Mechanical properties characterize the ability of materials to resist external forces. The main mechanical properties include strength, hardness, impact strength, elasticity, ductility, brittleness, etc.

Strength is the ability of a material to resist the destructive effects of external forces.

Hardness is the ability of a material to resist the penetration of another, harder body into it under load.

Viscosity is the property of a material to resist destruction under dynamic loads.

Elasticity is the property of materials to restore their size and shape after the load is removed.

Plasticity is the ability of materials to change their size and shape under the influence of external forces without collapsing.

Fragility is the property of materials to collapse under the influence of external forces without residual deformation.

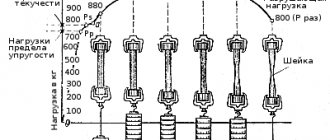

In static tensile tests, values characterizing the strength, ductility and elasticity of the material are determined. Tests are carried out on cylindrical (or flat) samples with a certain ratio between length l0 and diameter d0. The sample is stretched under the action of the applied force P (Fig. 1, a) until destruction. An external load causes stress and deformation in the sample. Stress σ is the ratio of force P to cross-sectional area F0, MPa:

σ = P/F0,

Deformation characterizes the change in sample dimensions under load, %:

ε = [(l1-l0)/l0] 100,

where l1 is the length of the stretched sample.

Deformation can be elastic (disappearing after the load is removed) or plastic (remaining after the load is removed).

During testing, a tensile diagram is drawn, which represents the dependence of stress on deformation. In Fig. 1 shows such a diagram for low-carbon steel. After testing, the following characteristics of mechanical properties are determined.

The elastic limit σу is the maximum stress at which plastic deformation does not occur in the sample.

The yield strength σт is the stress corresponding to the yield area on the tensile diagram (Fig. 1). If there is no yield plateau on the diagram (which is observed for brittle materials), then the conditional yield strength σ0.2 is determined - the stress causing plastic deformation equal to 0.2%. Ultimate strength (or temporary resistance) σв is the stress corresponding to the maximum load that the sample can withstand during testing.

Relative elongation after rupture δ is the ratio of the increment in length of the sample during tension to the initial length l0, %:

δ = [(lk-l0)/l0] 100,

where lк is the length of the sample after rupture.

Rice. 1. Static tensile tests: a – test diagram;

b – tension diagram

Relative narrowing after rupture ψ is the decrease in the cross-sectional area of the sample, related to the initial cross-section of the sample, %:

ψ = [(F0-Fk)/F0] 100,

where Fк is the cross-sectional area of the sample at the fracture site. Relative elongation and relative contraction characterize the plasticity of the material.

The hardness of metals is measured by pressing a hard tip of various shapes into the test sample.

The Brinell method is based on pressing a hardened steel ball into the metal surface under a certain load. After the load is removed, an imprint remains in the sample. The Brinell hardness number HB is determined by the ratio of the load acting on the ball to the surface area of the resulting print.

The Rockwell method is based on pressing a hardened steel ball with a diameter of 1.588 mm (scale B) or a diamond cone with an apex angle of 120° (scales A and C) into the test sample. Indentation is carried out under the action of two loads - preliminary equal to 100 N and final equal to 600, 1000. 1500 N for scales A, B and C, respectively. The Rockwell hardness number HRA, HRB and HRC is determined by the difference in indentation depths.

The Vickers method uses indentation of a diamond tetrahedral pyramid with an apex angle of 136°. The Vickers hardness number HV is determined by the ratio of the applied load to the surface area of the indentation.

Impact strength is determined by the work A spent on the destruction of the sample, divided by its cross-sectional area F; J/m2:

KC=A/F

Tests are carried out by hitting a special pendulum pile driver. For testing, a standard notched sample is used, mounted on the supports of the pile driver. A pendulum of a certain mass strikes the side opposite the cut.

The physical properties of materials include density, melting point, electrical conductivity, thermal conductivity, magnetic properties, coefficient of thermal expansion, etc.

Density is the ratio of the mass of a homogeneous material to a unit of its volume.

This property is important when using materials in aviation and rocket technology, where the structures created must be light and durable.

Melting point is the temperature at which a metal changes from solid to liquid. The lower the melting temperature of the metal, the easier the processes of its melting and welding proceed and the cheaper they are.

Electrical conductivity is the ability of a material to conduct electric current well and without heat loss. Metals and their alloys, especially copper and aluminum, have good electrical conductivity. Most non-metallic materials are unable to conduct electric current, which is also an important property used in electrical insulating materials.

Thermal conductivity is the ability of a material to transfer heat from more heated parts of bodies to less heated ones. Metal materials are characterized by good thermal conductivity.

Magnetic properties i.e. Only iron, nickel, cobalt and their alloys have the ability to be magnetized well.

The coefficients of linear and volumetric expansion characterize the ability of a material to expand when heated. This property is important to take into account when building bridges, laying railway and tram tracks, etc.

Chemical properties characterize the tendency of materials to interact with various substances and are associated with the ability of materials to resist the harmful effects of these substances. The ability of metals and alloys to resist the action of various aggressive environments is called corrosion resistance, and the similar ability of non-metallic materials is called chemical resistance.

Operational (service) properties include heat resistance, heat resistance, wear resistance, radiation resistance, corrosion and chemical resistance, etc.

Heat resistance characterizes the ability of a metal material to resist oxidation in a gas environment at high temperatures.

Heat resistance characterizes the ability of a material to maintain mechanical properties at high temperatures.

Wear resistance is the ability of a material to resist destruction of its surface layers due to friction.

Radiation resistance characterizes the ability of a material to resist the effects of nuclear radiation.

Technological properties determine the ability of materials to be subjected to various types of processing. Casting properties are characterized by the ability of metals and alloys in the molten state to fill the mold cavity well and accurately reproduce its outline (fluidity), the amount of volume reduction during solidification (shrinkage), the tendency to form cracks and pores, and the tendency to absorb gases in the molten state. Malleability is the ability of metals and alloys to undergo various types of pressure treatment without destruction. Weldability is determined by the ability of materials to form strong welded joints. Machinability is determined by the ability of materials to be processed by a cutting tool.

Types of crystal lattices

All metals in the solid state are crystals.

