 32,5 | 31 | 0,817 | |

| 53213+U213 | 18213 | 65 | 100 | 100 | 105 | 82 | 9,00 | 80 | 40 | 32 | 0,912 | |

| 53214+U214 | 18214 | 70 | 105 | 105 | 110 | 88 | 9,00 | 80 | 38 | 32 | 0,967 | |

| 53215+U215 | 18215 | 75 | 110 | 110 | 115 | 92 | 9,50 | 90 | 49 | 32 | 1,018 |

Double row thrust ball bearings

| ISO marking | Analogue GOST | d mm | d1 mm | D mm | D1 mm | T mm | S mm | Weight, kg | Scheme |

| 29428 | 9039428 | 140 | 257 | 280 | 198 | 85 | 86 | 24,1 | |

| 29436 | 9039436 | 180 | 342 | 360 | 250 | 109 | 110 | 52,6 | |

| 29452 | 9039452 | 260 | 460 | 480 | 346 | 132 | 154 | 107,8 | |

| 29488 | 9039488 | 440 | 745 | 780 | 576 | 206 | 260 | 413 |

Housing bearings - description and dimensions

Bearing units consist of a single row deep groove ball bearing with two seals and a housing that can be made of cast iron, synthetic rubber or extruded steel and which can be configured in various configurations. A bearing with a spherical ground outer diameter is installed in a corresponding spherical seat in the housing, which ensures self-centering of the bearing in the housing during installation.

Designation

Popular designs of bearing units with UC bearing.

| Bearing UC | Case P | Housing F | FC housing | Housing FL | T body |

| UCP 2XX, UCP 3XX (example UCP 205, UCP 305) | UCF 2XX, UCF 3XX (example UCF 205, UCF 305) | UCFC 2XX (example UCFC 205) | UCFL 2XX, UCFL 3XX (example UCFL 205, UCFL 305) | UCT 2XX, UCT 3XX (example UCT 205, UCT 305) |

In the number, the last two digits indicate the shaft diameter (in general, you need to multiply by 5, for example 05 is 25 mm), the third from the end is the series (the light series is indicated by the number 2, the series for moderate operating conditions is indicated by the letter X, the heavy series is indicated by 3) .

Type UC

| Name | d, mm | D, mm | Bi, mm | Weight, kg |

| UC 201 | 12 | 47 | 31,0 | 0,21 |

| UC 202 | 15 | 47 | 31,0 | 0,190 |

| UC 203 | 17 | 47 | 31,0 | 0,180 |

| UC 204 | 20 | 47 | 31,0 | 0,160 |

| UC 205 | 25 | 52 | 34,0 | 0,190 |

| UC 206 | 30 | 62 | 38,1 | 0,310 |

| UC 207 | 35 | 72 | 42,9 | 0,480 |

| UC 208 | 40 | 80 | 49,2 | 0,620 |

| UC 209 | 45 | 85 | 49,2 | 0,670 |

| UC 210 | 50 | 90 | 51,6 | 0,780 |

| UC 211 | 55 | 100 | 55,6 | 1,030 |

| UC 212 | 60 | 110 | 65,1 | 1,450 |

| UC 213 | 65 | 120 | 65,1 | 1,710 |

| UC 214 | 70 | 125 | 74,6 | 2,060 |

| UC 215 | 75 | 130 | 77,8 | 2,220 |

| UC 216 | 80 | 140 | 82,6 | 2,820 |

| UC 217 | 85 | 150 | 85,7 | 3,380 |

| UC 218 | 90 | 160 | 96,0 | 4,340 |

Type UCP 200

For normal operating conditions. Fastening with locking screws

| Name | Shaft diameter, mm | h, mm | a, mm | e, mm | b, mm | s1, mm | s2, mm | g, mm | W, mm | Bi, mm | n, mm | Bolt | Weight, kg |

