Ion plasma nitriding (IPA)

Ion plasma nitriding (IPA) is a modern strengthening method of chemical-thermal treatment of products made of cast iron, carbon, alloy and tool steels, titanium alloys, metal ceramics, and powder materials.

The high efficiency of the technology is achieved by using different gas media that influence the formation of a diffusion layer of various compositions, depending on the specific requirements for its depth and surface hardness. Nitriding by the ion-plasma method is relevant for processing loaded parts operating in aggressive environments subject to friction and chemical corrosion, therefore it is widely used in the mechanical engineering industry, including machine tool building, the automotive and aviation industries, as well as in the oil and gas, fuel and energy and mining sectors, instrumental and high-precision production.

In the process of surface treatment by ion nitriding, the surface characteristics of metals and the operational reliability of critical parts of machines, engines, machine tools, hydraulics, precision mechanics and other products are improved: fatigue and contact strength, surface hardness and resistance to cracking are increased, wear and tear resistance, heat and corrosion resistance.

Advantages of ion plasma nitriding

IPA technology has a number of undeniable advantages, the main one of which is stable processing quality with minimal variation in properties. The controlled process of diffusion gas saturation and heating ensures a uniform coating of high quality, a given phase composition and structure.

- High surface hardness of nitrided parts.

- No deformation of parts after processing and high surface cleanliness.

- Reducing the processing time of steel by 3-5 times, titanium alloys by 5-10.

- Increasing the service life of a nitrided surface by 2-5 times.

- Possibility of processing blind and through holes.

The low-temperature regime eliminates structural transformations of steel, reduces the likelihood of fatigue failures and damage, and allows cooling at any speed without the risk of martensite. Treatment at temperatures below 500 °C is especially effective in strengthening products made from alloyed tool, high-speed and maraging steels: their performance properties increase without changing the hardness of the core (55-60 HRC).

The environmentally friendly method of ion plasma nitriding prevents bending and deformation of parts while maintaining the original surface roughness within Ra=0.63...1.2 microns - that is why IPA technology is effective as a finishing treatment.

Installations for IPA operate in a rarefied atmosphere at a pressure of 0.5-10 mbar. An ionized gas mixture is supplied to the chamber, which operates on the principle of a cathode-anode system. A glow pulse discharge is formed between the workpiece being processed and the walls of the vacuum chamber. The active medium created under its influence, consisting of charged ions, atoms and molecules, forms a nitrided layer on the surface of the product.

The composition of the saturating medium, temperature and duration of the process affect the depth of penetration of nitrides, causing a significant increase in the hardness of the surface layer of products.

Equipment for nitriding [ edit | edit code]

To carry out gas nitriding, shaft, retort and chamber furnaces are mainly used. A dissociator is used to prepare the ammonia before entering the furnace.

To carry out catalytic gas nitriding, mainly shaft, retort and chamber furnaces are used, equipped with built-in catalysts and oxygen probes to determine the saturation capacity of the atmosphere.

To carry out ion-plasma nitriding processes, specialized installations are used, in which the products are heated due to cathode bombardment with ions and, in fact, saturation occurs.

For nitriding from electrolyte solutions, installations for electrochemical-thermal treatment are used.

Ion plasma nitriding (IPA) is a method of chemical-thermal treatment of steel and cast iron products with great technological capabilities, which makes it possible to obtain diffusion layers of the desired composition by using different gas media, i.e. The diffusion saturation process is controllable and can be optimized depending on the specific requirements for layer depth and surface hardness. plasma nitriding microhardness alloyed

The temperature range of ion nitriding is wider than that of gas nitriding and is in the range of 400-600 0 C. Treatment at temperatures below 500 0 C is especially effective in strengthening products made from tool alloy steels for cold working, high-speed and maraging steels, because their performance properties are significantly increased while maintaining core hardness at the level of 55-60 HRC.

Read also: Making a screw with your own hands video

Parts and tools from almost all industries are subjected to hardening treatment using the IPA method (Fig. 1).

Rice. 1. Application of ion plasma nitriding to strengthen various products

As a result of IPA, the following product characteristics can be improved: wear resistance, fatigue endurance, anti-scuff properties, heat resistance and corrosion resistance.

In comparison with widely used methods of strengthening chemical-thermal treatment of steel parts, such as carburization, nitrocarburization, cyanidation and gas nitriding in furnaces, the IPA method has the following main advantages:

- · higher surface hardness of nitrided parts;

- · no deformation of parts after processing and high surface cleanliness;

- · increasing the endurance limit and increasing the wear resistance of processed parts;

- · lower processing temperature, due to which structural transformations do not occur in the steel;

- · ability to process blind and through holes;

- · maintaining the hardness of the nitrided layer after heating to 600-650 C;

- · the possibility of obtaining layers of a given composition;

- · ability to process products of unlimited sizes and shapes;

- · no environmental pollution;

- · improving production standards;

- · reduction in processing costs several times.

The advantages of IPA are also manifested in a significant reduction in basic production costs.

For example, compared to gas nitriding in furnaces, IPA provides:

- · reduction of processing time by 2-5 times, both by reducing the heating and cooling time of the charge, and by reducing the isothermal holding time;

- · reduction of fragility of the strengthened layer;

- · reduction in the consumption of working gases by 20-100 times;

- · reduction in energy consumption by 1.5-3 times;

- · exclusion of the depassivation operation;

- · reduction of deformation so as to eliminate finishing grinding;

- · simplicity and reliability of screen protection against nitriding of non-hardening surfaces;

- · improvement of sanitary and hygienic production conditions;

- · full compliance of the technology with all modern environmental protection requirements.

Compared to hardening, IPA processing allows :

- · eliminate deformations;

- · increase the service life of the nitrided surface by 2-5 times.

The use of IPA instead of carburization, nitrocarburization, gas or liquid nitriding, volumetric or high-frequency hardening allows you to save capital equipment and production space, reduce machine tool and transportation costs, and reduce the consumption of electricity and active gaseous media.

The principle of operation of the IPA is that in a discharged (p = 200-1000 Pa) nitrogen-containing gas environment between the cathode - parts - and the anode - the walls of the vacuum chamber - an anomalous glow discharge is excited, forming an active medium (ions, atoms, excited molecules), ensuring the formation of a nitrided layer consisting of an outer nitride zone and a diffusion zone located underneath it.

Technological factors influencing the efficiency of ion nitriding are process temperature, saturation duration, pressure, composition and flow rate of the working gas mixture.

The process temperature , the area of the charge involved in heat exchange and the efficiency of heat exchange with the wall (number of screens) determine the power required to maintain the discharge and ensure the desired temperature of the products. The choice of temperature depends on the degree of alloying of the steel being nitrided with nitride-forming elements: the higher the degree of alloying, the higher the temperature.

The processing temperature must be at least 10-20 0 C lower than the tempering temperature.

The duration and temperature of the saturation process determine the depth of the layer, the distribution of hardness along the depth and the thickness of the nitride zone.

