sells rolled metal products of its own production. Our consultants will answer your questions and help you navigate the assortment. And the educational minimum from a short course on metal science will give an idea of the requirements for the material when choosing an option for a specific purpose. The scope of application and method of operation are dictated by the structural properties of materials specified in state standards. All metals are divided into ferrous and non-ferrous, and different chemical elements of two types with unique properties can be combined into alloys.

The group of metals includes:

- pure iron;

- alloys;

- metallides;

- intermetallic compounds.

In the last two cases we are talking about complex connections of elements that increase the strength of the material. Depending on the tasks, metals and alloys can be cast, powdered or wrought.

general characteristics

Metals are a group of elements, in the form of simple substances, that have metallic properties (ductility, malleability, luster, electronic conductivity, etc.)

The main difference between metal elements is that they have only reducing properties, and in reactions they can only oxidize. In compounds they can only have positive oxidation states, both in elementary positively charged ions and in complex ions, where they form positive centers.

Rice. 1. List of metals.

As a rule, at the outer level of metal elements there is a small number of electrons (1-3), electronegativity values are low. Metals include all s-elements (except hydrogen and helium), d- and f-elements, as well as p-elements under the boron-astatine line. Typical metals have large atomic sizes, which makes it easy for them to lose valence electrons. The resulting positive ions are stable because they have a complete outer electron shell.

Copper and copper alloys

In its pure form it has a pinkish-red color, low resistivity, low density, good thermal conductivity, excellent ductility, and is resistant to corrosion. It is widely used as a conductor of electric current. For technical needs, two types of copper alloys are used: brass (copper with zinc) and bronze (copper with aluminum, tin, nickel and other metals). Brass is used for the manufacture of sheets, strips, pipes, wires, fittings, bushings, and bearings. Flat and round springs, membranes, various fittings, and worm pairs are made from bronze.

Table "Metals"

The following table shows the groups of main metals:

| Group of metals | Metal |

| Alkaline | lithium, sodium, potassium, etc. |

| Alkaline earth | calcium, strontium, barium, etc. |

| Transitional | uranium, titanium, iron, platinum, etc. |

| post-transition | aluminum, lead, tin, etc. |

| Refractory | molybdenum, tungsten |

| Colored | copper, titanium, magnesium, etc. |

| Noble | gold, silver, etc. |

Metals are ductile and malleable, especially if there is only one electron at the outer electronic level of the atoms: layers of atoms move relative to each other without destroying the crystal lattice (alkali metals, copper, silver, gold). The atoms of the non-plastic brittle metals chromium and manganese have a large number of valence electrons.

The density, hardness, and melting point of metals vary over a wide range and depend on the atomic mass, atomic structure and crystal lattice geometry. The lightest metal is lithium (density 0.53 g/cm3), the heaviest is osmium (density 22.5 g/cm3). Metals with a density of more than 5 g/cm3 are classified as heavy metals, and less than 5 g/cm3 are classified as light metals.

The lowest melting point is mercury (-39 degrees Celsius), the most refractory metal is tungsten (melting point 3410 degrees Celsius.) The atomization energy of tungsten is 836 kJ/mol, and its boiling point is 5930 degrees.

Metals react with both simple and complex substances. As typical reducing agents, metals react with almost all non-metal oxidizing agents (oxygen, sulfur, nitrogen, etc.):

4Al+3O2=Al2O3

Metals also react with complex substances such as oxides and hydroxides, dilute solutions of acids, and alkalis dissolved in water.

Within the same period, metallic properties weaken and non-metallic properties increase; within the same group (in the main subgroup), metallic properties increase, and non-metallic properties weaken

Rice. 3. Metals of the main subgroups.

Categories of Ferrous Secondary Metals

There are certain requirements for ferrous metal waste. To send alloys to steel furnaces, certain processing operations will be required. Before submitting an application for waste transportation, you must familiarize yourself with the GOST ferrous metals to determine its cost. Black secondary scrap is classified into steel and cast iron. If the composition contains alloying additives, then it is classified as category “B”. Category “A” includes carbon materials: steel, cast iron, additives.

