Operating principle of the ejector

The deeper the well, the more difficult it is to draw water from it. Therefore, a pump is used to move fluid through the pipeline. However, with a well depth of more than 7 meters, a conventional such device will not be enough. In this case, you can purchase a more powerful submersible device or supplement the system with an ejector, which will completely solve this problem.

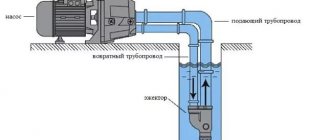

The principle of operation of the ejector can be understood by studying the illustration presented.

An ejector pump is a device that moves the energy of one medium to another. Its operating principle is based on increasing the water pressure in the pipeline due to the rapid movement of liquid along a special branch.

This operating principle allows you to increase the capacity of an existing surface pumping station. Thanks to this, it is possible to extract water from a well up to 40 meters deep. To better understand how this device works, it is necessary to monitor its operation.

Operating principle of the ejector pump:

- Water flows through the nozzle into the ejector. In this case, the cross-sectional diameter of the nozzle is less than the diameter of the entrance to the ejector system.

- By passing through a narrow nozzle into a chamber with a larger diameter, the liquid is significantly accelerated. Thus, its pressure increases. An area of lower pressure is formed in the mixer chamber.

- Thanks to the rarefied atmosphere, liquid, which is under higher pressure, begins to be sucked into the chamber at tremendous speed.

This device is very useful for deep wells. After all, it allows you to quickly pump out water from the deepest holes.

The process of creating a BIM model can be schematically depicted using the following algorithm:

creation request (Customer);

formation of technical specifications, EIR;

formation by the contractor of a BEP project implementation plan;

pre-design, equipment layout;

design work;

design work;

approval, agreement;

development of working documentation;

transfer of the model to construction;

updating the model during the life cycle;

archiving.

Information entering the BIM model, stored and processed in this model, and obtained from it for further use is shown in the figure below:

The development and development of the model is carried out in a common data environment (CDE), which means that all interested parties have constant access to a model filled with useful and relevant information: engineering, chronological, financial, and so on:

Delegation of access levels for different circles of persons participating in the interaction process when creating an object ensures the clarity and relevance of the received data for each task. Thus, BIM covers all stages of the life cycle of a building or structure, continuously filling it with valuable information, which, in turn, significantly reduces the cost of its maintenance (OPEX), reduces the speed of construction, minimizes design errors, and allows all interested parties to have prompt access to information .

Types of ejector pumps

An ejection pump is a useful thing on the farm, especially if there are deep wells on the site. To make it convenient to use them, you need to choose the pumping equipment option that suits you.

Ejectors have a fairly simple design. That is why they are easy to make with your own hands.

There are several types of ejector pumps, they are divided according to their operating principle and design:

- A steam ejector pump pumps out gaseous media from confined spaces. Thanks to this, a rarefied environment is maintained. Such ejectors are used quite often.

- A jet steam ejector sucks gases or water out of a confined space using the energy of steam jets. In this case, jets of steam exit the nozzle and force water to move, which exits the annular channel through the nozzle.

- A gas (or air) ejector compresses gases that are already in a rarefied environment using highly directed gases. This process occurs in a mixer, from which water flows into a diffuser, where it is slowed down and the voltage increases.

Ejector pumps have excellent performance properties.

Ejectors also differ in their location of installation:

- The built-in water ejector is installed inside or next to the pump. Thanks to this arrangement, the device takes up minimal space and is not afraid of dirt. In addition, such devices do not require the installation of additional filters. They are used for wells whose depth is no more than 10 meters. In addition, built-in ejectors make a lot of noise during operation and require a powerful pump.

- The device, which is called remote (or external), can be installed at a certain distance from the pump, but not more than 5 meters. They are often placed in the well itself.

All types of ejectors are suitable for use in a private home. They help to quickly pump water out of a well, despite its depth.

