Methods for calculating specific gravity

- length;

- height, width or diameter;

- wall thickness.

Therefore, it is indicated as a mass of volume (in sq. m.) of a profile or cylindrical shape, filled with homogeneous steel with the required density (in kg/m. cu.). The length of the pipe when determining its specific gravity is one meter. For rolled steel pipes, in any calculations, the density of the composition from which it is made is always taken as 7850 kg/m. cube To determine the weight of one meter of steel pipe (specific gravity), choose one of the following methods:

- according to calculation formulas;

- using tables where the required data is indicated for standard sizes of rolled pipes.

In any case, the data obtained are only theoretical calculations. This is due to the following reasons:

- when making calculations, it is often necessary to round the calculated values;

- in the calculations, the shape of the pipe is assumed to be geometrically correct, that is, metal deposits at the welding joint, roundings in the corners (for rolled profiles), reduction or excess of dimensions relative to standard ones within the permissible limits of GOST are not taken into account;

- The density of different steel grades differs from 7850 kg/m. cube and for many alloys the difference is quite significant when determining the weight of a large number of pipe products.

With the help of special tables, the most approximate theoretical indicator of the specific gravity of pipe products is determined, since in their compilation complex mathematical formulas were used that took into account the production technology and geometry of the products as much as possible. To use this calculation option, first, using the available data on the pipe, its type is determined. Then they find in the reference literature a table corresponding to this rolled metal product or GOST for this assortment.

The good thing about the tabular version of the calculation is that it does not require any calculations, which eliminates the possibility of making a mathematical error when making calculations. But this method requires the availability of special literature. The most universal option is to use mathematical formulas. This method can be used in any conditions, even, so to speak, “in the field,” far from the opportunities and benefits of civilization.

Determining the specific gravity of a pipe using formulas

As mentioned above, the calculation is based on determining the volume of raw materials consumed to produce one meter of rolled pipe. Then this value must be multiplied by the density of the composition (in the case of steel by 7850 kg/m3). The required volume is determined in this way:

- Calculate the volume of a part of a pipe one meter long based on its external dimensions. Why determine the cross-sectional area of the pipe, which is multiplied by the length, in our case by 1 meter.

- Calculate the volume of the hollow part of a pipe 1 meter long. Why do we first determine the dimensions of the cavity (for a round product, the internal diameter is calculated by subtracting double the wall thickness from the external diameter, and for profile pipes, the height and width of the internal diameter are determined by subtracting double the thickness from the external dimensions). Afterwards, based on the results obtained, a calculation similar to that indicated in the first paragraph is made.

- At the end, the second result is subtracted from the first result, this is the volume of the pipe.

All calculations are made only after converting the initial indicators into kilograms and meters. The volume of round and cylindrical pipe sections is determined using the following formula:

V = RxRx3.14xL, where:

- V – volume;

- R – radius;

- L – length.

Another simple formula, but for round steel pipes:

Weight =3.14x(D – T)xTxLxP, where:

- D – outer diameter;

- T – wall thickness;

- L – length;

- P – steel density.

data needs to be converted to millimeters

Specific gravity = (A–T)xTx0.0316

For rectangular pipes:

Specific gravity = (A+B–2xT)xTx0.0158

That is, to determine the exact weight of the material, you can use special tables that indicate the weight of the pipes, taking into account the cross-section, diameter and other indicators. If you don’t have this table at hand, you can always use a special calculator, where to calculate the required values you only need to enter the necessary data, such as wall thickness and type of section of the structure. Everyone chooses how to determine specific gravity.

https://youtube.com/watch?v=z4AjL8HmOcw

Steel Pipe Weight Chart: Tips for Use

In this case, a special table can serve as a data source. Its selection depends on the type of product. In addition to GOSTs, diagrams can be found on many specialized sites. Today on the Internet you can easily find tables for determining the mass of parts made of different materials (for example, the weight of a cast iron pipe is 100 mm).

Finding mass by tabulation requires compliance with two basic rules

First of all, it is very important not to make a mistake in choosing a table. To do this, you need to check whether the name of the state standard corresponds to the material of the product whose mass you want to determine

The second rule is that you should not rely entirely on the data determined using the table. As a rule, the specific gravity of the pipe does not correspond to the actual one. Therefore, any calculation will only be an approximation. For small batches, this difference is not a serious problem.

On the Internet you can easily find tables for determining the mass of metal pipes

As an example, we can take a steel part with dimensions 60x60x3. The weight of 1 meter of pipe of this type is 5.25 kg, if you are guided by the tabular calculation. This product belongs to the profile group and has walls equal in width. The actual weight of a product with these dimensions may vary. The maximum allowance in this case is 10% of the total mass (52.5 g).

The tabular method is very good when you do not have time to carry out lengthy, complex calculations. However, it is always worth remembering the error that is present in this case.

Determination of the mass of round pipes

Regardless of the chosen calculation option, the following data will be required:

- product wall thickness;

- outer diameter size;

- section - comes in different shapes;

- steel grade.

The last value is a constant parameter, and the first still needs to be calculated.

There are two ways to do this:

- Calculation of the volume of the sheet from which a round pipe is formed.

- Determination of the difference between the volumes of two cylinders - external and internal.

Option one. To find out the weight of a pipe based on a diameter of 168 millimeters and an 8-mm wall thickness, first calculate the circumference.

To do this, use the formula:

L = πxD - 3.14x0.168 =0.52752 m, where

D – diameter;

Π – constant value – constant.

Next, the outer surface area is determined by multiplying the circumference of one unit of pipe products by its length according to the formula:

S = 0.52752x1 =0.52752 m², where

S is the surface area of a meter of round pipe.

Then you should find out the volume of steel that was used in the manufacture of this product by multiplying the surface area by the wall thickness. For calculation use the formula:

V = SHxW = 0.52752x0.008 =0.00422 m³, where

W – wall thickness value.

At the final stage, in order to calculate the weight of a round pipe, you need to take into account the density of the steel. This parameter can be found in a special table, and it is equal, as already mentioned, 7850 kg/m³. Density must be multiplied by volume:

P = 7850x0.00422 = 33.13 kg.

