Many people buy chainsaws for the first time, without any experience with this tool. Despite this, to learn how to use the tool, there is no need to take special courses. After the purchase, there is a great desire to quickly test the tool in use. To do this, be sure to first read the operating instructions for the tool, as well as safety precautions when working with a chainsaw. In this article we will look at how to start a chainsaw correctly and how to operate it.

How to start a chainsaw: preparation for launch

Every master who owns a chainsaw should know how to start it correctly. Initially, it should be noted that in order to start the tool, it must be filled with fuel. For this, not just gasoline is used, but a gasoline-oil mixture.

It is important to know! Pure gasoline cannot be used to operate chainsaws. It is necessary to refuel exclusively with a mixture of gasoline and the appropriate oil for two-stroke engines.

First you need to figure out how to properly prepare the gasoline-oil mixture. These proportions are naturally indicated in the instructions, but since few people read them, this issue should be considered in detail.

Gasoline grade AI92 and higher is used as fuel. You will also need to use the appropriate oil, which can be purchased at the same place where you bought the chainsaw. The proportion of gasoline and oil is 1 to 50, after mixing which must be thoroughly stirred. In this case, the mixture should be prepared in a separate container (plastic bottle), since it is not only convenient to store the prepared fuel mixture in it, but also convenient to fill it into the tool tank through the small diameter of the gas tank hatch.

It is always necessary to monitor the level of oil and fuel mixture in the tanks, but it is recommended to perform refueling according to the following scheme:

- Fill the fuel-oil mixture into the tank until it is full.

- At the same time, oil to lubricate the chain is also filled to full.

- The consumption of oil and fuel mixture is approximately the same, so it is recommended to fill both tanks at the same time.

How to start a chainsaw: starting features

Once the tool is ready to run, you can begin. The process of starting a chainsaw is as follows:

- First, check the chain tension. You need to try to lift the middle links of the chain at the top of the tire by hand. If the chain stretches with force, then everything is in order, but if it is easy, then you need to tighten it. Do not overdo it, as excessive chain tension is also highly undesirable.

- Checking the chain for tightness. If, after tightening the chain, you have doubts about its tightening, you can check the correctness by manually rotating it on the bar. The chain should rotate normally without tension.

- Installing the hand brake. The chain hand brake is located at the front near the top handle to hold the tool. If you press the lever forward, then after starting the chain will not rotate, and when returning to the reverse position, the cutting product will begin to move. Before starting, you need to put the tool on the brake.

- Fixing the tool on a flat surface and starting. To prevent the tool from jerking when starting, you need to grab the upper handle with your left hand and rest your right foot on the lower handle. The chainsaw is fixed, now you can turn on the ignition button, pull out the throttle, and then pull the starter handle 2 to 5 times. When you pull the handle 2-3 times, the engine should give the first flash, indicating that you can close the throttle and start. You must pull the starter handle sharply, and then immediately return it to its original position without holding it in the extended position.

- Removing the hand brake. As soon as the chainsaw starts, you should let it run for 1 minute without rotating the chain with medium throttle. The engine will have time to warm up, after which it is necessary to release the handbrake. If a hot engine starts, you can start working immediately after starting.

- Checking the presence of oil supply. To do this, you need to bring the file to a sheet of paper and press it, after which traces of oil should appear on it.

Having started the chainsaw, you can begin cutting wood.

It is important to know! The material describes the process of launching the tool, after which you can start working with it. Do not forget that if you bought a new chainsaw, you should first break it in.

How to use a chainsaw correctly

Working with a chainsaw is one of the most dangerous, so it is very important to control the position of the bar as far away from you as possible. Each subsequent action must be deliberate, otherwise the consequences in the form of serious injuries cannot be avoided. If you have to work with a chainsaw, you should know the following features:

- Work is required only in appropriate protective clothing: protective helmet, headphones, suit, gloves and shoes. This will increase the safety of the master several times.

- You need to hold the tool exclusively with both hands, and take the appropriate position with your feet in the form of a reliable support. Working while standing in an awkward position is strictly prohibited.

- The tool should be leaned against the wood with the chain moving at medium speed.

- Sawing with the tip of the tire should be done with extreme caution, as the likelihood of a kickback is quite high.

- When working, you should exclude from the sawing area all unnecessary objects that could cause imbalance.

- If you are tired, then you need to turn off the instrument, allowing not only yourself, but also him, to rest.

- When working, your legs should be spread wide apart and your back should be straight.

- You can cut wood not only with the bottom of the bar, but also with the top, but it is important to know that the chain will lead in the appropriate direction.

- When moving with a chainsaw to another place, the tool should be turned off or put on the hand brake.

The above-described features are also suitable for working with an electric saw. It is better to do the work in tandem with a partner who can not only provide backup, but also replace you when you get tired. After all, working with such a tool is not easy, since in addition to physical strength, intelligence is also required. By following the rules described above for working with a chainsaw, all types of manipulations performed will have a successful conclusion.

Read also: Vaccination on rowan, what can be grafted

Chainsaw care

Another important condition for working with a tool is to ensure proper care for it. After finishing the work, you should not leave the chainsaw at the workplace until the next time. It is necessary to clean it of sawdust and debris, periodically check the chain tension, as well as the fullness of the gas tank and oil tank. It is also important to monitor the air filter for clogging.

It is not recommended to store a chainsaw with fuel filled for a long time, so it is better to drain it. It is necessary to replace the chain, tire and drive sprocket in a timely manner, as these are elements that wear out quickly.