| UCP201 | 12 | 30,2 | 127 | 96 | 38 | 13 | 19 | 15 | 62 | 31 | 12,7 | M10 | 0,6 |

| UCP202 | 15 | 30,2 | 127 | 96 | 38 | 13 | 19 | 15 | 62 | 31 | 12,7 | M10 | 0,6 |

| UCP203 | 17 | 30,2 | 127 | 96 | 38 | 13 | 19 | 15 | 62 | 31 | 12,7 | M10 | 0,6 |

| UCP204 | 20 | 33,3 | 127 | 95 | 38 | 13 | 19 | 15 | 65 | 31 | 12,7 | M10 | 0,7 |

| UCP205 | 25 | 36,5 | 140 | 105 | 38 | 13 | 16 | 16 | 70 | 34 | 14,3 | M10 | 0,8 |

| UCP206 | 30 | 42,9 | 165 | 121 | 48 | 17 | 21 | 18 | 83 | 38,1 | 15,9 | M14 | 1,3 |

| UCP207 | 35 | 47,6 | 167 | 127 | 48 | 17 | 21 | 19 | 94 | 42,9 | 17,5 | M14 | 1,6 |

| UCP208 | 40 | 49,2 | 184 | 137 | 54 | 17 | 25 | 19 | 100 | 49,2 | 19 | M14 | 2 |

| UCP209 | 45 | 54 | 190 | 146 | 54 | 17 | 22 | 20 | 108 | 49,2 | 19 | M14 | 2,3 |

| UCP210 | 50 | 57,2 | 206 | 159 | 60 | 20 | 25 | 22 | 114 | 51,6 | 19 | M16 | 2,7 |

| UCP211 | 55 | 63,5 | 219 | 171 | 60 | 20 | 25 | 22 | 126 | 55,6 | 22,2 | M17 | 3,3 |

| UCP212 | 60 | 69,8 | 241 | 184 | 70 | 20 | 25 | 25 | 138 | 65,1 | 25,4 | M18 | 4,7 |

| UCP213 | 65 | 76,2 | 265 | 203 | 70 | 25 | 29 | 27 | 150 | 65,1 | 25,4 | M20 | 5,6 |

| UCP214 | 70 | 79,4 | 266 | 210 | 72 | 25 | 31 | 27 | 156 | 74,6 | 30,2 | M20 | 7,3 |

| UCP215 | 75 | 82,6 | 275 | 217 | 74 | 25 | 31 | 28 | 163 | 77,8 | 33,3 | M20 | 7,9 |

| UCP216 | 80 | 88,9 | 292 | 232 | 78 | 25 | 31 | 30 | 175 | 82,6 | 33,3 | M20 | 10 |

| UCP217 | 85 | 95,2 | 310 | 247 | 83 | 25 | 31 | 32 | 187 | 85,7 | 34,1 | M20 | 12,2 |

| UCP218 | 90 | 101,6 | 327 | 262 | 88 | 22 | 33 | 34 | 200 | 96 | 39,7 | M20 | 14,7 |

Type UCF

| Name | a, mm | e, mm | i, mm | g, mm | l, mm | s, mm | Z, mm | Bi, mm | n, mm | Bolt | Weight, kg |

| UCF201 | 86 | 64 | 15 | 12 | 25,5 | 12 | 33,3 | 31,0 | 12,7 | M10 | 0,640 |

| UCF202 | 86 | 64 | 15 | 12 | 25,5 | 12 | 33,3 | 31,0 | 12,7 | M10 | 0,620 |

| UCF203 | 86 | 64 | 15 | 12 | 25,5 | 12 | 33,3 | 31,0 | 12,7 | M10 | 0,610 |

| UCF204 | 86 | 64 | 15 | 12 | 25,5 | 12 | 33,3 | 31,0 | 12,7 | M10 | 0,590 |

| UCF205 | 95 | 70 | 16 | 14 | 27,0 | 12 | 35,7 | 34,0 | 14,3 | M10 | 0,820 |

| UCF206 | 108 | 83 | 18 | 14 | 31,0 | 12 | 40,2 | 38,1 | 15,9 | M10 | 1,100 |

| UCF207 | 117 | 92 | 19 | 16 | 34,0 | 14 | 44,4 | 42,9 | 17,5 | M12 | 1,500 |

| UCF208 | 130 | 102 | 21 | 16 | 36,0 | 14 | 51,2 | 49,2 | 19,0 | M14 | 2,000 |

| UCF209 | 137 | 105 | 22 | 18 | 38,0 | 16 | 52,2 | 49,2 | 19,0 | M14 | 2,400 |

| UCF210 | 143 | 111 | 22 | 18 | 40,0 | 16 | 54,6 | 51,6 | 19,0 | M14 | 2,500 |

| UCF211 | 162 | 130 | 25 | 20 | 43,0 | 19 | 58,4 | 55,6 | 22,2 | M16 | 3,400 |

| UCF212 | 175 | 143 | 29 | 20 | 48,0 | 19 | 68,7 | 65,1 | 25,4 | M16 | 4,600 |

| UCF213 | 187 | 149 | 30 | 20 | 50,0 | 19 | 69,7 | 65,1 | 25,4 | M16 | 5,500 |

| UCF214 | 193 | 152 | 31 | 24 | 54,0 | 19 | 75,4 | 74,6 | 30,2 | M16 | 6,100 |

| UCF21S | 200 | 159 | 34 | 24 | 56,0 | 19 | 78,5 | 77,8 | 33,3 | M16 | 6,900 |

| UCF216 | 208 | 165 | 34 | 24 | 58,0 | 23 | 83,3 | 82,6 | 33,3 | M20 | 7,800 |

| UCF217 | 220 | 175 | 36 | 26 | 63,0 | 23 | 87,6 | 85,7 | 34,1 | M20 | 9,300 |

| UCF218 | 235 | 187 | 40 | 26 | 68 | 23 | 96,3 | 96 | 39,7 | M20 | 11,300 |

Type UCFL

| Name | a, mm | e, mm | i, mm | g, mm | l, mm | s, mm | b, mm | z, mm | Bi, mm | n, mm | Bolt | Weight, kg |