Option two. When calculating using this method, you need to calculate the volumes of the inner and outer cylinders. First of all, you should find out the areas of two surfaces - external and internal, respectively. The first of them will be:

Snar. = πxD - 3.14x0.168 =0.5278 m².

To determine the second area, it is necessary to know the cross-section of the inner cylinder, in this case it is: 0.168-0.016 = 0.152 m.

Hence, the internal area:

Sinternal = 3.14x0.152=0.4773 m².

Then you can begin to calculate the volumes of the cylinders using simple mathematical calculations, as a result of which they will be:

- for the external parameter - 0.5278×1=0.5278 m³;

- for internal value - 0.4773×1=0.4773 m³.

The difference between them is: 0.5278-0.4773=0.00505 m³.

To complete the calculation of the weight of a steel pipe, you only need to multiply the value of volume and density. In this case it will be: 0.00505×785≈39.6 kg.

Alternative calculation of the weight of 1 m of steel pipe

To find out the weight of a round pipe, it is not at all necessary to engage in complex calculations. Connecting to the Internet will allow you to easily find and use an online mass calculator to calculate materials of both types - round and profile.

However, to find out the weight of the pipe, you can do the following: simply read the table located in the corresponding standard. Again, this can be done via the Internet. For example, if you need to purchase a water pipe, enter the phrase “GOST 3262 75” into the Yandex or Google search bar. In response, you will receive about a million options. Click on the most suitable one and on the first page of this regulatory document you will see a table of the weight of a steel pipe. All you have to do is find the row and column that display the dimensions of your pipe products. It shows the theoretical weight of a round steel pipe. But it differs little from the actual one. And the most accurate mass of the pipe can only be determined by weighing.

The most accurate result is obtained by weighing pipes; it can be done with crane scales when purchasing pipes at a metal depot

Features of calculating pipe volume

Calculating the exact volume of pipe used is a mandatory procedure when installing any communication system. If this step is skipped or treated irresponsibly, too much pressure will build up in the functioning pipeline.

It will accelerate the wear of the material and will lead to the fact that the system will require constant repairs and will eventually simply fail, without even completing the established warranty period.

Correct calculation of pipe volume will ensure high-quality water supply to the house and allow owners to use it in the most convenient mode for themselves. The complex, installed on the basis of accurate data, will operate for a long time and reliably, without requiring complex maintenance or major repairs.

Low pressure will also have a negative impact, because it will significantly complicate or even make it completely impossible to fully and comfortably operate the system in a mode convenient for the consumer.

General parameters and required calculations

To calculate the volume of a given section of a pipe part, first determine the circumference of the pipe by its outer diameter. They do this using formulas

S=π(D/2)² or S=πR²

In this case, D means a digital indicator of the outer diameter of the pipe, and R is half the outer diameter, that is, the radius. The resulting value is multiplied by the length of the processed fragment and the resulting volume in cubic meters is obtained.

Further necessary calculations are carried out using the formula for calculating the volume of a cylinder

V=SH

where V is the volume of the pipe expressed in cubic meters, S is the external cross-sectional area expressed in square meters, and H is the length of the pipe section expressed in meters. For the correctness of actions, first all units of measurement are converted into a single vector and only after that the necessary calculations are carried out.

Calculation of the volume of pipes for water and gas supply

Correct calculation of the volume of steel pipes intended for communications responsible for water and gas supply begins with determining the diameter. The most popular models are reinforced pipes with a base diameter of 25.5 millimeters and ordinary universal ones with a diameter of 27.1 millimeters.

According to professionals, when laying a simple system, the accuracy of the indicators is not very important, since the volume of the pipe is calculated using generally established dimensionless indicators called nominal bore. The digital value of these values is determined using special tables and only in the case when it is necessary to calculate the pressure.

If you plan to use antifreeze, try to make the calculations more accurately. This allows you to avoid unnecessary material costs and significantly reduces the overall costs of laying communications.

Glycerin-based antifreeze is absolutely safe for humans, does not cause corrosion in equipment and does not damage the internal pipe surface. However, its cost is quite high. To save yourself from spending extra money, you need to very clearly calculate the volume of pipes and buy exactly as much substance as required

Next, calculate the radius of the part. To do this, use the formula:

R=D/2

they enter the data contained in the accompanying documentation or in the pipe markings (D means the base diameter declared by the manufacturer), and then, using the obtained figures, they perform the necessary computational actions.

You can calculate the radius of the pipe material in a simpler way using the formula R = L/6.28318530. L here denotes the circumference, which can be easily measured with a tape measure or rope, and the digital symbols imply the letter Pi multiplied by 2

At the next stage, the cross-sectional area is found. To do this, the numerical value of the radius is squared and multiplied again by the number PI (3.14). If the radius of the part is expressed in millimeters, the cross-sectional area is calculated in square millimeters. At the end, all the obtained values are put into the formula V=SH and the desired number is obtained.

Determination of pipe surface area

In addition to determining the volume of pipes, it is sometimes necessary to calculate the area, for example, in order to know how much paint is required for painting or covering with some other material. Area calculations can also be done either using online calculators or using a formula.

Thus, you can calculate in advance how much material will be required for:

- Painting;

- Insulation coatings;

- Degreasing the pipe surface.

The formula used to calculate the area is not complicated. First you need to measure the length of the pipe, as well as determine its outer radius; all centimeters obtained (if the pipe is small) are converted into meters. Pi, equal to 3.14, must be multiplied by 2, then the resulting number is multiplied by the length and radius of the pipe.

To determine the area of a square pipe, you must first calculate its perimeter and multiply the resulting number by the length. The same applies to a pipe in the shape of a rectangle - the calculation is carried out in exactly the same way. But it’s easy to calculate this way if the pipes have a straight shape, and if they are curved, then it is necessary to add certain tolerances to the obtained figures. Such information can be found in special building codes.

For a variety of purposes, it is necessary to know how much area a pipe will have. You can calculate it using an online calculator or using simple formulas. To calculate the area of a pipe, for example a steel pipe, you need to use an algorithm.

Algorithm:

- First you need to determine the diameter of the pipe, the resulting result must be multiplied by the number Pi.

