Home \ Laboratory research \ Metallurgical examination →

The study is carried out to determine compliance with the declared characteristics of the metal, structure or product. In addition, metallurgical examination allows us to determine whether a defect in the product could lead to failure.

As part of the metallurgical examination, the following is carried out:

- study of the chemical composition of metals and alloys;

- study of material damage;

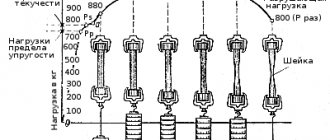

- checking strength characteristics.

Research prices

| Type of study | Cost of rubles |

| Determination of the mass fraction of elements (spectral analysis) in a metal, alloy (1 sample/1 study) | 14000 |

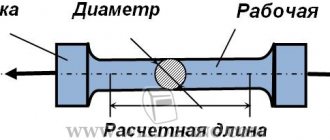

| Static Tensile Test | 6500 |

| Impact bending test | 6500 |

| Metallographic analysis | from 19000 |

| Metal hardness measurement | 6500 |

| Determining the causes of corrosion of a metal product | from 140,000 |

| Determining the causes of destruction of a metal product | from 150,000 |

| Corrosion and climate tests | from 60 000 |

| Extruding sheets and tapes according to Eriksen | 14000 |

| Fractographic analysis of fractures | 32000 |

Connect with us

How to get to us

The study of the characteristics of metals and alloys is in demand in various fields: in construction, engineering design, mechanical engineering and machine tool building. As part of the examination, it is possible to study the characteristics of metal structures, pipes, fittings, the qualitative and quantitative composition of alloys, metals and products made from them.

The purpose of metallurgical examination may be to detect traces of metallization at an object, to identify the chemical composition of metals and alloys. Research of this kind helps to establish the facts of counterfeit production of products. Based on physical and chemical examination, it is possible to establish a violation of the production process caused by various defects in the metal or alloy. Such violations may affect the service life of the product.

Examination of metals, alloys and products made from them has a wide range of applications in various fields. Metallurgical expertise is also used in areas related to consumer protection.

Metal examination is widely used in forensic science to examine products of their precious metals. Such objects include all parts whose composition includes noble metals (gold, silver, platinum, etc.).

Contact us How to get to us

Determination of steel grade in the laboratory

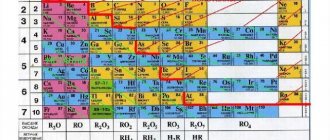

In the laboratory, it is possible to determine the grade of steel and alloy using an optical emission spectrometer. Laboratory staff will determine the percentage of elements in ferrous and non-ferrous metals and alloys:

- carbon, low-alloy, medium-alloy;

- high-alloy chromium steels;

- high-alloy chromium-nickel steels;

- high-alloy manganese steels;

- high-speed steels;

- cast iron;

- aluminum alloys;

- titanium alloys;

- copper alloys (bronze, brass).

- Nickel-based alloys

SAM_0516-min

But despite all the advantages of spectral analysis, chemical analysis of metals from chips is still the most accurate and most accurate in its readings, so in the laboratory it is possible to determine the content of some elements from chips.

The price of chemical analysis of metals will depend on the grade of steel.

Objects provided for examination of metals, alloys and products made from them:

The list of objects of this examination is very wide, which is a consequence of the use of metal products and their alloys in modern life. All metal objects are usually classified according to the material from which they are made and according to their functionality.

- edged weapons (knives, sabers, dirks, daggers, brass knuckles, swords, stilettos, etc.);

- automobile spare parts;

- products made of ferrous metals (wires and cables, rails, butt plates, cast iron products, etc.);

- products made of non-ferrous metals (fittings, pipes, blanks, etc.);

- products made of precious metals (electronic parts, jewelry, etc.);

- household items (dishes, items of clothing, furniture parts, lamps, etc.).

We work with a laboratory complex equipped with the necessary equipment. Our company employs specialists who have the opportunity to conduct a wide range of research

High precision method

This method allows for a quick analysis of the content of precious metals, without the use of unnecessary harmful substances that can negatively affect the metal being tested. Spectral analysis of precious metals shows the content of expensive materials and other elements in the product, with the highest possible accuracy and a small percentage of error.

For all industries related to products made of metal, the composition of the material is important. Since it must meet established requirements in order to produce a high-quality finished product. The composition is also important when purchasing materials for an objective assessment. This composition analysis is one of the ways to test materials without conducting complex experiments and waiting for long reactions.

