If in Soviet times there was a game for schoolchildren, the essence of which was to solder a radio-electronic microcircuit on their own, which they successfully did, but now the question of how to properly use a soldering iron puts many in a difficult position. Although learning how to solder with a soldering iron is not so difficult, and having mastered the basics for “dummies”, you will be able to carry out simple work on your own without turning to specialists.

Silver and its properties. When is silver soldering necessary?

(function(w, d, n, s, t) { w[n] = w[n] || []; w[n].push(function() { Ya.Context.AdvManager.render({ blockId: "RA-805736-2", renderTo: "yandex_rtb_R-A-805736-2", async: true }); }); t = d.getElementsByTagName("script")[0]; s = d.createElement(" script"); s.type = "text/javascript"; s.src = "//an.yandex.ru/system/context.js"; s.async = true; t.parentNode.insertBefore(s, t) ; })(this, this.document, "yandexContextAsyncCallbacks");

Silver is a “white” precious metal that is actively used to create jewelry. Its sacred properties have been known since ancient times, but it was precisely its physical properties, such as softness, plasticity, and fusibility that made it popular in the jewelry industry.

When it is necessary to restore a broken piece of jewelry or correct a deformed area, silver soldering is used.

Soldering silver is used not only for repairing jewelry, but also for making new products or updating old ones. 925 standard is used as a basis.

Soldering a silver ring

Safety precautions for repair work

Since soldering is a process that involves the use of acids, a high-temperature soldering iron and a gas torch, it is necessary to follow basic safety rules:

- work is carried out only on a fire-resistant surface;

- When working with acid, you must use tight rubber gloves and safety glasses;

- the gas burner flame must be extinguished whenever work stops;

- A special stand is used for the soldering iron.

The action of the acid is neutralized by simple baking soda. You need to put it on a saucer next to you to remove the acid if it suddenly gets on your skin. Afterwards, the surface of the skin is washed with water.

Technique for soldering a silver chain with a soldering iron

In order to understand how to repair a silver chain using a soldering iron, you must complete the following steps at each stage:

- Surfaces are cleaned of dirt and degreased with acid, and then wiped with a flannel cloth. It is advisable to perform everything on a sterile surface. This means that the fireproof stand is also pre-wiped and degreased.

- Two surfaces for soldering are heated with a soldering iron. It is important that the temperature of the surfaces becomes higher than the reflow temperature of the solder, otherwise it will not be possible to solder the silver chain.

- Molten solder coated with a layer of flux is applied to the surfaces.

- The surface is additionally heated with a soldering iron until the flux melts. The soldering iron tip transfers the melt from one surface to another, forming a connection.

- After cooling, a small groove forms at the joints, which must be sanded to a smooth surface.

If the master solders 925 sterling silver, then the polishing is done with high-precision tools.

Soldering a silver chain with a soldering iron

Soldering process on a gas torch step by step

Action plan when working with a gas burner:

- Darkening and traces of oxidation are removed from the surface of silver.

- A layer of liquid flux is applied to the soldering area.

- A small piece of solder is applied to the soldering site. Its dimensions should be comparable to the dimensions of the faces being connected.

- A flame from a torch is supplied to the soldering site, but so that the solder is not blown away.

- Once the solder begins to melt, the torch flame is gradually increased until the solder becomes molten and forms a single edge joint.

- After cooling, the joint is cleaned and polished. It is necessary to smooth out all roughness and clean off the remaining flux.

How is steel soldered?

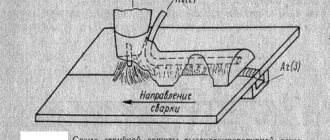

The process of any soldering is carried out in three stages: cleaning the surfaces to be joined from oxide films, heating the solder to the melting temperature, applying solder (soldering).

So how do you solder tin to steel? To perform steel soldering, you must perform the following steps:

- Remove foreign materials and shavings from the surface of the parts to be joined. To do this, you can use a wire brush or sandpaper.