- The resulting figure should be multiplied by the length of the pipe, as a result of which the external area will be known.

- If you need to calculate the internal area of the pipe, the formula changes slightly, first the diameter is also determined, then the thickness of its walls is measured.

- The thickness of the pipe walls is subtracted from the diameter, and the result obtained is again multiplied by the length.

Calculating the external area is necessary in order to know how much paint or covering material will be needed for the pipe. This knowledge will also help when designing heat supply systems in order to know what heat losses may occur.

In addition to calculating the area of pipes intended for liquid, there are air duct options; for round pipes, the calculation is approximately the same. But to calculate the area of an oval or an oval pipe, you should determine 2 radii, after which they should be multiplied together, and the resulting result multiplied by the number Pi.

Most calculations for various needs in the modern world are made using online calculations. Knowing the necessary parameters, they should be substituted into the appropriate fields in order to find out the result. But it is not always possible to use such “helpers”. In this case, for example, the cross-sectional area of a pipe has to be calculated manually.

Calculation:

- The pipe most often has the shape of a circle and is less common in the shape of a square or oval.

- To calculate a round pipe, it is necessary to determine its diameter, the learned value should be multiplied by the number Pi.

- To determine the internal cross-section of the pipe, the resulting number should be added to the wall; for convenience, all calculations are best done in meters.

Calculation of the cross-sectional area is necessary in order to know the speed of movement of liquid or gases, and for this it is necessary to select the most optimal diameter of the round pipeline. Also, when calculating, you should take into account the temperature of the gas or liquid with which they move through the pipes.

But, if the cross-section of gravity pipelines is being calculated, one should take into account not the full cross-section of the pipe, but the so-called live or actual one. The cross-section of the live flow is usually equal to half the actual cross-section of the pipe.

It is important to determine the surface area, as this allows you to calculate how much primer, paint or covering material will be required for a particular pipe, taking into account its shape, material and weight. The weight of pipes made of PVC or propylene is significantly less than steel pipes, although their area is the same.

To calculate the pipe area, you will need to perform the following steps:

- First determine the radius of the pipe in centimeters;

- Then convert the result into meters;

- Then you should calculate the length of the pipe, also in meters;

- Multiply the result by the known radius, as a result of which you can find out the outer area of the pipe.

You can calculate the area of a rectangular pipe taking into account the weight; it is enough to know how much a linear meter weighs; the tonnage can be determined using special tables used in construction. This value should be multiplied by the length of the pipe in meters. Such calculations make it possible to determine the amount of paint, primer and thermal insulation material, as well as heat loss during the transfer of the latter from a thermal unit such as a boiler room.

As a rule, when describing how to calculate the volume of rolled pipes, by default we are talking exclusively about products with a round cross-section. However, profile pipes with cross-sections of different shapes are increasingly being included in modern use:

- oval;

- square;

- rectangular;

- trapezoidal.

With a rectangular cross-section, the volume of the pipe is calculated using the formula V = SH (in expanded form - abH), i.e., data on the dimensions of the product is required - length, width, height. With a cross section of 15x10 mm for a five-meter segment we get 0.015x0.010x5, which equals 0.0075 m3 or seven and a half liters.

V = a2H.

With a cross section of 180x180 mm for a five-meter segment we get 0.182x5, which equals 0.16 m3 or 160 liters.

V = SL.

The area of an oval cross-section is calculated using the formula S = πав, where you need to substitute the lengths of the major and minor semi-axes of the ellipse (oval).

The easiest way is to calculate the volume of a square profile pipe, since all four of its sides are the same

The trapezoidal cross-section of pipes, increasingly used, along with the rectangular one, when arranging a sewer or chimney, to determine the volume involves the use of the same formula V = SL. To calculate the area of a trapezoid, take the formula S = 0.5 av.

The emergence of an increasing number of special computer programs for carrying out calculations for rolled pipes of various profiles can significantly simplify the process. It is enough to use the services of any online calculator and enter the available data to instantly get the necessary results.

Obtaining the result using the experimental method

In practice, problematic situations arise when the hydraulic system has a complex structure or some of its fragments are laid in a secret way. In this case, it becomes impossible to determine the geometry of its parts and calculate the total volume. Then the only way out is to conduct an experiment.

Using a collector and laying pipes under a screed is an advanced method of secretly supplying hot water to heating radiators. It is impossible to accurately calculate the length of communications in the absence of a plan.

It is necessary to drain all the liquid, take some kind of measuring container (for example, a bucket) and fill the system to the desired level. Filling occurs through the highest point: an open-type expansion tank or an upper drain valve. At the same time, all other valves must be open to avoid the formation of air locks.

If the water movement along the circuit is carried out by a pump, then you need to let it run for an hour or two without heating the coolant. This will help expel any remaining air pockets. After this, you need to add liquid to the circuit again.

This method can also be used for individual parts of the heating circuit, for example, a heated floor. To do this, you need to disconnect it from the system and “spill” it in the same way.

This is interesting: Foundation made of asbestos pipes

Calculation methods in industry

At large and large-scale facilities under construction or renovation, the process of determining parameters begins with incoming inspection. Engineers and installers check the accompanying documentation, certificates and company markings applied to the pipe rolling by the manufacturer.

A thorough inspection of a batch of pipe material at the time of delivery allows us to identify potential inconsistencies and, if detected, to reasonably refuse the supplier to accept substandard products

From this data, one finds out the nominal dimensions of the resulting material, the grade of metal or type of plastic, the batch number of the goods, the results of X-ray flaw detection carried out by the manufacturer and the chemical analysis of the smelting, the type of heat treatment and the date of specifications.

In production conditions, the actual length of the pipe is measured using a measuring wire or tape measure. Deviation from the figures stated in the factory documentation, up or down, for first class products is considered acceptable if it does not exceed 15 millimeters, for second class – 100 millimeters.

Basic data about the pipe can be obtained from the markings. It is usually applied to the outer or inner part of the product at a short distance from one of the ends. There they indicate the name of the manufacturer, heat number, equivalent carbon content (for metals), production date, number and nominal dimensional parameters

The outer diameter of pipes used in industry is checked using the formula:

D = L:π-2Δр-0.2 mm

It takes into account such parameters as:

- D – required diameter;

- L – length of the outer circumference of the pipe;

- Δр – thickness of the material from which the tape measure is made;

- 0.2 millimeters is the permissible allowance for contact with the surface of the measuring tool.