Sell chips

Spectral analysis of precious metals will accurately identify the composition of a metal product. The method is based on the interaction of chemical elements with the emission spectrum. The atoms of each matter have their own frequency at which they can absorb light rays or glow. The test is carried out using a special device - a spectrometer. The number of metals in the product determines how many lines will be shown on the device and what their intensity will be. Depending on the purpose of diagnosis, different research options are performed.

Examination of a stainless steel pan: cross-sectional view

Connect with us

Precious metals analysis

In order to determine the composition of the material, elemental analysis is used. A special device for research affects the metal with electromagnetic waves. The spectrometer detector reflects the remaining energy in the form of elementary particles, the value of which is strictly responsible for a specific chemical element. The indicator is converted into a voltage pulse, the device takes readings that are reflected on the screen in the form of a digital symbol or graph.

This research method was discovered in the 20th century, and the device for carrying out such an analysis was invented only 70 years ago. Currently, spectrometers are widely used in various industries. The use of the device in jewelry research, metallurgical testing, and chemical work is relevant. Using the device, you can determine the presence of heavy metal in soil, water, and food. It is used in their activities by ecologists and geologists. The spectrometer is used to take and test samples from other planets. This method has become so popular due to the high accuracy of analysis and speed of verification.

At the moment our specialists

They trust us

Applying a check

Spectral analysis of precious metals helps in sorting different types of scrap for recycling. Also, this testing method helps determine the penetration; with the help of it, when casting metal, finished products undergo certified tests. In industrial production, a spectrometer is necessary to confirm the quality of the metal that arrives at the plant.

Depending on the volume of material being tested and the purpose, there are different types of devices for spectral analysis. Portable devices are widely used in metal purchasing points. They are portable in size and light in weight, with high performance and inspection accuracy.

Sell chips

There are companies in the capital that accept old electronic goods, catalysts, scrap gold, gold-plated products and radio components.

Muscovites pass the latter most often. Moreover, you can sell radio components in Moscow at an attractive price. ◄ Back to news

Types of spectral analysis

It is customary to distinguish four main groups of spectral analysis.

- Emission

- Absorption

- Luminescent

- Combinative

Emission analysis is based on recording the emission spectrum of a substance. It is commonly used to analyze atomic composition. To do this, a sample of the substance under study is introduced into an electric arc or spark, in which vapors of the substance are heated to a temperature of several thousand degrees and emit radiation, the spectrum of which determines the atomic composition. The method is widely used for quantitative analysis of multicomponent alloys in metallurgy.

Absorption analysis uses the absorption (absorption) spectra of a substance. A beam of light is passed through the substance under study, part of the energy is absorbed and, as a result, absorption bands appear in the spectrum of the transmitted radiation. The position and intensity of these bands determine the composition and structure of the substance under study. The method is used mainly to analyze the molecular composition in the infrared region of the spectrum, where the main absorption lines of molecules lie.

Luminescence analysis is based on the ability of certain substances to glow when irradiated with exciting radiation, i.e. emit absorbed light. As a result of this radiation, a change in the wavelength of the radiation occurs, and the emitted luminescent radiation has a spectrum characteristic of the given substance being irradiated.

Raman analysis uses the phenomenon of Raman scattering of light. This phenomenon consists of scattering of radiation incident on a substance with a change in the wavelength of this radiation. This change is explained by the fact that when light is scattered, molecular vibrations are excited and, thus, part of the light energy is spent on excitation. As a result, the wavelength of radiation with a narrow spectrum incident on the substance is shifted to the red side by an amount characteristic of the light-scattering molecule.

By the magnitude of the change in wavelength, one can judge the frequencies of natural vibrations of molecules. Highly intense monochromatic radiation sources are used to obtain Raman spectra.

Advantages of the method

Thanks to high selectivity, it is possible to quickly and with high sensitivity determine the chemical composition of the analyzed material. to study the composition of a metal by spectrum without affecting its suitability for use, i.e. non-destructive testing of samples can be Despite the huge number of analytical techniques designed to study various objects, they are all based on a common principle: each chemical element has its own spectrum.

Thanks to the individuality of the spectra, it is possible to determine the chemical composition of the body. The comparative simplicity and versatility of spectral analysis have made the method the main method for monitoring the composition of a substance in metallurgy, mechanical engineering, and the nuclear industry. With its help, chemical ores and minerals are determined; non-destructive testing of metals occupies a special place in this area.