Identification or confirmation of properties and characteristics are of great importance for enterprises in all industries producing products from steel, cast iron, non-ferrous metals, and their alloys. This is a guarantee that products or components for them are made of material that complies with national and international norms and standards.

Durability, reliability, environmental safety, trouble-free operation in extreme conditions, under high loads, in aggressive environments. These properties often require additional mechanical tests of the metal and other checks with documentary evidence.

Examination of failed metal parts and assemblies, construction and pipe products, and other products for compliance with the declared brand makes it possible to identify unscrupulous suppliers. Avoid equipment and machine failures in the future.

Checking and monitoring of metals for compliance with parameters is carried out according to the methods set out in standards and norms. They are carried out by accredited enterprises, including LITs LLC. The laboratory is fully equipped for research (including non-destructive research) as well as for analysis of metals and alloys of any composition.

Quality and strength of welded joints

Checking seams is a mandatory condition for the manufacture of any product whose parts or components are connected by welding.

Particular attention is paid to critical objects: technological equipment, pressure tanks, metal structures of public facilities, transport infrastructure.

Produced using non-destructive or destructive methods. Portable equipment allows non-destructive inspections to be carried out directly on the construction site. Both the metal itself and the welding materials are subject to examination.

Technical control with destruction

This test method is used to check the quality of metals and products made from them. The maximum load on the part is created in the flesh before its destruction in order to determine how much time and what force will be required until the moment after which the part collapses.

Destructive testing methods of metals are carried out with the implementation of a static or dynamic load on the product. Subsequently, the documentation includes information about the types of load and time spent, as well as the nature of metal destruction as a result of control operations.

Dynamic loads allow testing:

- for metal fatigue;

- to determine the hardness and viscosity of a material;

- for wear and tear of metal products.

Among the destructive methods of testing metal products for the required parameters:

- tensile;

- for compression;

- shock resistance;

- for repeated-variable exposure;

- for hardness (Vickers).

Destructive methods are carried out as control methods - checking the first created parts from a batch for compliance with specified characteristics, testing alloys and other materials received for the first time for the production of metal products.

Determination of the chemical composition of a metal

Determination of the chemical composition of the metal is necessary to determine the grade of the material provided for research. The actual properties of steels, cast irons and non-ferrous metal alloys, the regulatory requirements imposed on them and test methods depend on the grade. Speaking about the research to establish the actual grade of steel or alloy, it should be noted that determining the grade in itself does not answer the question about the reasons for the destruction or deformation of a metal product, which is necessary in 90% of cases of forensic metallurgical examination. The determination of the grade of steel or alloy itself, without other additional research (which will be discussed below), may be required only if the buyer of metal products doubts that he is purchasing metal products from exactly the material that is stated in the quality certificate or that is provided for by the terms of the supply agreement . In all other cases, the results of determining the chemical composition of a steel grade, cast iron or alloy are only initial data, based on which experts determine which methods and what kind of research should be carried out additionally. It is possible to draw a full conclusion about the causes of destruction, deformation or rapid wear of a metal product (part) only by conducting a study to determine the mechanical properties and metallographic examination of the macro- and microstructure of the metal.

Another common common misconception is that technical metallurgical expertise is classified as a chemical expertise. In reality, technical metallurgy has nothing in common with chemical expertise and chemistry in general. Materials science is a technical applied science studied in engineering, machine-tool, etc. specialties. In judicial practice, metallurgical examination is carried out by engineering experts, often within the framework of engineering and technological examination. The only thing that unites chemistry as a science and metallurgical expertise is the common root in the phrase “chemical composition of a metal.”

In forensic examination, spectroscopic research methods are currently used to determine the chemical composition of a metal. The main, most frequently used methods in forensic examination are the method of X-ray fluorescence analysis and atomic emission spectroscopy. Without going into the specifics of the technical implementation of both methods, we can say that the atomic emission spectroscopy method is more accurate and more universal, which is significant when studying forensic objects. This method involves excitation of atoms of elements of a material, decomposition of the radiation of atoms of elements into a spectrum and measurement of signals proportional to the intensity of spectral lines, followed by determination of the mass fractions of elements using a calibration characteristic. Experts from the ANO Center for Technical Expertise use the atomic emission analysis method in their work, which allows them to achieve an accuracy of determining the chemical composition of a metal up to one thousandth of a percent.

Non-destructive testing - flaw detection

NMK is a way to detect defects in integrity and homogeneity, changes in the chemical composition of various materials, including metals and their alloys, without destroying the product. The simplest, but unreliable method is a visual or auditory test. Today, many types of equipment have been developed that help identify defects, defects and deviations in the chemical composition of materials:

- magnetic;

- ultrasonic;

- radiation (radiographic).

Among the advantages of using modern equipment are a minimum amount of time spent, the accuracy of monitoring instruments, and the ability to conduct tests during the operation of structures or during a short stop of current processes. Special technical methods and technologies for testing without destroying parts are used to test critical components, parts, structures, and products intended for long-term operation.