Errors and deviations of the actual diameter from those declared by the manufacturer for products with a cross-section of up to 200 millimeters are allowed within 1.5 millimeters. For pipes with a large cross-section, this figure is considered normal if it does not exceed 0.7% of the diameter specified in the documentation.

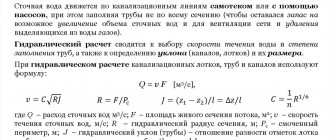

Methods for calculating pipeline capacity

Hydraulic calculations are carried out in order to select system elements with optimal characteristics to ensure uninterrupted operation, reduce operating costs and reduce equipment wear.

Hydraulic calculation of the pipeline

Calculations are carried out using Shevelev tables according to the following algorithm:

- The required flow rate Q and the optimal speed of the medium in each section are set.

- The diameter of the pipe is selected, and the pressure loss along the length is determined.

- The procedure is repeated for all sections.

- The specific value of pressure loss per 1 linear line is found. m.

- All other losses from suction, local resistance, etc. are summed up. The resulting value must be less than or equal to the pump power.

- Based on the technical characteristics of the equipment, the flow rate Q of the pump is determined.

- Q and Qpump are compared. If the values are approximately equal, the pump is selected correctly. If not, you need to set new parameters and calculate again.

Calculation of sewer pipe capacity

The diameter and angle of inclination are set at which wastewater flows randomly, and the system constantly cleans itself (from 0.005 to 0.035 depending on the cross-section):

The degree of filling of the pipe according to the standard is 0.6-0.8 and also depends on the diameter:

Dependence of filling on pipe diameter

Using the Lukin tables, it is clarified whether the selected diameter corresponds to the specified parameters. If there are deviations, the cross section needs to be changed up/down. For more accurate calculations, graphs, formulas and correction factors are used.

Calculation of gas pipeline capacity

In accordance with the parameters of the designed network, the diameters of the pipes at the inlet and outlet of the gas distribution system are set. Then, comparing the values in the tables, they find a ratio in which the conditions are maximally met.

Gas pressure in a gas pipeline: classification, types and categories of pipes Natural gas is used in everyday life and in industrial enterprises. Pipelines are used to deliver it to its destination. The most important indicator for them is the gas pressure in the gas pipeline. This…

How to calculate chimney parameters

The main characteristics that are determined during the calculations are the length of the chimney pipe and its working cross-section. If the parameters are incorrectly selected, toxic substances are not removed from the combustion chamber and penetrate into the room.

When designing, the standards SP 7.13130.2013 and SNiP III-G.11-62 are used. Although the latest regulation is considered ineffective, it contains recommendations specifically related to chimneys.

Complex industrial devices are calculated in professional bureaus; for home ovens, a simpler method is used.

Example:

- The speed of smoke movement is set to U=2 m/s.

- In an hour, approximately B = 6 kg of wood with a humidity of 20-25% burns in the firebox.

- Temperature of heated smoke T=140°.

The volume of emanating smoke is determined by the formula:

Vgas = (B x Vfuelx (1+T/273))/3600, m3/s, where Vfuel is the volume of air required to burn 1 kg of wood. In this case it is 10 m³, for a brown corner 12 m³, for a stone corner 17 m³.

Vgas=6x10x(1+140/273))/3600=0.025 m³/s.

Knowing the volume of outgoing gas and its speed, you can find the cross-sectional area of the chimney pipe:

S=Vgas/U=0.025/2=0.0126 m².

The diameter is determined by the geometric formula:

D=2√(S/p)=2√(0.0126/3.14)=0.126 m = 126 mm.

The nearest pipe diameter, rounded up, is 150 mm.

The length of the chimney to ensure normal draft is selected according to SP 7.13130.2013, which standardizes the height from the head to the stove grate, the roof ridge, as well as the distance to surrounding large objects.

How to calculate the cross-sectional area of a pipe

For a circular pipe, the cross-sectional area is calculated using the area of the circle using the following formula:

Str = ∏ x R2;

Where:

- R – internal radius of the pipe;

- ∏ – constant value 3.14.

Example:

Str Ø = 90 mm, or R = 90 / 2 = 45 mm or 4.5 cm. According to the formula, Str = 2 x 20.25 cm2 = 40.5 cm2, where 20.25 is 4.5 cm squared .

Pipeline parameters

The cross-sectional area of a profiled pipe Spr must be calculated using the formula used to calculate the area of a rectangular figure:

Spr = a x b;

Where:

a and b are the sides of a rectangular profiled pipe. With a pipeline cross-section of 40 x 60 mm, the parameter Spr = 40 mm x 60 mm = 2400 mm2 (20 cm2, or 0.002 m2).

How to calculate the volume of water in a plumbing system

To calculate the pipe volume in liters, the internal radius should be substituted into the formula, but this is not always possible, for example, for radiators of complex shape or an expansion tank with partitions, for a heating boiler. Heating boiler.

Therefore, you first need to find out the volume of the product (usually from the technical data sheet or other accompanying documentation). So, for a standard cast iron radiator the volume of one section is 1.5 liters, for aluminum ones - depending on the design, the options of which can be quite numerous.

Geometric parameters of aluminum radiators

You can find out the volume of the expansion tank (as well as other non-standard containers for any purpose) by pouring a pre-measured volume of liquid into it. To calculate the volume of any pipe, you need to measure its diameter, then calculate the volume of one linear meter, and multiply the result by the length of the pipeline.