A crystal is a collection of atoms located in space not randomly, but in a geometrically correct sequence. The spatial arrangement of atoms forms a crystal lattice. Positively charged ions are correctly located at the nodes of the spatial crystal lattice of the metal, and free electrons—electron gas—move between them. Moving from one cation to another, they bond between the ions and transform the metal crystal into a single whole. This bond, called a metallic bond, occurs between metal atoms due to the overlapping electron clouds of outer electrons. A metallic bond differs from a non-polar covalent bond in that it is non-directional. In a metal-type crystal, electrons are not fixed between two atoms, but belong to all atoms of a given crystal, that is, they are delocalized. Features of the structure of metal crystals include large coordination numbers – 8÷12, which correspond to a high packing density.

The crystal lattice of each metal consists of positively charged ions of the same size, located in the crystal according to the principle of the most dense packing of balls of the same diameter.

There are three main types of packaging, or crystal lattice.

1. Body-centered cubic lattice with a coordination number of 8 (sodium, potassium, barium). The metal atoms are located at the vertices of the cube, and one is in the center of the volume. The packing density of spherical ions in this case is 68%.

2. Face-centered cubic lattice with a coordination number of 12 (aluminum, copper, silver). Metal atoms are located at the vertices of the cube and at the center of each face. Packing density – 74%.

3. Hexagonal lattice with coordination number 12 (magnesium, zinc, cadmium). Metal atoms are located at the vertices and center of the hexagonal bases of the prism, and three more are located in its middle plane. Packing density – 74%.

Due to the unequal density of atoms in different directions of the crystal, different properties are observed. This phenomenon, called anisotropy, is characteristic of single crystals - single crystals. However, most metals under normal conditions have a polycrystalline structure, that is, they consist of a significant number of crystals, or grains, each of which is anisotropic. Different orientations of individual grains lead to averaging of the properties of a polycrystalline metal.

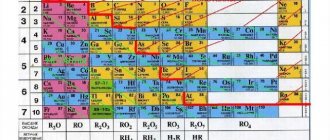

The characteristics of crystal lattices determine the characteristic physical properties of metals.

Properties of alloys

The properties possessed by metal alloys are divided into:

- Structurally insensitive. They are determined by the properties of the components and their percentage. These include :

- density;

- melting temperature;

- thermal and elastic characteristics;

- coefficient of thermal expansion;

- structurally sensitive. Determined by the properties of the element - the base.

- https://www.youtube.com/watch?v=qgzo40bfL1o

- All alloy materials exhibit characteristic metallic properties to one degree or another:

- shine;

- plastic;

- thermal conductivity;

- electrical conductivity.

- In addition, properties are divided into:

- Chemical, determined by the relationship of the material with chemically active substances.

- Mechanical, determined by interaction with other physical bodies.

- The main characteristics of alloy materials that influence their suitability for use in a particular engineering structure are:

- Strength is a characteristic of the strength to withstand mechanical loads and destruction.

- Hardness is the ability to resist the penetration of solid bodies into a material.

- Elasticity is the ability to restore the original shape of a body after deformation caused by external load.

- Plasticity is the opposite property of elasticity. Determines the ability of a material to change the shape of a body without its destruction under an applied load and maintaining this new shape.

- Viscosity - the ability to resist rapidly increasing (shock) loads

Rolled metal

There are physical, chemical, mechanical and technological properties of metals and alloys.

The physical properties of metals are determined by their physical state or relationship to various physical processes (the action of high and low temperatures, electric current, etc.). These include density, melting point, crystallization point, thermal conductivity, thermal expansion, electrical resistance, electrical conductivity, etc.

Density -

this is the mass of a unit volume of metal in an absolutely dense state (kg/m3). Absolute density is also called specific gravity (mass).

Melting temperature

is the temperature at which a metal changes from a solid state to a liquid (molten) state.

The temperature at which a metal, when cooled, passes from a molten state to a solid state is called the crystallization temperature.

The ability of a material to transfer heat through its thickness from one surface to another is called thermal conductivity.

It is determined by the thermal conductivity coefficient, which shows the amount of heat passing through a sample of material with a thickness of 1 m and an area of 1 m2 within an hour when the temperature difference on opposite sides of the sample is 1 ° C.

Temperature expansion

is the ability of a material to expand due to heating. It is characterized by the coefficient of linear expansion, which shows by what fraction of the original length the material expanded when the temperature increases by 1°C.

Electrical resistance

determined by the ability of a material to resist the passage of electric current. It is measured in ohms (ohms).

Electrical conductivity

- the ability of a material to conduct electric current. The unit is Siemens (Sm).

The chemical properties of metals are determined by their resistance to the environment, acids, alkalis and other chemical reagents. To assess the degree of destruction of metals in various environments, an indicator called corrosion resistance is used.

It is determined by the corrosion rate, i.e., the mass of material converted into rust per unit surface per unit of time, or the thickness of the destroyed layer (mm/year). Characteristics of corrosion resistance can also be changes in the mass of the product, its mechanical properties, electrical resistance and the amount of hydrogen released over a certain period of time.

The mechanical properties of metals determine their ability to resist external mechanical forces. These include strength, ductility, hardness, brittleness, endurance, fatigue, elasticity, abrasion, wear resistance and creep.

Strength

- this is the property of a material to resist destruction under the influence of applied mechanical forces.

Plastic

— the property of a metal to deform irreversibly without breaking its continuity under the influence of mechanical loads, while absorbing mechanical energy.

Hardness

- this is the property of a material to resist penetration into it by another, which does not receive residual deformation of the body.

Fragility

determined by the ability of a material to collapse without noticeable absorption of mechanical energy.

The ability of a material to withstand, without breaking, a large number of repeatedly alternating stresses is called endurance.

The gradual destruction of a material under a large number of repeatedly alternating stresses is called

fatigue.

Elasticity

- the property of a material to restore its shape and volume after removing the load. It is caused by the interaction between atoms and their thermal motion.

Abrasion

- the property of a material to resist the action of external mechanical forces (friction forces), causing gradual destruction of its surface.

Wear resistance

- the property of a material to resist the simultaneous action of abrasion and impact.

Creep

- the property of a material to slowly and continuously deform under constant stress and elevated temperature.

To determine the mechanical properties of metals, static tests for tension, compression, bending and torsion, dynamic tests for impact strength, as well as tests for fatigue, creep, long-term strength and hardness are carried out.

The main characteristics of mechanical properties, determined by static tests for tension, compression, bending and torsion, are the limits of yield, proportionality, elasticity, true and temporary tensile strength, measured in pascals (Pa), as well as relative and permanent elongation and relative contraction.

Dynamic tests make it possible to determine the most important mechanical characteristic of metals exposed to shock loads—impact strength (J/m2).