- In the joint area, on the surfaces of the parts, it is necessary to apply flux (for example, BS-35, when soldering ordinary steel, and BS-45, when soldering stainless steel).

- Heat the parts to the required temperature, connect and apply solder.

- Use water or a special chemical cleaner to remove flux residues. If this is not done, then rust will appear at the soldering site, since the flux contains chloride.

Solder quality: how to fix it efficiently

Soldering efficiency directly depends on the quality of the solder . In workshops where they repair jewelry, high-quality alloys based on silver with the addition of purified copper or tin are mandatory.

To give the solder a silver shine, up to 20% zinc powder is added to it, which, when melted, forms the corresponding color.

You can make solder yourself, but for this you will need a muffle furnace and the starting elements: tin, silver or copper. If soldering is done at home yourself, then it is better to buy a ready-made rod or wire. In this case, you can count on the quality of the future connection .

High-quality solder has the following characteristics:

- it has a uniform shade; if the solder is made in powder form, then it has a uniform structure;

- When melted, the solder does not bubble or “splash,” as this means the presence of contaminants in the alloy.

To test, you can preheat and melt a small piece of solder.

Soldering iron for silver

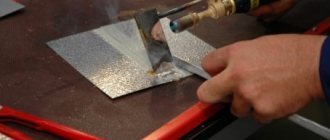

Soldering galvanized iron at home: tips from professionals

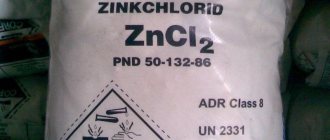

Soldering galvanized iron requires a specific approach to the process. Flux is required for this. This substance is both a solvent and an oxidizing agent. Additionally, this substance allows the metal to be wetted with iron, so you can get a high-quality seam. Most often, rosin or hydrochloric acid is used as a flux for working with galvanized parts or products at home. In some cases, it is possible to use boric acid or zinc chloride.

- When is galvanized metal suitable for soldering?

- Solder for household work, its composition and properties

- Equipment for work at home

When is galvanized metal suitable for soldering?

To correctly solve the question of how to solder galvanized steel, it is necessary to consider some of the properties of zinc. This metal begins to melt at a temperature of +460 o C. And at a temperature of +960 o C it begins to evaporate. Above these temperature values, pores, cracks and solder joint defects begin to form in the material. Therefore, the procedure can be carried out only with lower rates. An alternative is to use filler wire. In industrial conditions, the procedure in this case is carried out in a protective gas environment. Wire containing copper with silicon, bronze and aluminum is more often used.

These materials provide the following advantages:

- the welding seam is protected from corrosion;

- Spattering during soldering is minimal;

- the coating fades slightly;

- the procedure requires low heat levels;

- processing the formed seam is simple;

- Natural cathodic protection is formed in the weld area.

Solder for household work, its composition and properties

Solders are usually classified into hard and soft. For soldering galvanized steel at home, only the second group is used. If you use hard solders, it is not only impossible to achieve a high-quality weld, but there is also a risk of warping of the galvanized iron products themselves. Filler materials must have a low melting point, the point should be lower than that of the base material. Most often, POS-30 solder is used at home; it is a tin-based substance. It is better to use zinc chloride as a flux. If the surfaces have been tinned in advance, then rosin can be used. POS 30 is characterized by the following properties:

- optimal fluidity, materials penetrate into all spaces, filling even small voids;

- relatively low melting point;

- POS 30 are produced in various standard sizes, which allows you to select the optimal modification for specific work;

- a high degree of wettability facilitates the process and guarantees higher quality results;

- materials can be used for tinning workpieces;

- POS 30 has good conductivity and low resistance, which allows it to be used for soldering small parts;

- After hardening, the materials rigidly fix the parts together.

The connections are smooth and tight. The seams are balls on top of the base material.

If the elements to be soldered are large, then before soldering they need to be tinned - cover the surfaces with a thin layer of solder. The same action is necessary when soldering cylindrical products that fit into each other. If these are pipes, then solder is applied to an element with a larger diameter from the inside, and for a part with a smaller diameter - from the outside.