The reference literature intended for regulating pipe parameters contains tables with values that are needed to calculate the volumes of pipes and other products. This information is indicative, but accurate enough to be used in practice. An excerpt from such a table is given below, and it is useful for home calculations:

| Ø internal, mm | Vinternal 1 linear meter of pipe, l | Vinternal 10 linear meters of pipe, l |

| 4,0 | 0,0126 | 0,1257 |

| 5,0 | 0,0196 | 0,1963 |

| 6,0 | 0,0283 | 0,2827 |

| 7,0 | 0,0385 | 0,3848 |

| 8,0 | 0,0503 | 0,5027 |

| 9,0 | 0,0636 | 0,6362 |

| 10,0 | 0,0785 | 0,7854 |

| 11,0 | 0,095 | 0,9503 |

| 12,0 | 0,1131 | 1,131 |

| 13,0 | 0,1327 | 1,3273 |

| 14,0 | 0,1539 | 1,5394 |

| 15,0 | 0,1767 | 1,7671 |

| 16,0 | 0,2011 | 2,0106 |

| 17,0 | 0,227 | 2,2698 |

| 18,0 | 0,2545 | 2,5447 |

| 19,0 | 0,2835 | 2,8353 |

| 20,0 | 0,3142 | 3,1416 |

| 21,0 | 0,3464 | 3,4636 |

| 22,0 | 0,3801 | 3,8013 |

| 23,0 | 0,4155 | 4,1548 |

| 24,0 | 0,4524 | 4,5239 |

| 26,0 | 0,5309 | 5,3093 |

| 28,0 | 0,6158 | 6,1575 |

| 30,0 | 0,7069 | 7,0686 |

| 32,0 | 0,8042 | 8,0425 |

Parameters of plastic pipes

The material from which pipes for water supply or sewerage are made may vary, and accordingly, the characteristics of the pipes will also differ. Steel pipes, for example, which have a large internal diameter, will allow much less water to pass through than similar pipes made of plastic or propylene.

This is due to the different smoothness of the inner surface of the pipe - for iron products it is much less, and PPR and PVC pipes do not have roughness on the inner surfaces. But metal pipes contain a larger volume of liquid than products made from other materials with the same internal cross-section. Therefore, all calculations for pipes made of different materials must be checked, and this can be done both in an online calculator and in a desktop computer program specifically designed for this.

Desktop program for volume calculations

| Conditional pass | Outside diameter | Pipe wall thickness | Weight of 1 m of pipes, kg | ||||

| Lungs | Ordinary | Strengthened | Lungs | Ordinary | Strengthened | ||

| 6 | 10,2 | 1,8 | 2,0 | 2,5 | 0,37 | 0,40 | 0,47 |

| 8 | 13,5 | 2,0 | 2,2 | 2,8 | 0,57 | 0,61 | 0,74 |

| 10 | 17,0 | 2,0 | 2,2 | 2,8 | 0,74 | 0,80 | 0,98 |

| 15 | 21,3 | 2,35 | – | – | 1,10 | – | – |

| 15 | 21,3 | 2,5 | 2,8 | 3,2 | 1,16 | 1,28 | 1,43 |

| 20 | 26,8 | 2,35 | 1,42 | – | |||

| 20 | 26,8 | 2,5 | 2,8 | 3,2 | 1,50 | 1,66 | 1,86 |

| 25 | 33,5 | 2,8 | 3,2 | 4,0 | 2,12 | 2,39 | 2,91 |

| 32 | 42,3 | 2,8 | 3,2 | 4,0 | 2,73 | 3,09 | 3,78 |

| 40 | 48,0 | 3,0 | 3,5 | 4,0 | 3,33 | 3,84 | 4,34 |

| 50 | 60,0 | 3,0 | 3,5 | 4,5 | 4,22 | 4,88 | 6,16 |

| 65 | 75,5 | 3,2 | 4,0 | 4,5 | 5,71 | 7,05 | 7,88 |

| 80 | 88,5 | 3,5 | 4,0 | 4,5 | 7,34 | 8,34 | 9,32 |

| 90 | 101,3 | 3,5 | 4,0 | 4,5 | 8,44 | 9,60 | 10,74 |

| 100 | 114,0 | 4,0 | 4,5 | 5,0 | 10,85 | 12,15 | 13,44 |

| 125 | 140,0 | 4,0 | 4,5 | 5,5 | 13,42 | 15,04 | 18,24 |

| 150 | 165,0 | 4,0 | 4,5 | 5,5 | 15,88 | 17,81 | 21,63 |

If your pipeline layout has its own specifics, you can calculate the exact parameters for the required fluid flow using the formulas given above.

Steel pipe weight: calculation calculator and formulas

Pipes, both round and profile, are sold at retail by the meter. However, when calculating future building structures, as well as when hiring a carrier, it is necessary to know the exact weight of the product. The steel pipe calculator calculates the weight of a pipe based on theoretical principles and allows you to calculate the mass of all existing types of pipes made from different grades of steel.

Round steel pipes

Purpose of the calculator

In order to find out the exact mass of a product, you need to calculate its volume, find out the grade of steel, then use GOST tables to determine its density. This is not an easy task, and its solution takes a lot of time. To save the builder from having to rummage through technical literature on his own, an online calculator was created.

Steel pipe weight calculator

This calculator takes into account all the elements that affect the determination of mass, so inaccuracies in calculations are minimized. When counting manually, the same data will be used as in the calculator on the site, but the time will be spent ten times more. At the same time, manual counting is fraught with technical errors, while automation does not have this drawback.

Principles and elements of calculation

Determining the weight of steel pipes using a calculator is based on the data contained in GOST standards. The programmers included the possibility of calculations depending on the following parameters:

- pipe cross-sectional shape – round, square or rectangular;

- outer diameter (for a round pipe) or side length (for a profile pipe);

- wall thickness, which is determined in accordance with the technical data sheet of the product;

- steel grade;

- product length in meters.

Section of steel pipes

From a physics course we know that the mass of an object is equal to its volume multiplied by the density of the material from which it is made. The volume is equal to the cross-sectional area multiplied by the height of the product. In the case of pipes, their length is taken as the height of the product. When making calculations, the greatest difficulty is the calculation of the cross-sectional area, since it has a complex geometric configuration.

The calculator calculates the weight of a square steel pipe using the following formula:

A rectangular pipe is calculated as follows:

The calculator calculates the weight of a round steel pipe using an algorithm described by the following formula:

π is a constant value, equal to 3.14, used when calculating the area of a circle.

Where to get the source data?