Fatigue tests are carried out for metals operated under conditions of long-term, repeatedly variable loads, which result in the appearance and growth of cracks on the surface, ultimately leading to destruction. Fatigue tests determine the endurance limit (Pa).

Creep and long-term strength tests are necessary for metals exposed to high temperatures and long-term loads. In this case, the main characteristics are the conventional creep strength and long-term strength.

The most common methods for determining the mechanical properties of metals are hardness tests. They are based on the static indentation of a hardened steel ball (Brinell method), a diamond cone or hardened steel ball (Rockwell method) or a diamond pyramid (Vickers method) on special devices called hardness testers. Accordingly, the hardness number according to Brinell (HB), Rockwell (HR) and Vickers (HV) is determined,

To determine the hardness of individual grains of metal or different parts of one grain, a microhardness test is performed. Measurements are made using special instruments by indenting a diamond pyramid and examining the resulting imprint using a metallographic microscope.

Dynamic methods for measuring hardness are also known.

These include the method of elastic rebound of the striker (according to Shore), as well as measuring hardness using the impact imprint method. The maximum hardness of materials, according to Shore, is 100 units.

The technological properties of metals determine their ability to be subjected to various processing methods. These include machinability by cutting and pressure, weldability, hardening, as well as casting and other properties.

Machinability

is estimated by the rate of blunting of the cutter when turning in given modes, ensuring the necessary parameters of the resulting

surfaces. It is measured as a percentage of the processing speed of steel or leaded brass.

Pressure workability

in hot and cold states, they are assessed by technological tests for shrinkage, bending, elongation of the spherical dimple, etc., as well as by indicators of ductility, hardness and hardening.

Weldability

- this is the property of metals to form permanent connections with the required mechanical properties.

Foundry properties

are determined by a combination of indicators such as melting and crystallization temperatures, density, fluidity, shrinkage, etc.

Hardening

is the ability of metals to acquire higher mechanical properties after mechanical and heat treatments.

Structure of metals and alloys, their crystallization

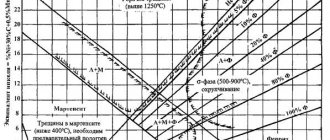

Technological properties of steel

Steel is considered one of the most common metals; its technological properties depend on its chemical composition; various impurities included in it can improve or worsen these characteristics.

- An increase in the carbon composition of steel significantly increases its hardenability, at the same time it reduces its suitability for forging. To perform this operation, as well as rolling, the carbon content should not exceed 1.4%.

- Adding manganese to steel significantly reduces the thermal conductivity of the material, which reduces its weldability. At the same time, with proper uniform heating (not too fast), such steels lend themselves well to forging.

- The use of nickel can improve the ductility of the alloy, so it facilitates forging. But one should take into account the fact that the same nickel forms stable scale during the heating process. It is not destroyed during forging, so it can be forged into metal, which will significantly reduce the quality of the product.

- An increase in chromium content leads to an increase in strength, so forging and rollingability of such alloys is satisfactory; there is a high probability of crack formation.

- Excess molybdenum leads to a decrease in thermal conductivity, which makes the steel very sensitive to the processing temperature; it should be heated and cooled in strict compliance with the technology. To forge these metals, it is necessary to use more powerful equipment.

- But the use of vanadium, on the contrary, improves malleability and makes the steel more resistant to overheating.

Negative impurities that significantly affect technological characteristics include sulfur and phosphorus. Excess of these substances can lead to red brittleness and cold brittleness, respectively. That is, steel with excess sulfur becomes brittle when heated, and if it contains a large amount of phosphorus, it will break at subzero temperatures. That is why, during steel smelting, many efforts are aimed at reducing these impurities in the metal, but, unfortunately, it is not possible to completely get rid of them.

As you can see, the chemical components of steel have a huge impact on its technological properties, therefore, when choosing a processing method, a thorough analysis of the composition of the alloy must be performed, otherwise problems may arise both in production and during operation of the product.

Mechanical properties

Mechanical properties are the reactions of materials to mechanical loads applied to them.

The physical and mechanical properties of materials often overlap, but there are a number of exclusively mechanical properties. From the mechanical point of view, substances are characterized by elasticity, strength, hardness, ductility, fatigue, fragility, etc.

Elasticity is the ability of bodies (solids) to resist influences aimed at changing their volume or shape. An object with a high elasticity value is resistant to mechanical stress and is capable of self-recovery, returning to its original state after the impact ceases.

Strength shows how resistant a material is to fracture. Its maximum value for a particular object is called tensile strength. Plasticity also refers to strength indicators. It is the property (characteristic of solids) to irrevocably change its appearance (deform) under the influence of forces coming from outside.

Fatigue is a cumulative process in which, as a result of repeated mechanical stress, the level of internal stress of a material increases. This level will increase until it crosses the elastic limit, causing the material to begin to fail.

One of the most common properties is hardness. It represents the level of resistance of an object to indentation.

Basic definitions

It is necessary to clearly understand that metal alloys in most cases are formed without any human involvement at all. The fact is that it is possible to obtain a material that is absolutely pure from a chemical point of view only in the laboratory. Any metal that is used in everyday life probably contains traces of another element. A classic example is gold jewelry. Each of them contains a certain proportion of copper. However, in the classical sense, this definition still means a compound of two or more metals, which was purposefully obtained by man.

The entire history of man is an excellent example of how metal alloys were able to have a huge impact on the development of our entire civilization. It is no coincidence that there is even a long historical period called the “Bronze Age”.

Aluminum alloys

If the first half of the 20th century was the century of steel, then the second was rightly called the century of aluminum.

Aluminum alloys are divided into:

- Foundry (with silicon). Used to produce conventional castings.

- For injection molding (with manganese).

- Increased strength, with the ability to self-harden (with copper).

https://youtube.com/watch?v=5v8kGT8HK5c

Main advantages of aluminum compounds:

- Availability.

- Low specific gravity.

- Durability.

- Cold resistance.

- Good machinability.

- Electrical conductivity.

The main disadvantage of alloy materials is low heat resistance. When reaching 175°C, a sharp deterioration in mechanical properties occurs.

Another area of application is the production of weapons. Aluminum-based substances do not spark under strong friction and collisions. They are used to produce lightweight armor for wheeled and flying military equipment.

Aluminum alloy materials are widely used in electrical engineering and electronics. High conductivity and very low magnetizability make them ideal for the production of housings for various radio and communications devices, computers and smartphones.