How the device works and how it works

The device uses Bernoulli's principle, from which it follows that an increase in the speed of fluid movement provokes the formation of a low-pressure area in close proximity to the flow (in other words, a rarefaction effect occurs). The ejector design includes:

The liquid medium, moving through the nozzle, picks up a very high speed at its exit. The resulting vacuum provokes the flow of water from the suction chamber. The pressure of this portion of liquid is much greater. Having mixed inside the diffuser, the water begins to move through the pipeline in a common flow. Strictly speaking, the principle of operation of an ejector pump is the exchange of kinetic energy between flows that have different speeds (not to be confused with an injector, which acts exactly the opposite).

There are steam and steam jet ejection pumps. Vacuum-type steam apparatus maintain a vacuum by pumping gas out of a confined space. Most often, such devices are used to supply water.

Steam jet pumps operate by air ejection. Here, the energy of the jet is used, which arises in the process of pumping out an aqueous, vaporous or gaseous medium. Most often, river and sea vessels are equipped with steam jet pumps.

DIY making

It is quite possible to make ejectors with your own hands. Of course, such work requires a certain responsibility and care, but it is still quite doable.

The vacuum pump is especially popular. The drawings and diagram of such a device are extremely clear.

The ejector, of course, can be easily purchased ready-made. However, if you want to save a lot, it is better to do it yourself.

Making an ejector with your own hands:

- It is necessary to take the tee and attach the fitting to it so that the fitting pipe fits inside the tee and does not protrude from it. If the pipe is too long or short, this can be corrected. In the first case, it can be ground off, and in the second, a polymer tube can be extended.

- Now you need to work with the part that will be connected to the pump. To do this, an adapter is screwed at the top of the tee.

- At the bottom of the tee, in the part where the fitting is located, a bend in the shape of an angle is screwed on. It will connect to the recirculation part of the ejector.

- An angle-type adapter is also screwed into the side of the tee. It is attached to the pipe using a collet clamp.

All connections must be sealed with special tape.

Installation rules and first launch

After you assemble the ejector, it must be installed correctly. If you follow the instructions, it will be easy to do. After all, the product itself has a very simple design. There are three outputs on the ejector. Each of these outputs must have its own pipe connected.

First of all, the pipe is attached to the outlet that will draw water from the well. It is located on the side of the device. A filter and check valve are mounted at the end of such a pipe. The pipe used for sampling should be long, but it does not need to reach the very bottom of the well.

A pipe with a narrowed fitting is connected to the bottom of the ejector. This is the main line for water circulation. The second end of the pipe is connected to the container. Water will be drawn from it to create a reverse flow. A third pipe is connected to the top of the ejector. The other end is mounted on the pump.

How to start the station for the first time:

- Pour water into the ejector hole and turn off the valve that allows water to move from the pump through the water supply.

- Next, you need to turn off the pump for half a minute and then turn it on. Open the tap and release some of the air from the system.

- Repeat these steps until the water line fills the pipes with water.

- Turn on the pump, wait until the system is filled with water, and the pump will automatically turn off. Open the tap and wait until the pipes are empty and the pump turns on again.

If water does not flow, the system is not assembled correctly. In this case, you will have to find the problem and fix it. That is why the first launch must be carried out in the described way.

An ejector is needed for those who live in a private house and have a very deep well. Such a system will allow you to use a not very powerful pump as efficiently as possible.

A deep aquifer is a common problem that is well known to many land owners. Conventional surface pumping equipment either cannot provide the house with water at all, or supplies it to the system too slowly and with low pressure.

This problem needs to be resolved as soon as possible. Agree, buying a new pump is an expensive undertaking and not always financially justified. A solution to this situation can be an ejector for a water supply pumping station.

We will tell you how to choose a suitable unit and install it without the help of specialists. We will also provide step-by-step instructions on how to make and connect a homemade ejector. All stages of work are accompanied by visual photographs.

Recommendations for maintaining and increasing device performance

Before installing the ejector pump, it is necessary to make the appropriate calculations. Its power must correspond to the depth of the well.

The pressure in the system is constantly monitored. If the station does not have a built-in pressure gauge, it should be installed. It is recommended to equip very deep wells with powerful equipment installed as close as possible to the water intake point. As a rule, such pumps have built-in ejectors.

If the depth of the well is between 15-40 m, it is advisable to use a remote ejector immersed in water.

