Mechanical properties of stainless steel

Grades, mechanical properties of stainless steel

If you're not sure what the properties listed mean, you can check our material properties overview to see a more detailed description of each one.

Yield strength

Depending on the grade, stainless steel may exhibit high strength and low elongation or low strength and high elongation. In terms of yield strength they compare very well with carbon steels.

Strength at high temperatures

Stainless steel performs comparatively better than other carbon steels at higher temperatures. It exhibits better fire resistance due to its high strength retention rate at elevated temperatures (above 500°C). It also has better rigidity retention rate than carbon steel at temperatures above 300°C.

Tensile strength

In terms of tensile strength, stainless steel is superior to materials such as aluminum, brass and mild steel.

The highest tensile strength is observed in dispersion-hardening and martensitic grades. These grades can have a tensile strength that is twice that of the commonly used grades 304 and 316. Duplex steel, in particular, has a high strength-to-ductility ratio.

Cryogenic resistance

Some grades of stainless steel perform well in a wider temperature range. Austenitic steels exhibit exceptional toughness and increased tensile strength at subzero temperatures. This expands the scope of their use, significantly opening up new opportunities for modern applications.

On the other hand, ferritic, martensitic, and dispersion-hard grades do not perform as well at cryogenic temperatures because their toughness decreases as the temperature decreases.

Plastic

The ductility of different grades of stainless steel can vary significantly. Some grades have high ductility, which allows the use of complex deep drawing processes.

Higher hardening speed

This property refers to the ability of a metal to increase its strength through cold working processes. Stainless steel can be annealed and cold worked to bring its strength to the desired level.

This means that the same grade can be used in multiple applications by varying its strength. For example, the same grade can be used as a spring or flexible wire by annealing and cold working.

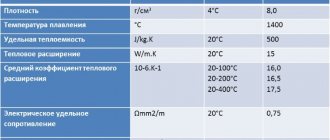

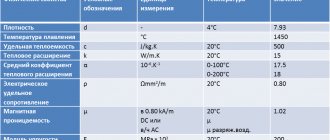

Electrical conductivity and magnetism

Like all metals, stainless steel conducts electricity. However, like all steels, this conductivity is extremely low.

In industries where hygiene standards are high or where electrical appliances may be exposed to corrosive or humid environments, stainless steel enclosures are used for protection.

Austenitic stainless steels are non-magnetic, but cold working can be used to create magnetic properties in some grades. All other types are magnetic.

Types of stainless steels, corrosion resistance

The concept of metal corrosion.

Corrosion

- This is the process of destruction of metal under the influence of the external environment.

According to the mechanism of occurrence, a distinction is made between chemical corrosion

, which occurs under the influence of gases and non-electrolytes (oil), and

electrochemical

, which develops in the event of metal contact with electrolytes (acids, alkalis, salts, humid atmosphere, soil, sea water).

Electrochemical corrosion has its own varieties: uniform

(over the entire surface) and

local

(in certain areas of the surface).

In a heterogeneous, and often in a homogeneous, metal, the corrosion process is often realized due to the appearance of microgalvanic elements on the surface of the steel due to the presence of areas there that have different electrochemical potentials. Electrochemical heterogeneity can be caused both by the presence of several phases in the alloy and by the difference in the electrochemical potential at the grain boundary and in the bulk of the grain. In this case, intercrystalline (intercrystalline) corrosion

. Steels that are resistant to electrochemical corrosion are called corrosion-resistant (stainless) steels. The resistance of steel against corrosion is achieved by introducing into it elements that form dense protective films on the surface, firmly connected to the base, preventing direct contact with the external environment, and also increasing its electrochemical potential in this environment. Figure 1 shows the distribution of the most popular grades of stainless steels of the AISI 400 group and the AISI 300 group in the coordinates: electrochemical potential of steel – PI index. The higher the steel grade is in this figure, the higher its electrochemical potential and, therefore, the higher the corrosion resistance of the steel.

PI=%Cr+3.3*%Mo for steels of the AISI 400 group PI=%Cr+3.3*%Mo+16*%N for steels of the AISI 300 group The studies were carried out in a 3.5% NaCI solution at a temperature of 30 degrees Celsius Fig. 1

The concept of intergranular corrosion (ICC) and ways to combat it.

Heating of steels containing a large amount of chromium in the range of 400-800°C leads to the precipitation of chromium carbide grains Cr23C6 in the boundary zones and, therefore, depletion of these zones in chromium below the 12% limit. This causes a decrease in the electrochemical potential of the boundary areas of the austenite grain and their dissolution in a corrosive environment. Corrosive destruction is intergranular in nature, leads to embrittlement of steel, and is called intergranular corrosion (ICC).