| UCFL201 | 113 | 90 | 15 | 12 | 25,5 | 12 | 60 | 33,3 | 31,0 | 12,70 | M10 | 0,500 |

| UCFL202 | 113 | 90 | 15 | 12 | 25,5 | 12 | 60 | 33,3 | 31,0 | 12,70 | M10 | 0,480 |

| UCFL203 | 113 | 90 | 15 | 12 | 25,5 | 12 | 60 | 33,3 | 31,0 | 12,70 | M10 | 0,470 |

| UCFL204 | 113 | 90 | 15 | 12 | 25,5 | 12 | 60 | 33,3 | 31,0 | 12,70 | M10 | 0,450 |

| UCFL205 | 130 | 99 | 16 | 14 | 27,0 | 16 | 68 | 35,7 | 34,0 | 14,33 | M14 | 0,630 |

| UCFL206 | 148 | 117 | 18 | 14 | 31,0 | 16 | 80 | 40,2 | 38,1 | 15,90 | M14 | 0,960 |

| UCFL207 | 161 | 130 | 19 | 16 | 34,0 | 16 | 90 | 44,4 | 42,9 | 17,50 | M14 | 1,200 |

| UCFL208 | 175 | 144 | 21 | 16 | 36,0 | 16 | 100 | 51,2 | 49,2 | 19,00 | M14 | 1,600 |

| UCFL209 | 188 | 148 | 22 | 18 | 38,0 | 19 | 108 | 52,2 | 49,2 | 19,00 | M16 | 1,900 |

| UCFL210 | 197 | 157 | 22 | 18 | 40,0 | 19 | 115 | 54,6 | 51,6 | 19,00 | M16 | 2,200 |

| UCFL211 | 224 | 184 | 25 | 20 | 43,0 | 19 | 130 | 58,4 | 55,6 | 22,20 | M16 | 3,200 |

| UCFL212 | 250 | 202 | 29 | 20 | 48,0 | 23 | 140 | 68,7 | 65,1 | 25,40 | M20 | 4,100 |

| UCFL213 | 258 | 210 | 30 | 24 | 50,0 | 23 | 155 | 69,7 | 65,1 | 25,40 | M20 | 5,100 |

| UCFL214 | 265 | 216 | 31 | 24 | 54,0 | 23 | 160 | 75,4 | 74,6 | 30,20 | M20 | 6,000 |

| UCFL215 | 275 | 225 | 34 | 24 | 56,0 | 23 | 165 | 78,5 | 77,8 | 33,30 | M20 | 6,500 |

| UCFL216 | 290 | 233 | 34 | 24 | 58,0 | 25 | 180 | 83,3 | 82,6 | 33,30 | M22 | 8,000 |

| UCFL217 | 305 | 248 | 36 | 26 | 63,0 | 25 | 190 | 85,7 | 85,7 | 34,10 | M22 | 9,500 |

| UCFL218 | 320 | 265 | 40 | 26 | 68 | 25 | 205 | 96 | 96,0 | 39,7 | M22 | 11,9 |

Type UCPA

| Name | h, mm | a, mm | e, mm | b, mm | r, mm | g, mm | w, mm | Bi, mm | n, mm | Bolt | Weight, kg |

| UCPA201 | 30,2 | 76 | 52 | 40 | 12 | 11 | 62 | 31,0 | 12,7 | M10x1.5 | 0,650 |

| UCPA202 | 30,2 | 76 | 52 | 40 | 12 | 11 | 62 | 31,0 | 12,7 | M10x1.5 | 0,630 |

| UCPA203 | 30,2 | 76 | 52 | 40 | 12 | 11 | 62 | 31,0 | 12,7 | M10x1.5 | 0,620 |

| UCPA204 | 30,2 | 76 | 52 | 40 | 12 | 1,1 | 62 | 31,0 | 12,7 | M10x1.5 | 0,600 |

| UCPA205 | 36,5 | 84 | 56 | 45 | 15 | 12 | 72 | 34,0 | 14,3 | M10x1.5 | 0,810 |

| UCPA206 | 42,9 | 94 | 66 | 50 | 18 | 12 | 84 | 38,1 | 15,9 | M14x2 | 1,200 |

| UCPA207 | 47,6 | 110 | 80 | 55 | 20 | 13 | 95 | 42,9 | 17,5 | M14x2 | 1,700 |

| UCPA208 | 49,2 | 116 | 84 | 58 | 20 | 13 | 100 | 49,2 | 19,0 | M14x2 | 1,900 |

| UCPA209 | 54,2 | 120 | 90 | 60 | 22 | 13 | 108 | 49,2 | 19,0 | M14x2 | 2,200 |

| UCPA210 | 57,2 | 130 | 94 | 64 | 25 | 14 | 116 | 51,6 | 19,0 | M16x2 | 2,600 |

UCT type

| Name | o, mm | g, mm | P, mm | q, mm | S, mm | b, mm | k, mm | e, mm | a, mm | w, mm | i, mm | l, mm | h, mm | Bi,m | n, mm | Weight, kg |