The surface pump and the ejector are connected only by a vertical pipeline. Otherwise, the system will regularly become airborne, which will cause a decrease in its performance.

If you follow all the rules for installation and use, pumping equipment with an ejector will ensure a high-quality water supply, satisfying all the necessary needs both in the house itself and on the site.

A pumping station with an ejector is part of a water supply system that operates in autonomous mode. The principle of operation of the ejector is that it regulates the water pressure in the pipe. In this case, water moves from the well to the surface - to the consumer.

The problem of low water pressure can be solved by installing an ejector for a pumping station

All design elements are responsible for the energy efficiency of such a station. At the same time, water supply from a depth of 10 m or more is provided only by an ejector pump. Without this device, the station pumps water only from a well, the depth of which is a maximum of 7 m.

Operating principle of the ejector

The deeper the water is, the more difficult it is to bring it to the surface. In practice, if the well depth is more than seven meters, the surface pump has difficulty coping with its tasks.

Of course, for very deep wells it is more appropriate to purchase a high-performance submersible pump. But with the help of an ejector, it is possible to improve the performance of a surface pump to an acceptable level and at significantly lower cost.

The ejector is a small but very effective device. This unit has a relatively simple design; you can even make it yourself from scrap materials. The operating principle is based on giving the water flow additional acceleration, which will increase the amount of water coming from the source per unit of time.

This solution is especially convenient for those who are going to install or have already installed a pumping station with a surface pump. The ejector will allow you to increase the depth of water intake to 20-40 meters.

It should also be noted that the purchase of more powerful pumping equipment will lead to a noticeable increase in energy consumption. In this sense, the ejector will bring noticeable benefits.

The ejector for a surface pump consists of the following elements:

- suction chamber;

- mixing unit;

- diffuser;

- narrowed nozzle.

The operation of the device is based on Bernoulli's principle. It states that if the speed of a flow increases, an area of low pressure is created around it. In this way, a rarefaction effect is achieved. Water enters through a nozzle, the diameter of which is smaller than the size of the rest of the structure.

A slight narrowing gives the water flow a noticeable acceleration. Water enters the mixer chamber, creating an area of reduced pressure inside it. Under the influence of this process, a stream of water under higher pressure enters the mixer through the suction chamber.

Water enters the ejector not from the well, but from the pump. Those. The ejector must be installed in such a way that part of the water raised by the pump returns to the ejector through the nozzle. The kinetic energy of this accelerated flow will be constantly transferred to the mass of water that is absorbed from the source.

This will ensure constant acceleration of the flow. Pumping equipment will require less energy to transport water to the surface. As a result, its efficiency will increase, as will the depth from which water can be drawn.

Part of the water extracted in this way is again sent through the recirculation pipe to the ejector, and the rest enters the water supply system of the house. The presence of an ejector has another “plus”. It sucks up water on its own, which additionally protects the pump from running idle, i.e. from the “dry running” situation, which is dangerous for all surface pumps.

To regulate the operation of the ejector, use a regular tap. It is installed on a recirculation pipe, through which water from the pump is directed to the ejector nozzle. Using a tap, the amount of water entering the ejector can be reduced or increased, thereby reducing or increasing the rate of return flow.

Ejector cooling systems

The main advantage of ejector cooling systems is their ability to produce cold using waste thermal energy with a temperature above 80°C obtained from various thermal sources.

In order to clearly understand the principle of operation of the equipment where the ejector is introduced, let’s analyze the classic scheme for producing cold. Such schemes are not widespread, but they are widespread and are used in a variety of areas of the national economy.

Structural action diagram: E - ejector; B - boiler (boiler); K - capacitor; I - evaporator; N - circulation pump; P - expansion device

The ejector cooling system consists of two circuits:

In the feed loop, low temperature heat (Qb) is used in a boiler or generator to evaporate high pressure liquid refrigerant (process 1-2).

High-pressure vapors resulting from the boiling of the liquid refrigerant rush through the ejector, where the flow speed is increased by passing through the nozzle.

The accelerated movement of the flow forms an area of low pressure in the first section of the ejector. Due to the pressure difference, saturated gaseous refrigerant rushes there from the evaporator (line 3).