To reduce the tendency of steels to MCC, strong carbide-forming elements - titanium or niobium - are introduced into their composition in an amount equal to five times the carbon content. In this case, carbides such as TiC and NbC are formed, and chromium remains in solid solution. This method of combating MCC is the most expensive. Another, cheaper and more widespread, way to combat ICC is the production of stainless steels with a minimum (less than 0.4%) carbon content (C). In such steels (for example, AISI 304, 304L, 316, 316L) the formation of chromium carbides Cr23C6 is sharply limited due to the absence of carbon. The addition of a small amount of titanium (Ti) to AISI 316Ti steel is caused by the need to impart special consumer properties to the steel (see Table 1)

Table 1. Stainless steel austenitic (chromium-nickel) series AISI 300. Examples of application.

| AISI | EN | Characteristics | Application examples |

| 304 | 1.4301 | Steel with low carbon content, austenitic, non-hardening, resistant to corrosion, non-magnetic under weak magnetization conditions (if cold worked). Easy to weld, resistant to intercrystalline corrosion. High strength at low temperatures. Can be electro-polished. | Installations for the food, chemical, textile, oil, pharmaceutical, paper industries; also used in the production of plastics for the nuclear and refrigeration industries, equipment for kitchens, bars, restaurants; cutlery; in shipbuilding, electronics, etc. |

| 304L | 1.4307 | Austenitic steel, non-hardening, especially suitable for welded structures. It is highly resistant to intercrystalline corrosion and is used at temperatures up to 425°C. | Finds the same applications as AISI 304, for the manufacture of welded structures and in industries where resistance to intercrystalline corrosion is required. |

| 310 310 S 314 | 1.4845 1.4841 | Refractory austenitic steel, non-hardening, non-magnetic, heat-resistant at high temperatures, finds the widest application. In an oxidizing environment, it can usually be used up to 1100°C and up to 1000°C in a reducing environment, but in any case in an atmosphere containing less than 2 g. sulfur (S) per 1 cubic meter. | Installations for heat treatment, for the production of alkalis, for hydrogenation; heat exchangers for furnaces; production of doors, grills, pins, brackets. Elements for air heaters, housings and pipes for heat treatments, conveyor belts for furnace conveyors, outlet pipes for gas turbines and motors, retorts for distillation, cracking and reforming units. |

| 316 | 1.4401 | The steel is austenitic and non-hardening; the presence of molybdenum (Mo) makes it particularly resistant to corrosion. Also, the technical properties of this steel at high temperatures are much better than those of similar steels that do not contain molybdenum. | Chemical equipment subject to particularly strong influences, tools that come into contact with sea water and the atmosphere, equipment for developing photographic film, boiler bodies, food processing plants, waste oil containers for coke plants. |

| 316L | 1.4404 | Steel similar to AISI 316, austenitic, non-hardening, with a very low carbon C content, especially suitable for the production of welded structures. It is highly resistant to intercrystalline corrosion, especially used at temperatures up to 450°C. | Finds the same applications as AISI 316 for the manufacture of welded structures where high corrosion resistance is required. Particularly suitable for the production of food products and ingredients (mayonnaise, chocolate, etc.). |

| 316Ti | 1.4571 | The presence of titanium (Ti), five times higher than the carbon content C, provides a stabilizing effect regarding the deposition of chromium carbides (Cr) on the surface of the crystals. Titanium (Ti), indeed, forms carbides with carbon, which are well distributed and stabilized inside the crystal. It has increased resistance to intercrystalline corrosion. | Parts with increased resistance to high temperatures and environments with the presence of new chlorine ions. Blades for gas turbines, cylinders, welded structures, manifolds. It is used in the food and chemical industries. |

| 321 | 1.4541 | Chromium-nickel steel with the addition of titanium (Ti), austenitic, non-hardening, non-magnetic, especially recommended for the manufacture of welded structures and for use at temperatures between 400°C and 800°C, resistant to corrosion. | Relief manifolds for aircraft engines, boiler bodies or ring manifolds for equipment in the petrochemical industry. Compensation connections. Chemical equipment and equipment resistant to high temperatures. |

Stainless steels are divided into two groups: chromium and chromium-nickel.

