Bolt and nut sizes

Recently, car manufacturers are increasingly using metric fasteners and moving further away from inch fasteners. But, it is important to know the difference between the sometimes used inch (also called American, or SAE standard) and the more universal metric fasteners in the system of measures, since, despite their external similarity, they are not interchangeable.

All bolts, nuts, studs and other fasteners, both inch and metric, are classified by diameter, thread pitch and length. For example, a standard 1/2 x 13 x 1 bolt is one-half inch in diameter, 13 threads per inch, and 1 inch long. A metric bolt M12 x 1.75 x 25 has a diameter thickness of 12 mm, a thread pitch of 1.75 mm (distance between threads) and a length of 25 mm. Both bolts are very similar in appearance, but are not interchangeable.

Operation of High Strength Bolts (Spheres, Areas and Examples)

The use of high-strength bolts is often found in such areas as construction, road equipment manufacturing, instrument and mechanical engineering, as well as other production-related areas. The high demand for them is due to the fact that such hardware has practically no restrictions on use and is used in toxic aggressive environments and at low temperatures (down to −60C).

High-strength fasteners can withstand both constant and variable loads, with a moving center of gravity, and even strong vibrations. Therefore, with the help of these hardware, buildings are built, industrial equipment, heavy equipment (including military) and special purpose vehicles (cranes, loaders, etc.) are manufactured.

Marking on the head of bolts and nuts

In addition to the characteristics listed, both metric and imperial bolts can be identified by inspection of the head. To begin with, the distance between the flats of the head of a metric bolt is measured in mm, while for an inch bolt it is measured in inches (the same applies to determining nuts). Accordingly, a standard inch wrench will not be suitable for use with metric fasteners, and vice versa as well. In addition, the heads of most inch bolts usually have radial notches (the same marking is also used on metric bolts, but less frequently), which determine the maximum permissible tightening force of the bolt (strength class). The greater the number of notches, the higher the strength class (on cars, bolts with a strength level from 0 to 5 notches are usually used). The strength class of metric bolts is determined by a digital code (we wrote more about this in this article). The code numbers are usually cast, as for inch ones, on the head of the bolt (on cars, bolts of strength classes 8.8, 10.9, and 12.9 are usually used).

Marking of high-strength bolts according to GOST 22353-77

Strictly speaking, GOST 22353-77 today has already lost force in the Russian Federation. Instead, bolts are now made according to GOST R 52644-2006, which we will talk about below.

But, since bolts manufactured according to this GOST are still found in practice, let's see what markings were made on them and what it means.

It consists of two parts: at the top there are some alphabetic symbols, at the bottom there are numbers.

So what do the numbers and letters on the head of the bolt mean according to GOST 22353-77?

1. The letter designation at the top, which comes first, is the manufacturer’s mark (D, OC, L, Ch, WT, etc.)

2. A series of numbers following the letters is the temporary resistance of the bolt in MPa, divided by 10

3. Climatic version HL (for cold climates)

4. Melt number.

If the thread on a bolt is left-handed, then such a bolt is additionally marked with an arrow (counterclockwise), if the thread is right-handed, then the bolt is not marked with any arrow.

Dimensions/markings of inch (SAE and USS) bolts

- G - strength class marking

- L - length (in inches)

- T - thread pitch (number of threads per inch)

- D - nominal diameter (in inches)

Dimensions and markings of the strength class of metric bolts

- P - strength class

- L - length (in mm)

- T - thread pitch (distance between adjacent turns in mm)

- D - nominal diameter (in mm)

Also, standard nuts can be distinguished from metric ones by strength class marks. To identify the strength of standard nuts, dot marks are used that are stamped on one of the end surfaces of the nut, while metric nuts are marked using numbers. The greater the number of points, or the higher the digital code value, the higher the permissible tightening force of the nut (strength class).

Modern marking of bolts by strength

The new GOST has changed little both in the arrangement of symbols and in their semantic meaning. At the top we can still see the maker's mark. Next comes the swim number.

The strength class of the hardware is indicated below according to the new GOST. Here you can also find the letter S, which says that we have a high-strength bolt with a hex head with an increased size. The designation of the class of resistance to harmful atmospheric influences also remains. It comes last.