The two gaseous media are combined in a mixing chamber. The mixed medium enters the diffuser section, where the flow slows down and pressure is restored.

The mixed refrigerant gas is then sent to the condenser. Here, the refrigerant vapor condenses (turns into a liquid state), and the resulting heat is removed to the environment (Qc).

One part of the liquid leaving the condenser (point 5) is pumped into the boiler to complete the power cycle. The other part of the liquid passes through the expansion device and enters the evaporator of the refrigeration circuit (point 6) in the form of a vapor-liquid mixture.

The vapor-liquid mixture of the refrigerant evaporates in the evaporator, creating an additional cooling effect (Qe). Next, the resulting vapor refrigerant is sent to the ejector (point 3).

The refrigerant (secondary gaseous mixture) is again mixed with the primary gaseous mixture in the ejector and compressed in the diffuser section before entering the condenser (point 4). The mixture is condensed in a condenser. The cycle repeats (point 5).

Choice: built-in or external?

Depending on the installation location, there are remote and built-in ejectors. There is no big difference in the design features of these devices, but the location of the ejector still affects in some way both the installation of the pumping station and its operation.

So, built-in ejectors are usually placed inside the pump housing or in close proximity to it. As a result, the ejector takes up minimal space and does not have to be installed separately; it is enough to carry out the usual installation of the pumping station or the pump itself.

In addition, the ejector located in the housing is reliably protected from contamination. Vacuum and reverse water intake are carried out directly in the pump housing. There is no need to install additional filters to protect the ejector from clogging with sludge particles or sand.

However, it should be remembered that this model demonstrates maximum efficiency at shallow depths, up to 10 meters. Pumps with a built-in ejector are designed for such relatively shallow sources; their advantage is that they provide excellent incoming water pressure.

As a result, these characteristics are sufficient to use water not only for domestic needs, but also for irrigation or other economic operations. Another problem is the increased noise level, since the vibration of the operating pump is added to the sound effect of water passing through the ejector.

If you decide to install a pump with a built-in ejector, you will have to take special care of sound insulation. It is recommended to install pumps or pumping stations with a built-in ejector outside the house, for example, in a separate building or in a well caisson.

The electric motor for a pump with an ejector must be more powerful than for a similar model without an ejector.

An external or external ejector is installed at a certain distance from the pump, and this distance can be quite significant: 20-40 meters, some experts even consider 50 meters acceptable. Thus, a remote ejector can be placed directly in a water source, for example, in a well.

Of course, the noise from the operation of an ejector installed deep underground will no longer disturb the residents of the house. However, this type of device must be connected to the system using a recirculation pipe through which the water will return to the ejector.

The greater the installation depth of the device, the longer the pipe will have to be lowered into the well or well.

It is better to provide for the presence of another pipe in the well at the design stage of the device. Connecting a remote ejector also involves installing a separate storage tank from which water will be drawn for recirculation.

Such a tank allows you to reduce the load on the surface pump, saving some energy. It is worth noting that the operating efficiency of the external ejector is somewhat lower than that of models built into the pump, however, the ability to significantly increase the intake depth makes one come to terms with this drawback.

When using an external ejector, there is no need to place the pumping station directly near the water source. It can be installed in the basement of a residential building. The distance to the source can vary within 20-40 meters; this will not affect the performance of the pumping equipment.

Main types of ejectors

Depending on the installation, ejectors may be different. They are usually divided into two main types: built-in and remote. The difference between these types is small, that is, they differ only in the installation location, however, this small difference may affect the operation of the pumping station . Both types have their own advantages and disadvantages .

Built-in, as you might guess from the name, is mounted directly into the pump housing, being its integral part.

Built-in model

The built-in ejector has its advantages:

Among the disadvantages, we can note only low efficiency at great depths exceeding 10 meters. However, the main purpose of built-in models is to use them for pumping water from shallow depths. And one more nuance in defense of built-in devices: they provide powerful and uninterrupted water pressure . Therefore, they are often used for irrigation and other household needs.

Device installation features

As already mentioned, installing an ejector built into the pump does not cause any particular problems, since the device is already located in the device body. The surface pump is simply connected to the water supply hose on one side, and also to the water supply system on the other side.