GOSTs contain information on the range and parameters of all standard types of pipes. In addition to dimensions, the calculations include a parameter such as steel density.

Density of steel of various grades

The letter designations in the steel grade indicate one or another impurity. Chemical elements that are added to steel have the following designations:

Designations of elements in alloys

Tolerances for calculations

Any inaccuracies that will be made when calculating the mass of pipes will be within the tolerances provided for by GOSTs. These inaccuracies will be higher for substandard products, and the mass of pipes of the highest quality will be calculated with maximum accuracy.

Profile steel pipe

The scatter is explained by the peculiarities of production. Pipes that meet quality requirements have constant wall thickness and perfect welds. The so-called substandard has flaws, which, however, allow the pipes to be used in construction, not necessarily for their intended purpose. These flaws affect the mass, which is reflected in the form of inaccuracies in the calculations.

Formula for calculating the weight of a profile pipe.

Formula for calculating the weight of rectangular and square profile pipes:

M – weight of 1 linear meter, kg;

A and B – side lengths, m;

B – cross-sectional length, m;

P – material density, kg/m3,

S – wall thickness, m.

When it is necessary to find out the total weight of the entire batch of pipes, the weight of a linear meter is multiplied by the total footage.

Draw your attention to! Profile pipe products from different suppliers can have different weights with the same dimensions (sectional index and wall thickness). The theoretical weight of pipes indicated in the GOST tables has deviations from real data. This is due to the fact that profile products are sold in accordance with certain tolerance limits specified in GOST tables, which may differ from real data.

How is the mass of a pipe calculated?

You need to find out all the information about the pipe whose mass you are interested in. This requires examination of the bill of lading or certificate. You need to decide on the type of pipe, outer diameter and wall thickness. After this, the length of one pipe is measured in meters and the total number of pipes ordered is calculated.

Using a reference book of theoretical scales, find the estimated mass of a linear meter of pipe that complies with GOST, has the required diameter and the required wall thickness. Once you know these numbers, it is easy to calculate the mass of one pipe. To do this, multiply the length of the pipe by the mass of the linear meter. After this, calculate the weight of all pipes by multiplying the weight of one pipe by the number of pipes.

Similarly, based on the type, diameter and wall thickness, the weight of polyethylene pipes can be calculated. To do this, use GOST data on polyethylene pipes. First, determine how much one linear meter weighs. To do this, you need to familiarize yourself with the standard dimensional ratio (SDR), which is not difficult to calculate: divide the pipe diameter by the wall thickness. Having found out the parameter of this value, using the reference book you need to find the estimated mass of 1 meter of pipe having a certain diameter, which is then multiplied by the length of the section or the entire pipe.

You can also calculate the mass using a special program called a calculator. Using this program, mass is easily calculated using geometric parameters: enter a known value in the appropriate field, select what you are looking for and wait for the answer. In order to know the density of the material, you need to look it up in special reference tables.

The simplest method for determining the weight of a pipe

There is a simple method that allows you to find out the weight of steel pipes by diameter. In addition to this parameter, information regarding wall thickness will be required. In this case, use the formula:

P = πх(D - Sst)xSst xT, where

D – outer diameter;

T – density;

Sst. – wall thickness.

As a result, the result will be like this:

P = 3.14x(0.168 - 0.008)x0.008x7850 = 31.55 kg.

Using this formula, you can always find out how much pipe products of any size weigh.

For example, one linear meter of a steel pipe with an outer diameter of 75.5 millimeters and a wall thickness of 4.5 millimeters will have a weight of:

P = 3.14x(0.0755 - 0.0045)x0.0045x7850 ≈7.8 kg.

To find out the mass of rolled products of a round or other shape, you need to multiply the resulting weight of one meter by the length of the product. Let's say that it is 10 meters, then: 7.8x10 = 78 kg.

But the final result will depend not on one grade of steel, but also on the production technology. Thus, the weight of an electric-welded pipe will not be the same as that of a seamless rolled product, provided that their basic parameters are the same.

Tabular standard data and average indicators for main parameters

To determine the estimated maximum water flow through a pipe, a table is provided for the 9 most common diameters at various pressures.

The average pressure value in most risers is in the range of 1.5-2.5 atmospheres. The existing dependence on the number of floors (especially noticeable in high-rise buildings) is regulated by dividing the water supply system into several segments. Water injection using pumps also affects the change in the speed of hydraulic flow. In addition, when referring to the tables, when calculating water consumption, not only the number of taps is taken into account, but also the number of water heaters, bathtubs and other sources.

Changes in the characteristics of the faucet's permeability with the help of water flow regulators, savers similar to WaterSave (https://water-save.com/), are not recorded in the tables and, as a rule, are not taken into account when calculating the water flow on (through) the pipe.

Inner and outer diameter, wall thickness, radius

Pipes are a specific product. They have an internal and external diameter, since their wall is thick, its thickness depends on the type of pipe and the material from which it is made. Technical specifications often indicate the outer diameter and wall thickness.

Pipe inner and outer diameter, wall thickness

Having these two values, it is easy to calculate the internal diameter - subtract twice the wall thickness from the external one: d = D - 2*S. If you have an outer diameter of 32 mm, a wall thickness of 3 mm, then the inner diameter will be: 32 mm - 2 * 3 mm = 26 mm.

If, on the contrary, there is an internal diameter and wall thickness, but an external one is needed, we add double the stack thickness to the existing value.

With radii (denoted by the letter R) it is even simpler - this is half the diameter: R = 1/2 D. For example, let’s find the radius of a pipe with a diameter of 32 mm. Just divide 32 by two, we get 16 mm.

Vernier caliper measurements are more accurate

What to do if there are no technical data for the pipe? To measure. If special accuracy is not needed, a regular ruler will do; for more accurate measurements, it is better to use a caliper.

How to calculate the weight of a pipe

Before ordering stainless steel products, the consumer often needs to know in advance how much the entire batch of goods will weigh, for example, to organize delivery or to design future structures. Moreover, the greatest number of questions arise regarding stainless steel pipes of various sections. It is not necessary to look for samples of products and weigh them separately - you can make all the calculations without leaving your desk. There are several options to solve the problem:

- use the mass calculator on our website or on the manufacturer’s website,

- find special tables (they are only suitable for standard products),

- apply the formula to calculate the theoretical weight of one linear meter.