Chromium corrosion-resistant steels

three types are used: with 13, 17 and 27% chromium. However, the carbon content in steels with 13% chromium can vary depending on the requirements. Steels with low carbon content (08Х13, 12Х13) are ductile, easy to weld and stamp. They are used for the manufacture of parts that experience shock loads (valves of hydraulic presses) or operate in slightly aggressive environments (blades of hydraulic and steam turbines and compressors). Operating temperature up to 450 degrees Celsius. Steels 30Х13 and 40Х13 have high hardness and increased strength. These steels are used for the manufacture of carburetor needles, springs, and surgical instruments. High-chromium steels (12Х17, 15Х25Т, 15Х28) have higher corrosion resistance and are often used as scale-resistant steels. Alloying with titanium (15Х25Т) is necessary to increase the resistance to intergranular corrosion (see Table 2). Steel 08Х17Т is heat-resistant up to 900 degrees Celsius and is used in heat exchangers.

Table 2. Stainless steel ferritic and martensitic series AISI 400.

Classification and recommendations for use.

| Classification of steels according to basic properties | steel grade > | Basic chemical components | Characteristics of steel and/or products made from it | Recommendations for use | |

| DIN standard (EN) | AISI standard | ||||

| Standard type | 1.4006 | 410 | 13%Cr | Basic ferritic low chromium steel with martensitic structure | Catering equipment, machine parts, valve parts, purification plants, pump parts (axles), copper rolling drums, coal grates and chutes |

| 1.4016 | 430 | 18%Cr | Ferritic stainless steel, non-hardening | >Everyday use products, kitchen equipment, decor, finishing, brass annealing containers, naphtha burners, nitric acid tanks and tanks, nitrogen installations | |

| 1.4000 | 410S | 13% Cr 0.08% C | Basic low chromium steel with reduced carbon content, improved machinability, corrosion resistance and weld strength | Table knives, tableware | |

| Deep drawing steels | 1.4016 | 430 | 18%Cr | Basic chromium ferritic steel with improved deep drawing ability, non-hardening | Everyday goods, kitchen equipment, decor, finishing |

| Weldable steels with high corrosion resistance | 1.4510 | 439 | 18% Cr Ti LC | Excellent corrosion resistance in vehicle exhaust gas condensate environments | Car mufflers, elevators and escalators, kitchen equipment |

| 1.4113 | 434 | 18% Cr 1% Mo | Steel similar to 430 steel, but resistance to general and pitting corrosion is better than 430 steel | Car exterior trim (bumpers or other protruding decorations susceptible to corrosion by antifreeze salts). | |

| — | 444 | 19%Cr 2%Mo Nb-UL | Excellent resistance to chemical and electrochemical corrosion, close to that of AISI 316 steel | Solar battery base, hot water tanks | |

| Steels for machine parts | — | 403 | 13%Сr – 0.1% С | Machine parts with high corrosion resistance and machinability | Machine parts |

| Steels for the manufacture of catering equipment | 1.4021 | 420 | 13%Cr – 0.2%C | Stainless steel martensitic, hardened to hardness HRC 50/52, parts with high wear resistance | Blades of household machines, bushings, screwdrivers, parts of high-temperature units, surgical and dental instruments, dies for plastic and glass products, parts of valves and shafts |

| 1.4028 | 420 | 13%Cr – 0.3%C | Stainless steel martensitic, hardened to hardness HRC 50/52, parts with high wear resistance | Equipment for public catering, nozzles of washing systems, taps (gates), bowls for scales | |

| Steels with high oxidation resistance | 1.4512 | 409 | 11%Cr Ti-LC | Low carbon content, high oxidation resistance and machinability | Exhaust gas exhaust pipes, manifolds, converter casings |

Chromium-nickel stainless steels

Depending on the structure, they are divided into austenitic, austenitic-martensitic and austenitic-ferritic. The structure of these steels depends on the content of carbon, chromium, nickel and other elements. Such steels are used in mechanical engineering, the chemical industry, the food industry, rocketry, shipbuilding, medicine and aviation.

Below is a description of the properties of the most popular imported chromium-nickel steels (the chemical composition of each steel can be viewed in the table, which is also shown on our website).

AISI 304 steel.

Basic austenitic stainless steel (analogue 08Х18Н9).

Excellent weldability properties. With prolonged use at temperatures from 450 to 850 degrees Celsius, the MCC process can develop in steel. This steel is the main steel for the food industry

AISI 304 L steel

.

A complete analogue of AISI 304 steel, but the carbon content is less than 0.03%, which guarantees minimal tendency to MCC even at temperatures of 450-850 degrees Celsius. This steel is the main steel for the food industry

.

AISI 321 steel.

Analogue of steel 08Х18Н10Т.

When the carbon content is sufficiently high, titanium alloying is used to protect against MCC. Long-term use is possible at temperatures of 700-800 degrees Celsius. This steel is actively used in mechanical engineering and petrochemistry.