The composition of the saturating medium depends on the degree of alloying of the steel being processed and the requirements for the hardness and depth of the nitrided layer.

The process pressure must be such as to ensure that the discharge tightly “fits” the surface of the products and obtains a uniform nitrided layer. However, it should be borne in mind that the discharge at all stages of the process must be anomalous, i.e. the surface of all parts in the charge must be completely covered with glow, and the discharge current density must be greater than the normal density for a given pressure, taking into account the heating effect gas in the cathode region of the discharge.

With the advent of new-generation IPA installations, using composition-controlled mixtures of hydrogen, nitrogen and argon as a working medium, as well as “pulsating” rather than direct current plasma, the manufacturability of the ion nitriding process has increased significantly.

The use of combined heating (“hot” chamber walls) or enhanced thermal protection (triple heat shield), along with the ability to independently regulate the gas composition and pressure in the chamber, allows, when processing cutting tools, to avoid overheating of thin cutting edges during the heating of the charge, and to accurately regulate the saturation time and , respectively, and the depth of the layer, because Products can be heated in a nitrogen-free environment, for example, in a mixture of Ar+H2.

Effective thermal insulation in the working chamber (triple heat shield) allows products to be processed with low specific energy consumption, which allows temperature differences inside the cage to be minimized during processing. This is evidenced by the distribution of microhardness along the depth of the nitrided layer for samples located in different places of the charge (Fig. 2).

Rice. 2. Distribution of microhardness along the depth of the nitrided layer for three samples located in different places of the charge.

a, c – gear weighing 10.1 kg, 51 pcs., st – 40X, module 4.5, exposure 16 hours, T = 530 0 C;

Read also: How to determine the power of a transformer based on the cross-section of the core

b, d – gear weighing 45 kg, 11 pcs., st – 38ХН3МФА, module 3.25 (outer ring) and 7 mm (inner ring), exposure 16 hours, T=555 0 C.

Ion nitriding is an effective method of hardening treatment of parts made of alloyed structural steels : gears, ring gears, shaft-toothed gears, shafts, spur, bevel and cylindrical gears, couplings, gear shafts of complex geometric configuration, etc.

Cementation, nitrocarburization and high-frequency hardening are justified in the manufacture of heavily loaded parts (gears, axles, shafts, etc.) of low and medium precision that do not require subsequent grinding.

These types of heat treatment are not economically feasible in the manufacture of medium- and low-load high-precision parts, because With this treatment, significant warping is observed and subsequent grinding is required. Accordingly, when grinding it is necessary to remove a significant thickness of the hardened layer.

IPA can significantly reduce warping and deformation of parts while maintaining surface roughness within the range of Ra = 0.63...1.2 microns, which makes it possible to use IPA as a finishing treatment in the vast majority of cases.

In relation to the machine tool industry, ion nitriding of gears significantly reduces the noise characteristics of machine tools, thereby increasing their competitiveness in the market.

IPA is most effective when processing large-scale parts of the same type: gears, shafts, axles, toothed shafts, shaft-toothed gears, etc. Gears subjected to plasma nitriding have better dimensional stability compared to cemented gears and can be used without additional processing. At the same time, the bearing capacity of the side surface and the strength of the tooth base, achieved using plasma nitriding, correspond to cemented gears (Table 1).

Table 1. Fatigue resistance characteristics of steels depending on the methods of hardening gears

Bending endurance limit, MPa

Surface contact endurance limit, MPa

The properties of a metal can be improved by changing its chemical composition. An example is steel nitriding, a relatively new technology for saturating the surface layer with nitrogen, which began to be used on an industrial scale about a century ago. The technology under consideration was proposed to improve certain qualities of products made from steel. Let's take a closer look at how steel is saturated with nitrogen.

Ionic nitriding of parts

Ion nitriding is widely used to harden machine parts, working tools and technological equipment of unlimited sizes and shapes: gear rims, crankshafts and camshafts, bevel and cylindrical gears, extruders, couplings of complex geometric configurations, screws, cutting and drilling tools, mandrels, dies and punches for stamping, molds.

For a number of products (large-diameter gears for heavy-duty vehicles, excavators, etc.), IPA is the only way to obtain finished products with a minimum percentage of defects.

Properties of products after hardening using the IPA method

Hardening of gears using the ion nitriding method increases the endurance limit of teeth during bending fatigue tests to 930 MPa, significantly reduces the noise characteristics of machine tools and increases their competitiveness in the market.

Ion plasma nitriding technology is widely used to harden the surface layer of molds used in injection molding: the nitrided layer prevents metal from sticking in the liquid jet supply zone, and the mold filling process becomes less turbulent, which increases the service life of the molds and ensures high quality casting.

Ion plasma nitriding increases the wear resistance of stamping and cutting tools made from steel grades R6M5, R18, R6M5K5, R12F4K5 and others by 4 or more times, with a simultaneous increase in cutting conditions. The nitrided surface of the tool, due to the reduced coefficient of friction, ensures easier removal of chips and also prevents chips from sticking to the cutting edges, which allows increasing feed and cutting speed.

provides services for surface hardening of structural materials of various types of parts and tools using the ion-plasma nitriding method - a correctly selected mode will allow you to achieve the required technical indicators of hardness and depth of the nitrided layer, and will ensure high consumer properties of the products.

- Strengthening the surface layer of fine- and coarse-module gears, crankshafts and camshafts, guides, bushings, sleeves, screws, cylinders, molds, axles, etc.

- Increased resistance to cyclic and pulsating loads of crankshafts and camshafts, tappets, valves, gears, etc.

- Increasing wear resistance and corrosion resistance, reducing metal adhesion when casting molds, press and hammer dies, punches for deep drawing, dies.

The nitriding process takes place in modern automated installations:

- table Ø 500 mm, height 480 mm;

- Table Ø 1000 mm, height 1400 mm.

You can find out the full range of products for hardening treatment, as well as the possibility of nitriding large parts with complex geometry, from specialists. To determine the technical conditions for nitriding and begin cooperation, send us a drawing, indicate the steel grade and an approximate technology for manufacturing parts.

Increased wear and fatigue resistance, eliminating the need for final grinding, increasing the lifespan of plastic processing machine parts and improving the quality of plastic products

Increased wear resistance and corrosion resistance, reduced metal adhesion during casting

Increasing tool wear resistance and cutting performance, improving cutting properties

For more details contact us:

- contact the sales department by phone;

- write an email;

- click on the “Order a call” button;

620017, Ekaterinburg, st. Turbinnaya, 7, office. 401

Mon – Fri: from 7.00 to 16.00 (MSK)

© 2021 Industrial metalworking

All information on the site is presented for informational purposes and under no circumstances constitutes a public offer. Detailed technical specifications are recorded in the relevant regulatory documents.

Ion nitriding units EVT 40, EVT 60, EVT 70, EVT 90, EVT 95

EVT installations are simple and reliable vacuum furnaces for performing a wide range of technological tasks for nitriding and nitrocarburizing of machine parts and tools.