In any case, you need to decide on the following points:

- what grade of steel are the products you are looking for?

- outer diameter of pipes,

- wall thickness,

- configuration (round, square, rectangular).

Pipe, as a molded product, has a constant cross-section, so using the formula to obtain the theoretical weight, we essentially determine the cross-section (essentially the volume of material per meter of pipe) and then multiply it by the density of the specific grade of stainless steel.

The weight formula for a round pipe is as follows: m = π * (d – e) * e * r π is a constant value equal to 3.142, d is the outer diameter, e is the wall thickness, r is the density of the steel.

For example, let’s determine the mass of a linear meter of a round pipe made of AISI 304 steel, 32 mm in diameter, with a wall of 2 mm. Note that the specific gravity (density) of stainless steel of this grade is 7.9 g/cm3. m = 3.142 * (32 – 2) * 2 * 790 kg/m3 = 188.5 mm2 * 7.9 g/cm3

Now let’s convert square millimeters into centimeters 188.5: 1000 = 0.1885 cm2 and finish the calculations. m = 0.1885 * 7.9 = 1.489 kg

To calculate the mass of a rectangular or square pipe, it is necessary to unwrap the section (determine its length), then, multiplying this figure by the wall thickness (e), we obtain the cross-sectional area, which we multiply by the steel density (r). You can use the following formulas: m (square pipe) = 4a * e * r where a is the length of the side in millimeters. m (for rectangular pipes) = (2a + 2b) * e * r where a and b are the sides of the rectangle in millimeters.

How to calculate the weight of a pipe

Detailed methodology for calculating the weight of a stainless steel pipe with a description of the nuances and formula.

Why do we need calculations of pipe parameters?

In modern construction, not only steel or galvanized pipes are used. The choice is already quite wide - PVC, polyethylene (HDPE and LDPE), polypropylene, metal-plastic, corrugated stainless steel. They are good because they do not have as much mass as their steel counterparts. However, when transporting polymer products in large volumes, it is advisable to know their weight in order to understand what kind of machine is needed. The weight of metal pipes is even more important - delivery is calculated by tonnage. So it is advisable to control this parameter.

What cannot be measured can be calculated

It is necessary to know the outer surface area of the pipe to purchase paint and thermal insulation materials. Only steel products are painted, because they are susceptible to corrosion, unlike polymer ones. So you have to protect the surface from exposure to aggressive environments. They are used more often for the construction of fences, frames for outbuildings (garages, sheds, gazebos, cabins), so the operating conditions are difficult, protection is necessary, therefore all frames require painting. This is where the area of the surface to be painted is required - the outer area of the pipe.

When constructing a water supply system for a private house or cottage, pipes are laid from the water source (well or borehole) to the house - underground. And still, to keep them from freezing, insulation is required. You can calculate the amount of insulation by knowing the outer surface area of the pipeline. Only in this case it is necessary to take material with a substantial margin - the joints must overlap with a substantial margin.

The cross-section of the pipe is necessary to determine the throughput - whether this product can carry the required amount of liquid or gas. The same parameter is often needed when choosing the diameter of pipes for heating and plumbing, calculating pump performance, etc.

Calculation of the thermal power of the heating system

The thermal power of a heating system is the amount of heat that needs to be generated in a house for comfortable living during the cold season.

Thermal calculation of a house

There is a relationship between the total heating area and the boiler power. In this case, the boiler power must be greater than or equal to the power of all heating devices (radiators). The standard thermal calculation for residential premises is as follows: 100 W of power per 1 m² of heated area plus 15 - 20% reserve.

Calculation of the number and power of heating devices (radiators) must be carried out individually for each room. Each radiator has a certain thermal power. In sectional radiators, the total power is the sum of the power of all used sections.

In simple heating systems, the above methods for calculating power are sufficient. The exception is buildings with non-standard architecture, having large glass areas, high ceilings and other sources of additional heat loss. In this case, a more detailed analysis and calculation using increasing factors will be required.

Thermal engineering calculation taking into account heat losses of the house

Calculation of heat losses at home must be performed for each room separately, taking into account windows, doors and external walls.

In more detail, the following data is used for heat loss data:

- Thickness and material of walls, coverings.

- The design and material of the roofing covering.

- Foundation type and material.

- Glazing type.

- Type of floor screeds.

To determine the minimum required power of the heating system, taking into account heat losses, you can use the following formula:

Qt(kWh) = V × ΔT × K ⁄ 860, where:

Qt is the heat load on the room.

V is the volume of the heated room (width × length × height), m³.

ΔT is the difference between the outdoor air temperature and the required indoor temperature, °C.

K is the heat loss coefficient of the building.

860 — conversion of the coefficient to kWh.

The heat loss coefficient of a building K depends on the type of structure and insulation of the room:

| K | Construction type |

| 3 — 4 | A house without thermal insulation is a simplified structure or a structure made of corrugated metal sheets. |

| 2 — 2,9 | A house with low thermal insulation - a simplified building design, single brickwork, simplified window and roof design. |

| 1 — 1,9 | Medium insulation - standard construction, double brickwork, few windows, standard roof. |

| 0,6 — 0,9 | High thermal insulation - improved construction, brick walls with thermal insulation, a small number of windows, insulated floors, roofing pie with high-quality thermal insulation. |

The difference between the outdoor air temperature and the required indoor temperature ΔT is determined based on specific weather conditions and the required level of comfort in the house. For example, if the temperature outside is -20 °C, and the temperature inside is +20 °C, then ΔT = 40 °C.

Examples of calculations

Specific examples will provide significant assistance in understanding the principles of calculations and the sequence of actions when performing calculations, which interested visitors should familiarize themselves with.

Calculation of the volume of required coolant

For a country house of temporary residence, you need to calculate the volume of purchased propylene glycol - a coolant that does not solidify at temperatures down to -30°C. The heating system consists of a 60 liter jacketed stove, four aluminum radiators of 8 sections each and 90 meters of PN25 pipe (20 x 3.4).