AISI 316 steel

.

This steel contains 2-3% molybdenum, which provides excellent resistance to corrosion in aggressive environments. At critical temperatures (about 800 degrees Celsius), there is a danger of ICC. This steel is the main steel for the food industry.

Steel AISI 316 L

.

An analogue of AISI 316 steel, but with a carbon content of less than 0.03%, which provides protection against MCC even in the critical temperature range. This steel is the main steel for the food industry.

AISI 316 Ti steel.

An analogue of AISI 316 steel, but with the addition of titanium, which provides protection against MCC even in the critical temperature range of 800-850 degrees Celsius.

This steel is actively used in mechanical engineering and petrochemistry.

Chemical properties of stainless steel

Chemical properties make this material special and give it uniqueness.

High oxidation resistance

This distinctive property of stainless steel allows it to be used in various industries. High oxidation resistance is a result of the presence of chromium in stainless steel. In some brands, the percentage of chromium can reach up to 26%.

Other metals can be protected with coatings and anti-corrosion paints, but once they wear away, corrosion begins. In the case of stainless steel, any removal of the natural chromium oxide coating due to surface damage is accompanied by the formation of a new coating on the exposed surface, which prevents corrosion.

Biologically inert

Stainless steel is biologically inert, making it a logical choice for medical equipment such as surgical instruments, trauma screws and plates. This property also makes it an ideal metal for making cutlery and kitchen appliances.

Resistant to acids, alkalis and organic materials

Stainless steel is resistant to a wide range of compounds. It is resistant to acids, alkalis, and organic compounds. Acid resistance varies between brands. Some varieties can withstand highly concentrated acids, while others may only be tolerant of low concentrations.

Similar inertness is observed with basic compounds and organic compounds. This makes stainless steel a very suitable material for use in the chemical industry for storage, transportation and other processes.

Stainless steel also easily resists moisture, salt, sulfur, carbon dioxide and chlorides. This helps it survive in several harsh environments for a longer period than most other metals.

Recommendations for the use of steel group 400

| steel grade | Characteristics of steel and/or products made from it | Recommendations for use | |

| AISI GOST standard | DIN standard (EN) | ||

| 410/12X13 | 1.4006 | Basic ferritic low chromium steel with martensitic structure. | Catering equipment, machine parts, valve parts, purification plants, pump parts (axles), copper rolling drums, coal grates and chutes. |

| 430/12X | 1.4016 | Ferritic stainless steel, non-hardening. | Everyday products, kitchen equipment, decor, finishing, brass annealing containers, naphtha burners, nitric acid tanks and tanks, nitrogen installations. |

| 410S/08X13 | 1.4000 | Basic low chromium steel with reduced carbon content, improved machinability, corrosion resistance and weld strength. | Table knives, tableware. |

| 439/08X17T | 1.4510 | Excellent corrosion resistance in vehicle exhaust gas condensate environments. | Car mufflers, elevators and escalators, kitchen equipment. |

| 434 | 1.4113 | Steel similar to 430 steel, but resistance to general and pitting corrosion is better than 430 steel. | Car exterior trim (bumpers or other protruding decorations susceptible to corrosion by antifreeze salts). |

| 444 | 1.4113 | Excellent resistance to chemical and electrochemical corrosion, close to that of AISI 316 steel. | Solar battery base, hot water tanks. |

| 403/12X13 | 1.4113 | High corrosion resistance and machinability. | Machine parts. |

| 420/20X13 | 1.4021 | Stainless steel martensitic, hardened to hardness HRC 50/52, parts with high wear resistance. | Blades of household machines, bushings, screwdrivers, parts of high-temperature units, surgical and dental instruments, dies for plastic and glass products, parts of valves and shafts. |

| 420/30Х13 | 1,4028 | Stainless steel martensitic, hardened to hardness HRC 50/52, parts with high wear resistance. | Equipment for public catering, nozzles of washing systems, taps (gates), bowls for scales. |

| 409 | 1,4512 | Low carbon content, high oxidation resistance and machinability. | Exhaust gas exhaust pipes, manifolds, converter casings. |

Other properties

Important properties are not limited to just mechanical and chemical properties. There are others in the list below that will be useful for various applications.

Recyclable

Sell steel for scrap in Simferopol. Recycling stainless steel to make new products is possible. This reduces the environmental burden of our steelmaking needs by requiring less raw materials and also reducing waste generation.

Its non-biodegradable nature also prevents it from polluting resources as it does not break down or seep into soil or water bodies.

Easy to work with metal

Stainless steel can be machined and processed well, allowing the designer to create complex shapes. Laser cutting of stainless steel, CNC machining services, bending, etc. available without special equipment.