The absence of massive thermal insulation ensures minimal inertia of the furnace. The use of a glow discharge as the only heating source ensures high operating efficiency (it is not the working volume that is heated, but only the part), especially when performing urgent work with a small number of parts.

Nitriding of steel

The properties of a metal can be improved by changing its chemical composition. An example is steel nitriding, a relatively new technology for saturating the surface layer with nitrogen, which began to be used on an industrial scale about a century ago. The technology under consideration was proposed to improve certain qualities of products made from steel. Let's take a closer look at how steel is saturated with nitrogen.

Purpose of nitriding

Many people compare the process of cementing and nitriding because both are designed to significantly improve the performance of a part. The technology of introducing nitrogen has several advantages over carburization, among which there is no need to increase the temperature of the workpiece to the values at which the atomic lattice is attached. It is also noted that the technology of introducing nitrogen practically does not change the linear dimensions of the workpieces, due to which it can be used after finishing processing. On many production lines, parts that have been hardened and ground are subjected to nitriding and are almost ready for production, but some qualities need to be improved.

The purpose of nitriding is associated with a change in the basic performance qualities during the heating of the part in an environment characterized by a high concentration of ammonia. Due to this effect, the surface layer is saturated with nitrogen, and the part acquires the following performance qualities:

- The wear resistance of the surface is significantly increased due to the increased hardness index.

- The endurance value and resistance to increased fatigue of the metal structure are improved.

- In many industries, the use of nitriding is associated with the need to impart anti-corrosion resistance, which is maintained upon contact with water, steam or air with high humidity.

The above information determines that the results of nitriding are more significant than carburization. The advantages and disadvantages of the process largely depend on the technology chosen. In most cases, the transferred performance qualities are maintained even when the workpiece is heated to a temperature of 600 degrees Celsius; in the case of cementation, the surface layer loses hardness and strength after heating to 225 degrees Celsius.

Nitriding process technology

In many ways, the process of steel nitriding is superior to other methods that involve changing the chemical composition of the metal. The nitriding technology for steel parts has the following features:

- In most cases, the procedure is performed at a temperature of about 600 degrees Celsius. The part is placed in a sealed iron muffle furnace, which is placed in the furnace.

- When considering nitriding modes, temperature and holding time should be taken into account. For different steels, these indicators will differ significantly. The choice also depends on what performance qualities need to be achieved.

- Ammonia is supplied from a cylinder into the created metal container. High temperatures cause ammonia to begin to decompose, causing nitrogen molecules to be released.

- Nitrogen molecules penetrate the metal due to the process of diffusion. Due to this, nitrides are actively formed on the surface, which are characterized by increased resistance to mechanical stress.

- The chemical-thermal treatment procedure in this case does not involve sudden cooling. As a rule, the nitriding furnace is cooled along with the ammonia flow and the part, due to which the surface does not oxidize. Therefore, the technology under consideration is suitable for changing the properties of parts that have already undergone finishing processing.

Ion-vacuum nitriding workshop

The classic process of obtaining the required product with nitriding involves several stages:

- Preparatory heat treatment, which consists of hardening and tempering. Due to the rearrangement of the atomic lattice under a given regime, the structure becomes more viscous and strength increases. Cooling can take place in water or oil, or another medium - it all depends on how high quality the product should be.

- Next, mechanical processing is performed to give the desired shape and size.

- In some cases, there is a need to protect certain parts of the product. Protection is carried out by applying liquid glass or tin in a layer about 0.015 mm thick. Due to this, a protective film is formed on the surface.

- Steel nitriding is carried out using one of the most suitable methods.

- Work is being carried out on finishing mechanical processing and removing the protective layer.

Steel nitriding modes

The resulting layer after nitriding, which is represented by nitride, ranges from 0.3 to 0.6 mm, which eliminates the need for a hardening procedure. As previously noted, nitriding has been carried out relatively recently, but the process of transforming the surface layer of the metal has already been almost completely studied, which has significantly increased the efficiency of the technology used.

Classification of nitriding processes

Nitriding processes

Nitriding does not require an extreme increase in temperature, which means that the steel object completely retains its given shape and parameters. This is important when processing parts that have already been ground to the desired size. Upon completion of the procedure, the product only needs to be polished.

This method of thermochemical treatment also has its disadvantages. The cost of the procedure is considerable. Enrichment of steel alloys with nitrogen is a complex and slow procedure. The effect of nitrogen on steel is very slow; it takes up to 2.5 days to process the part. It is carried out in a specially equipped production workshop.

Gas nitriding

Traditionally, nitriding is carried out under the influence of gas. For this type of working medium, ammonia and propane or ammonia and endogas are mixed in equal parts. The nitriding procedure in such an environment is carried out at temperatures up to 570 °C. The diffusion process itself takes about three hours. The steel product receives a thin protective layer, but it is characterized by high hardness.

Gas nitriding

A variation of the traditional type of nitriding is catalytic gas nitriding. In this case, ammonia is pretreated to speed up diffusion and produce a larger number of ionized radicals.

The use of a liquid nitriding medium can speed up the process somewhat.

Sometimes the diffusion itself takes place in half an hour. The working medium here is molten cyanide salts; the process is carried out at temperatures up to 570 °C.

But technology does not stand still. Ion-plasma nitriding is becoming increasingly popular at metallurgical enterprises. It is also called glow discharge treatment.

The main difference of this technology is that a rarefied environment and the effect of electric current are used. A voltage source is connected to the sealed container. The retort acts as a positively charged electrode, and the part itself acts as a negatively charged one. A flow of ions appears between them. The resulting plasma heats the top layer of the steel product, due to which the surface is saturated with nitrogen compounds and becomes harder.

Design features of gas nitriding

Thermochemical process

Nitriding of steel is carried out in a muffle - an iron retort, which is hermetically sealed. Steel parts are immersed in this container, and then it is sent to a special oven. Under the influence of the required temperatures and ammonia released from a cylinder connected to the muffle, the steel is nitrided.

The fact is that ammonia contains nitrogen, and under certain conditions releases it during decomposition. Nitrogen diffusion occurs: atoms of this element gradually penetrate into the upper layer of the material, forming nitrides in the metal structure. These compounds give the surface of the product the necessary hardness and resistance to corrosion. The thickness of the protective layer can reach 0.6 mm. To avoid the oxidation process, the furnace is cooled slowly.

The main factors influencing nitriding are:

- selected temperature mode;

- gas pressure;

- degree of ammonia decomposition;

- the time the muffle is in the furnace.

As the temperature rises, the level of hardness due to coagulation of nitrides may become lower, but the effect occurs faster.

General technology for all types of nitriding

The metallurgical industry does not stand still, and variations have appeared on traditional gas nitriding. But the sequence of technological operations is almost the same:

- Preliminary processing.

- Protection of parts that do not require nitriding.

- Nitriding of parts.

- Final finishing.