Pipes of the PN25 20 x 3.4 standard are most often used to organize a small heating circuit with radiators connected in series. Its internal diameter is 13.2 mm

The volume of liquid in the pipe must be calculated in liters. To do this, you need to take the decimeter as a unit of measurement. The formulas for converting from standard length values are as follows: 1 m = 10 dm and 1 mm = 0.01 dm.

The volume of the boiler jacket is known. V1 = 60 l.

The passport of the aluminum radiator Elegance EL 500 indicates that the volume of one section is 0.36 liters. Then V2 = 4 * 8 * 0.36 = 11.5 l.

Let's calculate the total volume of pipes. Their internal diameter d = 20 – 2 * 3.4 = 13.2 mm = 0.132 dm. Length l = 90 m = 900 dm. Hence:

V3 = π * l * d2 / 4 = 3.1415926 * 900 * 0.132 * 0.132 / 4 = 12.3 dm3 = 12.3 l.

Thus, we can now find the total volume:

V = V1 + V2 + V3 = 60 + 11.5 + 12.3 = 83.8 l.

At industrial and agricultural facilities, homemade heating radiators are often installed, arranged like registers. Knowing the dimensions of the pipes, you can calculate their volume

Calculation of the volume of a homemade radiator

Let's look at how to calculate a classic homemade heating radiator made from four horizontal pipes 2 m long. First you need to find the cross-sectional area. You can measure the outer diameter from the end of the product.

Let it be 114 mm. Using the table of standard parameters of steel pipes, we find the wall thickness characteristic of this size - 4.5 mm.

Let's calculate the internal diameter:

d = 114 – 2 * 4.5 = 105 mm.

Let's determine the cross-sectional area:

S = π * d2 / 4 = 8659 mm2.

The total length of all fragments is 8 m (8000 mm). Let's find the volume:

V = l * S = 8000 * 8659 = 69272000 mm3.

The volume of vertical connecting tubes can be calculated in a similar way. But this value can be neglected, since it will be less than 0.1% of the total volume of the heating radiator.

The resulting value is not informative, so let’s convert it to liters. Since 1 dm = 100 mm, then 1 dm3 = 100 * 100 * 100 = 1000000 = 106 mm3.

Therefore V = 69272000 / 106 = 69.3 dm3 = 69.3 l.

Therefore, since it will be necessary to calculate the volume of pipes in m3, then all dimensions will need to be immediately converted into meters before substituting them into the formula.

Weight of pipes with water and insulation table

To calculate the weight of water in a pipe, you need to know the internal diameter of the pipe and its filling with water. Below are the common diameters of water pipes and the weight of water in them.

The weight is indicated for 1 linear meter, at 50% and 100% filling of the pipe with water. 1 liter = 1 kg.

| Inner diameter, mm | water in pipe, l | |

| 50% | 100% | |

| 16 | 0.1 | 0.2 |

| 20 | 0.16 | 0.32 |

| 25 | 0.24 | 0.49 |

| 32 | 0.4 | 0.8 |

| 40 | 0.63 | 1.26 |

| 50 | 0.98 | 1.96 |

| 65 | 1.66 | 3.32 |

| 80 | 2.5 | 5 |

| 90 | 3.18 | 6.36 |

| 100 | 3.92 | 7.85 |

| 110 | 4.75 | 9.5 |

| 125 | 6.13 | 12.27 |

| 150 | 8.83 | 17.67 |

| 200 | 15.71 | 31.42 |

| 250 | 24.5 | 49 |

| 300 | 35.3 | 70.7 |

| 400 | 62.8 | 125.6 |

| 500 | 98.15 | 196.3 |

Weight taking into account pipes is difficult, due to the wide variety of materials from which pipes are made. Therefore, we suggest going to special pages with scales of pipes of various diameters and materials.

');> //—> The volume of water in a pipe is a quantitative characteristic of the space occupied by water inside the pipe.

The mass of water in a pipe is a quantitative characteristic of the mass of water located inside the pipe.

Volume calculation formula:

V = π * d 2 * l / 4

l is the length of the pipe; d is the internal diameter of the pipe.

The relationship between volume and mass is determined by a simple mathematical formula:

v—volume; m—mass; p—density.

In the calculation, the density of water is taken to be 1000 kg/m3.

You can quickly perform this mathematical operation using our online program. To do this, enter the initial value in the appropriate field and click the button.

This page presents a program for calculating the volume and mass of water in a pipe in accordance with the internal diameter of the pipe and its length.

Appendix D (for reference)

Estimated weight of one meter of insulated pipe

| Outer diameter of steel pipes and wall thickness, mm | Pipe weight, kg | ||

| in a polyethylene shell | in a steel shell | ||

| Type 1 | Type 2 | — | |

| 32x3.0 | 4,08 | — | 6,70 |

| 38x3.0 | 4,50 | — | 7,12 |

| 45x3.0 | 4,98 | — | 7,60 |

| 57x3.0 | 5,79 | 6,17 | 8,41 |

| 76x3.0 | 7,41 | 7,96 | 10,35 |

| 89x4.0 | 10,81 | 11,40 | 14,16 |

| 108x4.0 | 13,04 | 13,79 | 16,81 |

| 133x4.0 | 16,95 | 18,21 | 21,37 |

| 159x4.5 | 22,16 | 23,86 | 26,79 |

| 219x6.0 | 38,97 | 41,87 | 43,95 |

| 273x7.0 | 58,19 | 62,59 | 63,00 |

| 325x7.0 | 69,61 | 74,65 | 74,16 |

| 426x7.0 | 94,14 | 102,79 | 97,04 |

| 530x7.0 | 125,90 | — | 121,04 |

| 630x8.0 | 150,22 | — | 143,06 |

| 720x8.0 | 193,32 | — | 181,65 |

| 820x9.0 | 243,33 | 266,81 | 226,07 |

| 920x10.0 | 278,07 | 303,89 | 253,14 |

| 1020x11.0 | 338,59 | — | 304,91 |

| 1220x11.0 | 403,34 | — | 363,99 |

| 1420x12.0 | 468,10 | — | 423,08 |

| Note - The density of polyurethane foam is taken to be 80 kg/m3. |