If it is used as part of a pumping station, then the pump is connected to the hydraulic accumulator through a special fitting with five outputs. In addition, the pump will need to be connected to the contacts of the pressure switch to ensure that it turns on and off automatically.

Before turning on the surface pump, it must be filled with water through the filling hole provided for this purpose. You cannot turn on such equipment without water, it may burn. If the pump is installed correctly, the ejector will operate without interruption.

But the installation of a remote ejector is carried out according to a more complex scheme. First, you will need to install a pipe that will ensure the return flow of water from the storage tank to the ejector. A check valve is installed on the suction section of the ejector. A mesh filter should be placed behind it to protect the device from clogging.

An adjustment valve must be installed on top of the recirculation pipe to regulate the amount of water that is directed to the ejector. This unit is not mandatory, but can significantly improve the situation with water pressure in the house.

The less water is returned to the ejector, the more of it will be left for the home's plumbing system.

This way you can influence the water pressure in the water supply. If it is insufficient, you should slightly tighten the adjusting valve on the return line.

If the pressure is too high and creates unnecessary stress on the plumbing system, it makes sense to direct more water to the ejector in order to increase the efficiency of the pumping equipment.

Some industrial models of ejectors are already equipped with such an adjustment system. The instructions that come with the device usually describe in detail how to configure the ejector.

Using a homemade external option

A built-in ejector is usually purchased at the same time as a pump, but the external model is often made by hand.

It will be useful to consider the creation process and the procedure for connecting such a device. In order to make an ejector, you will need such parts as a tee with internal threaded connections, fittings, fittings, bends, couplings, etc.

Personal assembly of the ejector

Assemble the device as follows:

- Connect the lower part of the tee to the fitting so that the outlet pipe is at the top, and the fitting with a smaller diameter is inside the ejector.

- Then you need to modify the design by cutting off the narrow part of the fitting if it protrudes from the tee.

- If the fitting is too short, it is extended using a polymer tube.

- An adapter with an external thread is screwed onto the top side of the tee.

- A PVC water pipe is connected to the other end of the adapter using a fitting.

- Now, a bend in the form of an angle should be attached to the lower side of the tee, into which a narrow fitting is already inserted.

- A pipe is connected to this outlet, through which the reverse flow of water will flow to the ejector.

- Another corner is attached to the side pipe of the tee.

- A pipe is attached to this corner using a collet clamp; water will be sucked through it from a well, well, etc.

The distance between the edge of the tee and the fitting should be approximately 2-3 mm. This will ensure the creation of a vacuum region with the necessary characteristics. To secure the recirculation pipe, use a crimp nut.

It turns out that two elements are simultaneously attached to the internal thread of the lower branch pipe of the tee. One of them (fitting) is located inside the tee, and the second (angle) is outside. In order for both of them to fit on one threaded connection, part of the thread of the fitting should be cut off.

Of course, all threaded connections must be sealed and sealed. Most often, FUM tape is used for this. Sometimes, to connect the ejector to the pumping station, not metal-plastic pipes are used, but polyethylene structures.

To install them, you should use special crimping elements, and collet clamps, which are good for metal-plastic, are not suitable in this situation.

Pipe connection procedure

You should think in advance about which pipes the remote ejector will be connected to. Polyethylene structures bend well when heated, which makes it possible to do without corners when connecting the ejector. The pipe is simply bent in a suitable place and at the desired angle, and then attached to the ejector.

So, the device has three outputs, to each of which a corresponding pipe should be connected. First, a pipe is usually installed through which water will be drawn from the source. It connects to the side outlet of the ejector.

A check valve must be installed at the end of this pipe, as well as a strainer. This pipe must be long enough to reach deep into the water. But you should not take water from the very bottom of the source, as this can lead to clogging of the ejector, even despite the presence of a filter.

You can then attach the pipe to the lower end of the ejector, which has a tapered fitting. This is the pipeline through which water is recycled. The second end of this pipe should be connected to a container from which water will be drawn to create a return flow.