In conclusion, it is important to note that over time, the chain tends to stretch, which results in it being impossible to tighten. If you observe this property, it is not recommended to continue using the tool until the cutting tool breaks or falls off the tire. If a person is not confident in his abilities, then it is better not to undertake sawing large-diameter trees.

The Partner 350 chainsaw, popular among gardeners, successfully combines endurance, the ability to cope with the most complex household tasks and efficiency. This model tolerates operation well in difficult weather conditions, which makes it possible to use it both in summer and winter, without the risk of unexpected breakdown of the main working units

How to start a chainsaw correctly

Before starting the tool, you should carefully study the work area and safety rules. The algorithm for starting a chainsaw consists of the following steps:

- Push the chain brake forward, activating it. Remove the tire protection from the tire.

- If there is a decompression valve or fuel pump, press it.

- Set the combination lever to the cold start (throttle) position.

- Place the chainsaw on a flat surface so that its cutting edge does not touch the ground.

- Grasp the handle with your left hand and the trigger cable with your right. Place the toe of your right foot on the rear handle to ensure stability of the tool.

- Gently pull the starting rope until there is distinct resistance, then jerk it sharply several times to briefly start the engine.

- Open the throttle by moving the combination lever one detent position to half throttle.

- Pull the cable again and press the gas lever when the engine starts. This moves the combination lever to the normal idle position.

- Carefully lift the chainsaw without touching the engine control lever.

- Pull the chain brake handle towards you until you hear a distinct click, which indicates that the chain is unlocked and is able to move along the tire.

It is also possible to start the chainsaw by holding it between your knees. At the same time, regardless of the chosen method of starting the chain saw, according to the instructions, the chain brake must always be turned on.

Sometimes a gasoline saw that is not equipped with a manual pump does not start after a long period of inactivity. In this case, you need to remove the air filter cover, remove the filter element and use a syringe to pour a few drops of gasoline directly into the carburetor. After about 30 seconds, steam will form and the starter handle can be pulled. As a last resort, you can use a more radical method - remove the spark plug, pour a few drops of gasoline inside the cylinder and screw the spark plug back in.

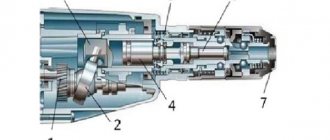

Chainsaw device Partner 350

The Partner model in the 350th configuration stands out for its excellent selection of components and high build quality. The basis of garden tools is a 2-stroke, 1-cylinder internal combustion engine, running on a mixture of AI-92 gasoline and motor oil. The piston group of the engine is forged and coated with a chrome alloy to extend the working life of the internal combustion engine. The factory engine includes a proprietary CCS filter, which is distinguished by its ability to capture the smallest foreign particles, preventing them from entering the fuel.

The Partner 350 chainsaw differs from its analogues in its simplified starting, which was achieved thanks to a modified starter with a self-cleaning drum, a professional fuel pump and durable electronic ignition. To pre-pump the used fuel into the cylinder, the model is equipped with a primer.

For the safety of the operator while operating a running chainsaw, the Partner company has equipped the garden tool with a high-quality inertia brake, which is instantly activated when the saw set hits a nail or any other foreign object.

The working parts of the Partner saw are a metal bar and a chain. Their tension is carried out using two keys, without the need to remove the protective cover of the plastic case.

One of the main advantages of the Partner 350 chainsaw is the convenient location of the controls necessary for operation. The throttle lever, combination switch and factory starter cable are located at the rear of the tool, making it much easier to operate in tight spaces.

Chainsaw oil Partner 350 – how to choose?

To extend the life of the engine and other working mechanisms of garden tools, it is necessary to use high-quality motor oil to prepare the fuel mixture. When burned in the cylinder, it should form as little ash as possible, which settles on the walls of the muffler and on the spark plug.

The engine oil used for refueling must quickly dissolve in gasoline and be thoroughly cleaned of harmful impurities, which, over time, settle in the narrow channels of the factory carburetor of the Partner saw.

In addition, Partner 350 chainsaw oil must have high lubricating and anti-corrosion properties, as well as good wear resistance.

It is best to use oils for 2-stroke engines from the Stihl and Husqvarna brands to prepare the fuel mixture. They lubricate the operating components of Partner garden tools well and, when burned, do not emit a large amount of ash.

Preparing a fuel mixture for a chain saw.

Since the majority of chain saws available to consumers are equipped with two-stroke engines that do not provide separate lubrication of rubbing parts, it is very important to prepare the correct fuel mixture during break-in. It is prepared from gasoline and two-stroke motor oil in a certain proportion recommended by the chainsaw manufacturer.

What gasoline should I use for the fuel mixture?

The basis is gasoline with an octane rating of at least 90. For Russia, Belarus, Kazakhstan and other CIS countries, the optimal fuel option is AI-92. Avoid using questionable fuels, as well as using any additives that increase the octane number. Over time, additives lose their properties, and gasoline becomes of low quality.

Chainsaw Partner 350 – model characteristics

The high efficiency of the Partner chain saw in the garden was achieved thanks to good factory parameters.

Garden tool specifications include:

- The power of the factory internal combustion engine is 1.8 liters. s./1.3 kW;

- volume of standard forged cylinder – 36 cm3;

- engine idling speed – 4000 rpm;

- fuel tank capacity – 400 ml;

- oil tank volume – 200 ml;

- recommended tire length – 40 cm;

- saw chain pitch – 3/8 “;

- weight – 4.7 kg.