Aluminum alloy ingots

The presence of even a small proportion of iron significantly increases the strength of the material, but also reduces its corrosion resistance and ductility. A compromise on iron content is found depending on the requirements for the material. The negative effect of iron is compensated by adding metals such as cobalt, manganese or chromium to the alloy composition.

Magnesium-based materials compete with aluminum alloys, but due to their higher price they are used only in the most critical products.

Methods for studying the structure of metals

The study of the structure of metals and alloys is carried out using macro- and microanalysis methods, the X-ray method, as well as flaw detection methods (X-ray, magnetic, ultrasonic).

The macroanalysis method is used to study the macrostructure, i.e. structure visible to the naked eye or with a magnifying glass. This reveals large defects: cracks, shrinkage cavities, gas bubbles, etc., as well as uneven distribution of impurities in the metal. The macrostructure is determined by the fractures of the metal, by macrosections (this is a sample of a metal or alloy, one of the sides of which is polished, thoroughly degreased, etched and examined with a magnifying glass with a magnification of 5–10 times).

Microanalysis reveals the structure of a metal or alloy using microsections, additionally polished to a mirror finish. The thin sections are examined in reflected light under an optical microscope at a magnification of up to 3000 times. Due to the different orientation of the metal grains, they are not etched to the same extent, and under a microscope, light is also reflected differently. Due to impurities, grain boundaries are etched more strongly than the base metal and are revealed more prominently. Knowing the microstructure, it is possible to explain the reasons for changes in the properties of the metal.

Using X-ray analysis, the atomic structure of metals, the types and parameters of crystal lattices, as well as defects lying in depth are studied. This analysis, based on the diffraction (reflection) of X-rays by rows of atoms in a crystal lattice, allows you to detect defects without destroying the metal. Instead of defects, X-rays are absorbed less than in solid metal, and therefore on photographic film such rays form dark spots corresponding to the shape of the defect.

The magnetic method is used to examine defects in magnetic metals (steel, nickel, etc.) at a depth of up to 2 mm. To do this, the product being tested is magnetized, its surface is coated with iron powder, the surface is inspected, and the product is demagnetized. A non-uniform field is formed around the defect, and the magnetic powder follows the contours of the defect. The ultrasonic method provides effective control of the quality of metal products and workpieces of almost any size. In pulsed ultrasonic flaw detectors, the ultrasonic wave from the probe-emitter propagates in the test product and, when it encounters a defect, is reflected from it. In this case, the reflected waves are received, amplified and transmitted to the indicating indicator.

Metal classification

In nature, there are several types of metals that differ in their properties, characteristics and appearance. Each variety behaves differently when interacting with other materials or under the influence of environmental factors.

Types of metals

Black

This group includes iron and alloys based on it. Characteristic features of ferrous metals:

- high density;

- the melting point is much higher than that of representatives of other groups;

- color - dark gray.

Representatives of the group of ferrous metals include: tungsten, chromium, cobalt, molybdenum, iron, nickel, titanium, manganese, uranium, neptunium, plutonium and others. They are used in various industries and have different properties. Steel and cast iron are considered popular.

The composition of ferrous metals includes not only iron, but also various impurities, which include sulfur, phosphorus or silicon. They contain different amounts of carbon in their composition.

Colored

Representatives of this group are more in demand. This is due to the fact that non-ferrous metals are used in more industries. They can be used in mechanical engineering, advanced technologies, radio electronics, and metallurgy. Key features of non-ferrous metals:

- low melting point;

- large color spectrum;

- good ductility.

Due to the low strength of representatives of the color group, they are used in conjunction with different types of denser materials. Representatives of this group: magnesium, aluminum, nickel, lead, tin, zinc, silver, platinum, rhodium, gold and others.

Soft

It is possible to distinguish certain types of metals, which will belong to the group of hard and soft. The soft ones are:

- Aluminum - has corrosion resistance, light weight, good ductility. It is used in the electrical industry, in the construction of aircraft and in the manufacture of dishes.

- Magnesium is a lightweight material that is susceptible to corrosive processes. To get rid of this drawback, it is used in alloys with other materials.

These are key representatives of the group of soft metals.

Solid

Popular materials in this group are:

- Tungsten is considered the most refractory metal. In addition to this, it is one of the most durable. Resistant to chemical influences.

- Titanium - the fewer inclusions of other materials in this metal, the stronger it becomes. It is used in the construction of cars, rockets, airplanes, ships, as well as in the chemical industry. It is well processed under pressure and is not susceptible to corrosive processes.

- Uranium is another metal considered one of the strongest in the world. It is radioactive and is used in various industries.

Representatives of the “hard group” are less amenable to processing and are used in fewer areas of human activity than soft ones.

Physico-chemical and chemical properties of materials

Note that it is during a series of analyzes that it is important to be able to not only identify the incoming elements, but their quantity and proportions.

And for this it is necessary to determine the chemical and physico-chemical properties of the objects of research . Basic chemical properties of materials:

- ability to react with volatile substances and oxygen;

- acid resistance;

- alkali resistance.

The properties of materials characterize the ability to interact with them or counteract the destructive properties of these solutions.

Physico-chemical properties of materials:

- color and density;

- the temperature at which the material melts and disintegrates;

- thermal conductivity and electrical conductivity of the material;

- magnetic properties and resistance to corrosion if metals are present.

What species are found?

The properties of metals largely depend on what type a particular ingredient belongs to. From this perspective, it is worth highlighting the black and colored components.

Chermet

This group is considered the most common and in demand from a volumetric perspective. They got their name due to their dark color. At the same time, a distinctive feature of ferrous ores is their low cost.

In turn, it is classified into:

- iron - this includes iron-containing materials and bases, as well as nickel and cobalt alloys;

- refractory bases for alloys (have a melting point equal to or exceeding 1600 degrees Celsius, which is a fairly high indicator);

- low-strength rare earth elements, such as cerium, neodymium and others (actively used in the production of microelectronics).

Tsvetmet

It is generally accepted that this group of elements is characterized by lower strength characteristics, melting point, resistance to mechanical loads, but a more respectable cost. It is clear that there are exceptions to all these positions.

People of color are ranked into the following categories:

- Lungs - lithium, sodium and so on. They are characterized by low density - up to 5 tons per cubic meter. This is only 5 times more water.

- Heavy - lead, silver, gold. Their density is several times higher than that of lungs.

- Noble ones are the same gold and silver, as well as platinum and plutonium.

“Colored” varieties can also be divided into refractory and low-melting.