| UCT201 | 16 | 10 | 51 | 32 | 19 | 51 | 12 | 76 | 89 | 94 | 32 | 21 | 61 | 31,0 | 12,7 | 0,790 |

| UCT202 | 16 | 10 | 51 | 32 | 19 | 0,51 | 12 | 76 | 89 | 94 | 32 | 21 | 61 | 31,0 | 12,7 | 0,770 |

| UCT203 | 16 | 10 | 51 | 32 | 19 | 51 | 12 | 76 | 89 | 94 | 32 | 21 | 61 | 31,0 | 12,7 | 0,760 |

| UCT204 | 16 | 10 | 51 | 32 | 19 | 51 | 12 | 76 | 89 | 94 | 32 | 21 | 61 | 31,0 | 12,7 | 0,790 |

| UCT205 | 16 | 10 | 51 | 32 | 19 | 51 | 12 | 76 | 89 | 97 | 32 | 24 | 62 | 34,0 | 14,3 | 0,820 |

| UCT206 | 16 | 10 | 56 | 37 | 22 | 57 | 12 | 89 | 102 | 113 | 37 | 28 | 70 | 38,1 | 15,9 | 1,300 |

| UCT207 | 16 | 13 | 64 | 37 | 22 | 64 | 12 | 89 | 102 | 129 | 37 | 30 | 78 | 42,9 | 17,5 | 1,600 |

| UCT208 | 19 | 16 | 83 | 49 | 29 | 83 | 16 | 102 | 114 | 144 | 49 | 33 | 88 | 49,2 | 19,0 | 2,400 |

| UCT209 | 19 | 16 | 83 | 49 | 29 | 83 | 16 | 102 | 117 | 144 | 49 | 35 | 87 | 49,2 | 19,0 | 2,400 |

| UCT210 | 19 | 16 | 83 | 49 | 29 | 86 | 16 | 102 | 117 | 149 | 49 | 37 | 90 | 51,6 | 19,0 | 2,500 |

| UCT211 | 25 | 19 | 102 | 64 | 35 | 95 | 22 | 130 | 146 | 171 | 64 | 38 | 106 | 55,6 | 22,2 | 4,000 |

| UCT212 | 32 | 19 | 102 | 64 | 35 | 102 | 22 | 130 | 146 | 194 | 64 | 42 | 119 | 65,1 | 25,4 | 5,100 |

| UCT213 | 32 | 21 | 111 | 70 | 41 | 121 | 26 | 151 | 167 | 224 | 70 | 44 | 137 | 65,1 | 25,4 | 7,000 |

| UCT214 | 32 | 21 | 111 | 70 | 41 | 121 | 26 | 151 | 167 | 224 | 70 | 46 | 137 | 74,6 | 30,2 | 7,100 |

| UCT215 | 32 | 21 | 111 | 70 | 41 | 121 | 26 | 151 | 167 | 232 | 70 | 48 | 140 | 77,8 | 33,3 | 7,500 |

| UCT216 | 32 | 21 | 111 | 70 | 41 | 121 | 26 | 165 | 184 | 235 | 70 | 51 | 140 | 82,6 | 33,3 | 8,500 |

| UCT217 | 38 | 29 | 124 | 73 | 48 | 157 | 30 | 173 | 198 | 260 | 73 | 54 | 162 | 85,7 | 34,1 | 11,200 |

Cylindrical roller bearings

These parts compare favorably with ball parts due to the increased load on the axle. The contact area of the roller is much wider than that of a spherical bearing. Some modifications allow longitudinal displacement along the axis.

We will show tables that can be used to determine the size by bearing number:

Without flanges on the outer ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| N 1007 | 2107 | 35 | 62 | 14 | 0,18 | |

| N 1008 | 2108 | 40 | 68 | 15 | 0,22 | |

| N 1009 | 2109 | 45 | 75 | 16 | 0,29 | |

| N 1110 | 2110 | 50 | 80 | 16 | 0,31 |

With single breasted inner ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| NJ 1034 | 42134 | 170 | 260 | 42 | 8,2 | |

| NJ 1036 | 42136 | 180 | 280 | 46 | 10,1 |

With one built-in and one free flange on the inner ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| NUP 305 | 92305 | 25 | 62 | 17 | 0,24 | |

| NUP 306 | 92306 | 30 | 72 | 19 | 0,36 | |

| NUP 307 | 92307 | 35 | 80 | 21 | 0,48 |

Designation of imported bearings - is there a foreign GOST for marking components?

If with domestic products everything is clear and each manufacturing company is obliged to adhere to the established numbering requirements for years, then abroad each manufacturer himself comes up with a system convenient for him. Usually it is less detailed and detailed than in Russia, and also has the following drawback - without detailed instructions, and for a Russian person translated into his native language, nothing is clear. You can trust the seller, but he himself often does not know the smallest details that make up the code.

How to determine the bearing series - instructions

There are four main categories. Extra light (number 1), light (2 or 5), medium (3 or 6) and heavy – 4.

To determine which of them the model belongs to, you should find the core of the marking; it is located between two dashes. If there is no suffix or postfix, then the number may stand alone. There are two situations. If there is a slash, then the indicator we need is the first one to the left of it. If there is no slash, then it is third.

How to find out the hole diameter - instructions

These are the very first (right) numbers of the kernel.

If the entry contains the ending - 0X, then this X is a number from 1 to 9 in millimeters. If the entry is 05X, then X is a rounded number, but not more than 10 mm.

The signs 00, 01, 02 and 02 indicate a range from 10 to 20; the code can be converted into exact values using the table above. If they are followed by 9 (i.e. 900 or 901), then again rounding has occurred.

If there is any two-digit value, it should be multiplied by 5. The rule with “nine” in third place remains appropriate here.

And if there is a slash in the marking, then either this is an exception, or the large diameter is more than 50 centimeters.

How to determine its external dimensions by the bearing number - instructions

This is the last kernel value. It stands on the edge, to the left. These are the dimensions, that is, the multiplied width and height. If the inner ring remains the same, then the outer one increases according to the following markings: 0, 8, 9, 1, 7, 2, 3, 4, 5. The ratio of the values can be determined using the table.

How to find out the number

The easiest way is to use electronic catalogs containing all dozens of values. Numbering is easier to master if you first measure the main parameters - outer and inner radius, width, height.

Tapered roller bearings

They have the same advantages as cylindrical ones: high load, the ability to disassemble. In addition, they allow you to adjust the gap between the rolling surfaces after working. These include the following types.