Marking of strength class of metric studs

The ends of metric studs are also marked according to their strength class. Large studs are marked with a digital code, while smaller ones are marked in the form of a geometric figure.

- Rhombus sign - Strength class 10.9

- PLUS sign - Strength class 9.8

- CIRCLE sign - Strength class 8.8

- TRIANGLE sign – — Strength class 12.9

It should be noted that a significant part of the fasteners, especially those with strength classes from 0 to 2, are not marked at all. In this case, the only way to distinguish a standard fastener from a metric one is to measure the thread pitch, or compare the thread with a uniquely identified one.

Inch fasteners are often also called, in contrast to metric, SAE standard fasteners, however, it should be remembered that only small fasteners fall under the SAE classification. Large fasteners with non-metric threads are American Standard (USS) fasteners.

Since fasteners of the same geometric size (both inch and metric) can have different strength classes, when replacing bolts, nuts and studs on a car, attention should be paid to whether the strength class of the new fastener being installed matches the strength class of the old one.

Bolt GOST 7798-70 high-strength with hex head: bolt m6, m8, m10, m12, m16, m20, m24

| Catalog / high-strength bolt GOST 7798-70: bolts m8, m10, m12, m16, m20, m24, m27, m30 |

Bolt GOST 7798-70 with a hexagonal head of accuracy class B with a thread diameter from 6 to 48 is most often used in mechanical engineering, industry and construction as connection parts.

The high-strength bolt GOST 7798-70 works reliably in aggressive environments, under high-temperature loads and at low temperatures. May have a thread with a fine or large pitch.

BSR bolts are used to secure parts of building structures, pipelines, and equipment to concrete, reinforced concrete and brick structures of buildings and structures.

The most widely used bolts are M6, M8, M10, M12, M16, M20, type 1. Types 2 and 3 are made to order.

The material for the manufacture of bolts in accordance with GOST 7798-70 using the cold heading method on machines with thread rolling uses steel wire with increased manufacturing precision. Requirements for wire diameter depend on the model of the press machine and the design of the bolt.

Hole bolts having a tensile strength of 800MPa and above are called high-strength. They perceive high static and dynamic stresses. The material for this fastener is 40X steel. It is used in metallurgy, in the chemical, pharmaceutical industries, for work in the Far North and in all cases where it is necessary to ensure high joint strength.

Bolt size range: bolt M6, M8, M10, M12, M16, M20, M24, M27, M30, M36, M42, M48, M52.

Bolt GOST 7798-70 is a foreign analogue of GOST 7805-70 or DIN 931, ISO 4014.

DIN 933 - full thread.

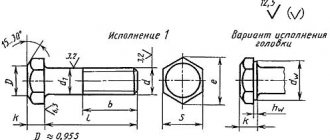

Bolt drawing GOST 7798 70:

Steel grade and main bolt dimensions. Bolt GOST 7798-70 m6, m8, m10, m12, m16, m20, m24 with hex head.

| NTD | GOST 7798-70 |

| Size range | bolt M6 - M48 |

| Accuracy class | IN |

| Thread tolerance field | 6g |

| Strength class | 3.6 4.6 4.8 5.6 5.8 6.6 8.8 10.9 |

| steel grade | 10kp 20kp 10,20,35 20G2R |

Hex bolt GOST 7798-70. Buy a construction bolt.

| d | M8 bolt | M10 bolt | M12 bolt | M16 bolt | M20 bolt | bolt M22 | bolt M24 | M27 bolt | bolt M30 |

| Thread pitch | 1,25 | 1,5 | 1,75 | 2 | 2,5 | 2,5 | 3 | 3 | 3,5 |

| k | 5,3 | 6,4 | 7,5 | 10 | 12,5 | 14 | 15 | 17 | 18,7 |

| b* | 22 | 26 | 30 | 38 | 46/52 | 50/56 | 54/60 | 60/66 | 66/72 |

| S | 13 | 17 | 19 | 24 | 30 | 32 | 36 | 41 | 46 |

| e, min | 14,2 | 18,7 | 20,9 | 26,2 | 30 | 35 | 39,6 | 45,2 | 50,9 |

| L | 20-70 | 25-90 | 25-90 | 30-120 | 50-150 | 60-150 | 60-150 | 80-200 | 80-200 |

Hex bolt GOST 7798-70. Bolt weight GOST 7798 70. Theoretical weight of 1000 pieces of bolts (in kg).

