What is a part?

This mechanism reduces friction when the axle rotates in the eye. Similar devices have been used by mankind since Neolithic times, when people first used fat to lubricate axles. An example of this is the potter's wheel. During construction and irrigation, the Egyptians widely used all types of blocks and lubricated all rotating parts with oil and water. Later they began to use tar, graphite, and wax to lubricate wheel axles.

Modern parts are completely different high-tech products.

In the article you can find general information about the sliding bearing and see a photo of what the mechanism looks like.

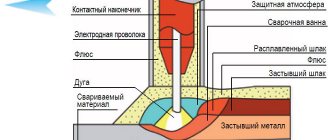

The classic device consists of two bushings tightly fitted to each other with a high degree of surface treatment. To slide between the planes, a lubricant is added, or one of the elements is made of a slippery substance, for example, graphite or fluoroplastic.

Rolling bearings: purpose

The advantages of devices of this design are primarily:

- low friction coefficient;

- low sensitivity to lubricant quality;

- cheapness.

The disadvantages of rolling bearings are primarily considered to be weak resistance to shock loads and the inability to operate at ultra-high speeds. Also, the disadvantages of devices of this type include restrictions on use in polluted environments.

A very wide range of applications is what certainly sets these bearings apart. Standards in their manufacture are strictly observed and they are recommended to be used wherever possible. At the moment, this type of device is the most popular and widespread.

The main purpose of rolling bearings, like sliding bearings, is to reduce friction between moving parts of a mechanism. Thus, they can be used in automotive and agricultural engineering, in the production of household appliances, and in the metallurgical industry. Very often, such devices are used in the manufacture of processing equipment. Rolling bearings are also indispensable in aircraft construction and even in the space industry.

Classification and types of plain bearings

At enterprises, three types of units are manufactured, based on the material of manufacture; sizes of bushings, rings; types of inserts; design features:

- linear with a cylindrical rod. This is a support that acts in a rectilinear direction and ensures operation with large movements and significant loads;

- spherical. It starts the friction process at low speed and allows a slight misalignment in the axis. It is mainly used in products with oscillatory motion (rolling).

- persistent. A support with such a bearing is also called a thrust bearing. It is used in machines where a certain rigidity is initially set (steam engine, turbine).

Classification of rolling bearings

Devices of this type have a very simple design. They usually consist of two rings, between which there are rolling elements. The latter are held inside the bearing using a special separator.

Rolling devices can be classified according to the following criteria:

- direction of the perceived load - axial, radial, radial thrust;

- type of rolling bodies - balls, rollers;

- arrangement of rolling elements - one-, two- or four-row;

- the shape of the central hole - conical, cylindrical.

There are also types of rolling bearings, such as conventional and self-aligning, as well as double and simple.

Lubricant for replacement parts of plain bearings

A certain type of product requires its own lubricating fluid, which ensures the operation of the entire assembly and is responsible for the reliability and reliability of the entire support.

The material is selected according to the compatibility of non-ferrous metals and their alloys from which the liners and bushings are made. It is also very important to take into account the parameters of dynamic and statistical loads on supports. An incorrectly selected fluid can simply change its structure (become liquid, which leads to leakage of the unit) or it can be pushed out of place due to friction.

There are several types of lubricant:

- Liquid. It may be based on synthetic or mineral oil or silicone. In ceramic structures, water can play the role of a lubricant.

- Hard (graphite).

- Gaseous.

- Consistent (plastic) - litol, grease, cyatim.

How to choose a lubricant

It is very important to choose the right lubricant. After all, the reliability and durability of the mechanism depends on this. It should protect the metal from corrosion, from contamination and soften the load upon impact. Then the product will be able to work stably in critical non-standard situations.

Almost 35 percent of cars break down due to incorrect fluid selection.

It is necessary to strictly follow the technical characteristics of this unit, make calculations based on speed, load, temperature fluctuations, and part dimensions.

When choosing a lubricant, the following requirements must be taken into account:

- In what climatic conditions will the work be carried out?

- What load will the support unit bear?

- Will this part come into contact with food?

- Minimum and maximum operating temperature. At high loads and high speeds, the surfaces heat up, which leads to a violation of the properties of the sliding layer. Extremely low values (in the far north) also have a negative effect.

We provide a table that will tell you how to lubricate the plain bearing.

Symbols for greases

| Grease brand designation code | Lubricant grade | Grease designation code | Lubricant grade |

| — | CIATIM-201 | C18 | VNIINP-233 |

| C1 | OKB-122-7 | S20 | VNIINP-274 |

| C2 | CIATIM-221 | S21 | ERA |

| C3 | VNIINP-210 | S22 | SVEM |

| C4 | CIATIM-221S | S23 | CV joint-4 |

| C5 | CIATIM-202 | S24 | SEDA |

| C6 | PFMS-4S | S25 | INDA |

| C7 | VNIINP-221 | S26 | LSD-3 |

| C8 | VNIINP-235 | S27 | FANOL |

| C9 | LZ-31 | S28 | CHEVRON SRI-2 |

| C10 | №158 | S29 | ROBOTEMP |

| C11 | SIOL | C30 | UNOLA |

| C12 | VNIINP-260 | C31 | LITIN-2 |

| C13 | VNIINP-281 | C32 | No. 158M |

| C14 | FIOL-2U | C33 | FIOL-2MR |

| C15 | VNIINP-207 | C34 | CV joint-4M |

| C16 | VNIINP-246 | S35 | BERUTOX FE 18 EP |

| C17 | LITOL-24 | C36 | VN-14 |

What are the types and types of bearings?