During operation, the Partner chainsaw creates minimal noise and vibration. The sound pressure on the operator when the engine is running at maximum speed does not exceed 108 dB.

Do-it-yourself adjustment of the Partner 350 chainsaw carburetor

Before you start tuning the standard carburetor of the Partner model, you need to thoroughly clean it of dust, dirt and carbon deposits that have accumulated on the walls. In addition to the carburetor, you will need to wash and dry the fuel and air filters. Otherwise, the operator will not be able to accurately set the required engine speed.

In the upper left part of the protective plastic body of the Partner saw there are holes, inside of which the manufacturer provides bolts for adjusting the carburetor. Having found them, you can begin basic configuration of the node. To do this, the left and right screws, which are responsible for the quantity and quality of revolutions, respectively, must be set to the fully tightened position. Immediately after this, they must be loosened by 1/5 of a turn. The third adjustment bolt, marked T, must be left in the position in which it is installed.

The final adjustment of the Partner 350 chainsaw carburetor is performed in the following order:

- First you need to start the saw and let its motor run to fully warm up;

- After 5 minutes you can start adjusting. First, you need to start turning the left bolt in the direction of the clock until the engine reaches maximum speed. Then the left bolt must be turned 1.4 turns in the opposite direction. After performing these steps, the Partner chainsaw engine should idle confidently;

- If, after manipulating the left adjusting screw, the chain on the bar begins to rotate, then it must be stopped by alternately turning the bolt T;

- Then you need to move on to adjusting the quality of the fuel mixture. To do this, the right adjusting screw will need to be turned in the direction of the clock hand. As soon as the motor reaches the maximum permissible speed, the screw must be unscrewed 1/4 turn in the opposite direction.

When setting the maximum engine speed of the Partner 350 saw, it is better to use a tachometer pre-connected to the motor. As soon as the device shows the same speed as indicated by the model’s original operating instructions, it means that you must stop turning the screw.

1. Start the chainsaw according to the instructions

Different chainsaws may start differently. Let's look at two more popular mechanisms that are used to start a chainsaw, available today. For example, let's take the Stihl MS 180 and Echo CS-352ES chainsaws. If you have a chainsaw of a different brand, then just try to start it by analogy, because most likely you have the same or a similar mechanism.

Before starting the description of the starting process, I would like to see that some chainsaws have written in the annotation that before starting the chainsaw it is necessary to turn on the critical stop brake. It's safer this way. But with a fixed brake, it is more difficult to start the chainsaw, so it is better to unlock it. If you do everything wisely, then the chainsaw will not do anything for you during startup. If you are afraid that without locking the brake, the chainsaw, when you try to start , will be able to cause harm to you, then it is better not to take up this tool at all.

So, let's start with the Stihl MS 180.

- The first thing you need to do before starting this chainsaw is to move the damper adjustment lever to the lower position (Fig. 1). Please note that this lever only moves all the way down on the chainsaw if the gas button is pressed. Therefore, we hold down the gas button and move the lever down. Then we close the valve in the carburetor and secure the gas in the pressed position on the chainsaw.

Rice. 1 After you have done this, then to start the chainsaw, you begin to vigorously pull the starter handle until you hear that the chainsaw tried to start and immediately stalled. Then we move the lever for adjusting the position of the damper on the chainsaw one step up (Fig. 2).

Rice. 2

- In this position, we again pull the starter handle until the chainsaw starts. With all this, if you manage to start it, due to the fact that the gas handle is fixed in the pressed position, it will immediately work at high speeds.

- Then we press and release the gas button on the chainsaw once - adjustment lever will automatically move to the working position (Fig. 3), and the speed of the chainsaw will drop. Now you can work.

Chainsaw Partner 350 – ignition adjustment

You need to think about adjusting the ignition of your Partner garden tool when its engine stops starting, or when the rated power of the engine has noticeably dropped. Before adjusting the ignition, you will need to thoroughly clean the spark plug, and also wipe the coil itself from dust.

The further procedure is as follows:

- First you need to remove the left cover of the protective plastic case;

- The flywheel and ignition coil are located under the cover. They must be located at a certain distance from each other. A template or a regular paper business card will help to set the gap between them;

- To make the adjustment, you will need to remove 2 screws located next to the flywheel. As they rotate, the element will move away from the coil;

- Next, you will need to place the template firmly on the side of the coil and start turning the screws in the opposite direction;

- Once the flywheel makes contact with the template, you will need to complete the adjustment.

After setting the ignition, you need to put the housing cover back in place and check the operation of the Partner 350 chainsaw. If the adjustment of the unit was done correctly, the chainsaw engine will start the first time.

Chainsaw Partner 350 – malfunctions and their elimination

Failures of Partner garden tools can occur for various reasons, the most common of which are improper operation and mechanical shock. To eliminate the malfunction, you will need to determine its exact cause in advance. After this, you can begin repairing the instrument yourself.

Read also: Tomato pink Koenigsberg variety description photo reviews

Chainsaw Partner 350 starts and stalls

There may be several reasons for this malfunction. Most often, the engine of the tool starts and immediately stalls due to a clogged factory breather, as a result of which fuel does not enter the engine cylinder in sufficient quantity for operation. To fix the damage, you will need to remove and clean the breather. If it is damaged, then it will need to be replaced.