At the first stage, the workpiece needs to be hardened. To do this, the product is cooled in oil or water at a temperature of 940 °C. Then comes the tempering process (temperature about 600 °C). The metal becomes harder and easier to cut. Next, the part is machined to clarify all the necessary parameters, for example, it is ground.

Nitriding process technology

The second stage involves applying a protective layer to areas that do not require nitrogen saturation. A thin layer of tin or liquid glass is applied to them by electrolysis. A protective film is created that interferes with nitriding - the atoms of the element cannot overcome it. Next comes the nitriding itself, the product will gradually become harder and more resistant to external factors.

At the final stage , the nitrided parts are ground to give them the exact desired shape. This process does not take a long time, since there is no noticeable deformation of the geometry of the product. The final finishing time depends on the temperature and thickness of the surface that has been treated with nitrogen.

A guarantee of no changes in the steel product is provided by a modern version of the technology - ion plasma nitriding. With it, the part is not deformed at all, since the action takes place at lower temperatures.

Metals and alloys subjected to nitriding

There are certain requirements that apply to metals before carrying out the procedure in question. Typically, attention is paid to carbon concentration. The types of steels suitable for nitriding are very different, the main condition is a carbon fraction of 0.3-0.5%. Better results are achieved when using alloyed alloys, since additional impurities contribute to the formation of additional solid nitrites. An example of chemical processing of metal is the saturation of the surface layer of alloys, which contain impurities in the form of aluminum, chromium and others. The alloys under consideration are usually called nitralloys.

Microstructure of steels after nitriding

Nitrogen is added when using the following steel grades:

- If the part will be subject to significant mechanical impact during operation, then choose grade 38Х2МУА. It contains aluminum, which causes a decrease in deformation resistance.

- In the machine tool industry, the most widely used steels are 40X and 40HFA.

- In the manufacture of shafts that are often subjected to bending loads, grades 38ХГМ and 30ХЗМ are used.

- If during manufacturing it is necessary to obtain high accuracy of linear dimensions, for example, when creating parts for fuel units, then steel grade 30ХЗМФ1 is used. In order to significantly increase the strength of the surface and its hardness, alloying with silicon is first carried out.

Metals subject to nitriding

The materials that we can strengthen are steels (carbon and low-alloy, medium-alloy, high-alloy, tool), titanium alloys and titanium, cermets, powder materials and cast irons.

The table below shows the surface hardness after chemical treatment for the steels and cast irons most widely used in industry:

| Steel and cast iron grades | Resulting surface hardness, HV | Steel and cast iron grades | Resulting surface hardness, HV | Steel and cast iron grades | Resulting surface hardness, HV |

| 45 | 350 — 500 | 38Х2МУА (1.8509) | 850 — 1250 | 5ХНМ (L6, 1.2711) | 900 — 1100 |

| 40X | 550 — 650 | 12Х2Н4А | 550 — 700 | 3Х2В8 | 900 — 1150 |

| 30ХГСА | 450 — 650 | 20Х3МВФ | 600 — 850 | 4Х4ВМФС | 900 — 1100 |

| 40ХНМА | 600 — 850 | 14Х17Н2 (AISI 431, X20CrNi72) | 900 — 1000 | 3Х3М3Ф | 900 — 1150 |

| 12ХН3МА | 500 — 650 | 12Х18Н10Т (AISI 321, 1.4541) | 900 — 1250 | 4Х5МФС | 900 — 1150 |

| 18ХГТ | 650 — 750 | 03N18K8M5 | 850 — 950 | X12 | 900 — 1100 |

| 38ХМА | 600 — 850 | 03N18K12M4T | 850 — 1000 | X12M | 900 — 1100 |

| 38HMFA | 850 — 1100 | 20Х13 (AISI 420, 1.4028, 2Cr13) | 900 — 1250 | X12MF | 800 — 1100 |

| 38ХН3МФА (34NiCrMoV14-5) | 500 — 800 | 20Х23Н18 | 850 — 950 | P18 | 900 — 1200 |

| 36Х2Н2МФА | 600 — 800 | SCH25 | 400 — 600 | Р6М5 (1.3343) | 900 — 1200 |

| 18Х2Н4МА | 750 — 900 | HF60-2 | 450 — 650 | R9K10 | 900 — 1200 |

If you do not find the material you need in the list, please contact our specialists.

Main types of nitriding

There are several technologies used to carry out nitriding of steel. Let's take the following list as an example:

- Ammonia-propane environment. Gas nitriding has become very widespread today. In this case, the mixture is represented by a combination of ammonia and propane, which are taken in a ratio of 1 to 1. As practice shows, gas nitriding when using such a medium requires heating to a temperature of 570 degrees Celsius and holding for 3 hours. The resulting layer of nitrides is characterized by a small thickness, but at the same time the wear resistance and hardness are much higher than when using classical technology. Nitriding of steel parts in this case makes it possible to increase the hardness of the metal surface to 600-1100 HV.

- Glow discharge is a technique that also involves the use of a nitrogen-containing environment. Its peculiarity lies in the connection of the nitrided parts to the cathode; the muffle acts as a positive charge. By connecting the cathode, it is possible to speed up the process several times.

- The liquid medium is used a little less frequently, but is also highly effective. An example is a technology that involves the use of a molten cyanide layer. Heating is carried out to a temperature of 600 degrees, the holding period is from 30 minutes to 3 hours.

In industry, the gas medium has become most widespread due to the ability to process large batches at once.

Why is ion nitriding necessary?

The main task performed by ion nitriding in Moscow

— reducing metal fatigue and extending its service life. Thanks to the high level of technology, it has certain advantages:

- accuracy of the manipulations;

- the ability to process products of any shape;

- speed of conduction;

- environmentally friendly and harmless.

By itself, ion nitriding

applicable only for four types of materials:

- become;

- cast iron;

- titanium alloys;

- aluminum alloys.

But given their prevalence in industry, the method is popular. To implement it, you need to find a Moscow company that specializes in high-tech metal processing. You must be confident in the qualifications of the employees who will carry out the entire scope of work.

Catalytic gas nitriding

This type of chemical treatment involves creating a special atmosphere in the stove. Dissociated ammonia is pre-treated on a special catalytic element, which significantly increases the number of ionized radicals. Features of the technology include the following points:

- Preliminary preparation of ammonia makes it possible to increase the proportion of solid solution diffusion, which reduces the proportion of reaction chemical processes during the transition of the active substance from the environment to iron.

- Provides for the use of special equipment that provides the most favorable conditions for chemical processing.

Steel nitriding process

This method has been used for several decades and allows changing the properties of not only metals, but also titanium alloys. The high costs of installing equipment and preparing the environment determine the applicability of the technology to the production of critical parts that must have precise dimensions and increased wear resistance.

Scope of application of steel nitriding

Nitriding of steel is one of the frequently used methods for processing alloy products to achieve maximum hardness and durability. Steel parts are not subject to deformation because they do not require subsequent hardening. Corrosion resistance increases significantly, which is important when operating mechanisms in humid environments.