Metallurgists and foundry workers, due to the limited primary raw material base, are showing an active interest in secondary raw materials. Using scrap ferrous metals instead of metal ore is a resource-saving as well as energy-saving solution. Recycled ferrous metal is used as a coolant for converter smelting.

The range of applications of metals is incredibly wide. Black and colored are used indefinitely in the construction and machinery industries. The energy industry cannot do without non-ferrous metals. Rare and precious ones are used to make jewelry. Both non-ferrous and ferrous metals are used in art and medicine. It is impossible to imagine a person’s life without them, from household supplies to unique instruments and apparatus.

Finding metals and methods of obtaining them

The most common metal element on earth is aluminum. It is followed by iron, calcium, sodium.

Some metals occur in nature in a native state (gold, mercury, platinum), but they are mainly found in nature in the form of oxides and salts.

Metals are produced using metallurgy (production from ores), pyrometallurgy (production using a reduction reaction at high temperature), hydrometallurgy (extraction from ores in the form of soluble compounds), electrometallurgy (production of metals by electrolysis of melts and solutions of their compounds).

Element properties

When you learned the alphabet in elementary school, you discovered that all letters have their own unique set of properties. For example, some had straight lines, some had curves, and others had both types of lines. The same can be said about the elements. Each of them has a unique set of physical and chemical properties. Physical properties are qualities inherent in certain substances. Shiny or not, how well it conducts heat and electricity, at what temperature it melts, how dense it is.

Chemical properties include those qualities that are observed when exposed to oxygen if they were to burn (how difficult it would be for them to retain their electrons during a chemical reaction). Different elements may have common properties. For example, iron and copper are both elements that conduct electricity. However, they do not have the same properties. For example, when iron is exposed to humid air, it becomes rusty, but when copper is exposed to the same conditions, it acquires a specific green patina. That's why the Statue of Liberty is green and not rusty. It is made of copper, not iron).

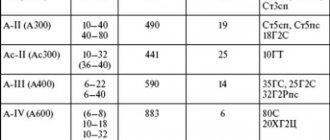

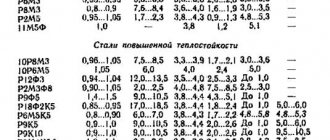

Classification in GOST

Finally, we must distinguish:

- Casting alloys and metals;

- Deformable by pressure;

- Powder.

From this classification it already becomes clear for what purpose this or that material serves. The following is an even more detailed classification:

- Metals with good anti-corrosion properties;

- With good anti-friction properties;

- Cryogenic;

- Magnetic and non-magnetic;

- Spring;

- Plastic metals;

- Automatic alloys for processing on machine tools;

- Forging alloys;

- Heat resistant;

- Weldable without restrictions or limited weldable;

- Lightweight (for use in the aviation industry);

- With good electrical conductivity and thermal conductivity, and many others.

In addition, metals differ according to their area of application:

- Structural alloys and metals - used for cladding and load-bearing structural elements;

- Electrical – for the manufacture of electrical parts;

- Instrumental - for making tools.

However, these definitions are given relatively within the framework of alloys based on a single metal, or within the entire variety of choices, which often leads to confusion. Therefore, a complete picture can only be obtained through a detailed comparison of different alloys. In this case, the most important parameters will be: strength, elasticity, viscosity, plasticity, hardness, thermal conductivity and electrical conductivity. In addition, it is necessary to distinguish between the nominal characteristics and structural properties of metals. For example, tensile strength does not indicate high structural strength, and at certain temperature values the properties of metals change. Only relying on an accurate analysis can one come to a conclusion about the advisability of using a particular material for one purpose or another.