Another reason is the missing connection between the spark plug and the electrical wiring cap. This can happen due to mechanical shock or the formation of carbon deposits from engine oil on the spark plug. To repair the Partner 350 chainsaw, the spark plug will need to be removed and cleaned. In some cases, completely replacing the spark plug may help.

The third reason for the malfunction is that the standard muffler of the chain saw is severely clogged. Over time, carbon deposits form on its walls, which prevents exhaust from leaving the engine. As a result, gases accumulate inside the engine and interfere with its proper operation. To fix the damage, you need to remove the muffler and clean it with compressed air. You will also need to disassemble the engine and bleed its cylinder.

Chainsaw Partner 350 will not start - how to fix the problem?

When this breakdown is detected, the first thing that needs to be inspected is the condition of the air filter. If a large amount of dust has accumulated on it, the filter will need to be washed using clean gasoline.

Another common cause of malfunction is problems with the ignition system. To repair the chain saw, you need to remove its left protective cover and set the correct clearance between the flywheel and the ignition coil.

In some cases, replacing the fuel mixture will help solve the problem. To do this, you will need to drain the used fuel and fill the tank with a new mixture of pure gasoline and motor oil.

What to do if the chain on the Partner 350 chainsaw is not lubricated?

If the chain for the Partner 350 chainsaw is no longer lubricated with oil, this can lead to overheating of the bar and rupture of the saw set. Ignoring this problem also risks increasing the load on the engine, which can lead to engine failure.

The first thing you need to inspect if there is no lubrication on the chain is the oil pump. Over time, the teeth on its drive wear out, which can also occur due to clogging of the pump. It is usually impossible to restore the element, so it is best to replace it.

Often, lubricant does not reach the chain of the Partner 350 chainsaw due to clogged oil pipes. In this case, the hoses will need to be replaced by treating the joints with the fittings with sealant.

Fills a candle on a Partner 350 chainsaw

This common problem is encountered by chainsaw owners who add too much motor oil to the fuel mixture. It does not have time to burn in the cylinder, so part of the lubricant settles on the spark plug and other important elements of the garden tool.

To fix the breakdown, you need to remove the factory spark plug, clean it of carbon deposits and dry it. After this, you need to blow out the cylinder of the factory chainsaw engine by sharply pulling the starter cable several times.

Next, you need to inspect the condition of the carburetor and fuel hoses. Often oil gets on the spark plug due to loss of tightness of the system. This occurs as a result of a break in one of the tubes or a breakdown of the oil pump. To repair a Partner 350 chainsaw, you will need to replace all faulty fuel system parts. After this, you need to install the spark plug in place, start the engine of the tool and check its operation at idle, low and high speeds.

a real owner do without a chainsaw? This is nonsense! Many small and not so small tasks will stop without this tool: cutting branches, pruning bushes, small carpentry repairs, etc. What can I say, you yourself know better how much you need a chainsaw.

And the popular chainsaw Partner is named so for a reason - it helps in the household just as well as a partner. And if this chainsaw breaks, it’s very difficult without it. Fortunately, you can try to repair the Partner chainsaw yourself. Let's see in what cases this is possible.

How to check the spark on a chainsaw spark plug

Although much less common, it also happens that it is impossible to start a chainsaw due to the lack of a spark at the spark plug electrodes. How to check its presence? It's very simple. Again, we unscrew the spark plug, put a high-voltage wire on it and ensure reliable contact of the spark plug body (that is, its skirt, where the thread is) with the cylinder block. After this, we pull the starter's hand as when starting.

You should clearly see the spark. If there is fuel supply, but no spark, then most likely the magneto is faulty or there is a broken wire somewhere in the system. In this case, check the serviceability of the magneto and the integrity of the electrical circuit. After all these operations, the engine should start. If it didn’t work, then write in the comments. Let's try to figure it out.

Preliminary running-in of the chainsaw after the first start is a mandatory procedure for both new and refurbished tools. The process allows you to increase the service life of the power unit and saw set by grinding in moving units and parts under gentle load conditions. For beginners, the break-in procedure allows you to acquire skills in working with chain tools.

Chainsaw Partner 350: characteristics and features

The Partner 350 chain saw belongs to the class of household or amateur hand-held gasoline saws. Amateur - does not mean a “club of interests” for chain saw lovers, but denotes the power and capabilities of the unit. This saw is one of the best in its class and is optimal for short-term work in the garden, on a summer cottage, etc.

With its help, you will trim bushes, prepare brushwood for the barbecue and wood for repairs, and cut down a small tree. All this is possible due to the following technical parameters:

- Weight: 4.7 kg

- Two-stroke engine power - 1.8 hp. (1300 W)

- Engine capacity: 34 cc.

- Electronic ignition system.

- The capacity of the oil tank is 0.2 l, the fuel tank is 0.4 l.

- Chain pitch: 3/8 inch.

- The maximum chain length is 41 cm, the optimal length is 35 cm.

- Primer for starting a cold engine.

The advantages of the Partner 350 chainsaw are its compact size and convenient operation. It has a built-in safety system: the double inertia brake is activated automatically as soon as an emergency situation occurs. potentially dangerous for the saw operator.

The chain is also automatically lubricated. At the same time, fuel is consumed very economically, and the air filter lasts longer thanks to the CCS system. It’s even surprising that at such high engine speeds the saw operates relatively quietly. As a nice “bonus”, the cylinder walls are coated with a special protective compound, and an anti-vibration system is built into the handles.

