– grade of steel used in production;

– standard and manufacturing technology;

– use of heat treatment.

The steel circle, wire rod and A1 reinforcement, which can be purchased in several types (rod, wire, etc.), have an external similarity, regardless of their purpose and applied production standards. But all of the listed round products differ in their mechanical characteristics, so replacing one type with another is unacceptable, despite the fact that they are similar in appearance.

Production technology

Depending on the production technology used in the manufacture of the profile, the circle can be divided into three categories:

- Hot rolled . The creation of this group of steel circles is regulated by GOST 2590-88. The application of the technology involves processing metal on special rolling mills, made in the form of a long installation equipped with rotating rolls of different diameters. Slabs with a solid cross-section or metal ingots of optimal thickness are used as the initial workpiece. Before rolling, the workpieces are heated to the recrystallization temperature and moved along the line. The required shape is given to the product due to the action of rotating rollers, which gradually stretch the workpiece in length and form the required circular cross-section. Hot rolling technology is characterized by excellent productivity and makes it possible to obtain profiles with a cross-sectional size of 5-270 mm.

- Cold rolled (calibrated). The production of wheels by cold rolling is regulated by GOST 7417-75, and the technology itself is also implemented by processing raw materials in rolling mills. The main difference from the hot rolling method is the absence of the need to heat the source material to high temperatures. The use of cold rolling technology makes it possible to produce rods with a diameter of 3 to 100 mm. The advantage of such production is higher accuracy of geometric parameters, improved mechanical and operational parameters.

- Forged . The production of forged steel circles is carried out mainly through machine forging, and all rolled parameters are regulated by GOST 1133-71 regulations. The formation of a circular cross-section profile is carried out due to mechanical action on the initial workpiece. By forming profiles by forging, it is possible to obtain round timber with a diameter of 40-200 mm, which in most cases finds its use as a workpiece and is subjected to subsequent processing.

Where are the products used?

The most popular is the method of manufacturing a calibrated circle by drawing, which allows you to obtain the most accurate dimensions while imparting special properties to the surface. Rods obtained using this technology have strength and elasticity and are used in the following areas and areas:

- Oil refining and gas production industry.

- Mechanical engineering.

- Machine tool manufacturing.

- Construction of fences and gates.

The reasons for the popularity of the product are due to the fact that it does not require additional mechanical processing. This reduces the financial costs of using processing equipment.

Thanks to special technology, the output is high-precision products that are free from all types of flaws on the surface. The advantage of calibrated steel is its long service life. The positive technical properties of this material make it possible to use it in various fields and industries and even in aggressive conditions.

Advantages

The first significant advantage of a steel circle is its round cross-sectional shape, which ensures maximum ease of processing the product using machine tools. Thanks to this feature, rolled steel has found application in many industrial sectors. Other advantages of rolled metal include:

- High strength, providing resistance to various types of loads.

- The ability to gradually restore its original shape after deformation.

- Wide range of sizes.

- Highest corrosion resistance provided by the presence of a zinc layer.

- The use of various grades of steel in production, providing the ability to select wheels with the required parameters that optimally correspond to operating conditions.

- Long service life.

- High level of resistance to external influences.

- Demand in various fields: construction, mechanical engineering, machine tool building, shipbuilding, agriculture and many other industries.

- A sufficiently simple production technology ensures a low cost of the finished product, which has a positive effect on the price of rolled products for consumers.

- Maximum ease of processing when using rolled steel as a blank for the manufacture of various parts, fasteners, fittings and other things.

- High reliability of the product, pronounced ability to withstand loads well.

- Possibility of using profiles instead of reinforcement when reinforcing various structures.

- Ideally smooth surface, without burrs and deformations of various kinds.

- The presence in the range of products with high manufacturing precision for creating parts with ideal geometry and use in various structures and mechanisms where this parameter is of significant importance.

The difference between a steel circle and wire rod and reinforcement

Often these three types of metal products overlap in use. Sometimes the question arises which type of rolled metal is better to choose; to do this, you need to understand the advantages and disadvantages of a steel circle over the other two types:

- The steel circle is more ideal and precise in its cross-section;

- High strength and smooth surface;

- High level of flexibility, able to restore its shape after bending;

- The steel circle is made with a diameter of up to 40 cm;

- The cost of a steel circle is higher than the cost of wire rod and reinforcement, since the properties of the circle are of a higher level.

Specifications and Features

Circular steel rolled metal (circle, round timber) is classified according to various parameters. By type of production there are:

- Hot rolled products.

- Cold rolled (calibrated).

- Forged.

Another technical parameter of rental is the length, which can be:

- Measured.

- Multiple measured.

- Unmeasured.

Hot rolled wheels have the following parameters:

- Diameter 5-270 mm.

- Length 1-6 meters when used in the production of high-alloy steels.

- Length 2-6 meters in the case of high-quality carbon and alloy steels.

- Length 2-12 meters in the case of production from carbon alloys of ordinary quality or when using low-alloy steels.

- Length 2-24 meters according to customer's request.

Calibrated profiles have the following characteristics:

- Diameter 3-100 mm.

- The length of the profiles is 2-6.5 meters (alloy, high-quality carbon, low-alloy and automatic steel).

- Length in the range of 1-6 meters when using high-alloy steel alloys.