| Length, mm | Theoretical weight 1000 pcs. bolts kg with nominal thread diameter d , mm | ||||||||||||||

| M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M36 | M42 | M48 | |

| 8 | 4,306 | 8,668 | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 10 | 4,712 | 9,394 | 16,68 | — | — | — | — | — | — | — | — | — | — | — | — |

| 12 | 5,118 | 10,120 | 17,82 | — | — | — | — | — | — | — | — | — | — | — | — |

| 14 | 5,524 | 10,850 | 18,96 | 27,89 | — | — | — | — | — | — | — | — | — | — | — |

| 16 | 5,930 | 11,570 | 20,10 | 29,48 | 43,98 | — | — | — | — | — | — | — | — | — | — |

| 18 | 6,336 | 12,300 | 21,23 | 31,12 | 46,21 | 65,54 | — | — | — | — | — | — | — | — | — |

| 20 | 6,742 | 13,020 | 22,37 | 32,76 | 48,45 | 68,49 | 95,81 | — | — | — | — | — | — | — | — |

| 22 | 7,204 | 13,520 | 23,51 | 34,40 | 50,69 | 71,44 | 99,52 | — | — | — | — | — | — | — | — |

| 25 | 7,871 | 14,840 | 25,22 | 36,86 | 54,05 | 75,87 | 105,10 | 133,3 | — | — | — | — | — | — | — |

| 28 | 8,537 | 16,330 | 26,92 | 39,32 | 57,40 | 80,29 | 110,60 | 140,2 | — | — | — | — | — | — | — |

| 30 | 8,981 | 17,120 | 28,52 | 40,96 | 59,64 | 83,24 | 114,30 | 144,8 | 193,0 | — | — | — | — | — | — |

| 32 | 9,426 | 17,910 | 29,43 | 42,59 | 61,87 | 86,19 | 118,00 | 149,4 | 198,6 | 237,0 | — | — | — | — | — |

| 35 | 10,090 | 19,090 | 31,28 | 45,34 | 65,24 | 90,62 | 123,60 | 156,3 | 207,0 | 246,9 | 340,6 | — | — | — | — |

| 38 | 10,760 | 20,280 | 33,18 | 48,00 | 68,59 | 95,04 | 129,20 | 163,2 | 215,4 | 256,9 | 353,3 | — | — | — | — |

| 40 | 11,200 | 21,070 | 34,36 | 49,78 | 71,25 | 97,99 | 132,90 | 167,8 | 221,0 | 263,5 | 361,8 | 474,8 | — | — | — |

| 45 | 12,310 | 23,040 | 37,45 | 54,22 | 77,30 | 105,70 | 142,10 | 179,4 | 235,0 | 280,1 | 373,0 | 500,9 | — | — | — |

| 50 | 13,420 | 25,020 | 40,53 | 58,67 | 83,35 | 113,60 | 152,40 | 190,9 | 249,0 | 296,7 | 404,1 | 526,9 | 834,5 | — | — |

| 55 | 14,530 | 26,990 | 43,62 | 63,11 | 89,39 | 121,50 | 162,40 | 203,7 | 263,1 | 313,3 | 425,3 | 553,0 | 872,1 | 1304 | — |

| 60 | 15,640 | 28,970 | 46,70 | 67,55 | 95,44 | 129,40 | 172,40 | 216,0 | 278,9 | 329,9 | 446,5 | 579,0 | 909,8 | 1356 | — |

| 65 | 16,760 | 30,940 | 49,79 | 71,99 | 101,50 | 137,30 | 182,40 | 228,4 | 293,8 | 348,8 | 467,7 | 605,1 | 947,4 | 1407 | 2009 |

| 70 | 17,870 | 32,910 | 52,87 | 76,44 | 107,50 | 145,20 | 192,40 | 240,7 | 308,8 | 366,5 | 491,1 | 631,1 | 985,0 | 1458 | 2076 |

| 75 | 18,980 | 34,890 | 55,96 | 80,88 | 113,60 | 153,10 | 202,40 | 253,0 | 323,7 | 384,3 | 513,6 | 659,7 | 1023,0 | 1509 | 2143 |