As for the shortcomings of the Partner 350 chainsaw , reviews on the forums speak volumes about them. It turns out that this model was first released in 2012 and then re-released in 2015. According to the documents, the updated model is more advanced. But in practice, copies of the first series are more reliable and break less often. In addition, this saw is not equipped with a shock absorber - this can be felt during prolonged use. Partner chainsaws are produced by the Swedish concern Husqvarna, which is well known to users of equipment for gardening, dacha and forestry. Factories producing Partner equipment are located not only in China, but also in the USA, Italy, and Great Britain.

Despite this, the price of Partner chainsaws is relatively low. Spare parts are also available. In Western countries, this brand is very popular due to its win-win combination of price and quality. But even Swedish quality sometimes fails.

Common Partner saw breakdowns: diagnostics at home

The Partner gasoline saw cannot be called unreliable. For many users it works without problems in winter and summer, for many years. But others complain about the same typical problems:

- The chainsaw won't start.

- The chainsaw starts but stalls.

- Fuel does not enter the cylinder.

All these problems have internal causes in the parts and components of the tool. This means that in order to get to the bottom of it and fix the breakdown, you will have to disassemble the electric saw. This is not as difficult as it may seem, because manufacturers always take this possibility into account.

To independently diagnose problems at home, you need to understand that common chainsaw problems in the vast majority of cases are caused by the same reasons. Therefore, just by the symptoms, you can guess where the source of the problem is.

For example, if a chainsaw does not start , then the reason most likely lies in the ignition system, namely the spark plug. If air leaks into the cylinder, then you need to look for a defect in the fuel system. A dirty filter causes the engine to stall and smoke, and so on. Let's look at these cases in detail so that you feel confident when repairing the Partner chainsaw yourself.

What to do if the Partner 350 chainsaw does not start

Now that you know what caused the breakdown , it's time to get down to business. A faulty ignition system can only be repaired after disassembly. To do this, remove any remaining fuel from the tank. Then carefully disconnect the wire and remove the spark plug (a special key is provided to remove it).

Read also: Lotus-like flowers

- Test it to see if it works . To do this, place the ignition cable on the spark plug, and connect the spark plug nut and cylinder using pliers. Now start the starter. Is there a spark? This means the spark plug is in working order. No spark? This means that it will not be possible to revive the spark plug, and it must be replaced. What can you do with a working candle? Already by the appearance of the spark plug one can judge the repair method.

- The candle is completely dry . This means that it is not wetted by the fuel mixture. The problem must be looked for at the stage of fuel entering the cylinder, it is disrupted. The spark plug and the ignition system as a whole have nothing to do with it. Reinstall the spark plug and look for the real cause of the problem.

- The spark plug is overfilled with fuel mixture . The first thing, of course, is to wipe it with a napkin and put it aside. Now you can look for the cause in incorrect carburetor adjustment. While the spark plug is air drying, you can shut off the fuel supply and turn on the starter to check the combustion chamber. After a few minutes, the spark plug can be replaced in its place in the mechanism and the chain can be restarted.

- The candle is covered with a layer of soot . Burning occurs as a result of improper fuel composition. There are two options here: either you saved money and filled the chainsaw with low-quality gasoline, or the proportions of the mixture of gasoline and oil were violated. The candle needs to be cleaned properly. To remove a plug from carbon deposits, a needle, thin awl or similar tool from available means will do. The electrodes also need to be cleaned.

In addition, in any case, it doesn’t hurt to make sure that the chainsaw’s carburetor is adjusted correctly. Do not begin adjustments until you have cleaned the air and fuel filters. If the filters are ok, use the adjustment screws.

One of them (S) is intended for idle speed , the other two are for maximum (H) and minimum (L) speeds, respectively. Gradually turn the screws clockwise. After stopping, make two turns in the opposite direction.

How to start a chainsaw partner

Chainsaw repair

.Carburetor repair. Carburetor adjustment.

Rice. 5 Then press the swap primer several times (Fig. 6). Gasoline will be pumped into it and then press it another 3-5 times. If you have a chainsaw without primer, then proceed to the next step.

Rice. 6 Now, on the chainsaw, pull out the damper position adjustment lever to the end (Fig. 7). In some chainsaws, in order to start it, this lever can only be pulled out when the gas button is pressed, while the gas button itself is locked in the pressed position. For others, you don't need to press the gas button. True, in this case, the gas on the chainsaw is fixed automatically or not fixed at all.

Rice. 7

Problem: chainsaw stalls after starting

A common situation : the Partner chainsaw stalls at high speeds, although before that it starts and runs without problems at medium gas. Sometimes at medium it also works intermittently - but at full throttle it immediately stalls. This problem is faced by many users who save on quality fuel.

Low-quality gasoline easily contaminates parts with soot. In this case, checking the filters (air and fuel) will not hurt. Moreover, the muffler suffers from poor fuel and the carbon deposits it creates.

The combustion products of dirty fuel simply clog it, forming an impenetrable plug of soot. This plug greatly reduces engine power. In this case, gasoline is consumed in large quantities, but there is no result in power. Check and clean the muffler:

- Remove any remaining fuel from the tank.

- Remove the muffler and take it apart.

- Do not leave the outlet open; cover it with a napkin or lid.

- Clean all carbon deposits from the muffler using a cable and/or detergent. According to reviews, “Mr. Muscle” for pipes or similar household chemicals has proven itself well.