Single row

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width T in mm | Weight in kg | Scheme |

| 30204 | 7204 | 20 | 47 | 15,25 | 0,12 | |

| 30205 | 7205 | 25 | 52 | 16,25 | 0,15 | |

| 30206 | 7206 | 30 | 62 | 17,25 | 0,24 |

With a large cone angle

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width T in mm | Weight in kg | Scheme |

| — | 27305 | 25 | 62 | 18,25 | 0,26 | |

| — | 27306 | 30 | 72 | 20,75 | 0,39 | |

| — | 27307 | 35 | 80 | 12,75 | 0,52 |

Double row

| ISO marking | Analogue GOST | Inner diameter mm | Outer diameter mm | Width T in mm | Width B in mm | Weight in kg | Scheme |

| — | 9716 | 340 | 520 | 180 | 135 | 118 | |

| — | 9717 | 360 | 540 | 185 | 140 | 132 | |

| — | 9718 | 380 | 560 | 189 | 141 | 169 |

Four-row

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width T in mm | Width B in mm | Weight in kg | Scheme |

| — | 2077140 | 200 | 310 | 275 | 10 | 75,8 | |

| — | 2077144 | 220 | 340 | 305 | 10 | 10,4 | |

| — | 2077148 | 240 | 360 | 310 | 10 | 108,7 |

Rules for working with bearings

A bearing must be reliable, but sometimes the conditions in which it must rotate are not suitable for its normal functioning.

Also, conditions can also influence the fact that a bearing, even in good conditions, can suddenly fail. Therefore, there are special rules for the operation of this part, and they should be taken very seriously so that your part can work as long as possible. For example, you should not overload it and make sure that it only works for the required time period and no more. Another rule should be considered that it should be selected so that it fits perfectly in size, diameter and other technical characteristics.

For example, by size you can find a variety of bearings: from miniature to the most gigantic sizes. There is another division: high-speed, low-speed, maximum precision and others. All of these divisions depend on where and how you intend to use this important element of the rotational movement.

Spherical roller bearings

They combine the ability to withstand high loads and have a deviation in the axes of landing and rotation. They are also called self-centering.

Double-row with sides on the inner ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 22208 | 3508 | 40 | 80 | 23 | 0,58 | |

| 22209 | 3509 | 45 | 85 | 23 | 0,6 | |

| 22210 | 3510 | 50 | 90 | 23 | 0,65 |

With beadless inner ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 22208 | 53508 | 40 | 80 | 23 | 0,58 | |

| 22209 | 53509 | 45 | 85 | 23 | 0,6 | |

| 22210 | 53510 | 50 | 90 | 23 | 0,65 |

Spherical double-row with sides on the inner ring with a landing cone 1:12

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 22208 CCK | 153508 | 40 | 80 | 23 | 0,58 | |

| 22209 CCK | 153509 | 45 | 85 | 23 | 0,6 | |

| 22210 CCK | 153510 | 50 | 90 | 23 | 0,65 | |

| 22211 CCK | 153511 | 55 | 100 | 25 | 0,88 | |

| 22212 CCK | 153512 | 60 | 110 | 28 | 1,2 |

Spherical double-row with sides on the inner ring with a cone 1:30

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 24024 K30 | 4113124 | 120 | 180 | 60 | 5,4 | |

| 24026 K30 | 4113126 | 130 | 200 | 69 | 7,95 | |

| 24028 K30 | 4113128 | 140 | 210 | 69 | 8,45 | |

| 24030 K30 | 4113130 | 150 | 225 | 75 | 10,5 |

Spherical double-row with a beadless ring with a hole with a taper of 1:30

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 24024 CCK30 | 4153124 | 120 | 180 | 60 | 5,4 | |

| 24026 CCK30 | 4153126 | 130 | 200 | 69 | 7,95 | |

| 24028 CCK30 | 4153128 | 140 | 210 | 69 | 8,45 | |

| 24030 CCK30 | 4153130 | 150 | 225 | 75 | 10,5 |

Flatbed with inner ring with seat cone 1:12

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 22208 CCK | 153508 | 40 | 80 | 23 | 0,58 | |

| 22209 CCK | 153509 | 45 | 85 | 23 | 0,6 | |

| 22210 CCK | 153510 | 50 | 90 | 23 | 0,65 | |

| 22211 CCK | 153511 | 55 | 100 | 25 | 0,88 |

Thrust spherical single row

| ISO marking | Analogue GOST | d mm | d 1 mm | D mm | D 1 mm | T mm | S mm | Weight in kg | Scheme |

| 29428 | 9039428 | 140 | 257 | 280 | 198 | 85 | 86 | 24,1 | |

| 29436 | 9039436 | 180 | 342 | 360 | 255 | 109 | 110 | 52,6 | |

| 29452 | 9039452 | 260 | 460 | 480 | 346 | 132 | 154 | 107,8 |

Double row ball bearings, sealed

Their design is similar to that of single-row sealed bearings installed in pairs in an “O” pattern.

They are non-separable and their internal geometry is improved, which is the main feature of the design - the presence of a spherical surface on the outer ring. The bearings are radial and have two rows of balls, which has a better effect on their ability to absorb radial load.