| 80 | 20,090 | 36,860 | 59,04 | 85,33 | 119,60 | 161,00 | 212,40 | 265,0 | 338,6 | 402,1 | 536,1 | 687,5 | 1061,0 | 1561 | 2211 |

| 85 | 21,200 | 38,840 | 62,13 | 89,77 | 125,70 | 168,90 | 222,40 | 277,7 | 353,6 | 419,8 | 558,6 | 715,2 | 1098,0 | 1612 | 2278 |

| 90 | 22,310 | 40,810 | 65,21 | 94,20 | 131,70 | 176,80 | 232,40 | 290,1 | 368,5 | 437,6 | 581,0 | 743,0 | 1141,0 | 1663 | 2345 |

| 95 | — | 42,790 | 68,30 | 98,64 | 137,80 | 184,70 | 242,40 | 302,4 | 383,4 | 455,4 | 603,5 | 770,8 | 1181,0 | 1715 | 2412 |

| 100 | — | 44,760 | 71,38 | 103,10 | 143,80 | 192,60 | 252,40 | 314,7 | 398,3 | 473,2 | 626,0 | 798,5 | 1221,0 | 1766 | 2479 |

| 105 | — | — | 74,47 | 107,50 | 149,90 | 200,50 | 262,40 | 327,1 | 413,3 | 490,9 | 648,5 | 826,3 | 1261,0 | 1826 | 2546 |

| 110 | — | — | 77,55 | 112,00 | 155,90 | 208,40 | 272,30 | 339,4 | 428,2 | 508,7 | 671,0 | 854,1 | 1301,0 | 1880 | 2614 |

| 115 | — | — | 80,63 | 116,40 | 162,00 | 216,30 | 282,30 | 351,8 | 443,1 | 526,5 | 693,5 | 881,8 | 1341,0 | 1934 | 2690 |

| 120 | — | — | 83,72 | 120,90 | 168,00 | 224,20 | 292,30 | 364,1 | 458,1 | 544,2 | 716,0 | 909,6 | 1381,0 | 1989 | 2760 |

| 125 | — | — | 86,80 | 125,30 | 174,00 | 232,10 | 302,30 | 376,4 | 473,0 | 562,0 | 738,5 | 937,4 | 1421,0 | 2043 | 2831 |

| 130 | — | — | 89,89 | 129,70 | 180,10 | 240,00 | 312,30 | 388,8 | 487,9 | 579,8 | 761,0 | 965,2 | 1461,0 | 2098 | 2903 |

| 140 | — | — | 96,06 | 138,60 | 192,20 | 255,80 | 332,30 | 413,5 | 517,8 | 615,3 | 806,0 | 1021,0 | 1541,0 | 2207 | 3045 |

| 150 | — | — | 102,18 | 147,50 | 204,30 | 271,60 | 352,30 | 438,1 | 547,6 | 650,8 | 850,1 | 1076,0 | 1621,0 | 2315 | 3187 |

| 160 | — | — | 108,38 | 156,40 | 216,40 | 287,40 | 372,30 | 462,8 | 577,5 | 686,4 | 895,9 | 1132,0 | 1701,0 | 2424 | 3329 |

| 170 | — | — | 114,58 | 165,30 | 228,50 | 303,20 | 392,30 | 487,5 | 607,4 | 721,9 | 940,9 | 1188,0 | 1780,0 | 2533 | 3471 |

| 180 | — | — | 120,68 | 174,20 | 240,60 | 319,00 | 412,30 | 512,2 | 637,2 | 757,5 | 985,9 | 1243,0 | 1860,0 | 2642 | 3614 |

| 190 | — | — | 126,88 | 183,10 | 252,70 | 333,80 | 432,30 | 536,9 | 667,1 | 793,0 | 1031,0 | 1299,0 | 1940,0 | 2751 | 3756 |

| 200 | — | — | 133,08 | 191,90 | 264,70 | 350,60 | 452,20 | 561,5 | 697,0 | 828,6 | 1076,0 | 1354,0 | 2020,0 | 2860 | 3898 |

| 220 | — | — | — | 209,70 | 228,90 | 382,20 | 492,20 | 610,9 | 756,7 | 899,6 | 1166,0 | 1465,0 | 2180,0 | 3077 | 4182 |