How to find the right alloy in the GOST classifier

Comprehensive information regarding these qualities and application possibilities is given in state standards, which should be relied upon in further work. To find the information you need, just:

- Determine the main element of the metal;

- Alloy or metal will be considered;

- Casting, pressure-formed or powder;

- And if you have not yet found the desired metal in the GOST classifier, you need to find out about the scope of the metal and whether this alloy is special.

In short, the classification of metals is extremely complex, and depending on the area of application of different materials, a certain structure of knowledge will be formed. Therefore, in each specific case, it is necessary to choose a narrow conceptual scope for defining the types of metals, so as not to delve into all the details as a whole.

Galvanomagnetic and thermomagnetic phenomena

If metallic sample through which electricity flows. current is placed in a constant magnetic field, then phenomena arise in it due to the curvature of electron trajectories in a plane perpendicular to ${\bf H}$, which leads to a change in kinetic. coefficients (coefficient of electrical and thermal conductivity, thermoelectric coefficient, etc.) and to a number of new phenomena: Hall effect, magnetoresistance, etc. On the dependence of kinetic. The coefficients of ${\bf H}$ are influenced by the features of the electronic energy. spectrum of M., in particular the topology of the Fermi surface (see Galvanomagnetic phenomena, Thermogalvanomagnetic phenomena). Even a not too strong magnetic field at low temp. pax (about 1 K) can change the kinetics. properties of M., e.g. increase the transverse (relative to the direction of ${\bf H}$) resistance (at $\ce{Bi}$) by tens of thousands of times or almost completely “turn off” the transverse electronic thermal conductivity of the metal.

Classification in chemistry

We can only try to give a classification of these objects, but it is impossible to offer a single picture on this matter, since it will largely depend on the professional point of view, convenient for use in a particular scientific or industrial field. At the most elementary level, classification is given in the periodic table of elements, but even in chemistry there is disagreement about this.

In chemistry, it is customary to classify metals according to the number of levels of the electron shell of atoms and the final level of filling the shell with electrons. Based on this criterion, substances are divided into –s –p -f -d metals. In addition, alkali, alkaline earth, transition and post-transition metals are distinguished. But this classification is not applicable in most cases, since it does not address many important utilitarian issues that are primarily of interest to the science of metallurgy.

Metals in electromagnetic fields

AC electrical a current of frequency $ω$ flows along the surface of the magnet, penetrating into it to the depth of a skin layer of thickness $δ=c\sqrt{2πσω}$, where $c$ is the speed of light (see High-frequency conductivity); for example, for $\ce{Cu}$ $δ≈$ 6·10–6 m at $ω=$ 6·10–8 Hz. When an electromagnetic wave falls on the surface of M., part of the electromagnetic energy is absorbed in the skin layer, and the other part is re-emitted by electrons and reflected from the surface of M. Coefficient. reflections (for $\ce{Cu}≈$ 2·10–5).

When electromagnetic waves, the frequency of which is equal to or a multiple of the cyclotron frequency of conduction electrons, fall on a magnet placed in a strong constant magnetic field, resonance phenomena are observed in the magnet (see Cyclotron resonance). In some M. (eg alkaline) one can observe electron paramagnetic resonance on conduction electrons and spin waves.

M., placed in a sufficiently strong magnetic field at a low temperature, has many. properties characteristic of plasma: various weakly damped waves (helicons, magnetoplasma waves, dopplerons, etc.) can propagate in it (see Plasma of solids).

Classification by crystal lattice structure

The differences in the structure of the crystal lattice for various metals in the solid state are obvious. They are characterized by the presence of one of three types of device:

- A body-centered cubic lattice with 8 equidistant atoms from the atom taken as the reference point and 6 more neighbors at a greater distance;

- Close-packed cubic lattice with 12 equidistant neighbors;

- A close-packed hexagonal lattice with 12 equally spaced neighbors.

For metals in the molten and gaseous state, these properties do not play a big role, since the crystal structure of atoms in these states becomes disordered.