- A clean muffler needs to be dried. To speed up the process, you can do this with a hair dryer.

Repairing the fuel system of a chainsaw

When the fuel supply is interrupted , it is not surprising that the chainsaw does not work. Moreover, in this case there is only one problem: no fuel enters the cylinder. And there may be several reasons for this problem, and you have to find that very reason.

First, try disconnecting the fuel hose and observing the fuel pressure. A weak, intermittent flow indicates a clogged filter. Take it out, rinse and dry it, and if possible, replace it with a new filter. Also clear the breather (valve) of any blockages.

Check the condition of the carburetor filter and, if necessary, rinse it thoroughly, dry it and reinstall it. We talked in detail about setting up the carburetor above, and these actions in this case will also not be superfluous.

If the reason is not in the breather or in the carburetor, then everything may turn out to be trivial. Make sure there is enough fuel in the tank.

There may also be problems with the cylinder-piston group (abbreviated CPG) of the Partner chainsaw. This failure can be considered serious because the cylinder and piston are the basis of the engine. Therefore, the CPG is an expensive component, the cost of which reaches half the cost of the entire tool.

on the coordinated operation of the cylinder and piston. During operation, especially if operating rules are not followed, the cylinder, piston and rings may wear out. In this case, only replacing parts will help.

CPG parts may be damaged mechanically. These defects can be diagnosed independently. Remove the muffler. You can see the CPG in the hole. Scratches and scuffs on the surface of the cylinder , located chaotically, occur when debris, fragments, or solid foreign particles enter.

If the cylinder is darkened , and this defect is observed over its entire surface, then, in all likelihood, you filled the chainsaw with low-quality fuel. Bad gasoline also affects oil scraper rings. A worn surface of the cylinder on the muffler side is a sign of critical overheating of the chainsaw during operation. Minor mechanical damage can be corrected by replacing bearings, rings, etc. But in case of deep scuffing, the CPG will have to be completely replaced by contacting a partner chainsaw repair shop.

We have prepared an entertaining article about caring for drimiopsis.

Find out more about ageratum care here.

Procedure if your chainsaw does not start

Read:

The first thing I would like to note is that if your chainsaw does not start, do not turn any screws on the carburetor. If you are not a specialist, you still won’t be able to set anything up on your own and you won’t be able to start the chainsaw.

Perform the following actions necessary to start the chainsaw in the order indicated, starting with the next action only if the previous one does not help.

- First, try just leaving the chainsaw alone for 5-10 minutes. Perhaps her spark plug was flooded during cranking - it happens. Then try starting it again according to the instructions.

- Remove the housing cover on the chainsaw, take out the air filter and try starting it without it. If the filter is dirty, it should be washed in soapy water and dried or replaced with a new one.

- Unscrew the spark plug from the chainsaw. Check for spark. If there is no spark, then try installing a new spark plug. If a spark does not appear, this means that the ignition unit is damaged and the saw must be taken in for repair. True, visual observation of a spark does not mean that the ignition unit is working. If there is a spark, but the chainsaw still fails to start, follow the steps listed below.

- If there is a spark, but the spark plug is wet, then turn the chainsaw over to drain excess gasoline from the cylinder if it has accumulated there. Pull the starter without a spark plug 10-15 times to ventilate the combustion chamber. Fire up the spark plug and screw it back in, or better yet, replace it with a new one, if available. Try starting it again according to the instructions.

- If the spark plug is dry, then fill a syringe with one or two cubes of the gasoline mixture and pour it into the cylinder. Try starting the chainsaw - perhaps a small speck has gotten into the carburetor, which is preventing fuel from getting into the combustion chamber. It is quite possible that this speck will be pulled out by the flow formed after starting the chainsaw by adding fuel directly to the cylinder.

- Unscrew the muffler and remove it, being careful not to damage the gasket between the muffler and the engine. Try starting it without a muffler and air filter. With the muffler removed from the chainsaw, you can inspect the piston from the inside. If there are burrs or scuffs on the walls of the cylinder or piston, or the ring on the piston is pinched by burrs, then you will be very upset, as this means that the piston is damaged or worn out. This usually happens when the fuel mixture is underfilled with oil. If such a malfunction occurs, you will have to contact a service center, and perhaps think about buying a new chainsaw, since replacing a piston chainsaw is a fairly expensive operation.

How to prevent chainsaw damage

Repairing a chainsaw can be very expensive in some cases. This can be avoided if you pay enough attention to the prevention and control of the condition of the instrument and all its parts. Moreover, it is not difficult to fulfill this condition - just use the operating instructions and adhere to rational accuracy:

To keep it in working order, you just need to strictly follow the instructions and follow some general rules:

- Do not allow the engine to overheat, take breaks in operation so that it can rest and cool down.

- Do not load the chainsaw beyond the capabilities of its class. For example, if you are using a household grade Partner 350 saw, then it is simply not designed to work for more than 40 minutes a day.

- Check the chain brake daily (this is done at maximum acceleration).

- Follow the manufacturer's requirements regarding the quality and composition of the fuel mixture.

- Check the condition of the spark plug weekly and clean the electrodes if necessary.

- Before using the saw, make sure the chain is sharp and installed correctly. Pay attention to the wear of the cutting links and sharpen them in a timely manner. Watch for cracks and breaks in the rivets.

- A properly tensioned chain does not sag, but it can be moved by hand. Never do this with a hot chain! Sharpen and/or tighten it after replacement.

