Vacuum deposition is a process that most modern enterprises need at this stage. This method is often used in those industries that produce various products that are somehow related to further operation.

This can be either conventional equipment or dental products, which also require a vacuum deposition process. No matter how strange it may sound, the medical industry is one of those areas where the vacuum deposition process is used most often. It can be used in this industry, both in the role of improving the properties of equipment for work, and in the role of coating various materials or products.

The vacuum deposition installation is one of the most important components of this process. Few people will argue with the fact that it is the vacuum deposition installation that allows this process to be carried out, and to do it quite quickly. The operating principle of such installations is as simple as possible. Initially, a state of primary rarefaction is created inside such systems, which allows the crystalline powder to be converted into a special mixture, which can subsequently be applied to various coatings. Further, the pressure level inside the installation rises significantly, which leads to the active formation of a vacuum inside the system. Next, the vacuum carries out the process of spraying the spray, which immediately settles on the desired material, which will be amenable to such processing.

Another very important issue is the reliability of this process. Judging by the design and principle of operation of such installations, it is not difficult to understand that they are made, they are thought out as much as possible. But we cannot exclude the possibility of breakdowns of such equipment. But even this situation will not turn out to be so difficult, because such equipment is quite repairable and quite easy to repair.

Vacuum deposition methods

Considering the fact that the modern market includes a huge number of different industries, it was decided to create several methods of vacuum deposition at once. They are all unique and work according to a completely different algorithm.

Now we will look at the most common methods of vacuum deposition:

- Vacuum ion plasma sputtering

- Vacuum plasma spraying

- Vacuum ion sputtering

These are the three most commonly used types of spraying at the moment. Most enterprises actively use this technology, getting the maximum benefit from it. And this already suggests that, if desired, you can really get the maximum benefit from this method.

Vacuum plasma spraying

One of the most common vacuum deposition methods is vacuum plasma deposition. The technology of this process is as simple as possible and it involves the work of internal plasma. This element serves as a kind of distributor, allowing you to make the spraying process as high quality as possible.

In addition, this method can also boast of the accuracy of coating the product. And all because inside an installation of this type, a code has been created and installed in advance, according to which such systems usually work.

Ion vacuum sputtering

This type of vacuum deposition is as similar as possible to the previous one. The most obvious difference between this technology. We can call it a preliminary ionization process, which can significantly speed up the work process.

The presence of working ions inside the vacuum deposition installation not only improves the quality of the working process, but also makes it more reliable and, importantly, faster.

Vacuum deposition of aluminum

If we talk about which material most often lends itself to the vacuum deposition process, then it is probably aluminum. The reason for this was the scope of application of this metal, which is actively used in almost all industries.

But in many of them, this method is required to be more durable and reliable. This is precisely why aluminum vacuum deposition installations have been created. This process is as easy as possible, since the material reacts very well with the mixture that is applied to it during vacuum deposition.

Vacuum deposition of metals

If we talk about the process of vacuum metal deposition, then this is an even easier process. The technology of metal spraying is as simple as possible, which is why all enterprises are accustomed to using it. To apply a high-quality coating layer on metal, you only need to bring it to the desired temperature. This is the only condition that should be adhered to during vacuum deposition.

Many believe that this is precisely the main advantage of the vacuum metal deposition process.

How we mastered vacuum magnetron deposition of films

Hello, friends. Since we have passed a relatively complete stage in mastering the technology of vacuum deposition of thin films, it was logical for me to share my accumulated experience with you. Of course, you might think that there was little on the cutting edge of science and technology in this movement. However, in our opinion, the experience itself can be useful.

So, the story began a little earlier, when we had a vacuum chamber. Her path to us was not close and can be described in a separate story, but this, as they say, is “a completely different story.” I will only say that even earlier it brought some benefit to people in one of the laboratories of the University of Gottingen.

The first thing we started using the vacuum chamber on was testing a method for thermal deposition of metals onto substrates. The method is simple and as old as the world. A target of sputtered metal, such as silver, is placed in a molybdenum crucible. A heating element is placed around it. We used tungsten rhenium alloy wire, which was wound in a spiral.

The complete thermal spray device looks like this:

Equipment for thermal spraying of metals. A. Assembled (protective screen and valve removed). Designations: 1 – crucible, 2 – heating element, 3 – steam line, 4 – current lead, 5 – thermocouple, 6 – sample frame.