Engineering steels

The use of nitrided steels is relevant not only in the engineering and machine tool industries, but also in the creation of household appliances - after all, consumers are becoming more demanding of the quality of purchased products every year.

This technique allows you to change the characteristics of not only steel, but also titanium alloys. The high cost of equipment and the difficulty of creating the required environment are compensated by the exact dimensions of the output parts and increased wear resistance. But there are also strength indicators that cannot be achieved by nitriding. Then the steel is alloyed, carrying out deep processing of its structure. The disadvantage of this method is the appearance of harmful impurities.

Video on the topic: Chemical-thermal treatment of steel

Properties of nitrided metal surfaces

Quite important is the question of what hardness of the nitrided layer is achieved. When considering hardness, the type of steel being processed is taken into account:

- Carbon steel can have a hardness in the range of 200-250HV.

- Alloy alloys after nitriding acquire a hardness in the range of 600-800HV.

- Nitralloins, which contain aluminum, chromium and other metals, can achieve a hardness of up to 1200HV.

Other properties of steel also change. For example, the corrosion resistance of steel increases, making it possible to use it in aggressive environments. The process of introducing nitrogen itself does not lead to the appearance of defects, since heating is carried out to a temperature that does not change the atomic lattice.

Steel nitriding: purpose, technology and process types

Nitriding, during which the surface layer of a steel product is saturated with nitrogen, began to be used on an industrial scale relatively recently. This processing method, proposed for use by Academician N.P. Chizhevsky, allows you to improve many characteristics of products made from steel alloys.

Ion-vacuum nitriding workshop

The essence of technology

Nitriding of steel, when compared with such a popular method of processing this metal as carburization, has a number of significant advantages. That is why this technology began to be used as the main way to improve the quality characteristics of steel.

When nitriding, the steel product is not subjected to significant thermal effects, while the hardness of its surface layer increases significantly. It is important that the dimensions of the nitrided parts do not change. This allows this processing method to be used for steel products that have already been hardened with high tempering and ground to the required geometric parameters. Once nitriding, or nitriding as the process is often called, has been completed, the steel can be immediately subjected to polishing or other finishing methods.

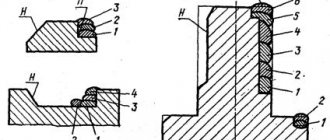

Scheme of a glow discharge nitriding installation

Nitriding of steel involves heating the metal in an environment characterized by a high ammonia content. As a result of this treatment, the following changes occur with the surface layer of the metal, saturated with nitrogen.

- Due to the fact that the hardness of the surface layer of steel increases, the wear resistance of the part improves.

- The fatigue strength of the product increases.

- The surface of the product becomes resistant to corrosion. This stability is maintained when steel comes into contact with water, moist air and air-steam environment.

Microstructure of a high-quality nitrided layer of steel grade 38Х2МУА

Nitriding allows you to obtain more stable steel hardness indicators than carburization. Thus, the surface layer of a product that has been subjected to nitriding retains its hardness even when heated to a temperature of 550–600°, while after carburization, the hardness of the surface layer may begin to decrease when the product is heated above 225°. The strength characteristics of the surface layer of steel after nitriding are 1.5–2 times higher than after hardening or carburization.

Technological scheme of nitridation

Although nitridation can be carried out in various ways, the scheme for preparing materials and technological operations is almost identical. There are several options for nitriding:

- gas;

- innovative plasma;

- ionic.

Despite the type of metal nitriding, the treatment result is aimed at obtaining the most durable and wear-resistant product.

Preparatory heat treatment

This type of processing consists of hardening the product and its high tempering. Hardening of a steel element is carried out at temperatures above 940 degrees. Cooling during preparatory processing is carried out exclusively in oil or water. After hardening the metal at a temperature of 940 degrees, tempering occurs at 600-700 degrees. The processed steel part is endowed with increased hardness.

Mechanical restoration

The operation consists of grinding the finished part. The precise geometry of parts is the key to acquiring the necessary strength properties and long-term operation in the future.

Protection of parts not subject to nitriding

This steel processing step is necessary to protect elements that should not be nitrided. For protection, tin or liquid glass is used, which is applied to the surface of the metal part in a thin layer of no more than 0.015 mm. The electrolysis technology for fastening these materials ensures its reliable fastening on the surface of the steel alloy, as well as high resistance to nitrogenous environments, so the substance does not penetrate into the internal structure of the steel part.

Nitriding

Different grades of steel require a certain heating temperature. The steel is kept at this temperature for a certain number of hours. Thanks to these parameters, a layer is formed at different depths, providing a certain nominal surface hardness. For steel grade 7ХЗ, the heating temperature is 500-520 degrees. The steel is aged for 48-60 hours, a layer depth of 0.4-0.5 mm is ensured, and the nominal surface hardness is 1000-1100.

Final processing

This stage of steel processing allows you to bring the geometric and mechanical parameters of the steel element to the required value. Since the geometry changes are very slight during nitriding, the changes at the finish will be minimal. Despite the fact that the part is subjected to minimal temperature treatment, the elements will still have to be slightly modified, since the nitrogen layer can slightly affect the geometry. In order to avoid any deformation during the nitriding process of the element, you can use a more advanced technology - ion nitriding. The technological process of ion-plasma nitriding involves minimal exposure to temperature conditions on steel parts, and the likelihood of steel deformation tends to a minimum.

Ion plasma nitriding has proven to be extremely positive. Among the advantages, it is worth emphasizing that nitridation occurs at low temperatures, unlike traditional options. In order to carry out ion-plasma nitriding, a replaceable muffle or a built-in part of the installation is most often used. These elements speed up the process of improving the metal, but are not economically justified in all cases.

How does the nitriding process proceed?

Metal parts are placed in a hermetically sealed muffle, which is then installed in a furnace for nitriding. In the furnace, the muffle with the part is heated to a temperature that is usually in the range of 500–600°, and then maintained for some time at this temperature.

Vacuum heat treatment furnace with gas nitriding system

To create the working environment inside the muffle necessary for nitriding to take place, ammonia is supplied to it under pressure. When heated, ammonia begins to decompose into its constituent elements; this process is described by the following chemical formula:

Atomic nitrogen, released during this reaction, begins to diffuse into the metal from which the workpiece is made, which leads to the formation of nitrides characterized by high hardness on its surface. To consolidate the result and prevent the surface of the part from oxidizing, the muffle, along with the product and the ammonia that continues to remain in it, is slowly cooled together with the nitriding furnace.

The nitride layer formed on the metal surface during the nitriding process can have a thickness in the range of 0.3–0.6 mm. This is quite enough to provide the product with the required strength characteristics. Steel processed using this technology does not need to be subjected to any additional processing methods.