- When refueling the chainsaw, make sure that dirt and other foreign particles do not get into the tank along with the fuel. Fill oil and gasoline carefully, do not spill them.

Often, when contacting a service center, it turns out that the Partner chainsaw broke down due to improper starting of the tool. Therefore, there is only one universal solution when a saw breaks down: handle it correctly, and most problems can be avoided.

And if you are interested in the reasons for breakdowns of the Stihl chainsaw, the second popular brand together with Partner, then the next article is about exactly that.

And for those who like to know more, we suggest you watch the video about chainsaw repair Partner

>

How to start a chainsaw correctly, what to do if it doesn’t start: we explain the question

Amateur and professional chainsaws are complex devices. The motor life of their two-stroke engines, components and assemblies has its limitations. For this reason, quite reliable and expensive tools, along with cheap Chinese units, periodically fail and refuse to start. The situation when a chainsaw does not start or stalls is not very pleasant and sometimes confuses the user. How to identify and eliminate the malfunction, restoring the functionality of the tool.

Identifying and eliminating obvious chainsaw problems

To determine the reason why the chainsaw does not start or stalls when starting, it is necessary to troubleshoot the tool. The essence of the procedure is a sequential inspection of the condition and operation of the main working elements of the saw engine. At this stage we check:

- Presence of a spark on the spark plug;

- Fuel supply;

- Filter status;

- Operation of the breather built into the fuel cap of the stalling unit;

- Functioning of the exhaust channel.

Checking the spark on the spark plug and eliminating the causes

The first step in finding the reasons why a gasoline saw does not start is to check the spark on the spark plug. There are many factors that influence the operation of this element. However, the main ones at the initial stage of tool troubleshooting are:

- Incorrect carburetor adjustment;

- The presence of more than the required amount of oil in gasoline;

- Air filter clogged.

All of them contribute to the formation of carbon deposits on the spark plug electrodes. In 50 cases out of 100, saws do not start when cold due to the lack of a spark due to carbon deposits on the electrodes and their corrosion. The result is either a decrease in the gap or an increase in it.

Checking the spark plug of a non-working chainsaw

Checking for spark is quite simple. To do this you will need:

- Remove the tip of the high-voltage wire;

- Unscrew the spark plug;

- Put the tip back on;

- Place the candle skirt against the cylinder;

- Start with the starter.

If at the moment the chainsaw engine starts, a good spark is observed between the electrodes, then everything is in order with the ignition unit. If it is not there, then it is worth cleaning the element itself and checking the electrode gap. If necessary, use a special probe to adjust the distance between the contacts.

For spark plugs from different manufacturers, the distance between the electrodes may vary. For some it may be equal to 0.5 mm. Others have 0.2 mm. Therefore, carefully study the manufacturer's recommendations.

There may be no spark at the spark plug for other reasons. The main malfunctions that affect poor starting of the chainsaw and unstable operation of the internal combustion engine at idle, which can cause the tool to stall, include the following:

- Overfilling of the spark plug channel with fuel;

- Lack of contact between the high-voltage cradle and the tip of the spark plug;

- Failure of the ignition unit.

How to start a cold chainsaw if the spark plug channel is constantly flooded with gasoline? You can fix the problem while starting the tool using the following algorithm:

- Unscrew the spark plug with a special wrench;

- Wipe it with a clean and dry cloth;

- Dry for 20...30 minutes;

- Remove carbon deposits with a file and adjust the gap between the electrodes;

- Drain the remaining fuel from the spark plug channel and dry it;

- Collect everything and try to start the mechanism.

As a rule, these measures are quite enough to start the chainsaw and get the job done. However, this extreme measure does not eliminate the main reason why the engine does not start or stalls - improper operation of the carburetor, which needs fine adjustment.

If there is no spark due to poor contact of the high-voltage cradle with the tip of the spark plug, it is necessary to check the connection. The test can be carried out using a regular tester. If a defect is detected and corrected, the chainsaw should start without any problems.

If the check shows that the contact is reliable, but the saw still does not start, look for the reason in the ignition unit. As a rule, a faulty unit cannot be repaired or restored. This will require a complete replacement.

We determine the availability of fuel and its supply

First, you need to make sure that there is a fuel mixture in the tank of the chainsaw that does not want to start, and that it is properly supplied to the carburetor. With a full tank, check how the mixture is supplied through the gas line. We disconnect the fuel system pipe from the carburetor and try to pump it up. In case of complete order, when pumping, gasoline will be supplied jerkily in accordance with the standards set by the manufacturer. Weak fuel supply or its absence can result from:

- The fuel supply channel is clogged;

- Fuel filter clogged with debris.

Often the cause of poor starting of a chainsaw can be a too full tank. In this case, you should pay attention to the presence of smudges under the saw housing cover. If they are present, then look at the connection of the gasoline supply pipe to the carburetor. Most often, it is squeezed out by pressure when screwing on the tank cap, which is tucked right under the neck, which prevents the engine from starting.

The quality of the fuel mixture can also be one of the reasons why the chainsaw does not start. If, after completing the work, you do not drain the remaining gasoline and leave the tool for long-term storage (more than 2 weeks), then the processes of resin formation and polymerization of the components will begin to occur inside the tank. What can cause carbon deposits to appear on the piston, rings and cylinder liner. Therefore, always prepare the mixture in only the required quantity before work.

Checking the condition of the fuel and air filters

If the fuel quality is fine, the chainsaw engine may not start due to clogged fuel and air filters. To diagnose these elements, you will need to perform a number of manipulations associated with their dismantling.