After passing current (it goes into the vacuum chamber through sealed leads), the spiral heats up, heats the boat, in which the target material also heats up and evaporates. A cloud of metallic vapor rises through the steam line and envelops the body on which the metal film must be deposited.

The method itself is simple and good, but there are also disadvantages: high energy consumption, it is difficult to locate the surfaces (bodies) in the vapor cloud on which the film needs to be deposited. Adhesion is also not the best. They were applied to various materials, including metals, glass, plastic, etc. Mainly for research purposes, since we were just mastering vacuum equipment.

Now it’s the turn to talk about the vacuum system. We carried out the experiments in a vacuum chamber equipped with a vacuum system consisting of a rotary forevacuum and turbomolecular pump and providing a residual pressure of 9.5•10 -6 – 1.2•10 -5 mmHg. If at first glance it seems that it is not complicated, then in fact it is not. First, the chamber itself must have the tightness necessary to maintain a high vacuum. This is achieved by sealing all functional flanges and openings. The upper and lower cover flanges have the same rubber seals, in principle, as the smallest holes intended for installing windows, sensors, devices, pressure glands and other flange covers, only with a much larger diameter. For example, to reliably seal such a hole

Requires flange, gasket and hardware as shown in this photo.

This sensor measures the vacuum in the chamber, the signal from it is sent to a device that shows the level of high vacuum.

The vacuum of the required level (for example, 10-5 mmHg) is achieved as follows. First, a low vacuum is pumped out to a level of 10-2 using a fore-vacuum pump. When this level is reached, a high-vacuum pump (turbo-molecular) is turned on, the rotor of which can rotate at a speed of 40,000 rpm. At the same time, the fore-vacuum pump continues to work - it pumps out pressure from the turbomolecular pump itself. The latter is a rather capricious unit and its “thin” structure played a certain role in this story. We use a Japanese turbomolecular pump from Osaka vacuum.

It is recommended to release the air with oil vapor pumped out of the chamber into the atmosphere, since fine droplets of oil can “spatter” the entire room.

Having figured out the vacuum system and worked on thermal sputtering, we decided to try another method of film deposition - magnetron. We had a long experience of communicating with one large laboratory, which applied functional nanocoatings to us for some of our developments using the magnetron sputtering method. In addition, we have quite close ties with some departments of MEPhI, MVTU and other universities, which also helped us master this technology.

But over time, we wanted to use more of the possibilities that the vacuum chamber provides.

Soon we had a small magnetron, which we decided to adapt for film deposition.

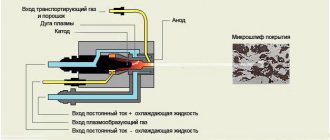

It is the magnetron vacuum method of deposition of thin metal and ceramic films that is considered one of the most productive, economical and easy to operate among all physical deposition methods: thermal evaporation, magnetron, ion, laser, electron beam. The magnetron is installed in one of the flanges, as convenient for use. However, this is still not enough for sputtering, since it requires the supply of a certain voltage, cooling water, and gases to ensure ignition of the plasma.

Theoretical excursion

Simplified, the magnetron is designed as follows. On the base, which also serves as a magnetic circuit, strong magnets are placed that form a strong magnetic field. On the other hand, the magnets are covered with a metal plate, which serves as a source of sputtered material and is called a target. Potential is applied to the magnetron, and ground is applied to the body of the vacuum chamber. The potential difference formed between the magnetron and the camera body under conditions of a rarefied atmosphere and magnetic field leads to the following. An atom of the plasma-forming gas argon is exposed to magnetic and electric field lines and is ionized under their influence. The escaped electron is attracted to the camera body. The positive ion is attracted to the magnetron target and, accelerated under the action of the magnetic field lines, hits the target, knocking out a particle from it. It flies out at an angle opposite to the angle at which the argon atom ion hit the target. A metal particle flies from the target towards the substrate located opposite it, which can be made of any material.

Our university friends made a DC power supply for this magnetron with a power of about 500 W.

We also built a gas injection system for plasma-forming argon gas.

To place objects on which films will be sprayed, we built the following device. The chamber cover has technological holes into which various devices can be installed: electrical power seals, motion seals, transparent windows, sensors, etc. We installed a pressure seal for the rotating shaft in one of these holes. Outside the camera, we applied rotation to this shaft from a small electric motor. By setting the drum rotation speed to about 2-5 hertz, we achieved good uniformity of film application around the drum circumference.

From below, i.e. Inside the chamber, we attached a light metal basket to the shaft, on which you can hang objects. In an office supply store, such a standard drum is sold as a waste basket and costs about 100 rubles.