All assemblies can be classified according to their operating principle. Two main groups are devices that provide rocking and sliding. They are the ones most often used in mechanical engineering. The first can be represented by ball and roller devices.

Magnetic structures deserve special attention. The principle of their operation is different from the others, and they are used less often. In addition, due to their functional features, they must be accompanied by spare units.

Bearings are parts that help to obtain maximum efficiency from a machine, maintaining its performance without special repairs and maintenance.

Sliding supports

This group of parts allows you to slide freely when two contacting surfaces rub against each other. In this case, various lubricants are used - oils, water, chemicals, graphite and some gases. Structurally, such devices can be either integral or collapsible. Manufactured complete with bushing and connecting part.

Devices by rolling type

Such units are made in the form of two rings, bodies that provide a rocking effect, and a separator. They are manufactured in accordance with established standards, which allows them to be used in most cars, complex equipment and aircraft.

Ball bearings

Functionally, they are part of a group of node parts that operate on the rolling principle. Ball bodies are located on the surface of the outer rings of the parts. During operation, they create a small friction moment, which means they practically do not limit the rotation speed.

Sliding or rolling bearings: what is the difference and what is better

Products that involve turning are equipped with parts for rolling or sliding, depending on what force will be applied to them and what impulse will be supplied.

The principle of a rolling bearing device looks like this. It consists of two rings, between which there is a special hollowed-out path. It is filled with elements that will be constantly in motion. These components mainly consist of metal balls of different diameters. An alternative solution is other shapes, such as needles and a cylinder.

Sliding and rolling bearings are difficult to repair and restore defects, since in most cases they are non-removable; their calculation and assembly is the work of professional turners, because the gap between the bushing and the axle is minimal. So that you do not have to frequently replace them with new ones, keep the parts in proper condition, namely, monitor the condition of the lubricant, and store them at positive temperatures indoors.

It is impossible to determine which bearings are better. Since their scope of use is different. Some are better used at high speeds and significant voltage, while others cope more effectively with low speeds. In this case, the dimensions of the bushings, inner and outer rings, and the diameter of the rotating elements (balls, rollers, needles, cylinders) should be taken into account. When choosing the right model, engineers always rely on regulations (SNIP, SanPiN and GOST).

In our article, we described in detail what types of sliding bearings there are, performance criteria and their storage using lubricants. We recommend that you order support units in the Mobi Bearing online store - a large assortment and high-quality parts.

How does a bearing work?

Different types and types of bearings are determined by the method of functional torque transmission device. This is where the classification of bearing products begins. Sliding bearings operate on the principle of minimal friction on the contact surfaces of the inner and outer rings. In rolling bearings, rolling bodies—balls or rollers—roll between the rings.

How does a plain bearing work?

A plain bearing, by and large, operates on the principle of a rotating bushing. The design of such a bearing is based on two steel rings, the third element is a liner made of antifriction material, which provides the necessary sliding properties. The mating contact surfaces form contact pairs with different characteristics. The spherical contact surface allows the plain bearing to guide the shaft with significant misalignment and angle relative to the housing. Resistance to strong vibration, shock and high radial-axial loads make spherical plain bearings indispensable in units of a certain design in transport and industry.

How do ball bearings work?

Rolling ball bearings create minimal friction due to point contact. To hold and guide the balls, they are held together with a separator, and tracks are made on the rings. The depth of the tracks, their placement relative to each other, determines the ability to absorb axial load and what functional type the bearing belongs to: radial or angular contact. If the tracks are located opposite each other without displacement, then it is a radial bearing that can handle fast and very fast rotation without axial load. If the tracks are offset at an angle of 10-40 degrees, then the bearing is angular contact and is designed for rapid rotation with a one-sided axial load. Double-row rolling bearings accept rotation in both directions and have a high load capacity. Bearings with a common outer spherical raceway are capable of self-aligning under the influence of centrifugal force and compensating for shaft deviations of 1-3 degrees.

How does a roller bearing work?

A roller bearing is designed similarly to a ball bearing, but has roller rolling elements. Rollers of cylindrical, spherical, conical, spheroconic shape form linear contact with the raceways, due to which, in addition to high rotation speed, they withstand high static loads. Cylindrical roller bearings are designed for high radial loads. Spherical rollers are installed in radial self-aligning models. Angular contact and radial thrust bearings with tapered rollers carry high axial one-sided loads. Spheroconic rollers allow self-alignment under high axial and radial loads.

How does a thrust bearing work?

Thrust bearings are installed in vertical rotation bearings to support high axial loads during slow rotation. Ball or roller bodies are placed horizontally in them. Single thrust bearings are designed to rotate in one direction, and double (double-row) bearings - in both directions. Thrust bearings with cylindrical and needle rollers are the most compact in cross-sectional height and can be made without rings.

Roller bearings and their varieties

In their structure, these supports are similar to the previous type, but instead of balls, a body shaped like a roller is used here. This way the device can take on a heavier load.

Description

The design is designed in such a way that it shows resistance to radial pressure, but at the same time the speed of the roller along the track is in no way inferior to ball bearings. The only thing you should pay attention to is the axial load. To make the device more resistant to it, the rolling element is replaced with a conical one.

This type is classified according to the body used. Separately distinguished:

- • Cylindrical.

- • Conical.

- • Needle-shaped.

- • Spherical.

Application

Roller bearings are often used in pumps, high-power gearboxes, the railway industry and the automotive industry. All types of roller bearings are presented in pictures on the website mirpl.ru.