The bearings are capable of supporting a small axial load, but less than single-row radial bearings. This allows us to eliminate the main disadvantage of a single-row machine, such as the inability to work when the shafts are skewed or bent. This type is widely used in agricultural machinery and other industries where long and thin shafts are used for light ball bearing loads. This is achieved by reducing the load on the ball. Double row deep groove ball bearing is used for heavy loads with high axial rotation frequency.

Cages for double row angular contact ball bearings are manufactured in two versions, depending on the internal design of the bearing, from stamped steel, polyamide or brass.

Contact seals (2RS) on 2 sides reliably protect the bearings of this series from large and fine dust, as well as moisture. Sealed bearings are already lubricated for life.

As a rule, the cage in bearings 22..-2RS is made of polyamide (plastic) or, less commonly, steel.

| Size table for deep groove ball bearings series 22..-2RS | |||

| Designation | d, mm | D, mm | B, mm |

| 2200-2RS | 10 | 30 | 14 |

| 2201-2RS | 12 | 32 | 14 |

| 2202-2RS | 15 | 35 | 14 |

| 2203-2RS | 17 | 40 | 16 |

| 2204-2RS | 20 | 47 | 18 |

| 2205-2RS | 25 | 52 | 18 |

| 2206-2RS | 30 | 62 | 20 |

| 2207-2RS | 35 | 72 | 23 |

| 2208-2RS | 40 | 80 | 23 |

| 2209-2RS | 45 | 85 | 23 |

| 2210-2RS | 50 | 90 | 23 |

| 2211-2RS | 55 | 100 | 25 |

| 2212-2RS | 60 | 110 | 28 |

| 2213-2RS | 65 | 120 | 31 |

| 2214-2RS | 70 | 125 | 31 |

| Designation | Dimensions, mm | Weight, kg | ||||

| according to GOST | international | d | D | B | r | |

| Width series 0, diameter series 1 | ||||||

| 246100 | – | 10 | 26 | 16 | 0,5 | 0,04 |

| 246101 | – | 12 | 28 | 16 | 0,5 | 0,05 |

| 246102 | – | 15 | 32 | 18 | 0,5 | 0,06 |

| 246103 | – | 17 | 35 | 20 | 0,5 | 0,08 |

| 246104 | – | 20 | 42 | 24 | 1 | 0,14 |

| 246105 | – | 25 | 47 | 24 | 1 | 0,16 |

| 246106 | – | 30 | 55 | 26 | 1,5 | 0,24 |

| 246107 | – | 35 | 62 | 28 | 1,5 | 0,32 |

| 246108 | – | 40 | 68 | 30 | 1,5 | 0,39 |

| 246109 | – | 45 | 75 | 32 | 1,5 | 0,5 |

| 246110 | – | 50 | 80 | 32 | 1,5 | 0,54 |

| 246111 | – | 55 | 90 | 36 | 2 | 0,79 |

| 246112 | – | 60 | 95 | 36 | 2 | 0,84 |

| 246113 | – | 65 | 100 | 36 | 2 | 0,9 |

| 246114 | – | 70 | 110 | 40 | 2 | 1,24 |

| 246115 | – | 75 | 115 | 40 | 2 | 1,31 |

| 246116 | – | 80 | 125 | 44 | 2 | 1,75 |

| 246117 | – | 85 | 130 | 44 | 2 | 1,83 |

| 246118 | – | 90 | 140 | 48 | 2,5 | 2,38 |

| 246120 | – | 100 | 150 | 48 | 2,5 | 2,58 |

| 246122 | – | 110 | 170 | 56 | 3 | 4,04 |

| 246124 | – | 120 | 180 | 56 | 3 | 4,34 |

| 246126 | – | 130 | 200 | 66 | 3 | 6,56 |

| 246128 | – | 140 | 210 | 66 | 3 | 6,96 |

| 246130 | – | 150 | 225 | 70 | 3,5 | 8,44 |

| 246132 | – | 160 | 240 | 76 | 3,5 | 10,38 |

| 246134 | – | 170 | 260 | 84 | 3,5 | 13,92 |

| 246136 | – | 180 | 280 | 92 | 3,5 | 18,18 |

| 246138 | – | 190 | 290 | 92 | 3,5 | 19,62 |

| 246140 | – | 200 | 310 | 102 | 3,5 | 24,6 |

| Width series 0, diameter series 2 | ||||||

| 246201 | – | 12 | 32 | 20 | 1 | 0,08 |

| 246202 | – | 15 | 35 | 22 | 1 | 0,1 |

| 246203 | – | 17 | 40 | 24 | 1 | 0,14 |

| 246204 | – | 20 | 47 | 28 | 1,5 | 0,22 |

| 246205 | – | 25 | 52 | 30 | 1,5 | 0,27 |

| 246206 | – | 30 | 62 | 32 | 1,5 | 0,4 |

| 246207 | – | 35 | 72 | 34 | 2 | 0,56 |

| 246208 | – | 40 | 80 | 36 | 2 | 0,74 |

| 246209 | – | 45 | 85 | 38 | 2 | 0,85 |

| 246210 | – | 50 | 90 | 40 | 2 | 0,96 |

| 246211 | – | 55 | 100 | 42 | 2,5 | 1,26 |

| 246212 | – | 60 | 110 | 44 | 2,5 | 1,6 |

| 246213 | – | 65 | 120 | 46 | 2,5 | 2 |

| 246214 | – | 70 | 125 | 48 | 2,5 | 2,2 |

| 246215 | – | 75 | 130 | 50 | 2,5 | 2,95 |

| 246216 | – | 80 | 140 | 52 | 3 | 3,68 |

| 246217 | – | 85 | 150 | 56 | 3 | 4,42 |

| 246218 | – | 90 | 160 | 60 | 3 | 4,52 |

| 246220 | – | 100 | 180 | 68 | 3,5 | 6,64 |

| 246222 | – | 110 | 200 | 76 | 3,5 | 9,24 |

| 246224 | – | 120 | 215 | 80 | 3,5 | 10,96 |

| 246226 | – | 130 | 230 | 80 | 4 | 12,4 |

| 246228 | – | 140 | 250 | 84 | 4 | 15,5 |

| 246230 | – | 150 | 270 | 90 | 4 | 19,5 |

| 246232 | – | 160 | 290 | 96 | 4 | 30,8 |

| 246234 | – | 170 | 310 | 104 | 5 | 36,6 |

| 246236 | – | 180 | 320 | 104 | 5 | 40,8 |

| 246238 | – | 190 | 340 | 110 | 5 | 48,8 |

| 246240 | – | 200 | 360 | 116 | 5 | 58 |

| 246244 | – | 220 | 400 | 130 | 5 | 80 |

| Width series 0, diameter series 3 | ||||||

| 246303 | – | 17 | 47 | 28 | 1,5 | 0,244 |

| 246304 | – | 20 | 52 | 30 | 2 | 0,318 |

| 246305 | – | 25 | 62 | 34 | 2 | 0,508 |