Hydrophysical properties

The consequences of exposure of a material to water or frost largely depend on the degree of its density and porosity, which affect the level of water absorption, water permeability, frost resistance, thermal conductivity, etc.

Water absorption is the ability of a substance to absorb and retain moisture. The high level of porosity plays an important role in this case.

Moisture loss is a property opposite to water absorption, that is, it characterizes the material from the point of view of the release of moisture into its environment. This value plays an important role in the processing of certain substances, for example, construction materials, which have high humidity during the construction process. Thanks to moisture transfer, they dry until their humidity is equal to the environment.

Hygroscopicity is a property that involves the absorption of water vapor from the outside by an object. For example, wood can absorb a lot of moisture, as a result of which its mass increases, its strength level decreases and its size changes.

Shrinkage or shrinkage is a hydrophysical property of materials, which involves a decrease in its volume and size during the drying process.

Water resistance is the ability of a substance to retain its strength when wet.

Frost resistance is the ability of a material saturated with water to withstand freezing and thawing repeatedly without reducing the level of strength and destruction.

Structure of a mechanical ingot

The shape of the growing crystals is determined by:

- the conditions of their contact with each other;

- alloy composition;

- presence of impurities;

- cooling mode.

The mechanism of crystal formation is dendritic (tree-like) in nature. Dendritic crystallization is characterized by the fact that the growth of nuclei occurs at an uneven rate. After the formation of nuclei, their development proceeds in those planes and lattice directions that have the highest packing density of atoms and the minimum distance between them. In these directions, long branches of the future crystal—first-order axes—are formed. From the axes of the first order, new axes of the second order begin to grow, from the axes of the second order, axes of the third order, etc.

Steel ingots are produced by cooling in metal molds (molds) or in continuous casting plants. In a mold, steel cannot harden simultaneously throughout its entire volume, since it is impossible to create a uniform rate of heat removal. Therefore, the process of steel crystallization begins at the cold walls and bottom of the mold and spreads into the liquid metal. When the liquid metal comes into contact with the walls of the mold, a zone of small equiaxed crystals is formed at the initial moment. Since the volume of solid metal is less than liquid, an air gap forms between the wall of the mold and the solidified metal and the wall itself heats up from contact with the metal, so the cooling rate of the metal decreases and the crystals grow in the direction of heat removal. In this case, a zone is formed consisting of tree-like (columnar) crystals.

In the inner zone of the ingot, as a result of slow cooling, equiaxed, non-oriented crystals of large sizes are formed. In the upper part of the ingot, which solidifies last, a shrinkage cavity is formed, since upon cooling the volume of the metal decreases. Under the shrinkage cavity, the metal turns out to be loose due to the large number of shrinkage pores.

To obtain products, only part of the ingot is used, removing the shrinkage cavity and loose metal of the ingot for subsequent remelting.

Classification of building materials

According to the method of production, all building materials are divided into:

- natural;

- artificial.

According to their origin they are:

- stone;

- forest;

- metal;

- glass;

- polymer, etc.

In general, nine groups of building materials can be roughly distinguished:

- Materials for the construction of foundations and walls (concrete, brick, timber, rubble and others).

- Roofing materials (tiles, slate, sheet steel, roofing felt).

- Finishing materials (plasterboard, primers, plaster mixtures).

- Decorative materials (paper wallpaper, parquet, laminate, artificial stone panels).

- Installation materials (nails, screws, staples, dowels).

- Construction mortars (cement, lime, adhesive mixtures, acoustic mortars).

- Polymer materials (plastic, polyethylene, polystyrene, polycarbonate).

- Insulating materials (sawdust, shavings, foam glass, mineral wool).

- Materials for road construction (asphalt, asphalt concrete, bitumen, paving stones).

Main types of alloys

The most numerous types of metal alloys are made based on iron. These are steels, cast irons and ferrites.

Steel is an iron-based substance containing no more than 2.4% carbon, used for the manufacture of parts and housings for industrial installations and household appliances, water, land and air transport, tools and devices. Steels have a wide range of properties. The common ones are strength and elasticity. The individual characteristics of individual steel grades are determined by the composition of alloying additives introduced during smelting. Half of the periodic table is used as additives, both metals and non-metals. The most common of them are chromium, vanadium, nickel, boron, manganese, phosphorus.

Alloy steel

If the carbon content is more than 2.4%, such a substance is called cast iron. Cast iron is more brittle than steel. They are used where it is necessary to withstand large static loads with small dynamic ones. Cast iron is used in the production of frames for large machine tools and technological equipment, bases for work tables, and in the casting of fences, gratings, and decorative items. In the 19th and early 20th centuries, cast iron was widely used in building structures. Cast iron bridges have survived to this day in England.

Cast iron radiators

Substances with a high carbon content and having pronounced magnetic properties are called ferrites. They are used in the production of transformers and inductors.

Copper-based metal alloys containing from 5 to 45% zinc are commonly called brasses. Brass is slightly susceptible to corrosion and is widely used as a structural material in mechanical engineering.

Yellow brass

If you add tin to copper instead of zinc, you get bronze. This is perhaps the first alloy deliberately obtained by our ancestors several thousand years ago. Bronze is much stronger than both tin and copper and is second in strength only to well-forged steel.

Lead-based substances are widely used for soldering wires and pipes, as well as in electrochemical products, primarily batteries and accumulators.

Two-component aluminum-based materials, which contain silicon, magnesium or copper, are characterized by low specific gravity and high machinability. They are used in the engine, aerospace, and electrical component and appliance industries.

Physical properties of metals

Among the main general physical properties of metals are:

- Melting.

- Density.

- Thermal conductivity.

- Thermal expansion.

- Electrical conductivity.

An important physical parameter of a metal is its density or specific gravity. What it is? The density of a metal is the amount of substance contained in a unit volume of the material. The lower the density, the lighter the metal. Light metals are: aluminum, magnesium, titanium, tin. Heavy metals include such metals as chromium, manganese, iron, cobalt, tin, tungsten, etc. (in total there are more than 40 types).

The ability of a metal to change from a solid to a liquid state is called melting. Different metals have different melting points.

The rate at which heat is conducted in a metal when heated is called the thermal conductivity of the metal. And compared to other materials, all metals have high thermal conductivity; to put it simply, they heat up quickly.

In addition to thermal conductivity, all metals conduct electric current, although some do it better and some worse (this depends on the structure of the crystal lattice of a particular metal). The ability of a metal to conduct electric current is called electrical conductivity. Metals with excellent electrical conductivity are gold, aluminum and iron, which is why they are often used in the electrical industry and instrument making.