POS 30 consists of 30% tin and 70% lead. The material has the following technical parameters:

- the material begins to melt at +180 o C;

- complete melting of POS 30 occurs at a temperature of +256 o C;

- density – 10.1 kg/m3;

- alloy elongation in relative terms – 58%;

- crystallization interval – 73 o C;

- tensile strength – 32 mPa.

Equipment for work at home

Before wondering how to solder galvanized iron at home, you need to prepare the necessary equipment. The main tool is a regular soldering iron with an awl-shaped tip. But other devices will also be useful. A soldering iron requires a special holder or stand that will hold the tool in a heated state. To accurately connect small parts, you will need tripods with optical lenses. To remove smoke from the room - smoke absorbers. Tin pumps will be needed to remove excess tin. There are various switches, thermal pastes, control modules and adapters. This equipment will not only allow you to perform the soldering process, but will also provide the highest quality results.

Section question - answer

Is it possible to solder silver with a regular soldering iron?

Expert opinion

Grishanov Mikhail Petrovich

Jeweler, director of the Grishanov and Co. workshop

Unfortunately, soldering silver with tin is not possible due to the different densities of the metals. Tin is able to connect the edges, but even with the slightest mechanical force the decoration will collapse again.

How to repair a silver chain with your own hands at home, is it real?

Expert opinion

Pribrezhny Gennady Valentinovich

Jeweler 6th category

You need to buy special tools and accessories, ensure your workplace and work safety, use the manual and carry out the repairs yourself.

How to choose a flux for soldering: materials for working with copper, aluminum, silver and stainless steel

Flux is a substance necessary to accurately remove metal oxides formed during soldering.

In addition, applying flux helps protect the metal being processed from oxidation and ensures optimal spreading of the solder.

What flux to use for soldering aluminum, stainless steel, silver, BGA chips, and other materials, and how to make it yourself?

The choice of flux depends on the characteristics of the surfaces being joined, as well as the materials used, because different compositions are used when soldering with tin and hard solders.

Varieties, types of flux

It is important to consider that the melting temperature of the solder must be higher than the melting temperature of the flux. It is important to take into account that only fluxes for reactive flux soldering can interact with solder - this is unacceptable for other materials.

When you need the help of a jeweler. Table: cost of services in your city

If you urgently need the help of a jeweler to repair silver jewelry, then it would be advisable to contact a workshop at the nearest address. A set price list is provided for each type of soldering.

Soldering prices vary depending on the type of work and region.

Krasnoyarsk:

| Type of soldering | Price |

| Soldering iron | from 800 rubles |

| Gas burner | from 1000 rubles |

Tyumen:

| Type of soldering | Price |

| Soldering iron | From 1000 rubles |

| Gas burner | From 1100 rubles |

SPB:

| Type of soldering | Price |

| Soldering iron | From 1000 rubles |

| Gas burner | From 1100 rubles |

Moscow:

| Type of soldering | Price |

| Soldering iron | From 600 rubles |

| Gas burner | From 900 rubles |

Novosibirsk:

| Type of soldering | Price |

| Soldering iron | From 700 rubles |

| Gas burner | From 900 rubles |

The price is also determined by the complexity of the decoration and the amount of work.

Soldering iron with tin solder

The soldering process is the chemical joining of two metals using solder. Moreover, the crystal structure of the metal does not change. That is, the connected parts remain with their technical characteristics.

The connection itself is quite reliable, but much will depend on the type of solder and soldering technology. In addition, it should be noted that not all metals can be joined by this process. Basic metals, especially steel (iron), can be soldered together.

Three technologies

There are three technologies for soldering iron with tin:

- soldering iron To do this, you will have to use soft solders with a high lead content;

- blowtorch. This will require hard solders with a high tin content;

- electrical soldering of iron.

The first method is used if the iron will not be subjected to heavy loads during operation. The second is tinning of iron with tin, when tin solder is applied to the surface of a metal product and rubbed over its entire plane in a thin layer.