| 246306 | – | 30 | 72 | 38 | 2 | 0,766 |

| 246307 | – | 35 | 80 | 42 | 2,5 | 1,014 |

| 246308 | – | 40 | 90 | 46 | 2,5 | 1,39 |

| 246309 | – | 45 | 100 | 50 | 2,5 | 1,854 |

| 246310 | – | 50 | 110 | 54 | 3 | 2,4 |

| 246311 | – | 55 | 120 | 58 | 3 | 3,1 |

| 246312 | – | 60 | 130 | 62 | 3,5 | 3,88 |

| 246313 | – | 65 | 140 | 66 | 3,5 | 4,76 |

| 246314 | – | 70 | 150 | 70 | 3,5 | 5,78 |

| 246315 | – | 75 | 160 | 74 | 3,5 | 6,94 |

| 246316 | – | 80 | 170 | 78 | 3,5 | 8,24 |

| 246317 | – | 85 | 180 | 82 | 4 | 9,68 |

| 246318 | – | 90 | 190 | 86 | 4 | 11,3 |

| 246319 | – | 95 | 200 | 90 | 4 | 12,5 |

| 246320 | – | 100 | 215 | 94 | 4 | 16,08 |

| 246322 | – | 110 | 240 | 100 | 4 | 21,6 |

| 246324 | – | 120 | 260 | 110 | 4 | 27,4 |

| 246326 | – | 130 | 280 | 116 | 5 | 33,6 |

| 246328 | – | 140 | 300 | 124 | 5 | 40,8 |

| 246330 | – | 150 | 320 | 130 | 5 | 48,8 |

| 246336 | – | 180 | 380 | 150 | 5 | – |

| 246340 | – | 200 | 420 | |||

| Attention Bearing Buyers Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: Delivery of bearings throughout the Russian Federation and abroad. Bearing catalog on the website |

Attention Bearing Buyers

Dear customers, send your questions and requests for the purchase of bearings and components by mail or call now: tel: +7 (495) 646 00 12 [email protected] Delivery of bearings in the Russian Federation and abroad. Bearing catalog on the website

themechanic.ru

Plain bearings

This unit does not have rolling elements. Its characteristics are as follows: the inner and outer cages are made along the same radius. Therefore, the axis, relative to the mandrel, has several degrees of freedom. Most often they are used in articulated joints.

Plain bearings with a hole and grooves for lubrication in the inner ring with a single-break ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 EC | ESHSP 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 EC | ESHSP 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 EC | ESHSP 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 EC | ESHSP 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

With double-break outer ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 20 EXC | ShSL 20 | 20 | 35 | 16 | 12 | 9 | 24 | 29 | 0,07 | |

| GEH 20 EXC | 2ShSL 20 | 20 | 47 | 26 | 15 | 22 | 23 | 35 | 0,19 | |

| GE 25 EXC | ShSL 25 | 25 | 42 | 20 | 16 | 7 | 29 | 35 | 0,12 | |

| GEH 25 EXC | 2ShSL 25 | 25 | 52 | 28 | 15 | 22 | 28 | 40 | 0,26 |

With holes and grooves in the inner ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 C | ESH 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 C | ShS 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 C | ESH 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 C | ESH 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

With grooves on inner and outer rings

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 S | ESH 10K | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 S | ShS 12K | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 S | ESH 15K | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 S | ESH 17K | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

Without holes and grooves with single break ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 E | ESR 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 E | ShP 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 E | ESR 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 E | ESR 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

With holes and grooves on outer and inner rings with single break ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10ES | ESHSP 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 ES | ShSP 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15ES | ESHP 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 ES | ESHSP 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

With double-break outer ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 EXS | ESHSL 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 EXS | ShSL 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 EXS | ESHSL 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 EXS | ESHL 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

Below we provide tables of closed sizes of rolling and sliding ball bearings.

Types of bearing seals

Bearing seals are divided into external and built-in. The external seal is a separate part and is supplied separately. They are usually used in conjunction with large bearings that operate under harsh conditions.