Forged products:

- Diameter 40-200 mm.

- Length up to 1.5 meters with a diameter of products less than 50 mm.

- Length up to 1 meter with profile diameter 50-70 mm.

The production of circles is carried out from:

- High-quality structural and low-alloy steel alloys (grades 30, 08, 10, 20, 09G2, 0HSND, 15HSND and others).

- Structural alloy steels (20Х, 35Х, 50Г, 40ХН, 20ХГНМ, 47ГТ and many others).

- Carbon of ordinary quality (St1kp, St1sp, St2ps and others).

- Structural spring-quality steel (60G, 65, 60S2 and others).

- Other types of steels, the use of which is provided for by GOST regulations.

Separately, we can highlight a stainless steel circle, which is characterized by maximum resistance to corrosion and external influences and is used under difficult operating conditions.

The method of delivery of products is determined depending on their diameter:

- Products up to 9 mm are in skeins.

- Circles with large diameters are in rods.

The accuracy of rolled metal production in accordance with GOST standards can be:

- Usual accuracy. Indicated by the marking “B”. The maximum tolerance for deviation from the cross-sectional dimensions ranges from -4 to +0.8 mm.

- Increased accuracy. Marked with “B”. The permissible deviation range is from -2 to +0.6 mm.

- High accuracy (marked “A”). Diameter deviation from -0.9 to +0.3 mm.

Often consumers of rolled products make a choice between reinforcement and steel circles. In most operational features, round steel is superior to reinforcement, since it has a more accurate cross-section geometry, has greater durability and reliability, a smooth and perfectly flat surface, without bends or burrs.

Types and their application

A high-quality result requires from the welder not art, but strict adherence to technology and knowledge of the theory of the process.

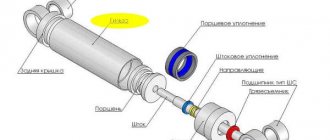

The main difficulty lies in selecting a rod with the necessary parameters . At the same time, they are guided by technological maps, regulations, and explanatory notes of projects. The necessary information can be provided by a drawing of the product being manufactured, or rather a specification with explanations on it.

The characteristics of the materials are indicated on the packaging, as well as the attached documents, the main one of which is the certificate. Some types of products are additionally marked. These can be colored marks, pictograms, digital and alphabetic codes.

Rods for welding and surfacing are produced in different sizes in length and diameter. Today the market offers rods ranging from 30 cm to a meter in length, as well as coils of wire of various weights.

Metal additives can not only form a weld, but also impart special properties to the working part of a part. This is done by fusing an additional layer, including a protective one.

This is how 8 mm hot-dip galvanized rods are produced for fastenings and rods, rods of other diameters with hot copper coating, and metalworking cutters. They make strong gear teeth, axle bearings, etc.

Storage and transportation

To minimize the negative influence of external factors and reduce the likelihood of corrosion destruction of metals, it is important to ensure optimal storage conditions for round rolled steel. From a practicality point of view, it is advisable to place rolled steel in covered warehouses, the territory of which is reliably isolated from precipitation and other external influences. The humidity level in warehouse areas should be low (optimal levels are less than 70%). If it is impossible to use covered warehouses, it is allowed to store profiles in open areas, while it is advisable to place the rolled products under a canopy. In both cases, it is necessary to prevent contact of products with the floor or ground, for which racks or special pallets are used.

If storage rules are not followed, the following problems may occur:

- Rolled products lose their marketable appearance, and their performance characteristics deteriorate.

- The profile is subject to defects as a result of mechanical damage.

- There is a mismatch and so on.

Packaging of round steel is carried out in accordance with a number of regulatory requirements and involves the following:

- Profiles with a diameter of less than 50 mm are packaged in skeins, bundles of skeins or bundles.

- Rolled products with a cross-section exceeding 50 mm are bundled into bundles.

- Coils or bundles can only include rolled metal of one type.

- Each pack is supplemented with markings that contain all the necessary information about the rolled metal.

- Fixation of profiles in coils or bundles is carried out by ligation using steel wire. The number of dressings depends on the weight of the package.

Transportation of packaged round steel products is carried out in open and closed bodies and on trailer platforms of freight transport or in gondola cars (when transporting cargo by rail). When using gondola cars, it is important to minimize the negative influence of external factors in order to ensure maximum safety of rolled products during transportation.

Application in construction

The most widespread use of steel wheels is in the construction industry, where this category of rolled products is used to solve a number of problems:

- As a structural element in various monolithic concrete structures.

- Creation of loop elements in concrete.

- Manufacturing of strength elements for balconies.

- Creation of fences, stairs and various architectural elements.

- Manufacturing of metal structures of various types and purposes, from domestic structures to industrial facilities.

- Reinforcement of concrete structures.

- Strengthening reinforced concrete floors.

- As a blank for the creation of pipes, fasteners, various construction fittings and components.

- Reinforcement of columns.

- Production of various decorative elements and forged products.

- Increasing the load-bearing capacity of a structure due to additional reinforcement. The circle is a good alternative to class A1 reinforcement.

- Landscaping of the territory, creation of various landscape design elements.

In most cases, the most optimal option for the construction industry is a hot-rolled circle, which has excellent operational and technical parameters and is sold at affordable prices.