| 240 | — | — | — | 227,50 | 313,10 | 413,80 | 532,20 | 660,3 | 816,4 | 970,8 | 1256,0 | 1576,0 | 2340,0 | 3295 | 4466 |

| 260 | — | — | — | 245,20 | 337,60 | 445,40 | 572,20 | 709,6 | 876,1 | 1042,0 | 1346,0 | 1687,0 | 2500,0 | 3513 | 4751 |

| 280 | — | — | — | — | 361,50 | 476,90 | 612,20 | 759,0 | 935,9 | 1113,0 | 1436,0 | 1798,0 | 2660,0 | 3730 | 5035 |

| 300 | — | — | — | — | 385,70 | 508,50 | 652,20 | 808,3 | 995,6 | 1184,0 | 1526,0 | 1910,0 | 2820,0 | 3948 | 5319 |

The thread length indicated in the denominator is for bolts with a length greater than 120.

It is possible to supply high-strength bolts in accordance with GOST 7798-70 in sizes from M6 to M24, strength classes 8.8, 10.9, made of steel 20G2R.

Example of a symbol:

Bolt GOST 7798-70 version 1 with thread diameter d

=8 mm, with a turnkey size

S

=13 mm, length

l

=60 mm, with a large thread pitch with a tolerance range of

6g

, strength class 5.8, uncoated:

Bolt M8 - 6gx60.58 (S13) GOST 7798-70

Bolt 7798-70 version 2 with thread diameter d

=10 mm, with a turnkey size

S

=16 mm, with a fine thread pitch with a tolerance range of

6g

, strength class 10.9, made of steel grade 40X, with coating 01 6 microns thick:

Bolt 2М10х1.25 - 6gх60.109.40Х.016 GOST 7798-70

Bolt GOST 7798-70 version 3 with thread diameter d

=12 mm, with a turnkey size

S

=18 mm, length

l

=60 mm, with a large thread pitch with a tolerance range of

6g

, strength class 5.8, uncoated:

Bolt 3M12 - 6gx60.58 (S18) GOST 7798-70

Bolt 7798 version 1 with thread diameter d

=16 mm, with turnkey size

S

=24 mm, with fine thread pitch with a tolerance range of

6g

, strength class 10.9, made of steel grade 40X, with coating 01 6 microns thick:

Bolt M16x1.25 - 6gx60.109.40X.016 GOST 7798-70

Bolt GOST 7798 version 2 with thread diameter d

=20 mm, with a turnkey size

S

=30 mm, length

l

=60 mm, with a large thread pitch with a tolerance range of

6g

, strength class 5.8, uncoated

Bolt 2M20 - 6gx60.58 (S30) GOST 7798-70

Sale of bolts: M6, M8, M10, M12, M16, M20, M24, M27, M30, M36, M42, M48, M52 of various lengths from 0.05 tons.

How to buy a bolt GOST 7798-70: bolts m8, m10, m12, m16, m20, m24 at low prices:

- fill out the simple “Place an order” form at the top of the page;

- call on the phone +7;

- send your application by email;

Terms of sale:

- Sales of metal products wholesale and retail;

- Cashless payment by transferring funds from a bank account;

- Possibility of deferred payments;

- Free consultations from our specialists;

- We provide packaging services according to customer requirements;

- We are ready to produce products of any complexity to order according to customer drawings.

Delivery terms:

- Products are delivered from the warehouse based on availability;

- If necessary, we can provide a storage service;

- We are ready to provide a discount on delivery according to the terms of partnership programs of transport companies;

- Possibility of self-pickup of goods from warehouses.

Guarantees:

- All products are certified and released after technological control;

- Hardware, fasteners, ropes, mesh, wire, electrodes and other metal products comply with GOST and TU;

- Possibility of returning goods in accordance with the legislation of the Russian Federation;

Delivery within the Russian Federation: Moscow, St. Petersburg, Arkhangelsk, Astrakhan, Barnaul, Belgorod, Bryansk, Vladimir, Volgograd, Vologda, Voronezh, Yekaterinburg, Ivanovo, Izhevsk, Yoshkar-Ola, Kazan, Kaluga, Kirov, Kostroma, Krasnodar, Kurgan, Kursk, Lipetsk, Omsk, Orenburg, Penza, Perm, Pskov, Rostov-on-Don, Ryazan, Samara, Saransk, Saratov, Sevastopol, Simferopol, Smolensk, Stavropol, Tambov, Tver, Tomsk, Tula, Tyumen, Ulyanovsk, Ufa, Chelyabinsk, Yaroslavl, etc.