Basic information about metal alloys (basics of general metal technology)

All metals and metal alloys have certain properties. The properties of metals and alloys are divided into four groups: physical, chemical, mechanical and technological.

Physical properties . The physical properties of metals and alloys include: density, melting point, thermal conductivity, thermal expansion, specific heat, electrical conductivity, and magnetizability. The physical properties of some metals are given in the table:

Physical properties of metals

| Name metal | Specific weight, g 1cm3 | Melting point, °C | Linear expansion coefficient, α 10-6 | Specific heat capacity C, cal/g-deg | Thermal conductivity λ, Cal/cm sec-deg | Electrical resistivity at 20°, Ohm mm/m |

| Aluminum | 2,7 | 660 | 23,9 | 0,21 | 0,48 | 0,029 |

| Vanadium | 6,0 | 1720 | 12,3 | 0,11 | — | — |

| Tungsten | 19,3 | 3377 | 45,0 | 0,34 | 0,38 | 0,053 |

| Iron | 7,86 | 1539 | 11,9 | 0,11 | 0,14 | 0,10 |

| Cobalt | 8,9 | 1480 | 12,7 | 0,10 | 0,16 | 0,097 |

| Magnesium | 1,74 | 651 | 26,0 | 0,25 | 0,37 | 0,044 |

| Manganese | 7,2 | 1260 | 23,0 | 0,12 | 0,05 | |

| Copper | 8,92 | 1083 | 26,7 | 0,09 | 0,92 | 0,044 |

| Molybdenum | 10,2 | 2622 | 5,2 | 0,065 | 0,35 | 0,054 |

| Nickel | 8,9 | 1455 | 13,7 | 0,11 | 0,14 | 0,070 |

| Tin | 7,31 | 232 | 22,4 | 0,055 | 0,16 | 0,113 |

| Lead | 11,3 | 327 | 29,3 | 0,031 | 0,084 | 0,208 |

| Titanium | 4,5 | 1660 | 7,14 | 0,11 | 0,048 | |

| Chromium | 7,1 | 1800 | 8,4 | 0,111 | 0,131 | |

| Zinc | 7,14 | 420 | 32,6 | 0,91 | 0,27 | 0,061 |

Density. The amount of substance contained in a unit volume is called density. The density of the metal can vary depending on the method of its production and the nature of processing.

Melting temperature . The temperature at which a metal completely changes from solid to liquid is called melting point . Each metal or alloy has its own melting point. Knowing the melting point of metals helps to correctly conduct thermal processes during heat treatment of metals.

Thermal conductivity. The ability of bodies to transfer heat from more heated particles to less heated ones is called thermal conductivity. The thermal conductivity of a metal is determined by the amount of heat that passes through a metal rod with a cross section of 1 cm2 and a length of 1 cm for 1 second. at a temperature difference of 1°C.

Thermal expansion. Heating a metal to a certain temperature causes it to expand.

The amount of elongation of a metal when heated is easy to determine if the coefficient of linear expansion of the metal α is known. The coefficient of volumetric expansion of the metal ß is equal to 3α.

Specific heat capacity . The amount of heat required to increase the temperature of 1g of a substance by 1°C is called specific heat capacity. Metals have a lower heat capacity compared to other substances, so they are heated without much heat.

Electrical conductivity. The ability of metals to conduct electric current is called electrical conductivity. The main quantity characterizing the electrical properties of a metal is the electrical resistivity ρ, i.e., the resistance that a wire of a given metal with a length of 1 m and a cross-section of 1 mm2 offers to current. It is defined in ohms. The reciprocal of electrical resistivity is called electrical conductivity.

Most metals are highly conductive, such as silver, copper and aluminum. With increasing temperature, electrical conductivity decreases, and with decreasing temperature it increases.

Magnetic properties. The magnetic properties of metals are characterized by the following quantities: remanent induction, coercive force and magnetic permeability.

Residual induction (Br) is the magnetic induction that remains in the sample after it is magnetized and the magnetic field is removed. Residual induction is measured in Gauss.

Coercive force (Hc) is the magnetic field strength that must be applied to the sample in order to reduce the residual induction to zero, i.e., demagnetize the sample. Coercive force is measured in oersteds.

Magnetic permeability μ characterizes the ability of a metal to be magnetized under determined by the formula

μ=Br/Hc.

Iron, nickel, cobalt and gadolinium are attracted to an external magnetic field much stronger than other metals, and permanently retain the ability to be magnetized. These metals are called ferromagnetic (from the Latin word ferrum - iron), and their magnetic properties are called ferromagnetism. When heated to a temperature of 768°C (Curie temperature), ferromagnetism disappears and the metal becomes non-magnetic.

Chemical properties. The chemical properties of metals and metal alloys are properties that determine their relationship to the chemical effects of various active media. Each metal or metal alloy has a certain ability to resist the effects of these environments.

The chemical effects of the environment manifest themselves in various forms: iron rusts, bronze is covered with a green layer of oxide, steel, when heated in hardening furnaces without a protective atmosphere, oxidizes, turning into scale, and dissolves in sulfuric acid, etc. Therefore, for the practical use of metals and alloys it is necessary know their chemical properties. These properties are determined by the change in the weight of the test samples per unit of time per unit of surface. For example, the resistance of steel to scale formation (heat resistance) is determined by the increase in the weight of the samples in 1 hour per 1 dm of surface in grams (the weight gain is obtained due to the formation of oxides).

Mechanical properties. Mechanical properties determine the performance of metal alloys when exposed to external forces. These include strength, hardness, elasticity, ductility, impact strength, etc.

To determine the mechanical properties of metal alloys, they are subjected to various tests.

Tensile test (tear test). This is the main test method used to determine the proportionality limit σпз, yield strength σs, tensile strength σb, relative elongation σ and relative contraction ψ.

For tensile testing, special samples are made - cylindrical and flat. They can be of different sizes, depending on the type of tensile testing machine used to test the metal.

The tensile testing machine operates as follows: the test sample is secured in the head clamps and gradually stretched with increasing force P until it breaks.

At the beginning of the test, under small loads, the sample is deformed elastically, its elongation is proportional to the increase in load. The dependence of the elongation of a sample on the applied load is called the law of proportionality.

The greatest load that a sample can withstand without deviating from the law of proportionality is called proportionality limit :

σпц=Рр/Fo,

where Рр - load at point Рр, kgf;

Fo is the initial cross-sectional area of the sample, mm2.