The third pipe is a regular water main. One end of it is mounted on the upper pipe of the ejector, and the other is connected to the surface pump. It should be remembered that the diameter of the pipe through which water is drawn from the source must exceed the size of the pipe through which water is supplied to the ejector.

If an inch pipe is used for supply, then it is recommended to use a quarter-inch larger pipe for suction. After all connections are made, the ejector is lowered into the water.

Before starting the system for the first time, it must be filled with water. The pump is primed through a special hole. The pipes leading to the ejector must also be filled with water.

Initial launch and further operation

It is recommended to perform the initial start-up of the pumping station according to the following scheme:

- Pour water into the pump through the special hole.

- Turn off the tap through which water flows from the pumping station to the water supply system.

- Turn on the pump for about 10-20 seconds and turn it off immediately.

- Open the tap and bleed some of the air from the system.

- Repeat the cycle of short-term pump on/off in combination with bleeding air until the pipes are filled with water.

- Turn on the pump again.

- Wait until the accumulator is filled and the pump automatically turns off.

- Open any water tap.

- Wait until the water flows out of the accumulator and the pump turns on automatically.

If water does not flow when starting up a system with an ejector, it is possible that air is somehow leaking into the pipes, or the initial filling with water was not performed correctly. It makes sense to check the presence and condition of the check valve. If it is not there, the water will simply pour into the well, and the pipes will remain empty.

These points should also be taken into account when using a pumping station with an ejector, which is started after long-term storage. It is best to check the check valve, the integrity of the pipes and the tightness of the connections immediately.

If everything is in order, but water does not flow, you need to check the voltage supplied to the pumping station. If it is too low, the pump simply cannot operate at full capacity. You should establish a normal power supply to the equipment, and the problem will disappear.

If an ejector is needed to improve the water pressure in the system, and not to increase the depth of water intake, you can use the homemade ejector model described above.

But it does not need to be immersed in water; it can be placed in a convenient place near the surface pump. In this case, the ejector will work approximately the same as the built-in industrial production model.

Conclusions and useful video on the topic

This video discusses in detail the issue of the suction depth of a surface pump and options for solving the problem using an ejector:

The principle of operation of the ejector is clearly demonstrated here:

An ejector is a simple but very useful device. This is a convenient and practical way to improve the performance of pumping equipment in a private home. But the installation of the ejector, especially the remote model, must be done correctly; this is the only way to ensure a noticeable increase in water pressure.

We invite everyone interested in the issue of choosing and connecting an ejector to join the discussions and leave comments on the article. The comment form is below.

What is an ejector

An ejector is a special device that is installed on hydraulic equipment if it is used to service a deep source of water supply. With the help of an ejector, the energy with which one medium moves is immediately transferred to another medium.

Almost any liquid from a source that is very deep is very difficult to bring to the surface. Surface pumps are not used to service such sources. Using an ejector, you can greatly increase the productivity of surface pumping hydraulic equipment.

Homemade ejector for a pumping station.

Hello, dear readers of “San Samych”.

Today, at your request, I will tell you how to assemble a simple ejector for a pumping station on your own in order to provide additional meters of water lifting from the well and to protect the operation of the pumping station from possible dry running in the event that the water level in the well suddenly drops. I wrote earlier about the connection diagram for such an ejector. The same article shows a sketch of this ejector. But how exactly to do it turned out to be unclear to many.

Let me make a reservation right away that in the process of writing this article I did not make this ejector. I don’t need it at the moment, but I can do it at any time, spending an hour and a half on it.

And yet I will start a little from afar so that there are as few questions as possible.

Names and symbols.

Having visited my wife’s parents in the Ulyanovsk region, I was surprised to find that salespeople in plumbing stores do not always understand what I am asking them for, although I did not experience such problems in St. Petersburg. Therefore, I would really like you and I to speak the same language and understand each other, especially in terms of names and designations related to plumbing.

In plumbing, it is customary to designate parts and threads on them with symbols, which, however, are understandable to anyone who speaks and writes in Russian.

The size or diameter of the thread is most often indicated in inches: ½, ¾, 1½. This also indicates that the threads on the parts are not metric, but conical - pipe. The letters next to the thread designation indicate which thread it is: internal ( B ) or external ( H ).