Integrated seals are already part of the sealed bearing and are supplied with the bearing. There are two types: shields and rubber seals.

Contact sealing is based on the action of a thin sealing lip, which fits tightly to the contacting surface and protects against the ingress of impurities, moisture or lubricant leakage. It is installed in a groove on the outer ring and touches the inner ring with one or more edges, thereby ensuring a seal. A tight fit is ensured either by the material itself or by a spring.

Non-contact seals are installed in places where, due to lack of space or cost, non-contact seals cannot be installed. The pressed steel shield is inserted into the outer ring and creates a small gap with the inner ring without touching it, so the frictional torque is not increased. Also used where there are high heating conditions or high engine speeds.

Seals are made from stamped steel rings of simple design.

Contact seals are made of metal rubber and have a labyrinth between the sheet element and the rubber lip. Increased protection against contamination. But it is used only at medium engine speeds. Rubber jaws are standardly made of nitrile butadiene rubber with sheet steel reinforcement, the edges of which touch the recesses on the side plane of the inner rings. All sealed bearings do not require re-lubrication; they are filled with grease once during manufacture. When filled with high-quality lubricant, the bearings do not require repeated maintenance.

Needle Bearing Size Chart

| International designation | Russian designation (GOST) | Dimensions (mm) | Load capacity (kN) | Weight (kg) | ||||

| d | Fw | D | B | Dynamic | Static | |||

| NK 32/20 | 524706 | 32 | 32 | 42 | 20 | 23,3 | 40,5 | 0,068 |

| RNA 49/28 | 42549/28 | 32 | 32 | 45 | 17 | 25,1 | 36,5 | 0,073 |

| RNA 69/28 | 62549/28 | 32 | 32 | 45 | 30 | 39,6 | 65,5 | 0,14 |

Dimensions

You can find out how bearing sizes depend on their series using the table of bearing sizes. It allows you to link a series with external and internal diameters and widths.

Rolling bearing dimensions.

Table 1. Bearing series by size

| Width | External diameter | Inner diameter | Series |

| 13 mm | 55 mm | 30 mm | 106 |

| 10 mm | 32 mm | 12 mm | 201 |

| 11 mm | 35 mm | 15 mm | 202 |

| 12 mm | 42 mm | 17 mm | 203 |

| 14 mm | 47 mm | 20 mm | 204 |

| 15 mm | 52 mm | 25 mm | 205 |

| 16 mm | 62 mm | 30 mm | 206 |

| 12 mm | 37 mm | 12 mm | 301 |

| 13 mm | 42 mm | 15 mm | 302 |

| 14 mm | 47 mm | 17 mm | 303 |

| 15 mm | 52 mm | 20 mm | 304 |

| 14 mm | 35 mm | 15 mm | 502 |

| 16 mm | 40 mm | 17 mm | 503 |

| 18 mm | 52 mm | 25 mm | 505 |

| 19 mm | 47 mm | 17 mm | 603 |

| 14 mm | 40 mm | 17 mm | 703 |

| 15.5 mm | 47 mm | 17 mm | 803 |

This is a table of rolling bearings, one of many tables describing this type of structural element.

Plain bearings

| International designation | Russian designation (GOST) | Dimensions (mm) | Load capacity (kN) | Weight (kg) | ||||

| d | Fw | D | B | Dynamic | Static | |||

| RNA 4010V | 4024110 | 62 | 62 | 80 | 30 | 59,6 | 153 | 0,44 |

| RNA 4911 | 4254911 | 63 | 63 | 80 | 25 | 57,2 | 106 | 0,26 |

| RNA 6911 | 6254911 | 63 | 63 | 80 | 45 | 89,7 | 190 | 0,47 |

Thrust-radial roller

| International designation | GOST | Dimensions (mm) | Weight (g) | ||||

| d | D | de | De | Bx | |||

| AXK 2035 | 999904 | 20 | 35 | 22 | 34 | 2 | 5 |

| AXK 2542 | 999905 | 25 | 42 | 29 | 41 | 2 | 7 |

| AXK 3047 | 219806 | 30 | 47 | 34 | 46 | 2 | 8 |

Table fields

They display the names of the main parameters and their geometric dimensions.

ISO marking

It is standard for most countries of the world, which indicates the number and design features.

GOST

It is a Russian analogue and performs the same functions.

Node internal diameter

It is measured in millimeters (mm) and is designated by the English letter d.

Outside diameter

Denoted as D.

Width

Measured in mm and identified by a capital B.

Weight

The measure is in kilograms (kg).

Scheme

Explains the basic structure.

How to determine ball bearing sizes using tables

Many machines that exist today have bearings that allow them to rotate. Therefore, no rotating movement can be carried out without them. But even such a seemingly irreplaceable, but at the same time inconspicuous part of the mechanism can be different in size and in its technical characteristics, especially taking into account the diameter, the dimensions of which are usually presented in the table. But whatever this part is, no matter how it looks and whatever its technical characteristics, it should perform only one task - to provide the part with rotation or the necessary rotation.

Product sizing

In everyday life or production, these parameters are measured with certain tools: calipers, micrometers, bore gauges.

External Diameter Measurement

Manufacturing parameters are maintained quite accurately. Therefore, you should not trust the readings of a caliper. If it shows a non-standard value, then the real data will be the closest indicators indicated in the register.