As the load increases, the curve deviates to the side, i.e., the law of proportionality is violated. Up to the point Рр the deformation of the sample was elastic. The deformation is called elastic if it completely disappears after unloading the sample. In practice, the elastic limit for steel is taken to be equal to the proportionality limit.

With a further increase in load (above point Pe), the curve begins to deviate significantly. The lowest load at which the sample deforms without a noticeable increase in load is called yield strength :

σs=Ps/Fo

where P s is the load at point Ps, kgf;

Fo is the initial cross-sectional area of the sample, mm2. After the yield point, the load increases to point Pe, where it reaches its maximum. The tensile strength is determined by dividing the maximum load by the cross-sectional area of the sample:

σb=Pb/Fo,

where Pb is the load at point Pb, kgf;

Fo is the initial cross-sectional area of the sample, mm2. At point Pk the sample breaks. By the change in the sample after rupture, the plasticity of the metal is judged, which is characterized by relative elongation δ and narrowing ψ.

Relative elongation is understood as the ratio of the increment in the length of the sample after rupture to its initial length, expressed as a percentage:

δ=l1-l0/l0 100%

where l1 is the length of the sample after rupture, mm;

l0 is the initial length of the sample, mm.

Relative contraction is the ratio of the reduction in the cross-sectional area of the sample after rupture to its initial cross-sectional area

φ=Fo-F1/F0·100%,

where Fo is the initial cross-sectional area of the sample, mm2;

F1 is the cross-sectional area of the sample at the rupture site (neck), mm2.

Creep test. Creep is the property of metal alloys to slowly and continuously deform plastically under constant load and high temperatures. The main purpose of the creep test is to determine the creep limit - the magnitude of the stress acting for a long time at a certain temperature.

For parts operating for a long time at elevated temperatures, only the creep rate during a steady process is taken into account and boundary conditions are set, for example, 1°/o per 1000 hours. or 1°/o per 10,000 hours.

Impact test The ability of metals to resist impact loads is called impact strength . Structural steels are mainly subjected to impact strength testing, since they must have not only high static strength, but also high impact toughness.

For testing, take a sample of standard shape and size. The sample is cut in the middle so that it breaks in this place during testing.

The sample is tested as follows. The test sample is placed on the supports of the pendulum pile driver with a notch towards the frame. A pendulum of weight G is raised to a height h1. When falling from this height, the pendulum destroys the sample with the tip of a knife, after which it rises to a height h2.

Based on the weight of the pendulum and the height of its rise before and after the destruction of the sample, the work A is determined.

Knowing the work of destruction of the sample, we calculate the impact strength:

αк=А/F

where A is the work expended on the destruction of the sample, kgcm;

F is the cross-sectional area of the sample at the incision site, cm2.

Brinell method . The essence of this method is that , using a mechanical press, a hardened steel ball is pressed into the test metal under a certain load and the hardness is determined by the diameter of the resulting imprint.

Rockwell method . To determine hardness using the Rockwell method, a diamond cone with an apex angle of 120° or a steel ball with a diameter of 1.58 mm is used. With this method, it is not the diameter of the imprint that is measured, but the depth of indentation of a diamond cone or steel ball. The hardness is indicated by the indicator arrow immediately after the end of the test. When testing hardened parts with high hardness, a diamond cone and a load of 150 kgf are used. Hardness in this case is measured on a C scale and designated HRC. If a steel ball and a load of 100 kgf are taken during testing, then the hardness is measured on a B scale and designated HRB. When testing very hard materials or thin products, use a diamond cone and a load of 60 kgf. Hardness is measured on the A scale and designated HRA.

Parts for determining hardness on a Rockwell device must be well cleaned and free of deep marks. The Rockwell method allows you to accurately and quickly test metals.

Vickers method. When determining hardness using the Vickers method, a tetrahedral diamond pyramid with an interface angle of 136° is used as a tip pressed into the material. The resulting print is measured using a microscope included in the device. Then the hardness number HV is found from the table. When measuring hardness, one of the following loads is used: 5, 10, 20, 30, 50, 100 kgf. Small loads make it possible to determine the hardness of thin products and surface layers of nitrided and cyanidated parts. The Vickers instrument is commonly used in laboratories.

Method for determining microhardness. This method measures the hardness of very thin surface layers and some structural components of metal alloys .

Microhardness is determined using the PMT-3 device, which consists of a mechanism for indenting a diamond pyramid under a load of 0.005-0.5 kgf and a metallographic microscope. As a result of the test, the length of the diagonal of the resulting print is determined, after which the hardness value is found from the table. Microsections with a polished surface are used as samples for determining microhardness.

Elastic recoil method . To determine hardness using the elastic recoil method, a Shore device is used, which operates as follows. A striker equipped with a diamond tip falls onto the well-cleaned surface of the test part from a height H. Having struck the surface of the part, the striker rises to a height h. The hardness numbers are calculated based on the height of the striker's rebound. The harder the metal being tested, the greater the rebound height of the striker, and vice versa. Shore's device is used mainly for testing the hardness of large crankshafts, connecting rod heads, cylinders and other large parts, the hardness of which is difficult to measure with other devices. Shore's device allows you to check ground parts without compromising the surface quality, however, the test results obtained are not always accurate.

Hardness conversion table

| Imprint diameter (m m) according to Brinell, ball diameter 10 mm, load 3000 kgf | Hardness number according to | ||||||