Incoming quality control of incoming metal products

In a modern market economy, the quality of a product is the main factor in the successful sale of it to consumers, as well as a decisive factor in a stable position in the market and in competition. The quality of products manufactured by our company largely depends on the quality of the materials used, semi-finished products and components. Therefore, when they arrive at the enterprise, they are subject to incoming control. Only those materials, semi-finished products and components for which the manufacturer’s quality control documents have been issued are allowed for incoming inspection and subsequent use. The performance of work on incoming inspection is entrusted, according to the regulations, to the quality control department personnel. The results of incoming inspection are recorded in the incoming inspection log. The list, scope, and sequence of work are determined by the instructions. Our company produces engineering products, so the main material in its production is rolled metal. Both low-carbon steels are used in the form of sheets and rolled profiles, as well as medium-carbon and medium-alloy steels. The quality of incoming metal is critical and is controlled from the moment it arrives at the enterprise (incoming control), and as it moves along the technological chain in the following sequence.

1. Checking the accompanying documentation:

- shipping documents for compliance with the name of the material across the entire range;

- documents certifying the quality of the metal (passports, certificates) for complete registration and compliance of the recorded steel grades with the markings on each rental unit;

- entering parameters into the incoming inspection log.

2. Geometry check:

- sheet steel for wave and deflection;

- round steel for bending, spiraling and ovality.

3. Checking geometric dimensions using a measuring tool:

- sheet thickness;

- strip in width and thickness;

- square in correct shape and size;

- hexagon on edge;

- pipe by outer diameter and wall thickness.

4. Checking the surface condition:

4.1. Casting

- for the presence of shrinkage cavities (closed or open cavities in the casting body that have an irregular shape, a rough or crystalline surface, sometimes oxidized);

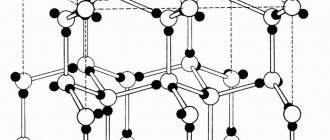

- for the presence of gas porosity (occurs during the crystallization process due to the release of gases dissolved in the metal during its melting);

- for the presence of non-metallic inclusions (external or internal cavities filled with molding sand or slag);

- for the presence of cracks using an optical instrument (they can be of either a cold or hot nature, depending on the shrinkage conditions during the crystallization process);

- for the presence of segregation (this is a local discrepancy in the chemical composition in certain zones. In the segregation zone, mechanical characteristics may be underestimated. Therefore, this defect is most often detected during mechanical processing).

4.2. Rental

- for the presence of surface scratches (occur when small particles get on the rolls during rolling);

- for the presence of hairlines (they look like thin cracks located on the surface and elongated along the direction of deformation; they are the result of deformation of non-metallic inclusions or gas bubbles);

- for the presence of sunsets (layers arising due to excess metal in the rolls);

- for the presence of a film (films peeling off from the surface that occur when rolling out an ingot that has frozen drops of liquid metal on its surface).

Flocking defects that occur in medium-carbon and medium-alloy steel grades require special attention. They appear in the central part of round rolled products of medium and large cross-section and have the appearance of thin winding cracks, which are spots in the fracture with a surface of a characteristic silvery color, round in shape. They arise with an increased content of hydrogen, which fills all the voids, right down to defects in the crystal lattice and, transforming from atomic to molecular, develops enormous pressure, leading to the brittle destruction of the metal. Flocks are most often discovered during hardening, after removing allowance by cutting, or, worst of all, when the part breaks.

5. Application of color markings in accordance with the color chart approved by the enterprise according to the grades of steel used:

- on sheet metal, alphanumeric steel markings are applied around the perimeter of the sheet through a stencil with paint in a color corresponding to this mark;

- on a round rolled end.

6. The chemical composition is checked by taking a sample from each rolled unit, before cutting the blanks, using the method of spectral analysis using a steeloscope SL-13 installation.

Our company uses capillary and magnetic particle methods as non-destructive testing methods for detecting cracks, both in the material when cutting workpieces and in finished parts, before their further use.

Problems of casting control and production features

The demand for premium quality castings with special surface properties is constantly growing. These include:

- high density;

- homogeneity of the material;

- absence of cuts and increased local stresses concentrated in one place.

In these cases, it is not enough to perform a quality check by simply determining the structure of the material and confirming the properties. Sometimes it is necessary to know the operating parameters:

- stress corrosion;

- tightness;

- resistance to alternating loads.

To confirm operational capabilities, the performance of products is assessed under conditions close to actual ones. To obtain a reliable result, laboratory conditions are required, the presence of:

- test bench;

- load simulator;

- identical operating conditions to the working environment;

- compliance with temperature conditions.

To confirm the quality of premium-segment castings, statistical methods of quality management are needed that identify defects in current production in order to eliminate them. A way to improve quality control is spectral analysis methods. Optical and X-ray spectrometers, quality analyzers, are used for express analysis of the chemical composition and determination of metal grades.