Classification of nitriding processes

The processes occurring in the surface layer of a steel product during its nitriding are quite complex, but have already been well studied by specialists in the metallurgical industry. As a result of such processes, the following phases are formed in the structure of the processed metal:

- Fe3N solid solution, characterized by a nitrogen content in the range of 8–11.2%;

- Fe4N solid solution, which contains 5.7–6.1% nitrogen;

- a nitrogen solution formed in α-iron.

An additional α-phase in the metal structure is formed when the nitriding temperature begins to exceed 591°. At the moment when the degree of saturation of a given phase with nitrogen reaches its maximum, a new phase is formed in the metal structure. Eutectoid decomposition in the metal structure occurs when the degree of its saturation with nitrogen reaches a level of 2.35%.

Review of nitriding methods

Nitriding methods are often distinguished by the aggregate state of nitrogen in the initial state:

— liquid: Carbonitriding (cyanidation) in molten salts

- gaseous: Gas nitriding and carbonitriding

— ionized gas: nitriding and carbonitriding in glow discharge plasma

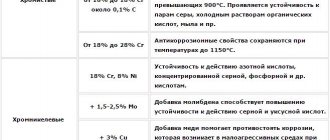

Table 1 - Overview of nitriding methods

The named nitriding methods, however, have their own advantages and disadvantages, which should be taken into account when choosing nitriding as an alternative to carburizing, depending on the required parameters of the part and the properties achieved during the nitriding process.

The molten salt nitriding process is very flexible due to its short process time. This method is most beneficial in cases where the first priority is to increase the wear and corrosion resistance of the surfaces being treated. However, some more and less significant disadvantages of this process limit the use of this method, especially for large parts:

This is interesting: At what angle to sharpen drills for metal. Sharpening options that can be done by hand

— High costs for cleaning after nitriding

— High costs for recovery and removal of salt and cleaning solution

— High energy consumption when operating the bath, which limits the size of the bath

— Processing temperature is highly limited

— Partial nitriding is difficult to implement

Gas nitriding and carbonitriding are more versatile nitriding processes that have undergone intensive development over the past 10 years in terms of technology, equipment and control systems. These two methods are very good alternatives to cementation. Particularly when machining large tools and gears, nitriding has economic advantages over carburization due to the significant reduction in processing temperature and the absence of further processing.

Despite the high technological level of these gas nitriding methods, there are several points that limit the applicability of these methods from technical, economic and environmental points of view:

— High gas consumption

— Use of flammable gases, which requires special protection measures

— There is no possibility of depassivation of the surface of parts during the nitriding process

— Nitriding of stainless steels is not possible

— High costs for applying and removing special products to protect non-nitrided surfaces

Factors influencing nitridation

The main factors that influence nitriding are:

- the temperature at which such a technological operation is performed;

- gas pressure supplied to the muffle;

- duration of exposure of the part in the oven.

The efficiency of this process is also influenced by the degree of ammonia dissociation, which, as a rule, is in the range of 15–45%. As the nitriding temperature increases, the hardness of the formed layer decreases, but the process of diffusion of nitrogen into the metal structure accelerates. A decrease in the hardness of the surface layer of a metal during its nitriding occurs due to the coagulation of nitrides of alloying elements included in its composition.

The influence of temperature and alloying elements on the formation of a nitrided layer

To speed up the nitriding process and increase its efficiency, a two-stage scheme is used. The first stage of nitriding when using this scheme is performed at a temperature not exceeding 525°. This makes it possible to impart high hardness to the surface layer of the steel product. To perform the second stage of the procedure, the part is heated to a temperature of 600–620°, while the depth of the nitrided layer reaches the required values, and the process itself is almost doubled. The hardness of the surface layer of a steel product processed using this technology is no lower than a similar parameter for products processed using a single-stage method.

Introduction

To increase the wear resistance of highly loaded interacting surfaces of tools and gearbox parts made of steel, the process of carburization followed by hardening is most often used to this day. Depending on the method of carburization and the operational characteristics of the part, the designer determines not only the material, but also such values as surface hardness and carburization depth. This means that the gears of gearboxes, for example for highly loaded drives of wind power plants, must be carburized before hardening at temperatures above 900 ºC for quite a long time in order to achieve a depth of the hardened layer of about 1..2 mm. Hardening after carburization leads to a change in the structure of the processed material and, as a consequence, to a change in weight and shape. After hardening, the parts must be additionally tempered to reduce internal stresses and obtain the required structure. To achieve the required surface quality and weight of parts after heat treatment, additional mechanical processing is necessary.

An alternative to carburization is surface hardening using the nitriding method. In this case, we are talking about a thermochemical diffusion process to enrich the surface layer of parts with nitrogen. In this case, nitrogen interacts with the base metal and alloying elements, forming chemical compounds. As a result of nitriding, a nitrided layer appears in the surface zone of the part with an outer region (the so-called binding layer SS) and an internal diffusion region (the so-called diffusion zone 3D). Due to the hardness of the nitrided layer and the stresses arising in it, wear resistance, corrosion resistance and resistance to long-term loads increase, regardless of the strength characteristics of the part. At the same time, a significant advantage of nitriding compared to carburizing is that the diffusion of nitrogen into steel requires temperatures equivalent to tempering temperatures for tempering and tool steels. Structural transformations and associated warping, changes in size and strength during nitriding are significantly lower. In addition, after nitriding, as a rule, no additional processing is required.

Types of Nitrided Steels

Both carbon and alloy steels, characterized by a carbon content in the range of 0.3–0.5%, can be processed using nitriding technology. The maximum effect when using such a technological operation can be achieved if steels are subjected to it, the chemical composition of which includes alloying elements that form hard and heat-resistant nitrides. Such elements, in particular, include molybdenum, aluminum, chromium and other metals with similar characteristics. Steels containing molybdenum are not subject to such a negative phenomenon as temper brittleness, which occurs when a steel product cools slowly. After nitriding, steels of various grades acquire the following hardness:

Hardness of steels after nitriding

Alloying elements found in the chemical composition of steel increase the hardness of the nitrided layer, but at the same time reduce its thickness. The thickness of the nitrided layer is most actively influenced by chemical elements such as tungsten, molybdenum, chromium and nickel.

Depending on the scope of application of the product that is subjected to the nitriding procedure, as well as on its operating conditions, it is recommended to use certain grades of steel to carry out such a technological operation. So, in accordance with the technological problem that needs to be solved, experts advise using products made from the following steel grades for nitriding. 38Х2МУА

This is steel, which, after nitriding, has a high hardness of the outer surface. Aluminum contained in the chemical composition of such steel reduces the deformation resistance of the product, but at the same time helps to increase the hardness and wear resistance of its outer surface. The exclusion of aluminum from the chemical composition of steel makes it possible to create products of more complex configurations from it.

These alloy steels are used for the manufacture of parts used in the machine tool industry.

30Х3М, 38ХГМ, 38ХНММА, 38ХН3МА

These steels are used for the production of products that are subjected to frequent cyclic bending loads during their operation.

Products are made from this steel alloy, the accuracy of whose geometric parameters is subject to high demands. To impart higher hardness to parts made of this steel (these are mainly parts of fuel equipment), silicon can be added to its chemical composition.