For fuel filter:

- Disconnect the gasoline supply line from the carburetor;

- Pump up the fuel.

If there is little or no pressure in the pipe, disconnect the filter. Before doing this, empty the tank of the mixture and remove the filter element itself. Dismantling is done using a wire hook. A clogged replacement cartridge that causes poor starting of the chainsaw engine can be cleaned, but it is best to replace it with a new one. When using the tool in dusty conditions, cleaning should be done on a regular basis.

A clogged air filter can cause the chainsaw engine to run rough, causing it to stall or be difficult to start. Dust and dirt deposited on the adsorbent material make it difficult for air to enter the system, making the fuel mixture so rich that it will sometimes be difficult to start the tool.

Checking the air filter is one of the first steps in finding the causes of poor starting.

Removing the air filter should be done with caution, since dust accumulated on its surface during operation of the saw can get into the carburetor. And this is fraught with more expensive repairs. After disconnecting the cartridge, thoroughly clean it of accumulated dirt and wash it with detergent. Dry the element and carefully put it back in place.

Checking the breather and cleaning it

The breather is another element, due to improper operation of which the chainsaw may not start or stall during the sawing process. This element is located on the fuel tank cap in the area of the air hole. This is a kind of valve that does not allow gasoline to leak out and equalizes the air pressure necessary for the free flow of fuel into the carburetor.

If the breather is dirty, the running chainsaw stalls, and when started, it refuses to start. The whole point is that air stops flowing through the hole. As a result, negative pressure (vacuum) is created inside the fuel tank, preventing the flow of gasoline to the carburetor.

Identifying the problem is quite simple. Disconnect the fuel supply hose from the carburetor and see what happens to the gasoline. If it flows freely in a good stream, then everything is in order with the breather. If it is absent or it flows weakly and intermittently, then the cause is identified - the breather is clogged with dirt. The problem can be solved by cleaning the air hole with a regular needle or a powerful jet of compressed air.

Checking the chainsaw exhaust channel

One of the reasons that a chainsaw is difficult to start may be a clogged exhaust channel or its muffler. At the same time, there is a drop in power during sawing of lumber and logs. Most often this occurs due to tarry deposits on the spark arrester or muffler channel, which are formed during the combustion of a low-quality mixture of gasoline and oil, preventing the exhaust gases from being vented.

A resonator clogged with carbon deposits can cause a gasoline saw to start poorly.

The cause of poor starting of the chainsaw, in this case, can be eliminated by removing the accumulated combustion products. To do this, perform a number of manipulations:

- Remove the muffler by unscrewing the screws;

- Remove the cooling panel and sealing gasket;

- Remove the spark arrester;

- Disassemble the resonator body;

- Wash all elements from carbon deposits using detergent;

- Let them dry completely;

- Reassemble everything in reverse order;

To prevent dust and sand from entering the cylinder when cleaning the muffler, cover the exhaust duct of the chainsaw engine with a clean rag.

What to do if the chainsaw continues to not start?

If the initial inspection did not yield anything or the defects were eliminated during the search process, but the chainsaw still does not start, then you need to look for more serious reasons. It is best to identify and repair such breakdowns at a service center. However, if you have experience, you can find and eliminate them yourself. What to diagnose and check?

- Compression in the cylinder;

- Compression in the crankcase;

- Carburetor operation.

In the first case, checking the compression in the cylinder will allow you to find out the condition of the cylinder-piston group (CPG) of a chainsaw that does not want to start when cold. To do this you need a compression gauge. The device is screwed into place of the spark plug and the engine is started idle. Measuring the readings allows you to judge the condition of the CPG. In the absence of a compression gauge, you can determine the compression in the cylinder offhand as follows:

- Place your finger on the spark plug hole;

- Try to start the chainsaw engine.

By placing your finger on the spark plug hole and pulling the starter, you can check the compression in the cylinder

If you feel that your finger is being pulled strongly into the spark plug channel, then everything is in order with compression. The absence of vacuum in the chamber indicates a malfunction. The cylinder-piston group needs a more detailed inspection, which will give an idea of the condition of the piston and cylinder, piston rings and bearings.

A chainsaw may not start when cold due to a lack of compression in the engine crankcase. The main reason for this is damage to the gasket located between the cylinder and the crankcase. It is quite easy to detect a lack of compression:

- Disconnect the upper tube from the carburetor;

- Pour gasoline into a regular cork;

- We immerse the removed tube in the fuel;

- We pull the starter several times.

If fuel is sucked out of the cap when the chainsaw starter starts, then everything is fine with compression. If not, look at the gasket.

If the fuel is drawn in, then everything is fine - the gasket is intact. Otherwise, you will have to purchase a repair kit and make a replacement. How to do this, watch the video why a Chinese chainsaw won’t start:

Starting the tool may be complicated by improper operation of the carburetor or its breakdown. It often happens that during the sawing process the fastening screws become loose and air is sucked into the cylinder. Check that the carburetor is securely fastened. Inspect it for fuel leaks. There can be many reasons for the malfunction. It is possible to accurately determine the malfunction, eliminate it and fine-tune the carburetor only at a service center.

After going through a step-by-step troubleshooting of the chainsaw engine, you will be able to find the malfunction, fix it yourself and successfully start your working tool. Do not take on types of work that you are not confident in. Entrust troubleshooting and troubleshooting to specialists from the service center.