| Brinell NV | Rockwell scale | Vickers HV | Shoru HSh | ||||

| H.R.C. | HRB | HRA | |||||

| 2,20 | 780 | 72 | — | 84 | 1224 | 106 | |

| 2,25 | 745 | 70 | — | 83 | 1116 | 102 | |

| 2,30 | 712 | 68 | — | 82 | 1022 | 98 | |

| 2,35 | 682 | 66 | — | 81 | 941 | 94 | |

| 2,40 | 653 | 64 | — | 80 | 868 | 91 | |

| 2.45 2,45 | 627 | 62 | — | 79 | 804 | 87 | |

| 2,50 | 601 | 60 | — | 78 | 746 | 84 | |

| 2,55 | 578 | 58 | .- | 78 | 694 | 81 | |

| 2,60 | 555 | 56 | — | 77 | 650 | 78 | |

| 2,65 | 534 | 54 | — | 76 | 606 | 76 | |

| 2,70 | 514 | 52 | — | 75 | 587 | 73 | |

| 2,75 | 495 | 50. | — | 74 | 551 | 71 | |

| 2,80 | 477 | 49 | 74 | 534 | 68 | ||

| 2,85 | 461 | 48 | — | 73 | 502 | 66. | |

| 2,90 | 444 | 46 | — | 73 | 474 | 64 | |

| 2,95 | 429 | 45 | — | 72 | 460 | 62 | |

| 3,00 | 415 | 43 | — | 72 | 435 | 61 | |

| 3,05 | 401 | 42 | — | 71 | 423 | 59′ | |

| 3,10 | 388 | 41 | _______ | 71 | 401 | 57 | |

| 3,15 | 375 | 40 | 70 | 390 | 56 | ||

| 3,20 | 363 | 39 | 70 | 380 | 54 | ||

| 3,25 | 352 | 38 | 69 | 361 | 53 | ||

| 3,30 | 341 | 36 | 68 | 344 | 51 | ||

| 3,35 | 331. | 35 | 67 | 334 | 50 | ||

| 3,40 | 321 | 33 | 67 | 320 | 49 | ||

| 3,45 | 311 | 32 | 66 | 311 | 47 | ||

| 3,50 | 302 | 31 | 66 | 303 | 46 | ||

| 3,55 | 293 | 30 | 65 | 292 | 45 | ||

| 3,60 | 285 | 29 | 65 | 285 | 44 | ||

| 3,65 | 277 | 28 | 64 | 278 | 43 | ||

| 3,70 | 269 | 27 | 64 | 270 | 42 | ||

| 3,75 | 262 | 26 | 63 | 261 | 41 | ||

| 3,80 | 255 | 25 | . | 63 | 255 | 40 | |

| 3,85 | 248 | 24 | 62 | 249 | 39 | ||

| 3.90 | 241 | 23 | 102 | 62 | 240 | 38 | |

| 3,95 | 235 | 21 | 101 | 61 | 235′ | 37 | |

| 4,00 | 229 » | 20 | 100 | 61 | 228 | 36. | |

| 4,05 | 223 | 19 | 99 | 60 | 222 | 35 | |

| 4,10 | 217 | 17 | 98 | 60 | 217 | 34 | |

| 4,15 | 212 | 15 | 97 | 59 | 213 | 34 | |

| 4,20 | 207 | 14 | 95 | 59 | 208 | 33 | |

| 4,25 | 201 | 13 | 94 | 58 | 201 | 32 | |

| 4,30 | 197 | 12 | 93 | 58 | 197 | 31 | |

| 4,35 | 192 | 11 | 92 | 57 | 192 | 30 | |

| 4,40 | 187 | 9 | 91 | 57 | 186 | 30 | |

| 4,45 | 6 | 183 | |||||

| 4,50 | 179 | 7 | 90 | 56 | 178 | 29 | |

| 4,55 | 174 | 6 | 89 | 55 | 174 | 28 | |

| 4,60 | 170 | 4 | 88 | 55 | 171 | 28 | |

| 4,65 | 167 | 3 | 87 | 54 | 166 | 27 | |

| 4,70 | 163 | 2 | 86 | 53 | 150 | 26 | |

| 4,75 | 159 | 1 | 85 | 53 | 159 | 26 | |

| 4,80 | 156 | 0 | 84 | 52 | 155 | 26 | |

| 4,85 | 152 | 83 | 152 | 25 | |||

| 4,90 | 149 | 82 | 149 | 24 | |||

| 4.95 | 146 | 81 | 148 | 24 | |||

| 5,00 | 143 | 80 | 143 | 24 | |||

Scratching method. This method, unlike those described, is characterized by the fact that during testing not only elastic and plastic deformation of the tested material occurs, but also its destruction.

Currently, to check the hardness and quality of heat treatment of steel blanks and finished parts without destruction, a device is used - an inductive flaw detector DI-4. This device operates on eddy currents excited by an alternating electromagnetic field, which is created by sensors in the controlled parts and the reference.

Alloy theory

A metal alloy is a material obtained by fusing two or more metals or metals with non-metals and having metallic properties. The substances that form an alloy are called components.

A phase is a homogeneous part of an alloy, characterized by a certain composition and structure and separated from other parts of the alloy by an interface. Structure refers to the shape, size and nature of the relative arrangement of phases in metals and alloys. Structural components are separate parts of an alloy that have the same structure with their characteristic features.

Types of alloys by structure. According to the nature of the interaction of the components, all alloys are divided into three main types: mechanical mixtures, chemical compounds and solid solutions.

A mechanical mixture of two components A and B is formed if they are not capable of interaction or mutual dissolution. Each component crystallizes into its own crystal lattice. The structure of mechanical mixtures is heterogeneous, consisting of separate grains of component A and component B. The properties of mechanical mixtures depend on the quantitative ratio of the components: the more of a given component in the alloy, the closer the properties of the mixture are to its properties.

A chemical compound is formed when alloy components A and B react chemically. Moreover, the ratio of the numbers of atoms in the compound corresponds to its chemical formula AmBn. A chemical compound has its own crystal lattice, which differs from the crystal lattice of its components. Chemical compounds have a homogeneous structure, consisting of grains of identical composition and properties.

When a solid solution is formed, atoms of one component enter the crystal lattice of another. Substitutional solid solutions are formed as a result of partial replacement of atoms of the crystal lattice of one component with atoms of the second (Fig. 6, b).

Interstitial solid solutions are formed when atoms of a dissolved component are introduced into the crystal lattice of a solvent component (Fig. 6, c). The solid solution has a homogeneous structure, one crystal lattice. Unlike a chemical compound, a solid solution does not exist at a strictly defined ratio of components, but in a concentration range. Solid solutions are designated by lowercase letters of the Greek alphabet: α, β, γ, δ, etc.

Chemical properties

Chemical properties characterize the ability of metals and alloys to resist oxidation or combine with various substances: atmospheric oxygen, solutions of acids, alkalis, etc. The easier a metal combines with other elements, the faster it is destroyed. The chemical destruction of metals under the influence of an external aggressive environment on their surface is called corrosion.

Metals that are resistant to oxidation under high heat are called heat-resistant or scale-resistant. Such metals are used for the manufacture of parts that are operated in high temperature zones.

The resistance of metals to corrosion, scale formation and dissolution is determined by the change in the mass of the test samples per unit surface per unit time.

The chemical properties of metals are necessarily taken into account in the manufacture of certain products. This especially applies to products or parts operating in chemically aggressive environments.