Cleanable

Stainless steel products are easy to clean with non-toxic household products such as detergent, soap or cleaning fluids. This preserves their appearance for a long time, increasing their service life.

This ultimately cuts down on losses and makes the initial relatively expensive purchase worth it in the long run.

Aesthetic appeal

Stainless steel products have a high shine, making them an ideal choice for exposed surfaces. A wide range of finishes are available, from bright to matte. It can be brushed, engraved, embossed and tinted to create an effect.

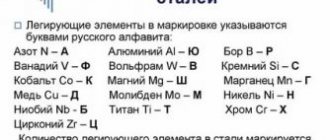

Alloying elements

When it comes to stainless steel, there are many grades to choose from. Depending on the alloying element added, properties can vary significantly. It all comes down to the requirements to choose the most suitable economical option.

Chromium

Chromium is the defining alloying element of stainless steel. This gives the steel the property of being “stainless”. The passive chromium oxide layer, along with protecting the surface, also blocks the diffusion of oxygen into the metal, protecting the internal structure of the metal from corrosion.

Chromium oxide ions are also similar in size to steel molecules, resulting in a strong bond between them. This allows the oxide ions to remain firmly attached to the surface under normal operating conditions.

For steel to be “stainless”, at least 10.5% is required. However, adding even more chromium is common to improve corrosion resistance.

Chromium also acts as a ferrite stabilizer, causing the formation of a ferrite microstructure in the alloy.

Nickel

Nickel is added to further improve corrosion resistance. It is also an austenite stabilizer, causing the formation of austenite.

The addition of 8-9% nickel produces a completely austenitic structure, which provides excellent welding properties. Further increasing the percentage of nickel improves machinability and corrosion resistance.

Copper

Copper also acts as an austenite stabilizer and improves corrosion resistance and work hardening properties.

When added, it produces stainless steel products that are suitable for working in cold conditions when using screws and nails.

Silicon

The addition of silicon improves the resistance of stainless steel to highly concentrated nitric and sulfuric acids. This also promotes the formation of ferrite and makes the metal resistant to oxidation.

Nitrogen

Nitrogen is an austenite stabilizer and improves strength and localized corrosion resistance. Local corrosion refers to phenomena such as pitting corrosion, crevice corrosion and intergranular corrosion.

Molybdenum

Molybdenum and tungsten improve overall and local corrosion resistance. The former is a ferrite stabilizer and therefore, when used in austenitic alloys, must be balanced with austenite stabilizers to maintain the austenitic composition.

Molybdenum also increases heat resistance when added to martensitic stainless steel. Adding tungsten to molybdenum also improves the properties mentioned above.

Manganese

Manganese improves the strength, toughness and hardenability properties of stainless steel. The addition of manganese helps the metal perform better during hot working.

Manganese also helps dissolve nitrogen in stainless steel and can therefore be added to replace nickel in stainless steel with nitrogen.

The use of stainless steels in household appliances

The uniqueness of the stainless steel surface is its density; it has no pores or microcracks for the penetration of dirt or bacteria. Ease of care and cleaning, its environmental neutrality and resistance to aggressive substances compared to other materials make it indispensable for the manufacture of household stoves and other kitchen appliances. An important factor is a good and smooth (without kinks, irregularities or scratches) metal surface.

Strict restrictions on the solubility of heavy metals present in food contact equipment are already in place and will certainly be tightened in the future. According to European standards, the amount of chromium and nickel dissolved from steel during the standard test according to ISO 6486/1 is allowed no more than 2 mg/dm2. For austenitic steels, the amount of dissolved nickel and chromium is less than 0.02 mg/dm2, i.e. about 1% of the permissible value.

The following grades are classified as food grade corrosion-resistant steels:

| Steel grade according to GOST 5632-72 | Analogous to ASTM A240/A 240M-05a |

| 08Х18H10 | 304 |

| 08Х18Н10Т | 321 |

| 12Х18Н10Э (T) | 303 |

Conclusion

Stainless steel, in addition to the usual properties of steel, is resistant to corrosion and heat. Does not corrode, withstands harsh environmental conditions better and has a longer service life.

Corrosion resistance depends on the brand. However, abnormal environmental conditions such as low oxygen levels, poor circulation and high salinity can be harmful.

Despite the above-mentioned risks, stainless steel is an excellent material and has a very positive impact on the industry as a whole. Due to the large number of brands with different properties, there is always a brand that is ideal for the application. It is important to choose the right variety to ensure a return on investment. Call +7 to check the price per kg. scrap metal in Simferopol.