Characteristics of some steels after nitriding

Benefits of the PulsPlasma® process

Temperature distribution

The use of a chamber with electrically heated walls, along with an energy-saving effect, influences the temperature distribution throughout the setting of parts.

In order to avoid a significant increase in temperature in the cage when using a chamber with cold walls, in many cases the use of the entire volume is abandoned. Instead, cylindrical cages are formed in a cylindrical chamber. When using a hot wall installation, due to the lower energy input, nitriding of a complete charge is carried out using pulsating plasma without the risk of overheating in some areas. Nitriding of both densely packed charges and very large parts can be successfully implemented using units for the PulsPlasma® process.

Often PulsPlasma® installations are manufactured with a built-in automation system for chamber movement, in contrast to shaft and chamber furnaces.

The cage is installed directly on the supplied base using a cage device. The frame with parts can, if necessary, be pre-prepared and, complete with parts, installed in the installation.

In the case of particularly large, heavy tools or parts, it makes sense to abandon the bell-type principle in favor of a chamber-type installation. Such an installation for processing car body dies with a unit load of up to 40 tons is shown in the figure below. Using a crane, the part is loaded onto a cart, after which the cart with the part is placed into the installation chamber.

Gas consumption during the process

With PulsPlasma® - nitriding, depending on the specific application and the properties of the layer, they work with nitrogen-hydrogen-methane mixtures. The nitriding process does not produce unfriendly reaction products, so the used gases can be released into the environment without additional treatment. Plasma nitriding is carried out at low pressures, so the consumption of process gases is quite low. A chamber with dimensions of 1200x2000 mm consumes an average of 180 l/h of gas mixture. A gas nitriding installation with the same dimensions consumes from 6,000 to 10,000 l/h of ammonia and carbon-containing mixture. With classical carburization, the gas consumption is similarly high. Therefore, during gas nitriding and carburization, a large amount of flammable exhaust gas is formed, which is harmful to the environment and requires additional energy for its additional afterburning.

Flexible processing temperatures

On the basis of exciting the plasma of the nitriding process and dosing power thanks to the pulsating operating principle, it is possible to carry out PulsPlasma® - nitriding processes in a wide temperature range between 350 ºC and 600 º.

This is interesting: Which electrodes are best to use for inverter welding? What types of electrodes are there?

Parts susceptible to warping can be nitrided in this case under optimal conditions. Changes in the dimensions of parts due to the release of internal stresses at high processing temperatures are minimized.

The strength of the base metal of nitrided parts also remains unchanged, because The nitriding temperature is determined slightly lower than the tempering temperature during improvement (heat treatment process before nitriding). After nitriding, no additional heat treatment is required. Parts after PulsPlasma® nitriding can be immediately used for their intended purpose.

Steels with a high chromium content, which can be nitrided in molten salts with loss of corrosion resistance and by gas nitriding with high losses, are processed without problems with PulsPlasma® nitriding. In this case, immediately before saturation, depassivation of the surface is necessary by bombarding the surface with ions. Thanks to the choice of nitriding temperatures below 450 ºС and precise control of the composition of the gas mixture, it becomes possible to obtain a hard, wear-resistant layer on the surface of parts without loss of corrosion resistance.

Powder steel processing

Processing of powder parts using carburization, molten salt carbonitriding and gas nitriding, due to the limited conditions of these processes, leaves more or less pores in the powder material. When processing in plasma, only the outer surfaces covered by the glow discharge are actually processed. Due to low pressures (vacuum) and small amounts of gas, there is no danger of over-nitriding and over-curing during plasma nitriding. When carrying out the process, a sample is placed along with the parts, made of the same material as the parts in the cage, and subjected to the same treatment before nitriding.

Partial processing

There are no simpler surface hardening methods that allow partial treatment than PulsPlasma® - nitriding. Areas not subject to saturation are closed by simple mechanical means. Special protective putties, which must be removed after the process, are not required in this case. The protected surface is not affected in any way during the plasma nitriding process.

Process combination

Due to similar processes and almost identical equipment, it is possible to combine several surface treatment processes in a dedicated installation. To further improve the corrosion resistance of nitrided parts, by simply changing the process parameters and process gas, in addition to the PulsPlasma® - nitriding process, the PulsPlasma® - oxidation process can be obtained. The oxidation process promotes the formation of a layer of iron oxide Fe3O4 with a thickness of 1 to 3 microns on the nitrided binder layer.

Depending on the quality of the steel and the previous nitriding process, corrosion resistance can reach up to 200 hours in a DIN salt spray chamber. Another advantage of oxidation is the improvement of the antifriction properties of the treated surfaces so that, under certain lubrication conditions, friction pairs treated in this way can be restored.

Another field of application opens up thanks to the combination of PulsPlasma® - nitriding with plasma CVD and DLC (Diamond like Carbon) coating processes. Thanks to the previously formed nitrided layer, additional CVD coating allows you to obtain extreme values of hardness and wear resistance. As a result of such treatment, the durability of the cutting tool usually increases significantly.

Table 2 Overview of the main differences between gas nitriding and PulsPlasma® nitriding

Nitriding of steel 38Х2МУА (1.8509)

During the process of ion nitriding, a diffusion surface layer and a nitride zone were formed on the surface of parts made of steel 38Х2МУА (1.8509), which are characterized by high hardness, scuffing and wear resistance. The diffusion layer is characterized by the absence of a brittle nitride network and has finely dispersed nitride inclusions in a strengthened matrix. The total layer depth is 0.36 - 0.4 mm, surface hardness is 1010 - 1050 HV5 (kgf/mm2).

Table 1. Characteristics of the nitrided layer on steel 38Х2МУА (1.8509)

| Surface hardness, HV5, kgf/mm2 | 1010 — 1050 |

| Surface microhardness, HV0.1, kgf/mm2 | 1090 — 1145 |

| Depth of the nitrided layer by microstructure, hm, mm. | 0,36 — 0,37 |

| Depth of the nitrided layer by microhardness, hс, mm. | 0,40 |

| Thickness of the nitride zone hn.z., microns. | 12 — 15 |

| Fragility according to VIAM scale | 1 point, not fragile |

Figure 1. Microstructure of the nitrided layer on steel 38Х2МУА (1.8509)

Nitriding of steel 40Х (AISI 5135, 1.7034)

On parts made of steel 40X (AISI 5135, 1.7034) a diffusion layer and a nitride zone are also formed. The surface acquires increased hardness, high scuffing and wear resistance. The surface layer is not brittle. The depth of the layer according to the microstructure is 0.28 - 0.3 mm.