Now we had in stock almost everything necessary for film deposition. We used the following metals as targets: copper, titanium, stainless steel, aluminum, copper-chrome alloy.

And they began to gather dust. Through the transparent windows into the chamber, it was possible to observe the glow of the plasma on the surface of the magnetron target. This is how we controlled “by eye” the moment of plasma ignition and the intensity of sputtering.

The method for controlling the coating thickness was invented quite simple. The same piece of foil with a measured surface area was placed on the drum and its mass was measured before and after the spraying session. Knowing the density of the sprayed metal, the thickness of the applied coating was easily calculated. The coating thickness was adjusted either by changing the deposition time or by adjusting the voltage on the magnetron power source. This photo shows precision scales that allow you to measure the mass of samples with an accuracy of ten thousandths of a gram.

We applied it to various materials: wood, metals, foil, plastics, paper, plastic films, fabrics, in short, to everything that could be placed in the chamber and attached to the drum. We were mainly focused on obtaining decorative effects - changing the color or tactile perception of the surface. These organic and inorganic samples show the difference in color before and after the application of different metal films.

The difference in color before and after spraying is even more clearly visible on fabrics and films. Here the right piece of ordinary plastic film is not sprayed, and the left one is covered with a layer of copper.

Another effect that can be used for various purposes is the conductivity of thin films on substrates. This photo shows the resistance of a piece of paper (in ohms) on which a titanium film a little more than a micron thick is applied.

We have chosen several directions for further development. One of them is to improve the efficiency of film deposition using magnetrons. We are going to “swing” at our own development and production of a more powerful magnetron as tall as a camera and with a power 2 times greater than that shown in this essay. We also want to test the technology of reactive sputtering, when, together with the plasma-forming gas argon, for example, oxygen or nitrogen is supplied into the chamber and during film sputtering, not pure metal films are formed on the surface of the substrate, but oxides or nitrides, which have a different range of properties than pure metal films.

Vacuum ion plasma sputtering

The most complex in terms of design and at the same time effective is the process of vacuum ion plasma sputtering. This technology includes a huge number of controversial and very important points, without which it is clearly impossible to achieve a high level of efficiency.

Using this method, it is possible to carry out vacuum deposition of titanium or vacuum deposition of glass without any problems. And this already suggests that the versatility of this method is at the highest possible level.

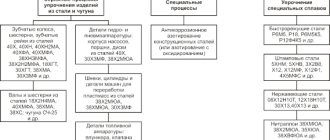

The essence and purpose of metal spraying

The application of protective coatings to metal is necessary for many industries. The purpose of spraying products is to increase the basic service life of the workpiece. The protective layer provides reliable protection against the following harmful factors:

- exposure to aggressive environments;

- vibration and alternating loads;

- thermal effects.

The composition of the multicomponent powder is selected based on the required performance qualities.

The use of several components increases the risk of obtaining a non-uniform coating due to delamination of the protective layer. To solve this problem, special rope-type materials are used, where the powder is fixed with a plastic binder.

During the spraying process, a stream of particles is directed onto the metal surface. When interacting with the surface, the sprayed elements are deformed, which ensures reliable contact with the product. The quality of adhesion to the workpiece depends on the nature of the interaction of particles with the substrate, as well as the crystallization procedure of the protective layer.

UVN vacuum spraying installation

But no matter what type of vacuum deposition you choose, without using UVN vacuum deposition installations, you are unlikely to achieve any success. At this stage, the cost of such installations is at a painfully high level.

But if we talk about their effectiveness, then there is no doubt about it at all. Having bought yourself a similar unit, you can be completely sure that over time, it will be able to recoup all the money invested in it.

Powder coating

Powder coating of metals with polymer materials is the most effective way to obtain high-quality coatings with decorative or protective properties.

Spray powder is a mixture of rubber and colored pigment. It is applied to the surface using a special electrostatic gun. In this case, the powder acquires a charge, which facilitates effective coupling with the workpiece.

To obtain a high-quality coating, it is necessary to carefully prepare the surface. The essence of the procedure is to clean the workpiece from dirt and traces of corrosion, followed by degreasing.

To use the technology on an industrial scale, special automatic or manual painting lines are used.

Metal spraying is one of the most effective surface modification technologies. Processing allows you to obtain a coating with decorative or protective qualities that increase the performance properties of the product. What do you think about this technology? Which method do you think is the most promising? Write your opinion in the comments block.