The information presented on this website contains a catalog of reference information on more than 3,000 types of metal products, is for informational purposes only, and can be used in various areas of enterprise activity.

Products without labeling

Bolts without any markings are also found. Here the immediate question is: does the manufacturer comply with GOST, do the products meet quality standards? It is better to “bypass” such fasteners altogether. If there is no other option, no one will prohibit the use of bolts without markings, but only in cases where the load on the joint will ultimately be minimal or close to it.

Don't ignore what's on the bolt head. The numbers and letters will tell you whether the products can be used, for example, in the process of repairing a car, various equipment, or the maximum they are suitable for is mounting a conventional shelf on the wall.

Comments

Steels for making bolts

For the manufacture of high-strength fasteners, alloy carbon steel of increased strength and durability is used. Special manufacturing technologies include hot or cold heading of blanks, which significantly increase the level of strength. Mandatory heat treatment in electric furnaces gives the product anti-corrosion properties, greatly increases strength, and extends service life.

Rules for installing high-strength bolts

Before starting work, a preliminary analysis of the technical operating conditions of the future structure is always carried out. The selection of the required hardware will be influenced by the following factors:

- Characteristics of additional accessories.

- Twist factor.

- Correspondence of the technical and mechanical properties of the hardware to the environment in which it will work.

- Resistance to various external influences.

- Properties of the steel from which it is made.

- Thread pitch and type.

The conditions for the correct choice are also influenced by the size, shape of the bolt head, the presence of heat treatment and protective coating. Always start from the purposes for which you need hardware. The further procedure is as follows:

- The holes in the connected elements are aligned and the elements are rigidly secured using assembly plugs. Usually a tenth of the holes are secured with plugs - this is quite enough for reliable fixation.

- High-strength bolts are inserted into the holes free of plugs and tensioned in accordance with the rules and with the force specified in the technical documents.

- Then remove the assembly plugs, install the remaining bolts and tighten all the parts to the design strength. After this, the working surface can be primed.

Use a calibration wrench that allows you to control and adjust the tension of the bolts.

GOST 1476-93

GOST 1476-93 (ISO 7434-83)

Group G32

________________ The letter “B” in the name of the standard in the original paper is in italics. — Note from the database manufacturer.

MKS 21.060.10 OKP 16 5000

Date of introduction 1995-01-01

1 DEVELOPED by Gosstandart of Russia INTRODUCED by the Technical Secretariat of the Interstate Council for Standardization, Metrology and Certification

2 ADOPTED by the Interstate Council for Standardization, Metrology and Certification on October 21, 1993. The following voted for adoption:

| State name | Name of the national standardization body |

| Republic of Belarus | State Standard of Belarus |

| Republic of Kyrgyzstan | Kyrgyzstandard |

| The Republic of Moldova | Moldovastandard |

| Russian Federation | Gosstandart of Russia |

| The Republic of Tajikistan | Tajikstandard |

| Turkmenistan | Main State Inspectorate of Turkmenistan |

| Ukraine | State Standard of Ukraine |

3 By Decree of the Committee of the Russian Federation on Standardization, Metrology and Certification dated February 2, 1994 N 160, the interstate standard GOST 1476-93 was put into effect as the state standard of the Russian Federation on January 1, 1995.

4 INSTEAD GOST 1476-84

5 REISSUE

REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

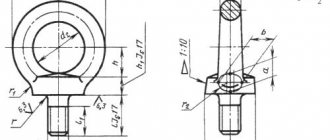

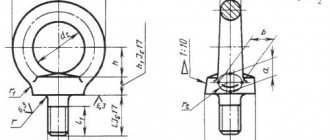

This standard applies to set screws with a tapered end and a straight spline, accuracy classes A and B

, nominal diameter from 1.2 to 12 mm. The requirements of this standard are mandatory. Additional requirements that meet the needs of the national economy are in italics. ________________ Designations and numbers of standards in the electronic version, marked in the text “*”, are in italics in the paper original; the rest of the document text is given in normal font. — Note from the database manufacturer.