Table 2. Characteristics of the nitrided layer on steel 40X (AISI 5135, 1.7034)

| Surface hardness, HV5, kgf/mm2 | 710 — 750 |

| Surface microhardness, HV0.1, kgf/mm2 | 750 — 810 |

| Depth of the nitrided layer by microstructure, hm, mm. | 0,28 — 0,30 |

| Depth of the nitrided layer by microhardness, hс, mm. | 0,30 |

| Thickness of the nitride zone hn.z., microns. | 6 — 9 |

| Fragility according to VIAM scale | 1 point, not fragile |

Figure 2. Microstructure of the nitrided layer on 40X steel (AISI 5135, 1.7034)

Nitriding of steel 30KhGSA

A diffusion layer and a nitride zone are also formed on parts made of Z0KhGSA steel. The surface acquires increased hardness, high scuffing and wear resistance. The surface layer is not brittle. The layer depth according to the microstructure is 0.35 - 0.4 mm.

Table 3. Characteristics of the nitrided layer on steel 30KhGSA

| Surface hardness, HV5, kgf/mm2 | 640 — 680 |

| Surface microhardness, HV0.1, kgf/mm2 | 840 — 910 |

| Depth of the nitrided layer by microstructure, hm, mm. | 0,35 — 0,36 |

| Depth of the nitrided layer by microhardness, hс, mm. | 0,40 |

| Thickness of the nitride zone hn.z., microns. | 9 — 12 |

| Fragility according to VIAM scale | 1 point, not fragile |

Figure 3. Microstructure of the nitrided layer on 40X steel (AISI 5135, 1.7034)

Figure 4. Graphs of microhardness distribution over the depth of the nitrided layer

Figure 5. Imprint of brittleness on steels, HV30, x100: a – 40X; b – 38Х2МУА; c – 30ХГСА

As a result of strengthening parts using the ion nitriding method, a diffusion layer and a high-quality nitride zone were obtained, which provide several times an increase in hardness, corrosion resistance and improved antifriction and tribological properties of parts. The technological capabilities of the ion-vacuum nitriding process make it possible to create surface diffusion layers of various chemical compositions on metals and alloys, which, in combination with the properties of the base metal, give the products a complex of physical and mechanical properties that determine their long-term operational reliability. Today, ion-vacuum nitriding is an advanced technology for surface hardening of parts, exceeding in its technical characteristics other types of coatings, including chrome plating. Currently, more than 10 R&D projects are underway to implement ion chemical-thermal treatment technologies with enterprises in various industries.

Technological scheme of nitriding

To perform traditional gas nitriding, innovative plasma nitriding or ion nitriding, the workpiece is subjected to a series of technological operations.

This processing consists of hardening the product and its high tempering. Hardening as part of this procedure is carried out at a temperature of about 940°, while the workpiece is cooled in oil or water. The subsequent tempering after hardening, which takes place at a temperature of 600–700°, allows the metal being processed to be given a hardness at which it can be easily cut.

Heat treatment modes before nitriding

This operation ends with its grinding, which allows the geometric parameters of the part to be brought to the required values.

Protection of areas of the product that do not require nitriding

Such protection is carried out by applying a thin layer (no more than 0.015 mm) of tin or liquid glass. Electrolysis technology is used for this. A film of these materials that forms on the surface of the product does not allow nitrogen to penetrate into its internal structure.

Carrying out the nitriding itself

The prepared product is processed in a gas environment.

Recommended steel nitriding modes

This stage is necessary in order to bring the geometric and mechanical characteristics of the product to the required values.

The degree of change in the geometric parameters of the part when performing nitriding, as mentioned above, is very insignificant, and it depends on factors such as the thickness of the surface layer that is saturated with nitrogen; temperature regime of the procedure. A more advanced technology – ion nitriding – can guarantee the almost complete absence of deformation of the processed product. When performing ion plasma nitriding, steel products are exposed to less thermal influence, due to which their deformation is minimized.

Unlike innovative ion plasma nitriding, traditional one can be performed at temperatures reaching up to 700°. For this purpose, a replaceable muffle or a muffle built into the heating furnace can be used. The use of a replaceable muffle, into which the parts to be processed are loaded in advance, before being installed in the furnace, can significantly speed up the nitriding process, but is not always an economically viable option (especially in cases where large-sized products are subjected to processing).

Punch weighing more than 230 kg, subjected to nitriding treatment

Factors affecting nitriding

The main parameters that have a significant impact on the nitriding process are:

- temperature;

- gas pressure;

- exposure duration.

These factors are the main parameters that influence the nitriding process, but there are also other indicators. For example, the degree of dissociation of ammonia components. Usually it is in the range of 15-45%. As the temperature in the gas treatment environment increases, the hardness may decrease significantly, but in contrast, the diffusion processes of nitrogenous components are accelerated. Such parameters are determined by the coagulation of nitrides of alloying components, which are noted in the composition of the metal. These parameters make it possible to reduce processing processes by several times.

If necessary, speed up the nitriding process and increase its efficiency, use a two-stage metal processing scheme. This scheme involves the first stage of processing metal alloys at a temperature that does not exceed 525 degrees. Thanks to the use of this particular temperature, high hardness values are imparted to the steel part. In the second part of the nitriding process, the part is heated to 600-620 degrees. With such temperature parameters, the nitriding process is significantly accelerated, and the depth reaches the required values. The strength data of the surface layer using two-stage technology are not inferior to the corresponding products that have undergone one-stage nitriding.

Types of working environments

Various types of working media can be used to perform nitriding. The most common of these is a gas environment consisting of 50% ammonia and 50% propane or ammonia and endogas, taken in the same proportions. The nitriding process in such an environment is performed at a temperature of 570°. In this case, the product is exposed to a gas environment for 3 hours. The nitrided layer created when using such a working medium has a small thickness, but high strength and wear resistance.

Recently, the method of ion-plasma nitriding, performed in a nitrogen-containing rarefied environment, has become widespread.

Ion plasma nitriding – a view from the inside

A distinctive feature of ion plasma nitriding, which is also called glow discharge processing, is that the workpiece and the muffle are connected to an electric current source, with the product acting as a negatively charged electrode, and the muffle as a positively charged one. As a result, a flow of ions is formed between the part and the muffle - a kind of plasma consisting of N2 or NH3, due to which the surface being treated is heated and it is saturated with the required amount of nitrogen.

In addition to traditional and ion-plasma nitriding, the process of saturating the steel surface with nitrogen can be carried out in a liquid medium. In such cases, molten cyanide salts are used as a working medium, which has a heating temperature of about 570°. The time of nitriding performed in a liquid working environment can range from 30 to 180 minutes.

"Yonitech" Ltd. offers the following models of "Cold Wall" type installations:

Installation, model

Working volume, mm, Ø xh

Installation types

Maximum weight of processed parts, kg

• Power supply: 3×400V(480V) +10%/-15%, 50Hz (60Hz); • All models can be made with two chambers - learn more about our two-chamber systems that prevent loss of process time; • Working gases: ammonia, nitrogen, hydrogen, propane, methane; • Cooling gas: nitrogen, argon; • Working pressure: 1 - 8 mbar; • Delivery time: from 5 to 6 months depending on the model.

For additional information about our “Warm Wall” installations, please contact us by email: .