1 Dimensions

1.1 The dimensions of the screws must correspond to those indicated in the figure and table 1.

________________

The 120° angle is required for short screws whose lengths are given above the dashed stepped line in Table 1. The 90° angle applies only to the portion of the end below the internal thread diameter of screws with nominal lengths given below the dashed stepped line in Table 1. For short screws whose length shown below the dashed stepped line in Table 1, an angle of 120° is required.

Table 1

In millimeters

1.2 The theoretical mass of the propellers is indicated in the appendix.

2 Technical requirements

Screws must be manufactured in accordance with the requirements specified in Table 2.

table 2

| Material | Steel | Corrosion resistant steel | Non-ferrous alloys | |

| Thread | Tolerance field | 6 | ||

| Standard | GOST 16093, GOST 24705 | |||

| Mechanical properties | Strength class or material group | 14H, 22H 33H, 45H | 21-26 | 31-35 |

| Standard | GOST 25556 | GOST 1759.0* | ||

| Tolerances | Accuracy class | A, B | ||

| Standard | GOST 1759.1* | |||

| Final surface treatment of the product | Smooth Requirements for electroplating according to GOST 9.301, GOST 9.303 Screws must be manufactured with coatings: zinc chromated, nickel, oxide, oil-impregnated, phosphate, oil-impregnated or uncoated. It is allowed to use other types of coatings as agreed between the manufacturer and the consumer | |||

| Acceptance | Acceptance rules according to GOST 17769 | |||

| Control methods | Dimensions, deviations in shape and location of surfaces - according to GOST 1759.1* | |||

| Surface defects - by GOST 1759.2* | ||||

| Mechanical properties: | ||||

| GOST 25556* | GOST 1759.0* | |||

| Labeling and packaging | GOST 1759.0*, GOST 18160* | |||

________________

The document is not valid on the territory of the Russian Federation. GOST R ISO 898-5-2009 is valid;

The document is not valid on the territory of the Russian Federation. GOST R ISO 8992-2011 is valid;

The document is not valid on the territory of the Russian Federation. GOST R ISO 4759-1-2009 is valid;

The document is not valid on the territory of the Russian Federation. GOST R ISO 3269-2009 is valid; The document is not valid on the territory of the Russian Federation. GOST R ISO 6157-1-2009 is valid. — Note from the database manufacturer.

3 Designation

Examples of symbols

Set screw with a conical end and a straight slot, accuracy class B , thread diameter 10 mm, with a tolerance range of 6 , length 25 mm, strength class 14 N, uncoated:

Screw M10-6g 25.14N GOST 1476-93

The same, accuracy class A , strength class 45H, made of steel 40X with a chemical oxide coating impregnated with oil:

Screw A. М10-6g 25.45Н. 40X. 05 GOST 1476-93

The same, from brass LS 59-1, without coating:

Screw A. M10-6g 25.32. LS 59-1 GOST 1476-93

APPENDIX (reference). Screw weight

APPENDIX (reference)

Table 3 - Weight of screws

| Length, mm | Theoretical weight 1000 pcs. steel screws, kg, with nominal thread diameter, mm | ||||||||||||

| 1,0 | 1,2 | 1,6 | 2,0 | 2,5 | 3,0 | (3,5) | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | |

| 2,0 | 0,011 | 0,015 | 0,026 | 0,040 | |||||||||

| 2,5 | 0,014 | 0,020 | 0,034 | 0,053 | 0,082 | ||||||||

| 3,0 | 0,017 | 0,024 | 0,042 | 0,065 | 0,101 | 0,148 | |||||||

| 4,0 | 0,023 | 0,033 | 0,058 | 0,089 | 0,139 | 0,202 | 0,260 | 0,343 | |||||

| 5,0 | 0,042 | 0,073 | 0,114 | 0,178 | 0,258 | 0,342 | 0,439 | 0,690 | |||||

| 6,0 | 0,051 | 0,089 | 0,138 | 0,216 | 0,313 | 0,418 | 0,537 | 0,839 | 1,174 | ||||

| 8,0 | 0,121 | 0,188 | 0,293 | 0,424 | 0,569 | 0,735 | 1,147 | 1,609 | 2,816 | ||||

| 10,0 | 0,237 | 0,370 | 0,535 | 0,720 | 0,932 | 1,455 | 2,052 | 3,605 | 5,523 | ||||

| 12,0 | 0,447 | 0,646 | 0,871 | 1,129 | 1,763 | 2,496 | 4,394 | 6,755 | 9,570 | ||||

| (14,0) | 0,757 | 1,022 | 1,326 | 2,071 | 2,940 | 5,183 | 7,988 | 11,345 | |||||

| 16,0 | 0,868 | 1,173 | 1,523 | 2,380 | 3,383 | 5,971 | 9,220 | 13,120 | |||||

| (18,0) | 1,324 | 1,721 | 2,688 | 3,827 | 6,760 | 10,453 | 14,895 | ||||||

| 20,0 | 1,475 | 1,918 | 2,996 | 4,271 | 7,549 | 11,685 | 16,669 | ||||||

| (22,0) | 3,304 | 4,714 | 8,338 | 12,918 | 18,444 | ||||||||

| 25,0 | 3,766 | 5,380 | 9,521 | 14,766 | 21,106 | ||||||||

| (28,0) | 6,046 | 10,704 | 16,615 | 23,768 | |||||||||

| 30,0 | 6,489 | 11,493 | 17,847 | 25,543 | |||||||||

| 35,0 | 13,465 | 20,929 | 29,980 | ||||||||||

| 40,0 | 15,436 | 24,010 | 34,417 | ||||||||||

| 45,0 | 27,091 | 38,853 | |||||||||||

| 50,0 | 30,172 | 43,290 | |||||||||||

| 55,0 | 47,727 | ||||||||||||

| 60,0 | 52,164 | ||||||||||||

| Note. To determine the mass of screws made of other materials, the mass values indicated in the table must be multiplied by the coefficient: 0.356 - for aluminum alloy; 0.970 - for bronze; 1.08 - for brass. | |||||||||||||

The electronic text of the document was prepared by Kodeks JSC and verified against: official publication Screws of accuracy classes A and B. Technical conditions: Sat. GOST. - M.: Standartinform, 2006

docs.cntd.ru

Application of bolts

The scope of use of hardware is huge. This connection is used in agricultural machinery for attaching attachments. In furniture making, bolts of a special design are used. This connection is used:

- on construction sites;

- in production;

- in mechanical engineering;

- in the manufacture of various devices;

- in car assembly.

Bolted connections have virtually no limitations. Hex bolts are used to fasten beams during the construction of wooden houses. In most cases, high-strength bolts are used. They provide a reliable and durable connection.

In construction, such fasteners with enlarged heads are often used. They are used in the construction of residential buildings and industrial facilities. Connections on such hardware can be found in the construction of tunnels, bridges and other objects where tensile strength and other qualities provided by this type of connection are important.

Bolts are widely used in railway transport. Depending on the place of application, hardware of varying degrees of strength is used. They may have semicircular or square heads. Often this connection is used in the assembly of metal railway fences. To protect against aggressive environmental influences, the bolts are coated with zinc alloy.

Today it is estimated that up to 90 bolts are used in a mobile phone, up to 130 in a washing machine, and about 4000 in a car. Bolted connections are used in almost all modern mechanisms. This type of hardware plays an important role in modern prefabricated structures. Thanks to the connection they provide, the assembly of any structure does not take as much time as when using welded joints.

Heavy Duty Fasteners

The heads of such bolts can convey more useful information. It is products in this category that should be given preference. But there is a nuance: it is quite difficult to find it in regular stores. This is explained by the fact that fasteners of this class are used, as a rule, where it is necessary to achieve increased strength characteristics of units at joints. Manufacturers can apply the following markings to such bolts:

- Maker's mark, for example, JX, THE, WT, L;

- Heat number;

- Strength class;

- The symbol “S” means that the product is a bolt with six sides;

- “ХЛ” symbols – information that the product is intended for use in cold conditions;

- An arrow whose direction is counterclockwise indicates that the thread is left-handed (right-handed is not marked).

The above are examples. Other symbols may be present.